Enhanced reaction system and method for preparing ethylene glycol by gas-phase catalytic hydration method

A gas-phase catalytic water and hydration reaction technology, applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and the preparation of hydrolysis, can solve problems such as incompatibility, and achieve the effects of improving efficiency, improving utilization, and reducing catalyst dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

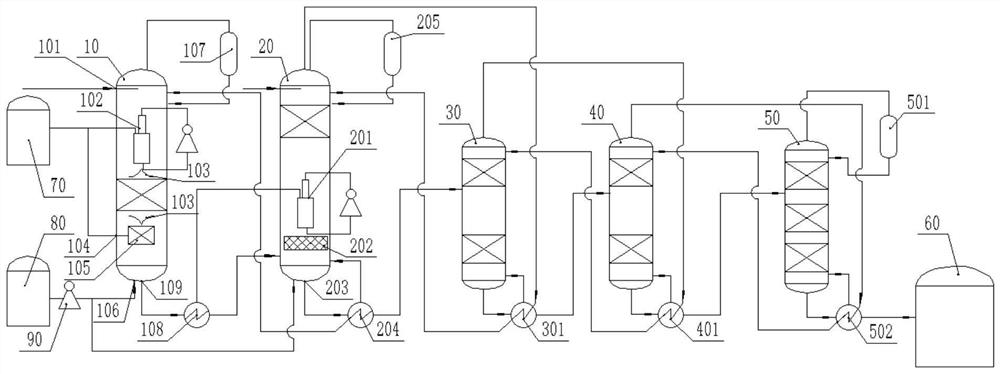

[0065] refer to figure 1 As shown, this embodiment provides an enhanced reaction system for preparing ethylene glycol by gas-phase catalytic hydration, including: a hydration reaction rectifier 10, an enhanced hydration reaction rectifier 20 and an evaporation tower 30; the hydration reaction rectifier 10 The side wall is provided with ethylene oxide inlet 104; the bottom of the hydration reaction rectifier 10 is provided with a water inlet 106; the ethylene oxide inlet 104 is connected with the ethylene oxide storage tank 70; the water inlet 106 is connected with the water storage tank 80 A water pump 90 is provided between the water storage tank 80 and the water inlet 106 .

[0066] Wherein, the tops of the hydration reaction rectifier 10 and the enhanced hydration reaction rectifier 20 are provided with dosing channels 101 for adding catalysts. A first condenser 107 is also connected to the top of the hydration reaction rectifier 10 , and the unreacted water and ethylene o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com