Patents

Literature

48results about How to "Reduce the effective contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

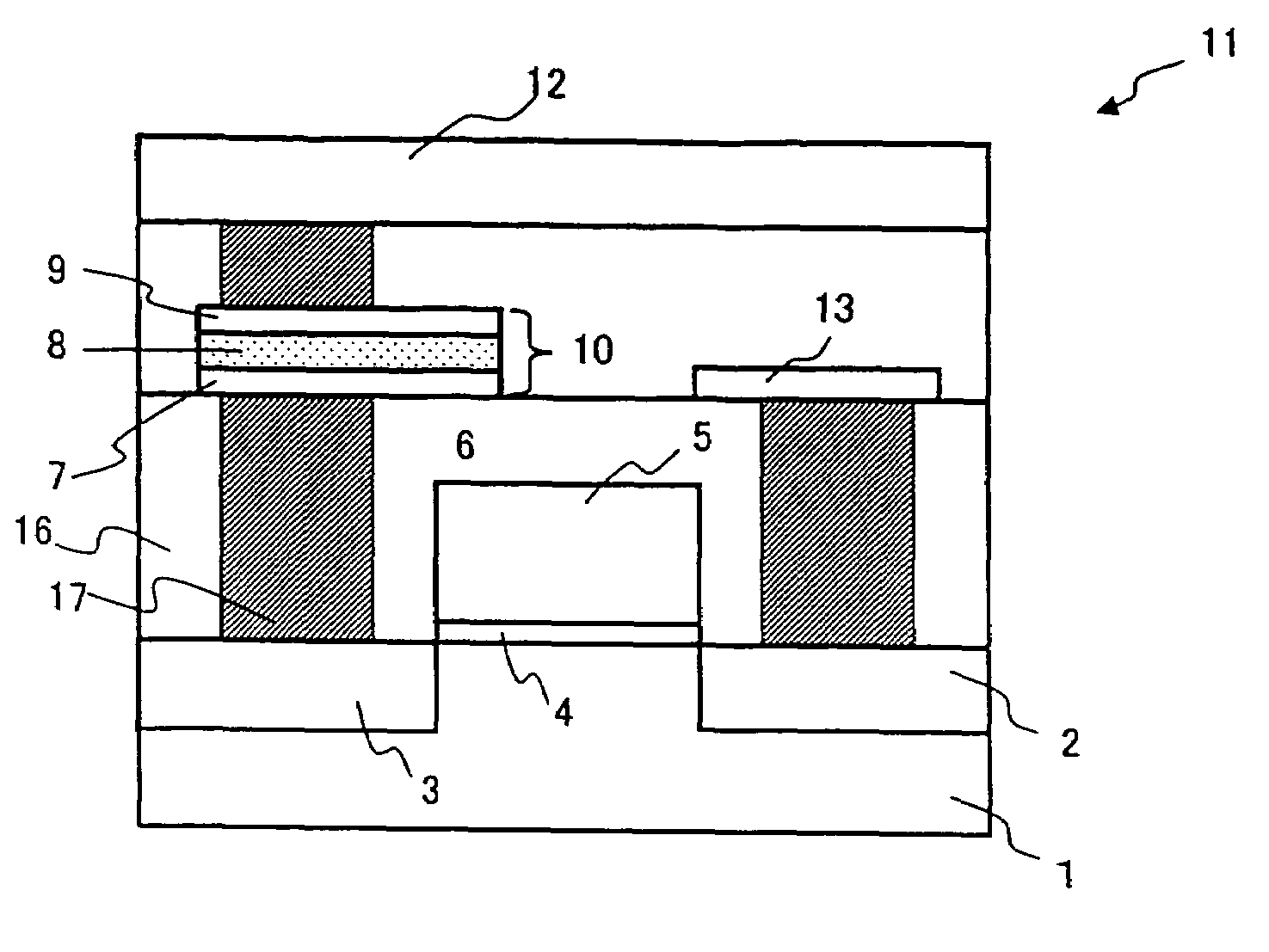

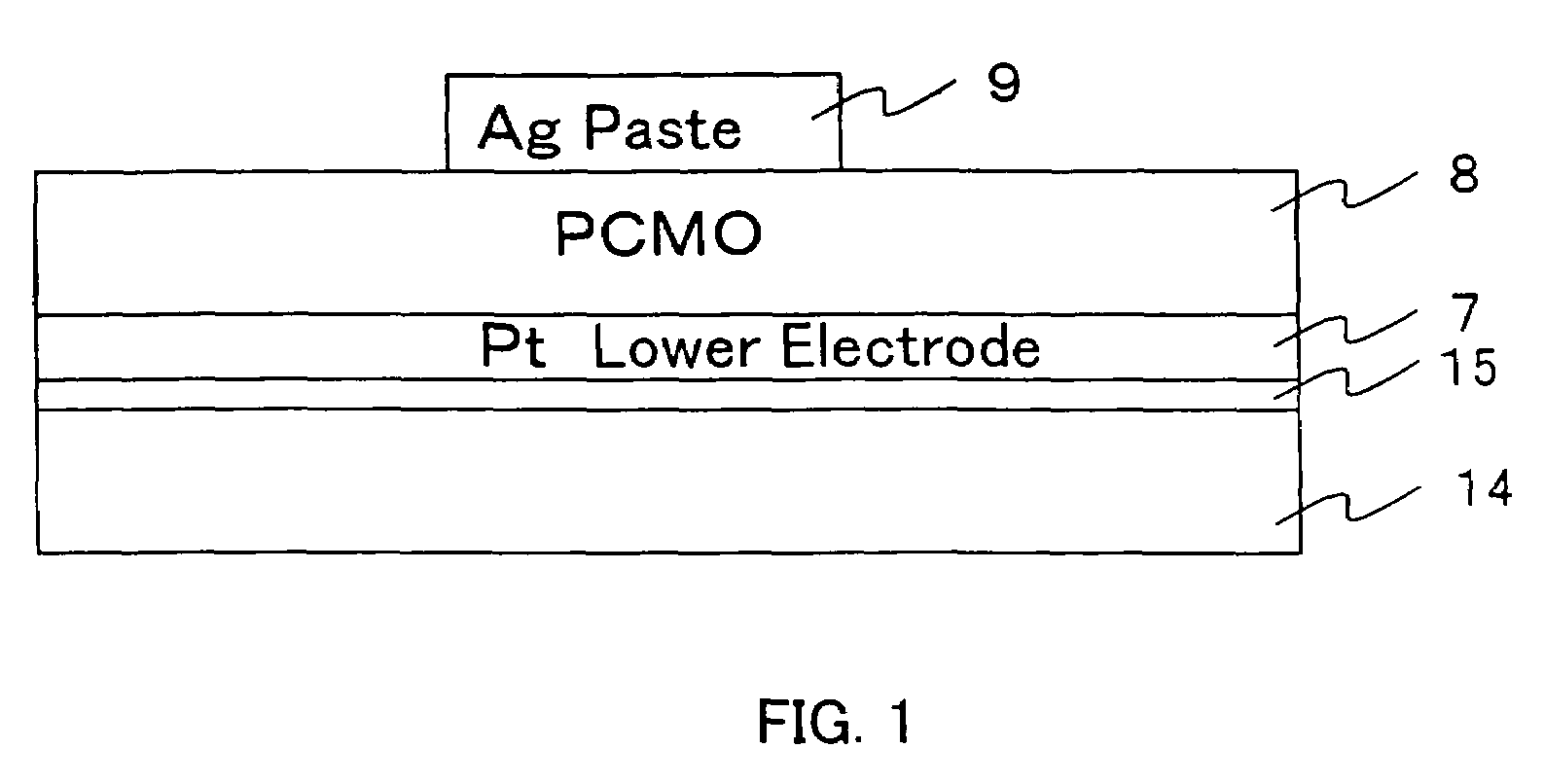

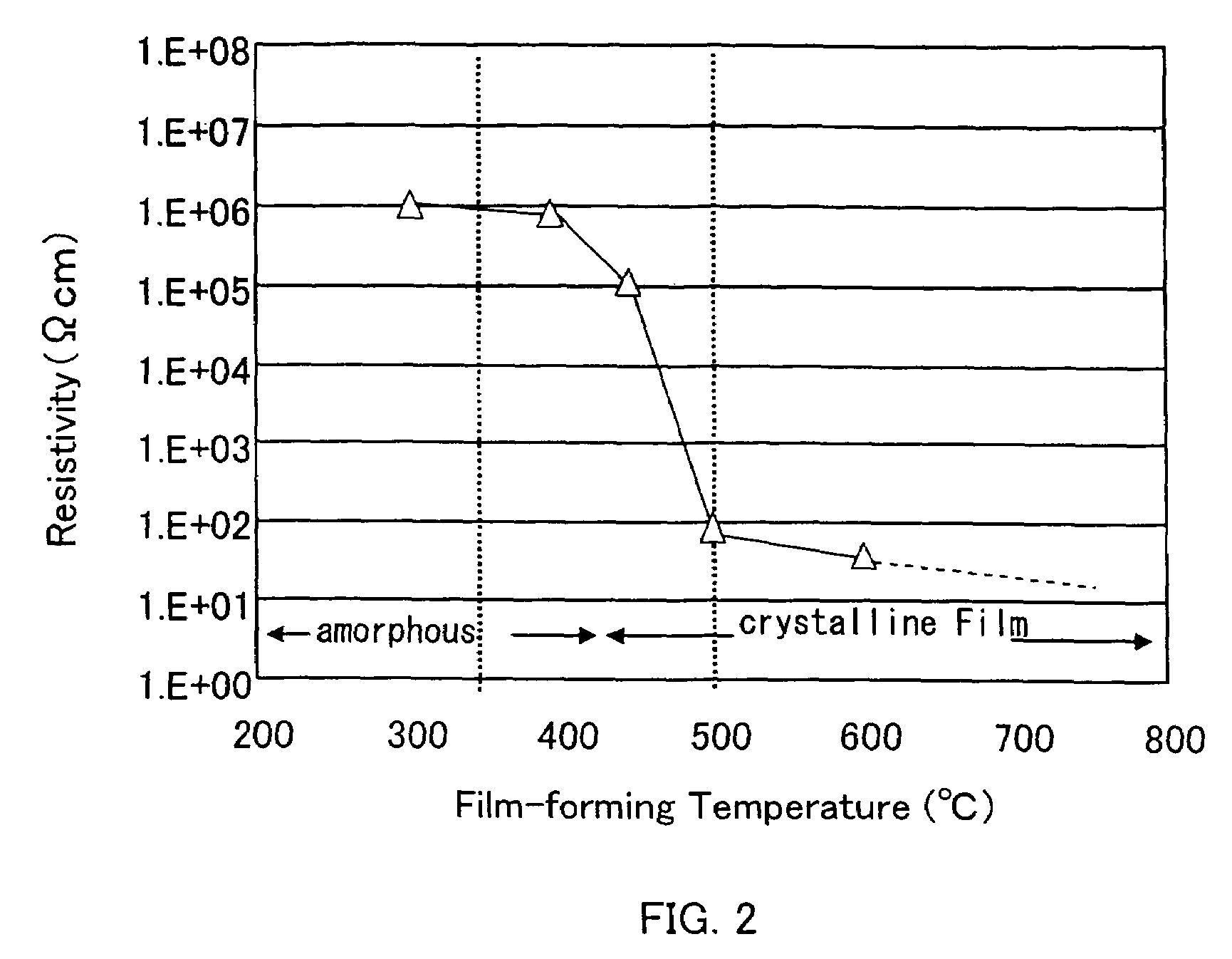

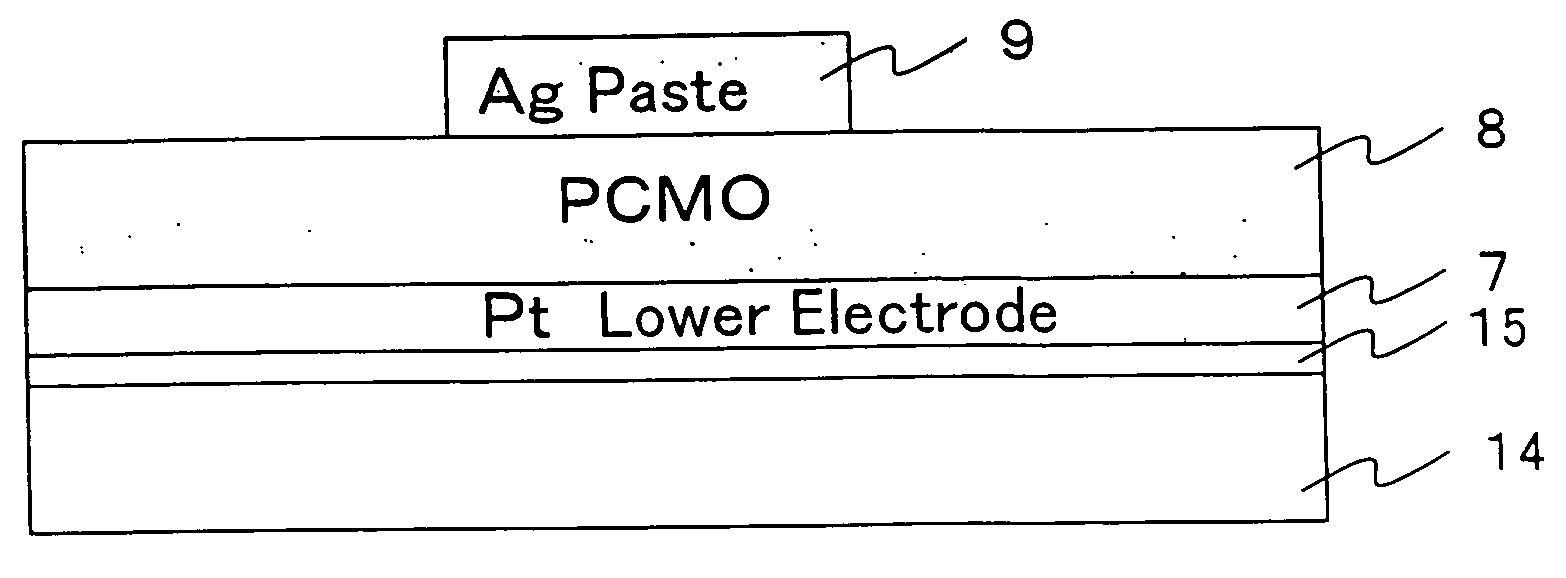

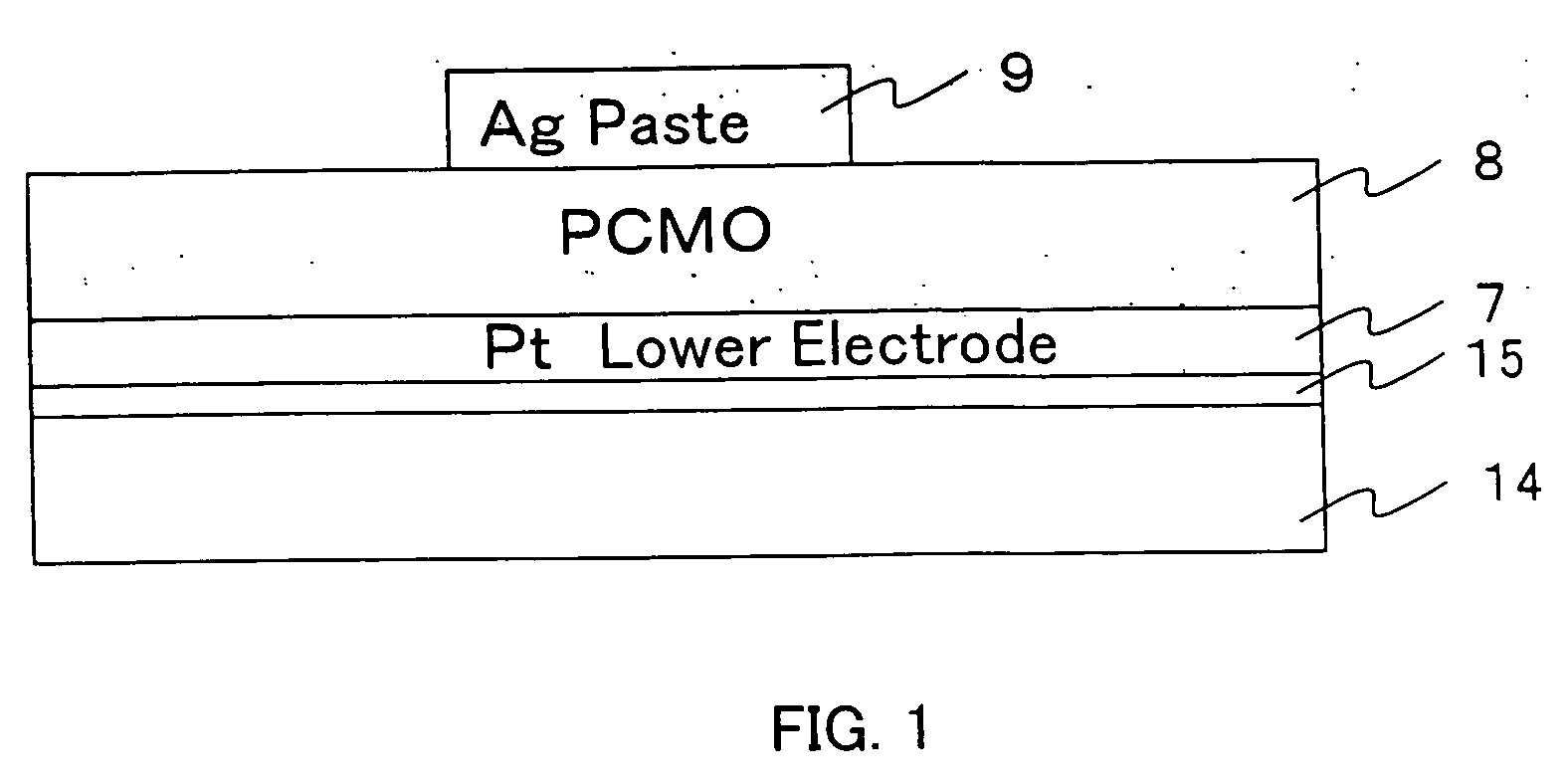

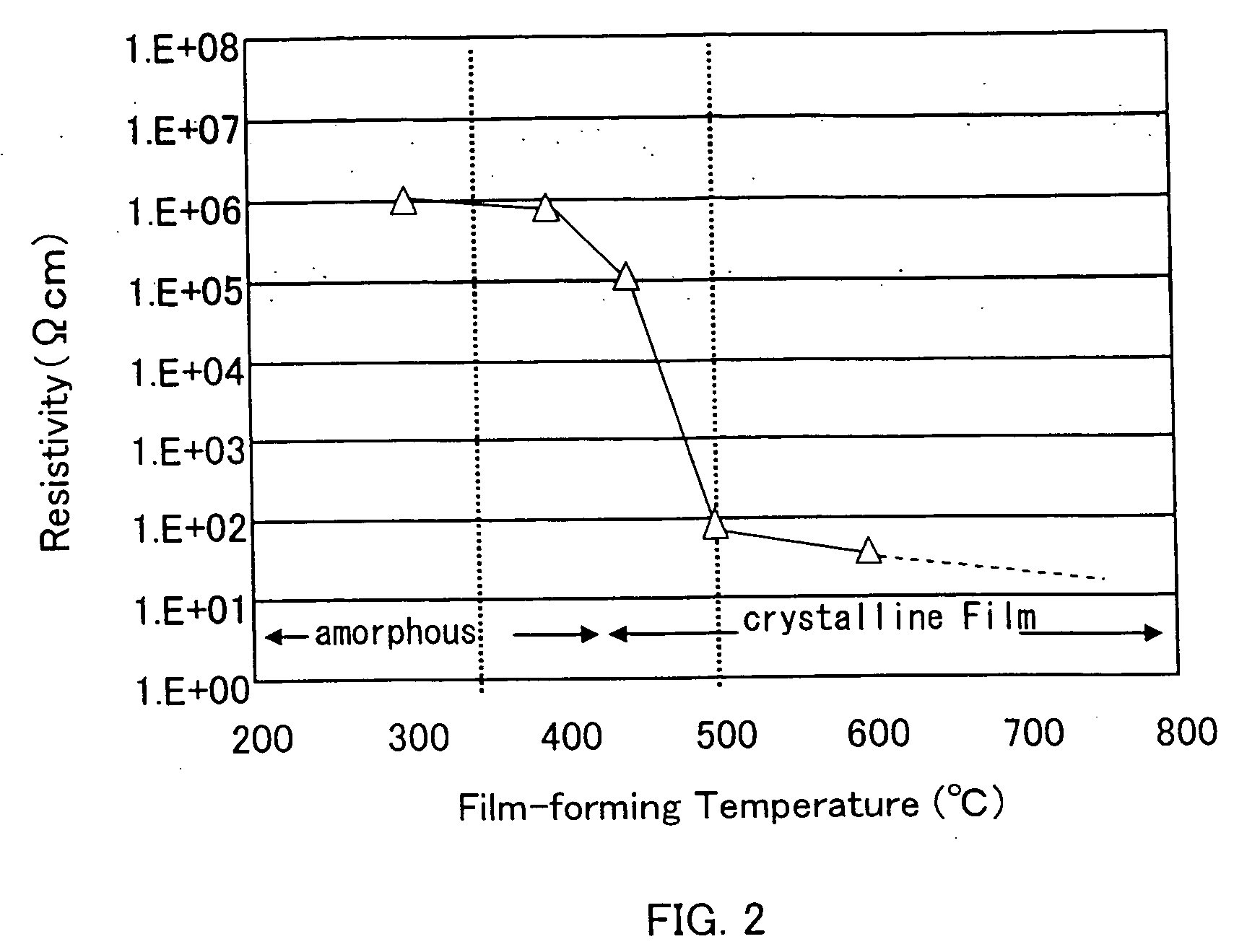

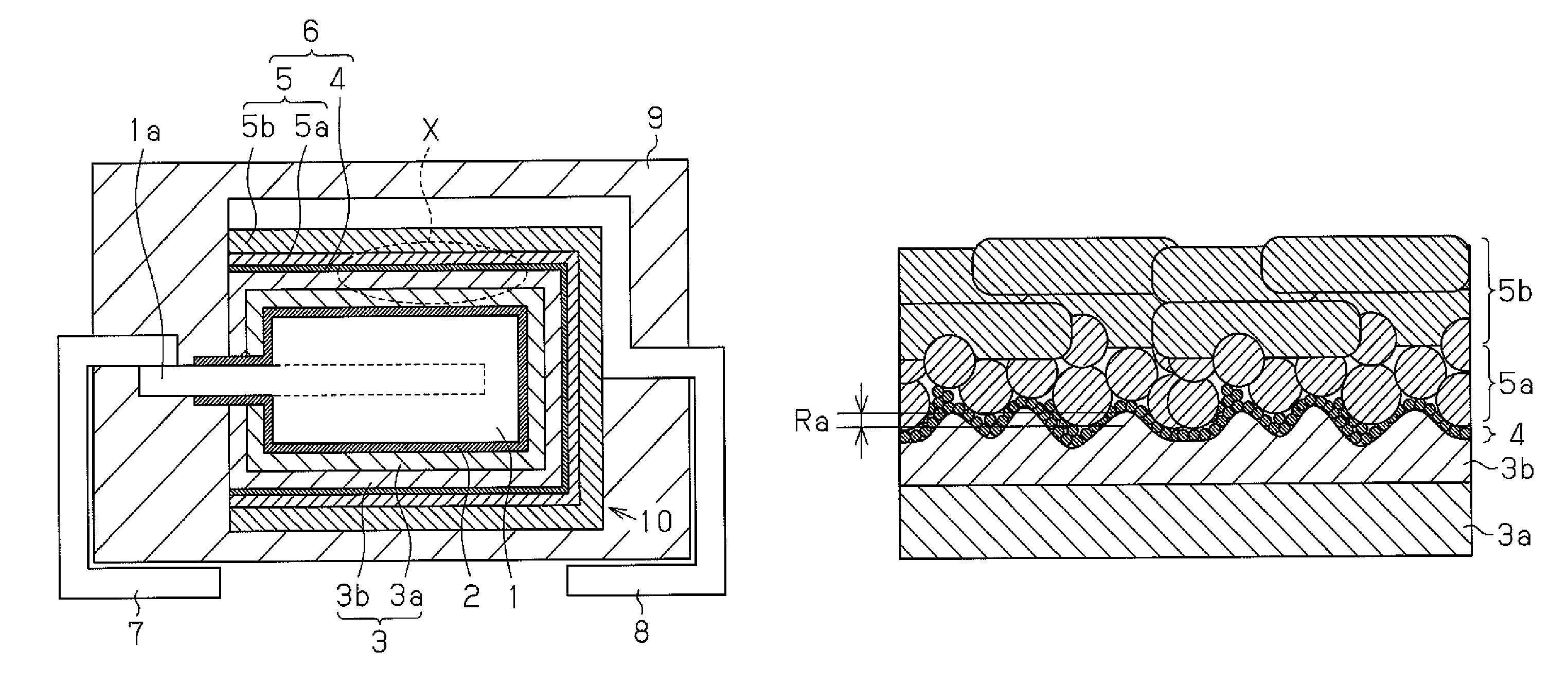

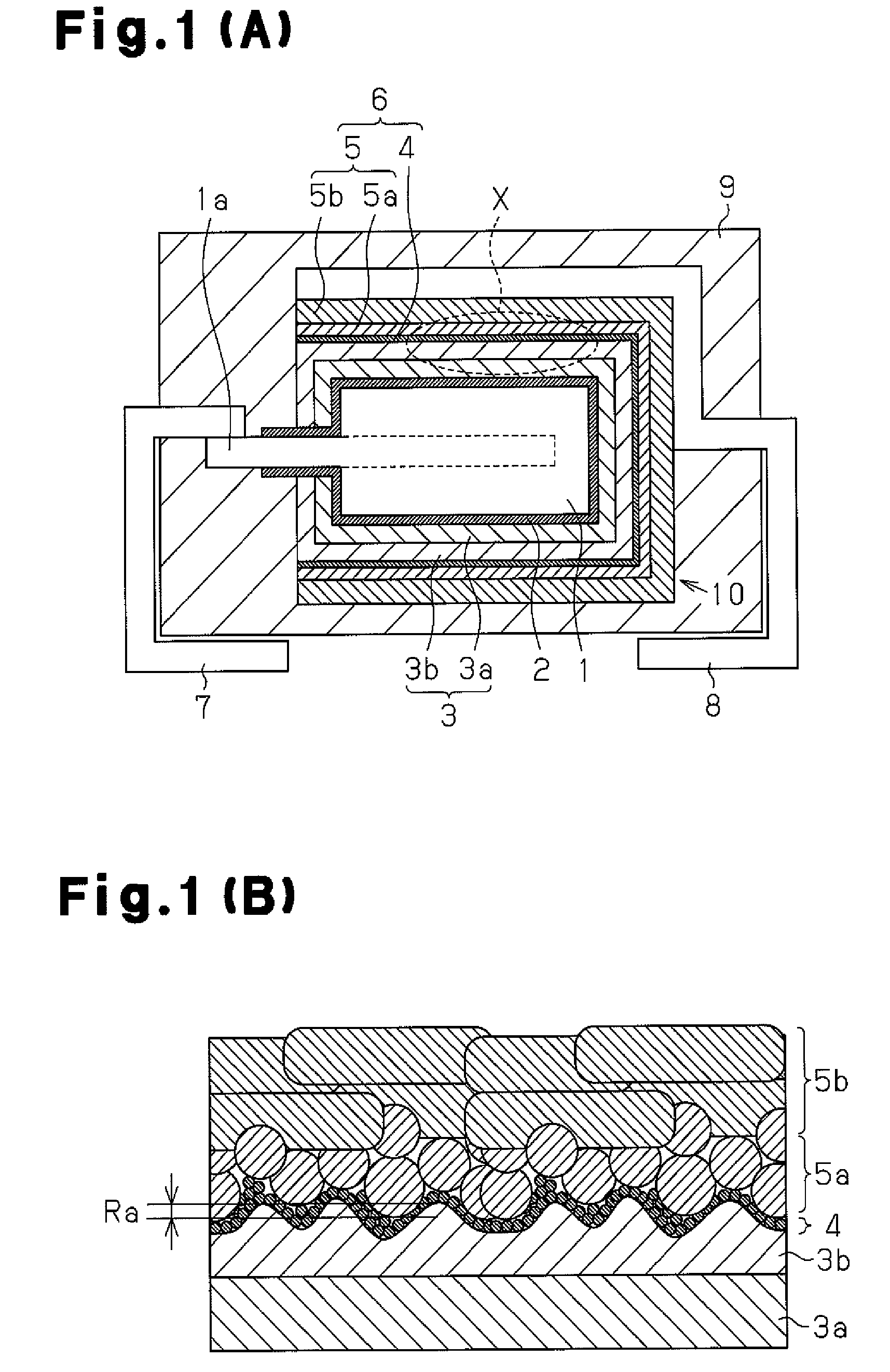

