Intelligent micro-interface reaction system and method for preparing ethylene glycol by ethylene oxide method

A technology of ethylene oxide method and interfacial reaction, which is applied in the fields of hydrolysis preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc. It can solve the problems of insufficient mixing of ethylene oxide and water source, high reaction pressure and low liquid hourly space velocity and other issues, to achieve the effect of improving the level of automated production and management, improving the application area, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

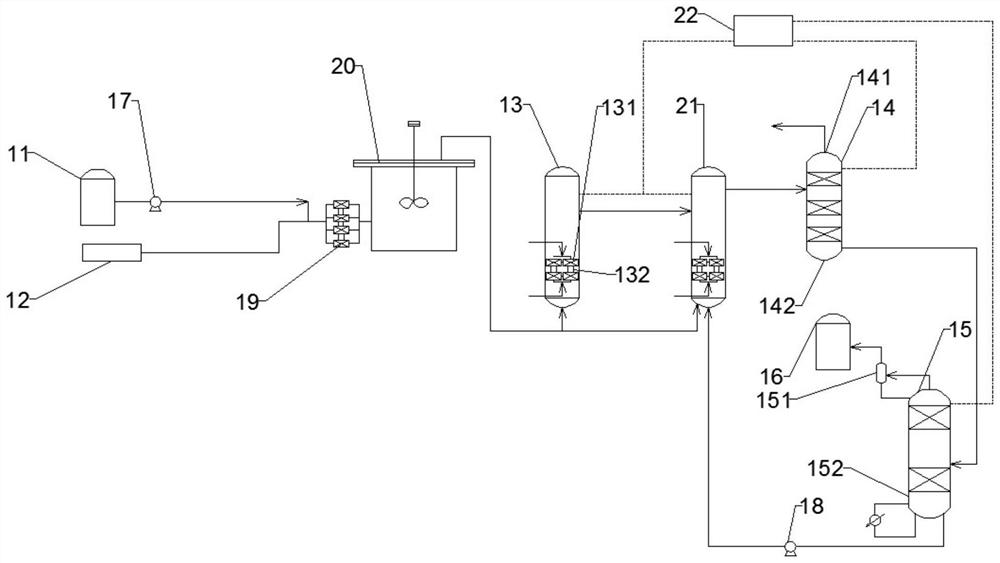

[0065] refer to figure 1 Shown is the reaction system for preparing ethylene glycol by the ethylene oxide method of the embodiment of the present invention, which mainly includes a stirred tank 20, a first reactor 13, and a second reactor 21, and the side of the stirred tank 20 is provided with an external The micro-interface unit is composed of several external micro-interface generators 19, and the external micro-interface generators 19 are arranged in sequence from top to bottom, and the bottom surface and the top surface between adjacent external micro-interface generators 19 There are connecting rods for fixing between them, and the number of external micro-interface generators 19 is preferably 4.

[0066] The main pipe leading to the external micro-interface unit is connected to the ethylene oxide feed pipe and two branch pipes of the water source feed pipe at the same time, and the water source feed pipe is connected to the external micro-interface generator through the...

