Built-in instant dehydration micro-interface reinforced DMC preparation system and method

A preparation system, built-in technology, applied in the field of built-in real-time dehydration micro-interface enhanced DMC preparation system, can solve the problems of small gas-liquid phase interface area, low gas-liquid mass transfer rate, low effective utilization rate, etc., to improve phase Boundary mass transfer area, improve fixation effect, improve the effect of application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

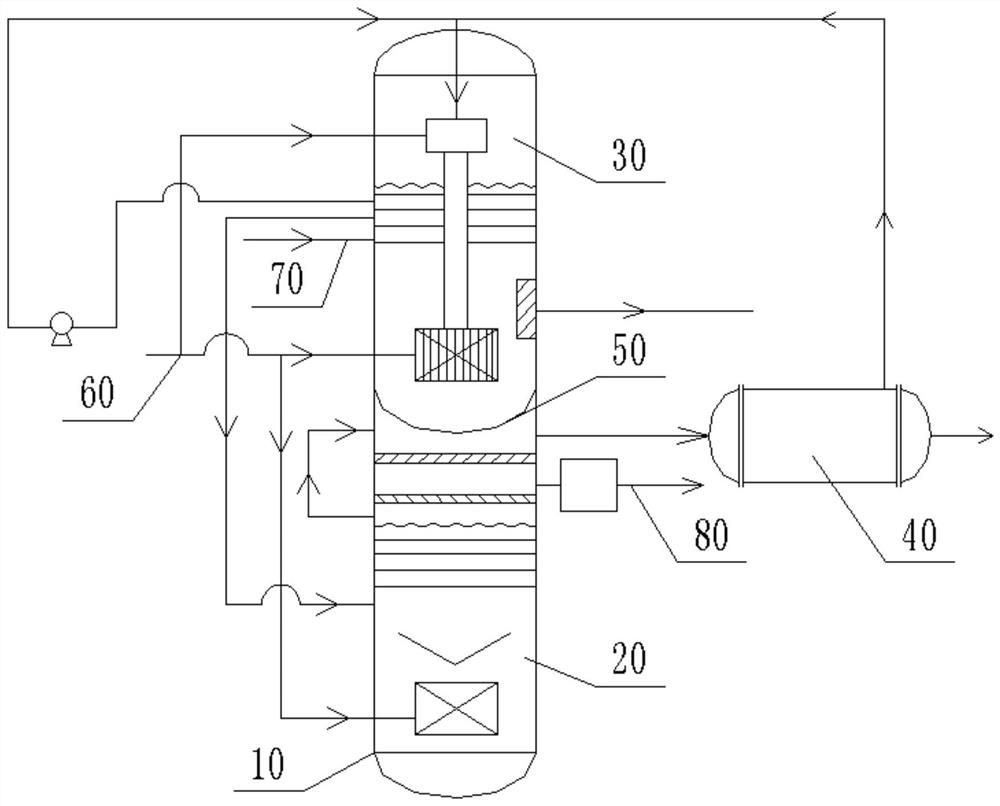

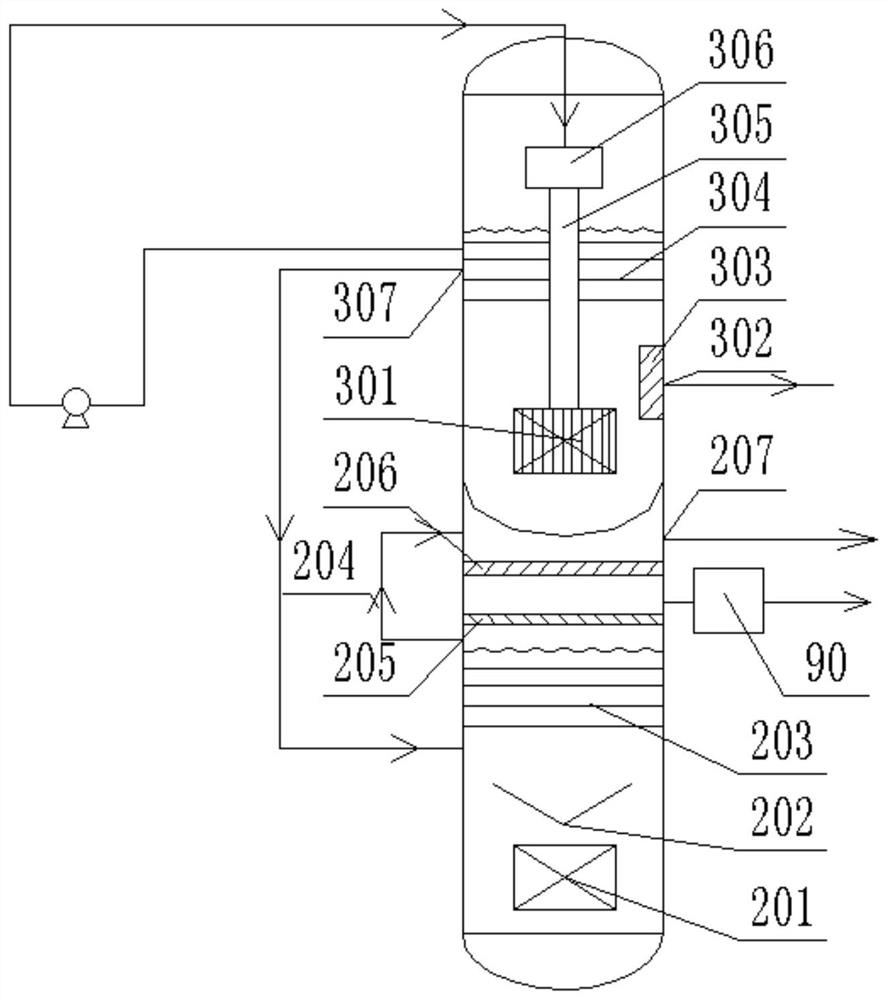

[0072] refer to Figure 1-3 As shown, the present embodiment provides a built-in instant dehydration micro-interface enhanced DMC preparation system, including: a reaction tower 10, the middle of the reaction tower 10 is provided with a sealing plate 50; the top of the sealing plate 50 is the first reaction section 30, and the bottom is The second reaction section 20; the side wall of the first reaction section 30 is connected with the methanol pipeline 70 and the mixed gas pipeline 60 from top to bottom; the side wall of the first reaction section 30 is provided with a first product outlet 307, and the first product outlet 307 is located below the first liquid level; the first product outlet 307 is connected with the second reaction section 20 .