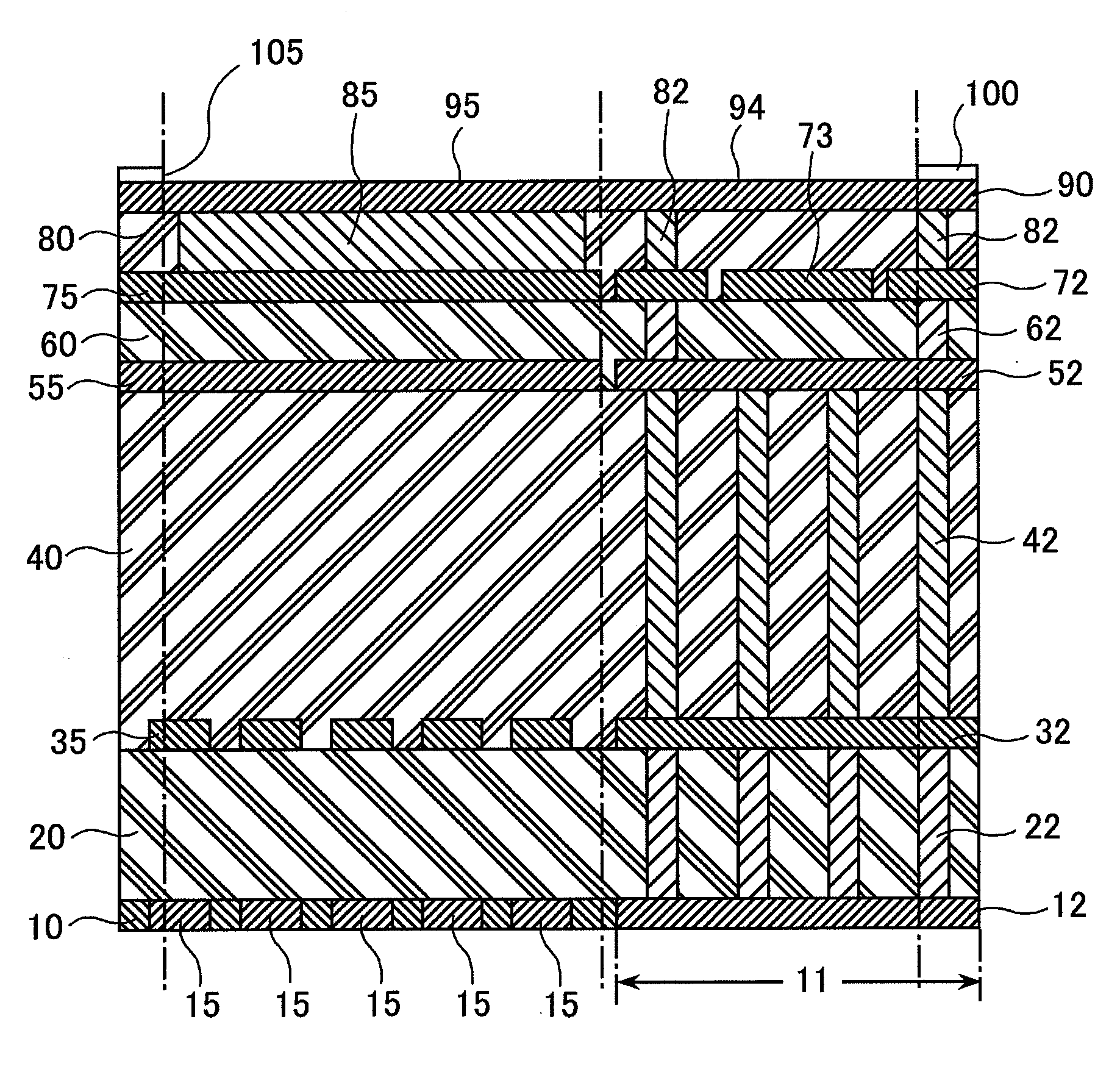

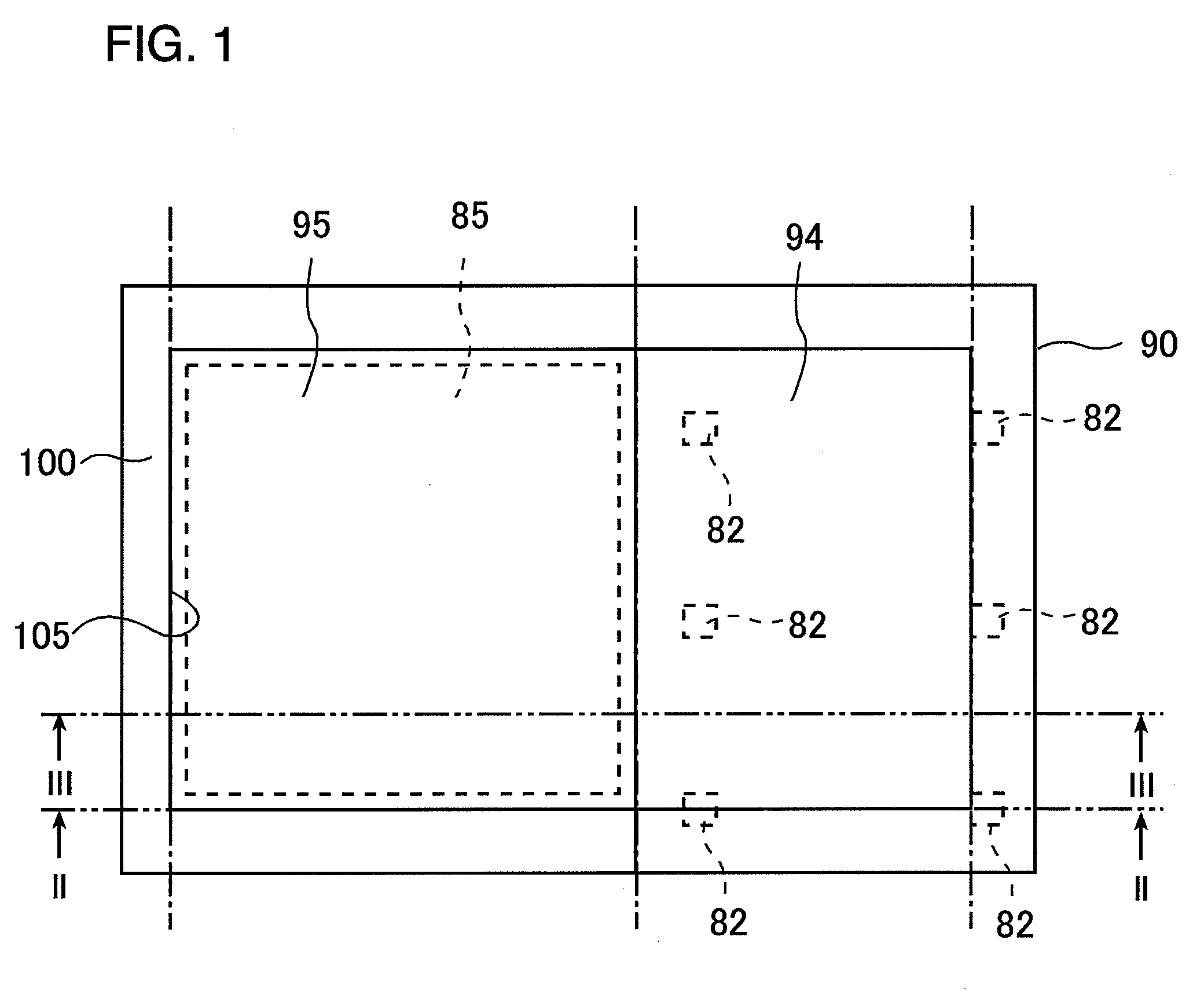

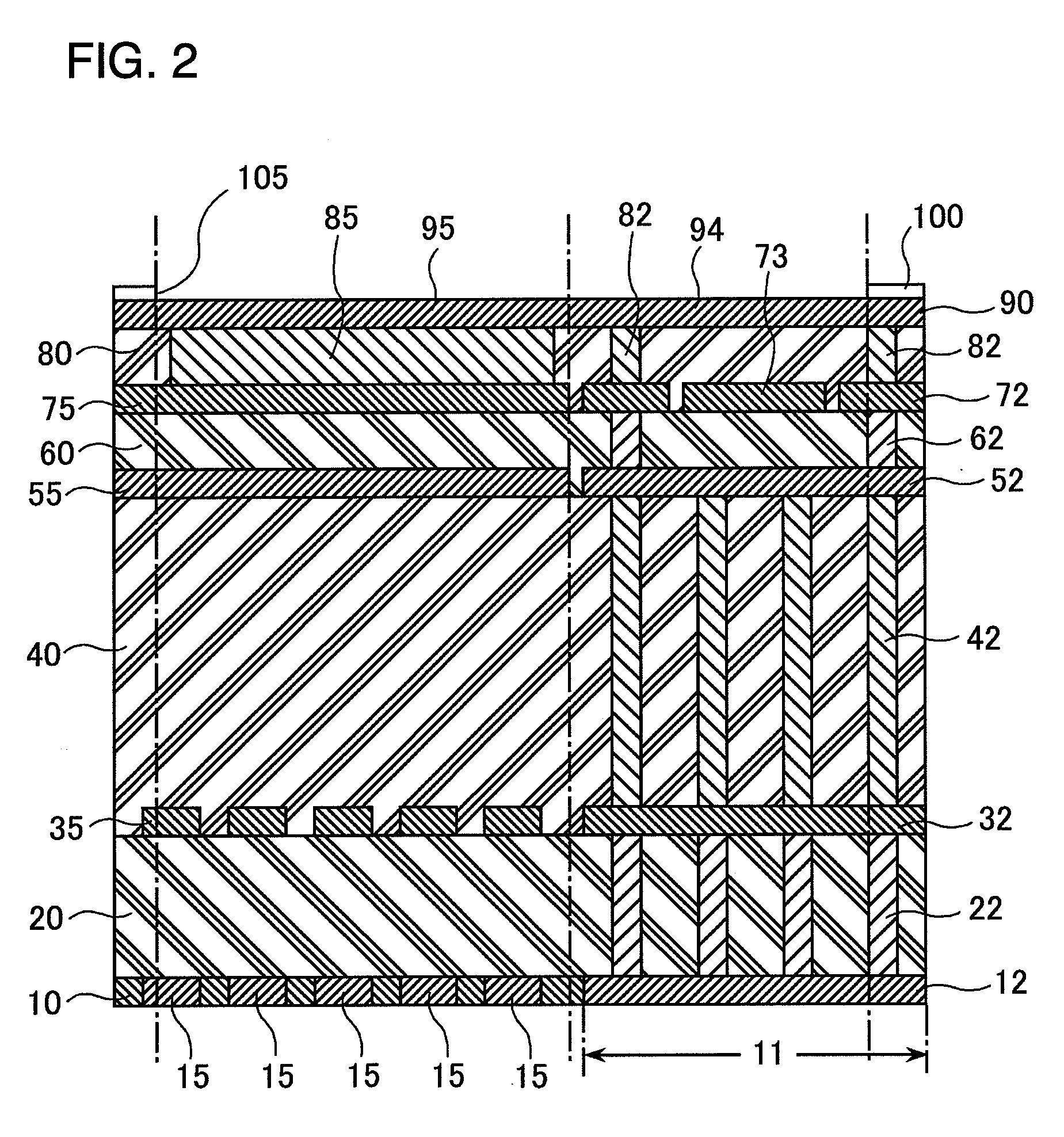

Nonvolatile semiconductor memory device comprising a variable resistive element containing a perovskite-type crystal structure

ActiveUS7045840B2Improve the immunityReduce the effective contact areaSolid-state devicesSemiconductor/solid-state device manufacturingParticulatesElectrical conductor

Owner:XENOGENIC DEV LLC

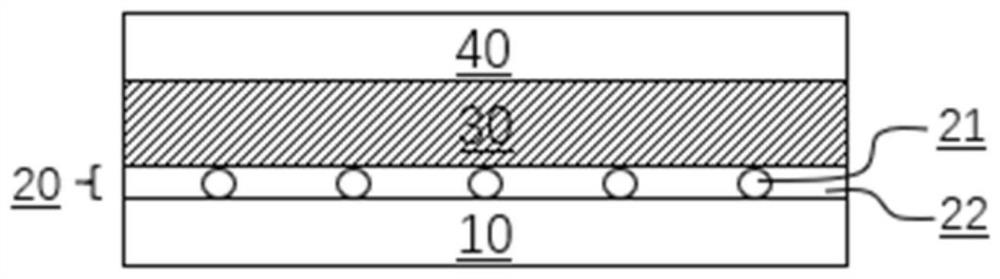