Embodiment 2

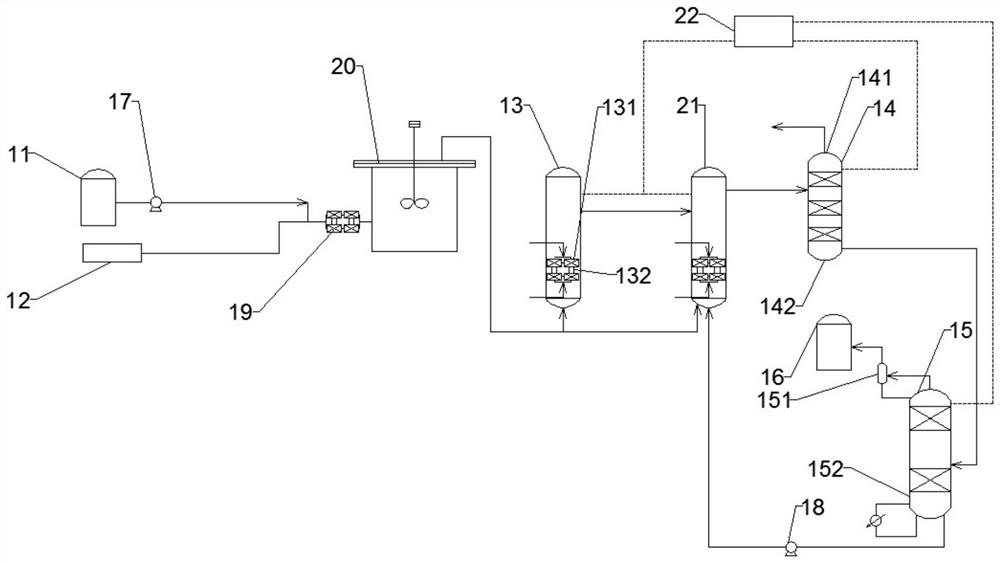

[0079] refer to figure 2 As shown, this embodiment is different from Embodiment 1 only in the number of external micro-interface generators 19, the temperature and pressure settings of the system, and the number of micro-interface generators in this embodiment is 4, and every 2 is One group is divided into two groups, and the two groups are arranged sequentially from top to bottom. Two micro-interface generators 131 in each group are connected in series, and the two groups are connected in parallel. The system temperature is set to 95°C, and the pressure is set to 2.0 MPa. The output of ethylene glycol was detected, and the conversion rate of ethylene oxide was calculated to be 97.5%.

Embodiment 3

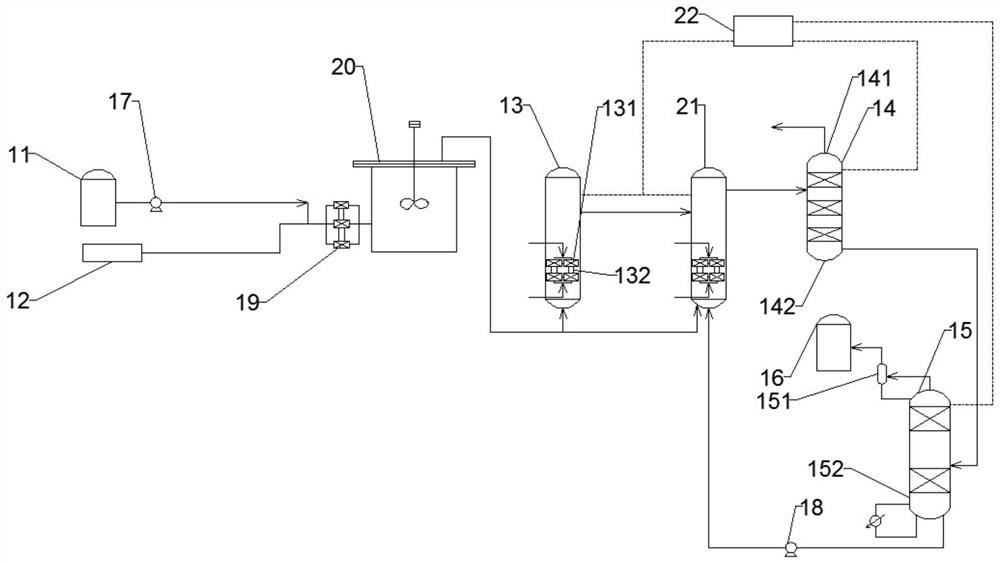

[0081] refer to image 3 As shown, this embodiment is different from Embodiment 1 only in the number of external micro-interface generators 19, the temperature and pressure settings of the system, the number of micro-interface generators in this embodiment is 3 and from top to bottom Arranged in sequence, the micro-interface generators are connected in parallel with each other, the system temperature is set to 86° C., and the pressure is set to 1.4 MPa. The output of ethylene glycol was detected, and the conversion rate of ethylene oxide was calculated to be 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com