Process for removing tobacco odour

An odor treatment and process technology, applied in the field of environmental protection equipment, can solve problems such as reducing energy conversion and photocatalytic degradation conversion efficiency of organic matter, photocatalytic odor treatment reactors not working properly, and ultraviolet lamps not having automatic cleaning functions. , to achieve the effects of preventing airborne diseases, low space utilization and equipment production intensity, and improved effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

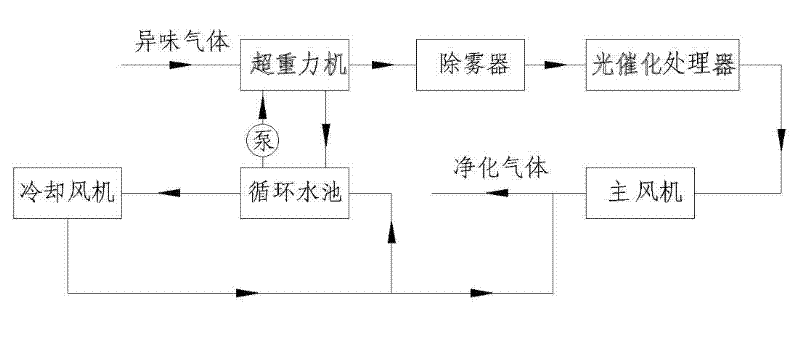

[0017] As shown in the figure: a tobacco odor treatment process, the process route is as follows: gas to be treated → wet scrubber to remove dust and harmful substances or components dissolved in water → demister to remove water in the gas Fog → photocatalytic odor processor oxidizes harmful substances or components in the gas → the main fan discharges the treated gas into the air; it is characterized in that: the wet scrubber is a supergravity flue gas dust removal and desulfurization integrated machine; The circulating water washes the gas passing through the overweight machine, and the cooling fan cools the circulating water; the photocatalytic odor processor is a lamp self-cleaning photocatalytic odor processor.

[0018] According to the content of dust and harmful substances or components in the gas to be treated, the supergravity flue gas dust removal and desulfurization integrated machine and the lamp self-cleaning photocatalyst odor processor can be used as a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com