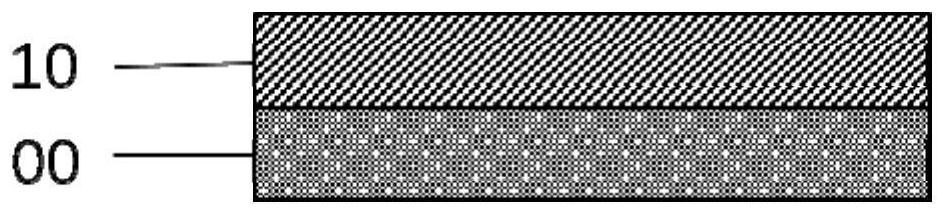

Nonvolatile semiconductor memory device

ActiveUS20050145910A1Improve the immunityReduce the effective contact areaTransistorSolid-state devicesElectrical conductorCrystal structure

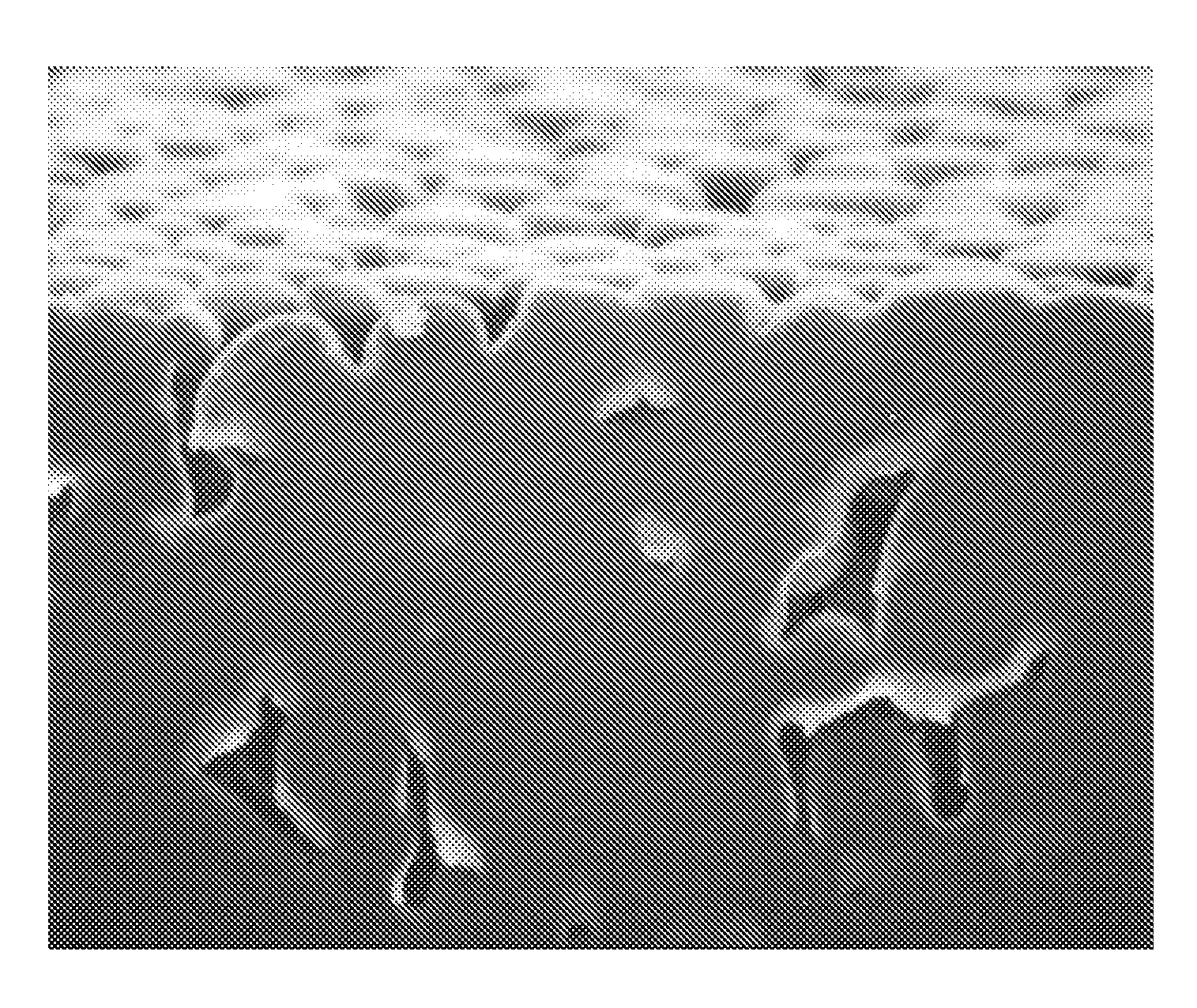

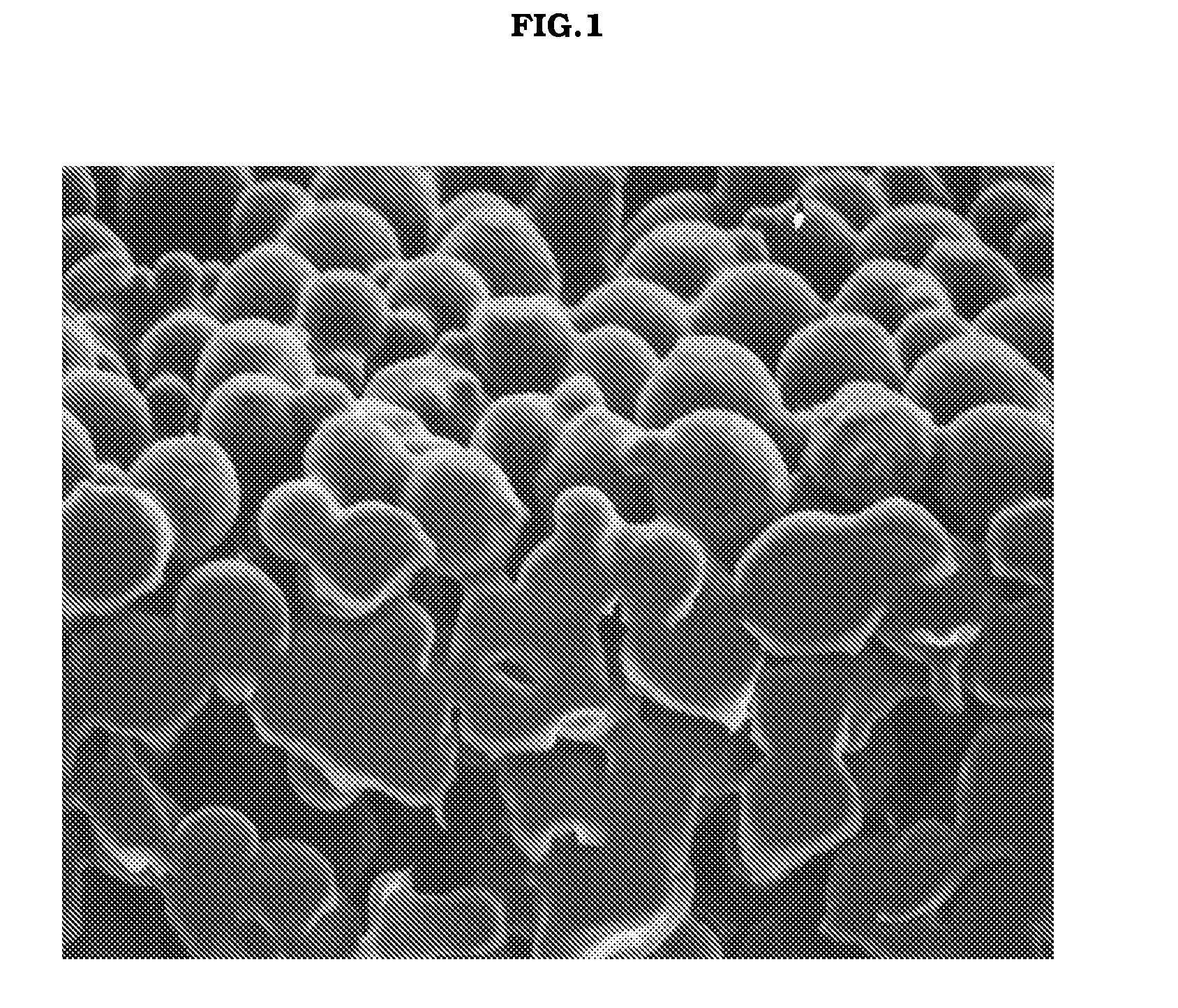

In a nonvolatile semiconductor memory device including a variable resistive element formed by sequentially stacking a lower electrode, a variable resistor with a perovskite-type crystal structure, and an upper electrode, at least one of the lower electrode and the upper electrode is a particulate electrode configured to include a particulate conductor aggregate, so that the contact area with the variable resistor at an interface is effectively reduced to realize high initial resistance of the variable resistive element. Further, a film of the variable resistor is preferably formed so as to be in a highly crystalline state.