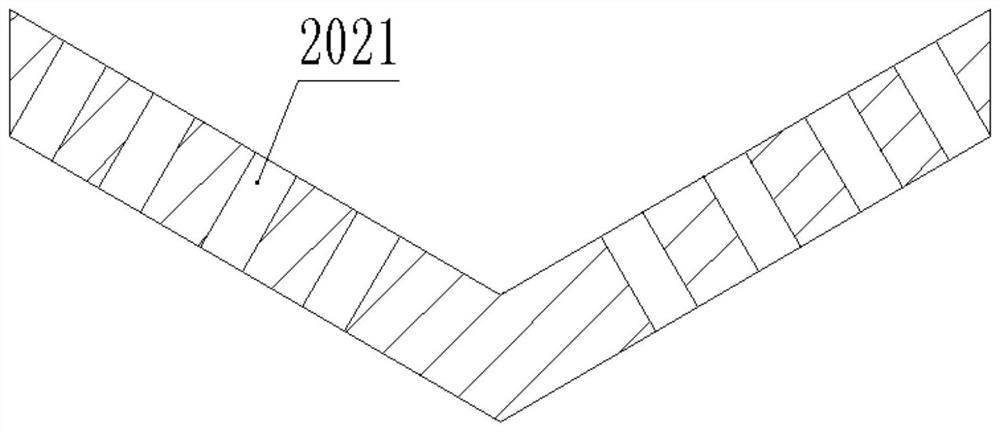

[0073] Wherein, the first micro-interface generator 301 is arranged in the first reaction section 30, the second micro-interface generator 306 is arranged above the first micro-interface generator 301, the first micro-interface gene...

Embodiment 2

[0090] Present embodiment and embodiment 1 are only different in process parameter, and concrete process parameter is as follows:

[0091]

[0092] Wherein, the reaction temperature is 110° C., and the pressure is 1.5 MPa.

[0093] After calculation, the single-pass conversion rate of methanol reached 21.07%, and the yield of DMC reached 18.42%. It can be seen that the temperature and pressure of the system of this embodiment are significantly lower than that of the existing process.

Embodiment 3

[0095] Present embodiment and embodiment 1 are only different in process parameter, and concrete process parameter is as follows:

[0096]

[0097]

[0098] Wherein, the reaction temperature is 113° C., and the pressure is 1.8 MPa.

[0099] It is calculated that the single pass conversion rate of methanol reaches 20.99%, and the yield of DMC reaches 18.45%. It can be seen that the temperature and pressure of the system of this embodiment are significantly lower than that of the existing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com