Owner:XENOGENIC DEV LLC

Solid electrolytic capacitor

ActiveUS8035953B2Lower equivalent series resistanceReduce the effective contact areaSolid electrolytic capacitorsLiquid electrolytic capacitorsCarbon layerElectrolysis

Owner:SANYO ELECTRIC CO LTD

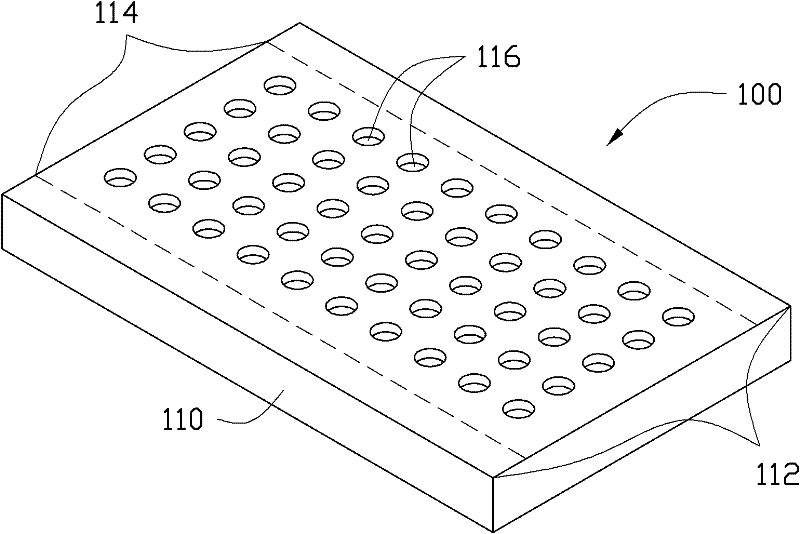

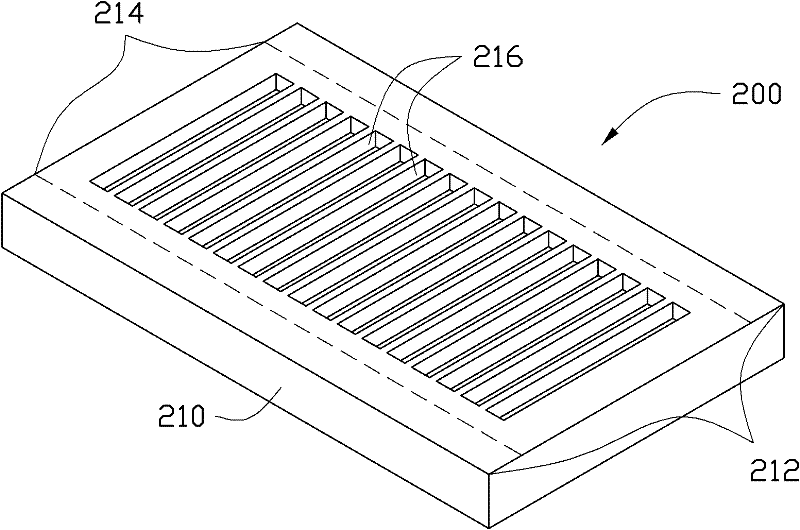

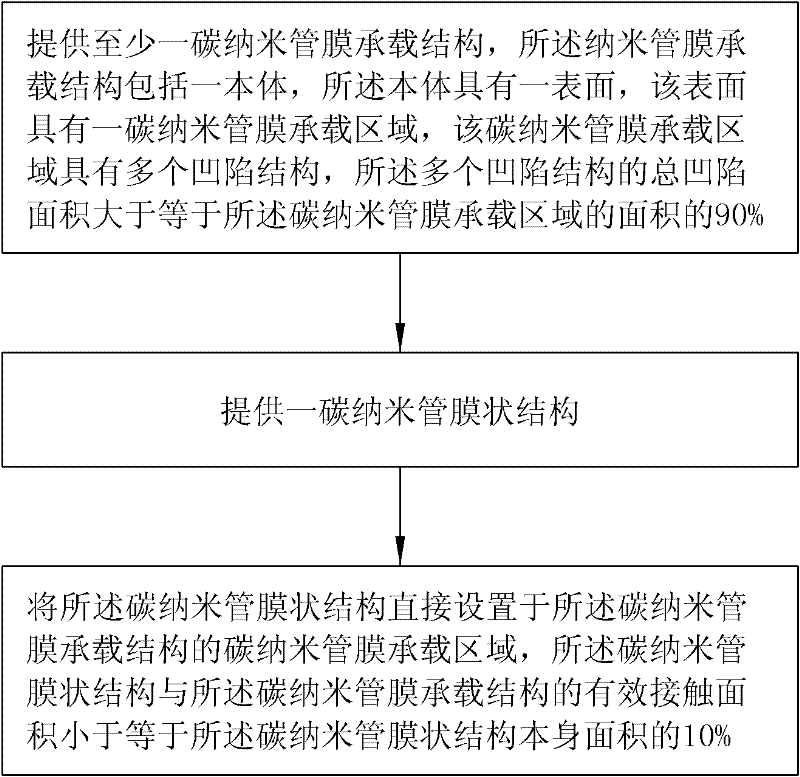

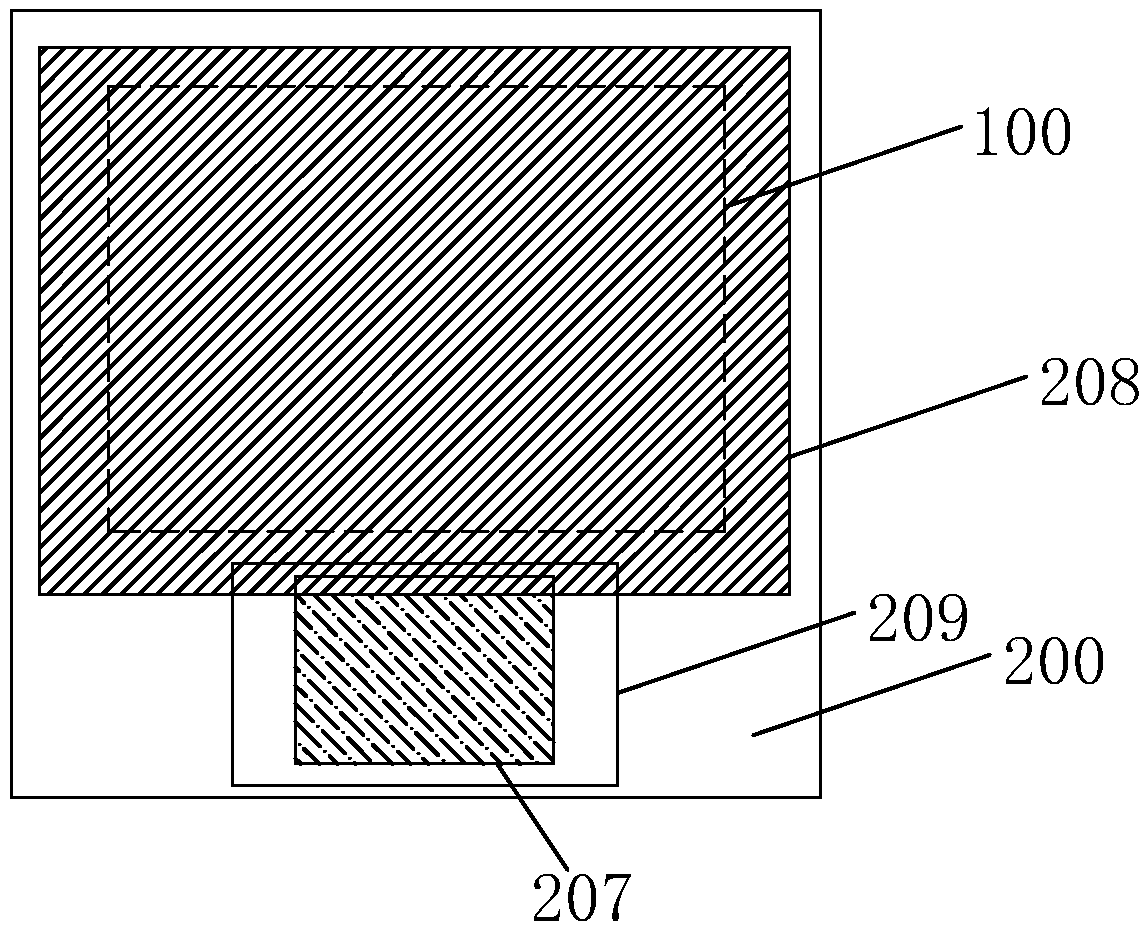

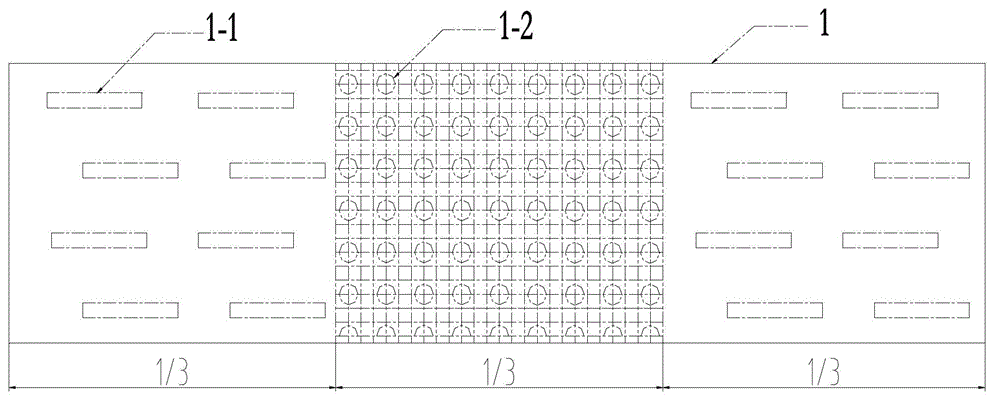

Carbon nanotube film carrying structure and use method thereof

ActiveCN102452647AAchieve preservationAchieve transferNanostructure manufactureCeramicwareCarbon nanotube

The invention relates to a carbon nanotube film carrying structure, which comprises a body, wherein the body is provided with a surface; the surface of the body is provided with a carbon nanotube film carrying area; the carbon nanotube carrying area is provided with a plurality of depression structures; and the total depression area of the plurality of depression structures is larger than or equal to 80 percent of the area of the carbon nanotube film carrying area. The carbon nanotube film carrying structure is used for carrying a carbon nanotube film-shaped structure, and the carbon nanotubefilm-shaped structure can be completely separated from the carrying structure after being contacted with the carrying structure. The invention further relates to a method for using the carbon nanotube film carrying structure.

Owner:BEIJING FUNATE INNOVATION TECH

Liquid crystal display panel

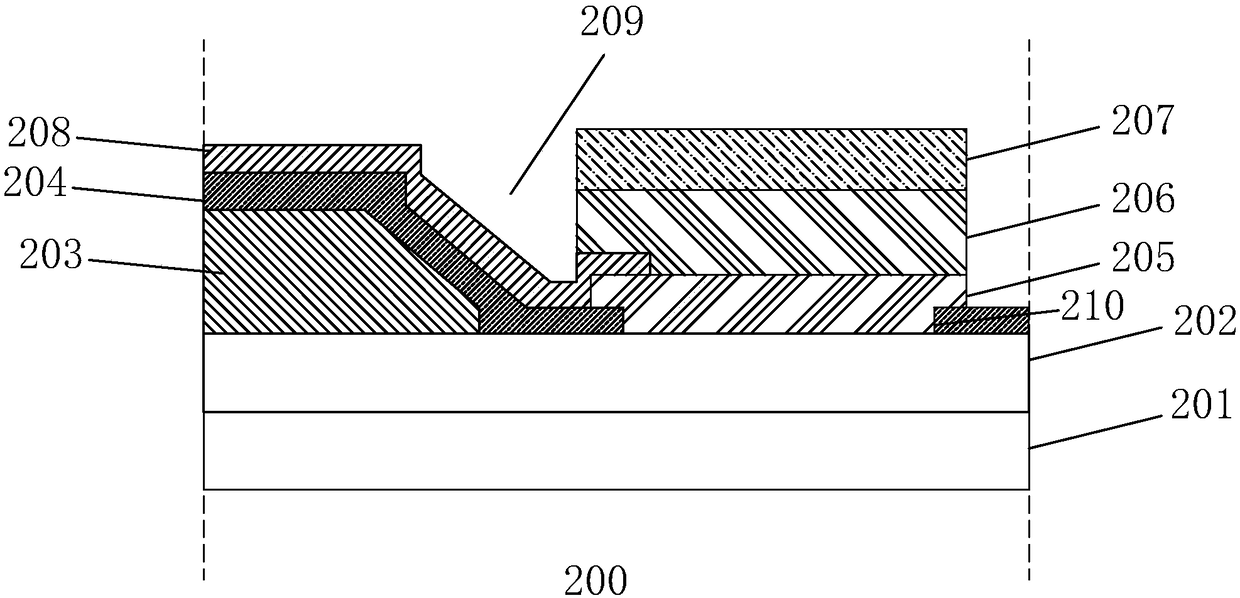

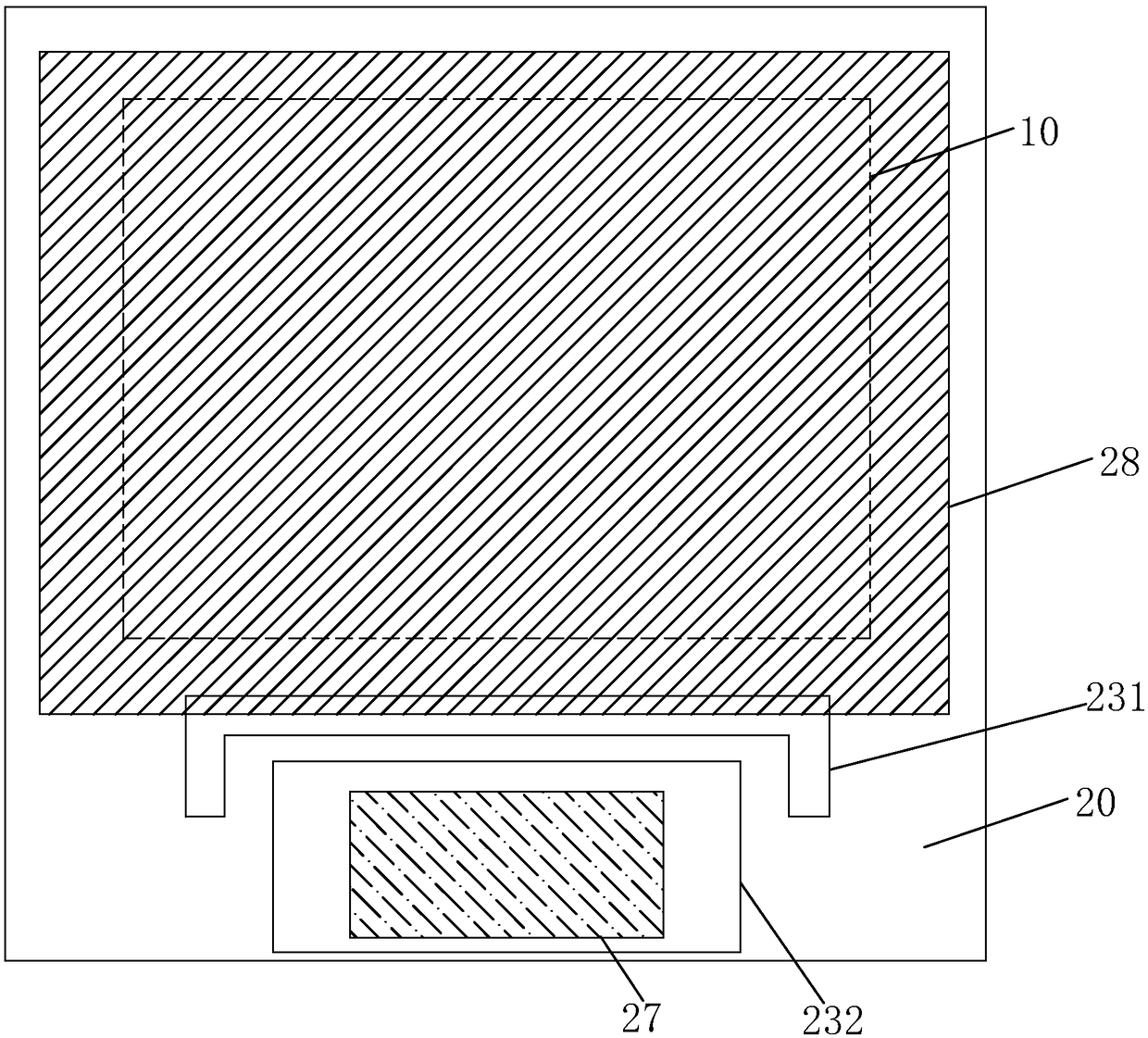

InactiveCN108761932AGood bondingAchieving Narrow BezelsNon-linear opticsLiquid-crystal displayAnisotropic conductive adhesive

The invention provides a liquid crystal display panel. The liquid crystal display panel comprises a display area and a border area which are adjacent, the border area comprises an underlayer substrate, a metal wiring layer arranged on the underlayer substrate, a flat layer arranged on the metal wiring layer, an insulating layer arranged on the flat layer and the metal wiring layer, a bonding terminal arranged on the insulating layer and the metal wiring layer, an anisotropic conductive adhesive arranged on the bonding terminal, a connecting terminal arranged on the anisotropic conductive adhesive and an alignment film arranged on the insulating layer; at least one blocking groove is formed between the display area and the bonding terminal, the alignment film of the border area can only flow into the blocking grooves, the phenomenon that the alignment film covers the bonding terminal due to certain mobility is prevented, the phenomenon that the effective contact area of the connecting terminal and the bonding terminal is reduced is avoided, the phenomenon that liquid crystal display panel bonding is poor is avoided, the display effect is improved, and narrow bezel of the liquid crystal display panel is facilitated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

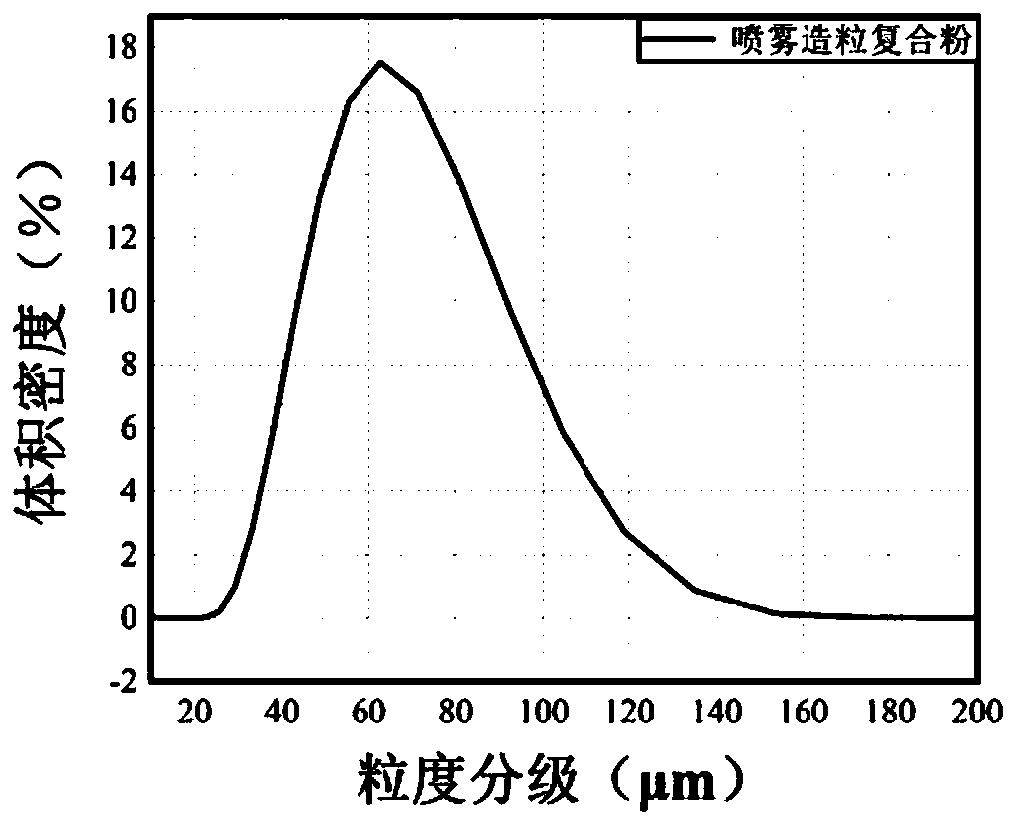

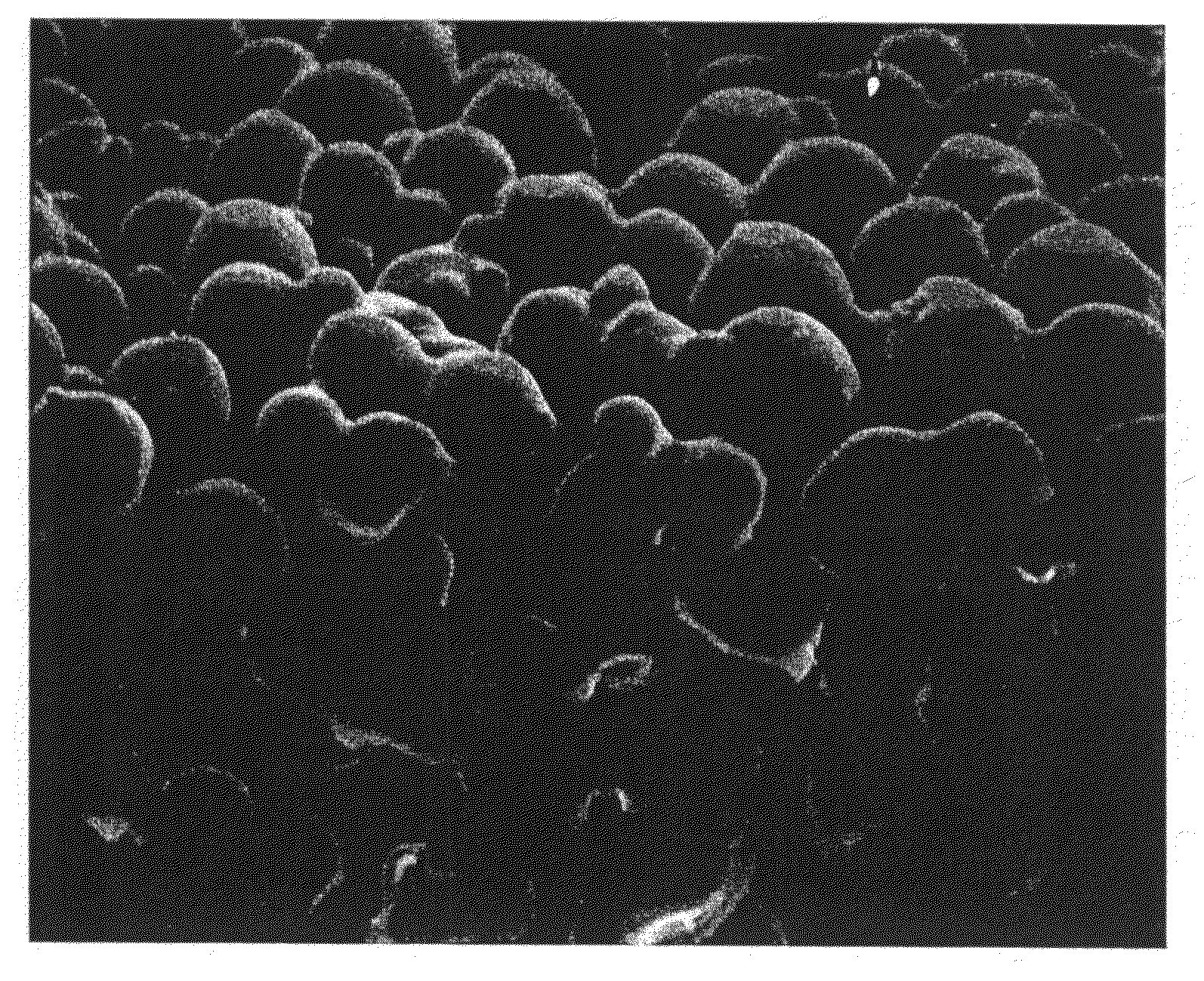

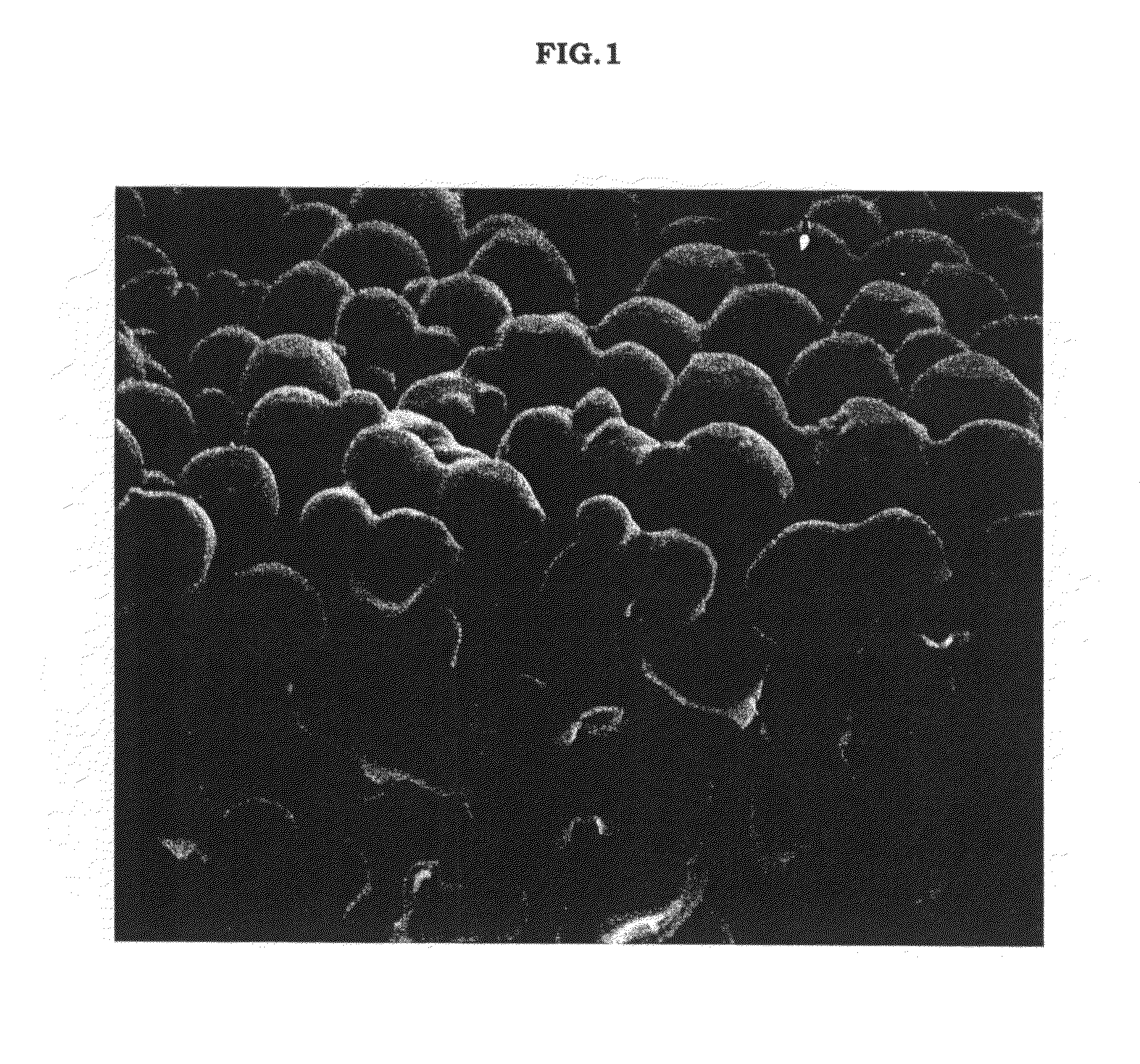

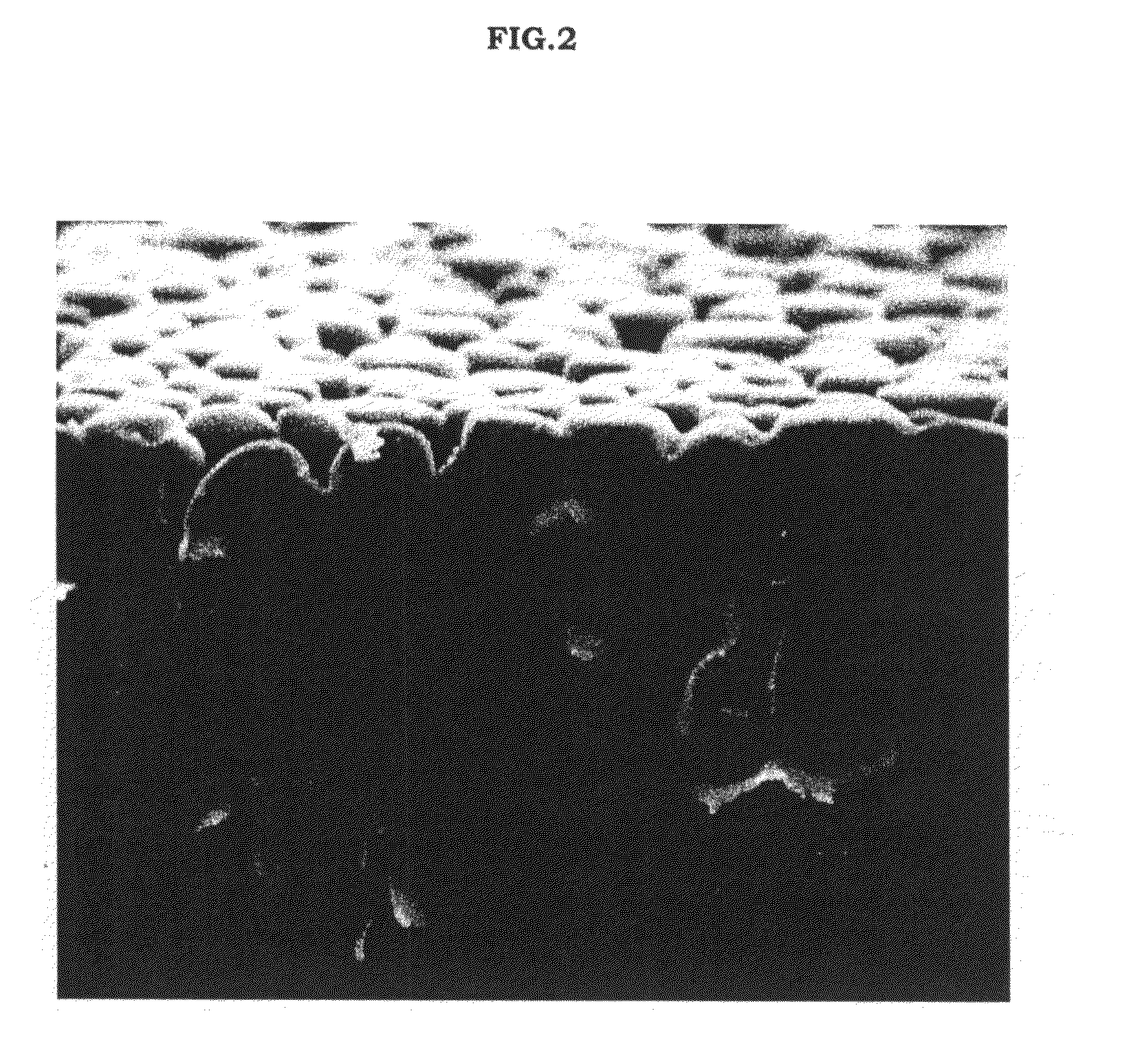

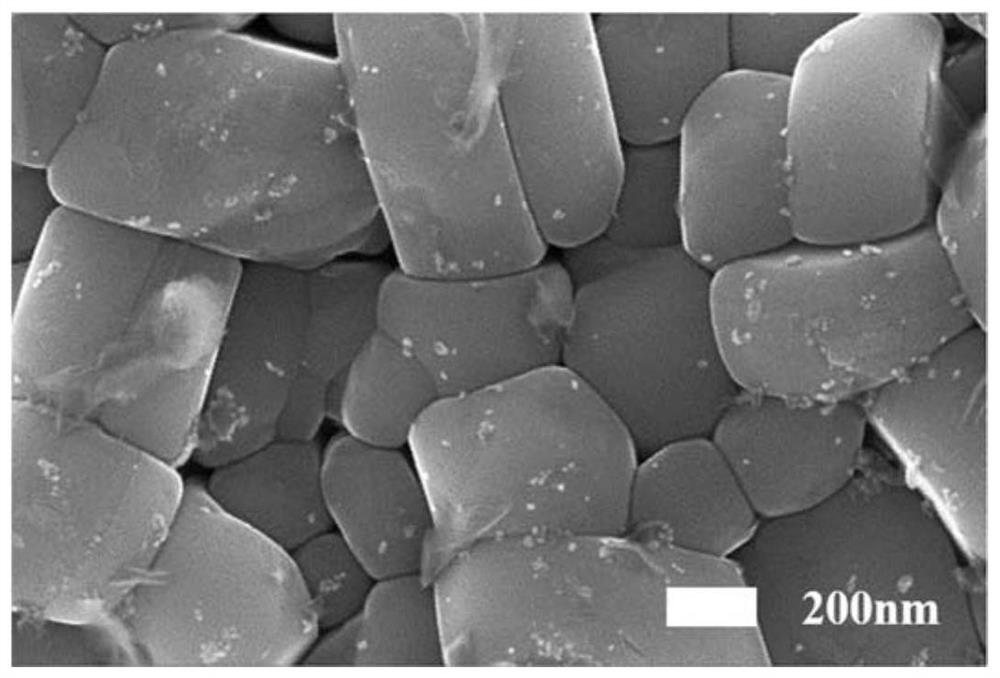

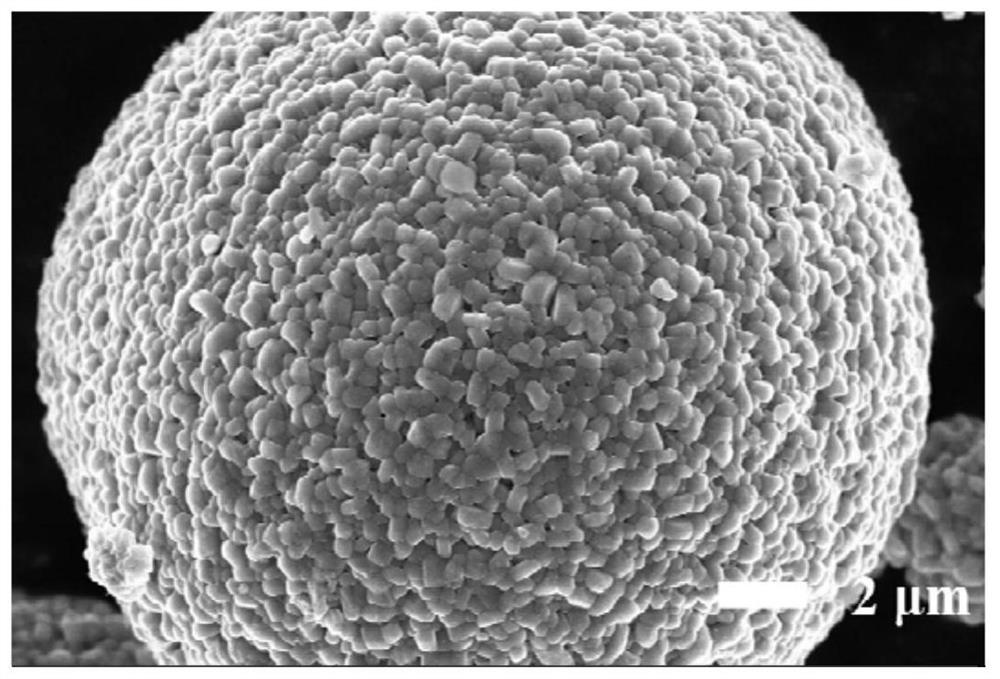

Preparation method of spray granulation Fe-Al2O3 spraying composite powder

InactiveCN110883337ALow viscosityHigh viscosityMolten spray coatingSpray GranulationCeramic composite

The invention belongs to a preparation method of metal / ceramic composite powder in spraying application, and particularly relates to a preparation method of spray granulation Fe-Al2O3 spraying composite powder. The preparation method is simple to operate, high in performance and free of screening. According to the preparation method, PEI is adopted as a binder, so that metal Fe powder and Al2O3 powder are tightly bonded and uniformly distributed; in addition, PEI also has the effect of a dispersing agent, so that the effect of two purposes is achieved, the requirement for preparing low-viscosity slurry is met, the possibility that the dispersing agent and the binder are adopted at the same time to react is avoided, and the obtained slurry is low in viscosity and high in solid content. Finally, on the premise that particles can be bonded with one another, the obtained powder is uniform in particle size distribution, high in sphericity degree and good in compactness and fluidity, the metal Fe powder has excellent oxidation resistance, and preparation of a subsequent spraying wave-absorbing coating is facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method of producing porous sheet and porous sheet obtained by the production method

InactiveUS20070202298A1Excellent in releasabilityGood surface smoothnessRecord information storageMagnetic recordingPorous sheetSolvent

A method of producing a porous sheet, which comprises the steps consisting of preparing a dispersion having ultra-high-molecular-weight polyethylene particles dispersed in a solvent, applying the dispersion onto a film to form a coating layer thereon, sintering the coating layer, and removing the solvent contained in the coating layer.

Owner:NITTO DENKO CORP

Semiconductor device

InactiveUS20090146319A1Ensure bonding reliabilityReduce chip sizeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor

A semiconductor device which can prevent damage to an ESD protection device by pressure when bonding is carried out, while having a pad configuration that can ensure bonding reliability, with the semiconductor device being made as small as possible. A bonding area that is an area for wire bonding with respect to an external electrode pad and a probing area that is an area in which a probe needle is applied when probing, are provided, and the ESD protection device and a discharge path therefor are arranged below the probing area. Arranged below the bonding area are a support via that is a little smaller than the bonding pad, and a support pattern having a size corresponding to the bonding pad and joined to the bonding pad by the support via.

Owner:ELPIDA MEMORY INC

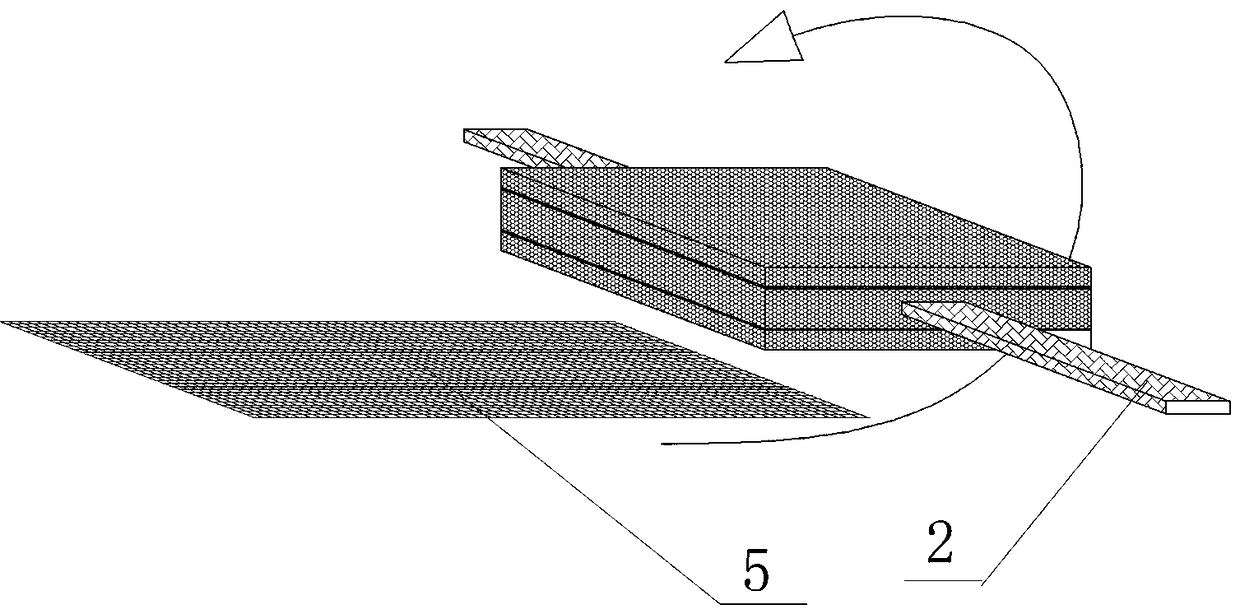

Lightweight graphite resistance reduction module and preparation method thereof

PendingCN108155489AImprove conductivityStrong moisture absorption and moisturizing abilityLine/current collector detailsConnection contact member materialGlass fiberGraphite

The invention discloses a lightweight graphite resistance reduction module and a preparation method thereof. The lightweight graphite resistance reduction module is prepared form expanded graphite, glass fiber mesh cloth, graphite resistance reduction cloth and graphite woven belt material. The lightweight graphite resistance reduction module can be made into a block shape, a plate shape or a cylindrical shape and is high in plasticity and structural strength. The preparation method includes the processes of laying, fixing, pressing, coating and re-pressing. The lightweight graphite resistancereduction module has the advantages of being small in density, light in weight, high in strength, good in water absorption, excellent in electrical conductivity and the like.

Owner:XIXIAXIAN JINFANGYUAN SEALING MATERIAL

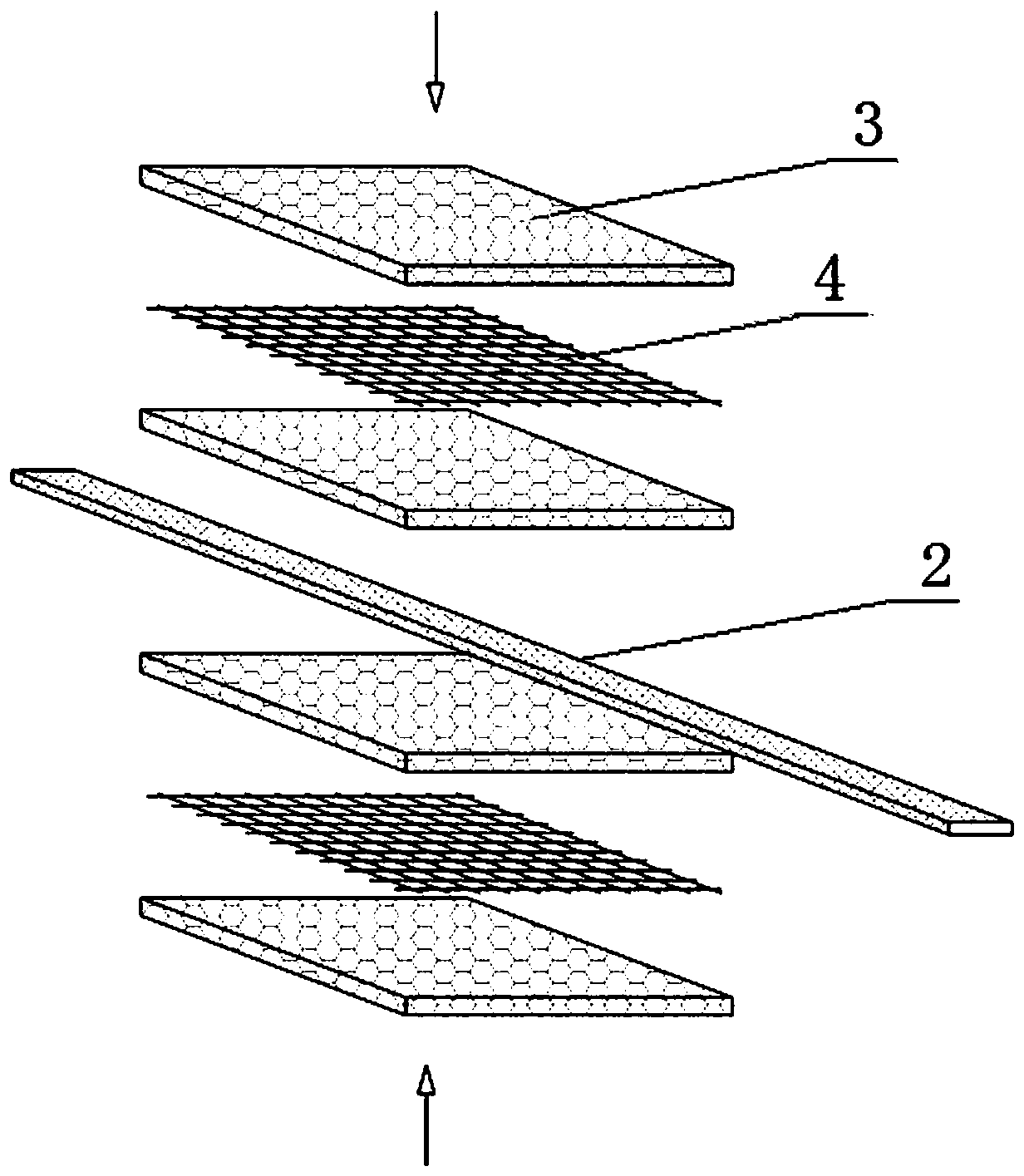

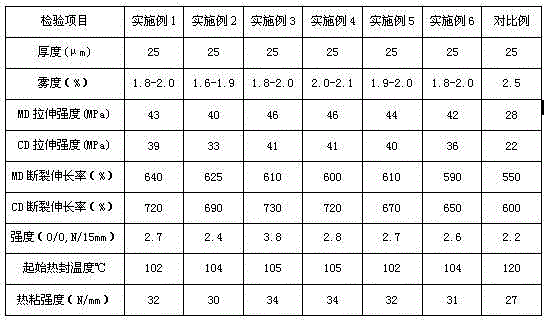

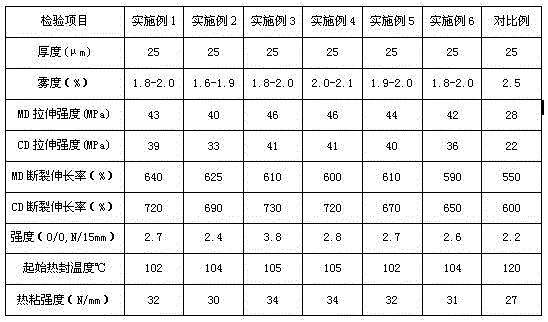

CPP direct response membrane

InactiveCN103182820AReduce the effective contact areaAvoid stickingSynthetic resin layered productsPolymer scienceAdhesive

An CPP (casting polypropylene) direct response membrane comprises an anti-sticking layer, a sandwich layer and a thermosensitive functional layer, wherein the sandwich layer is positioned between the anti-sticking layer and the thermosensitive functional layer, the thickness of the anti-sticking layer accounts for 10 to 20 percent of the total thickness, the thickness of the sandwich layer accounts for 40 to 60 percent of the total thickness, and the thickness of the thermosensitive functional layer accounts for 10 to 30 percent of the total thickness; the anti-sticking layer provided by the invention is made of propylene binary random copolymer with better temperature resisting performance and can provide better temperature endurance, so that a thin film is prevented from causing thermal contraction during direct response; the sandwich layer ensures that the stiffness and the temperature endurance of material are improved, the thermosensitive functional layer adopts a vinyl-type copolymer with higher hot sticking performance and ethylene-acrylic acid copolymer, the hot sticking problems of the material are reduced greatly, the material is enabled to have a better direct response performance, and adhesive is not required to be used when the material is combined with BOPP, BOPET thin film and print film. Therefore, the cost is lowered and the CPP straight complex membrane is beneficial to environmental protection.

Owner:湖北慧狮塑业股份有限公司

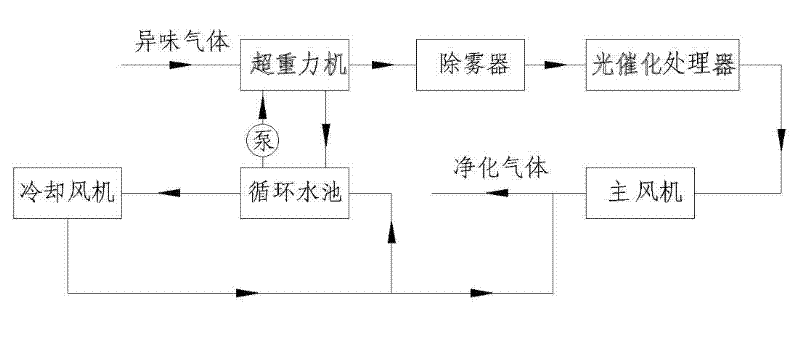

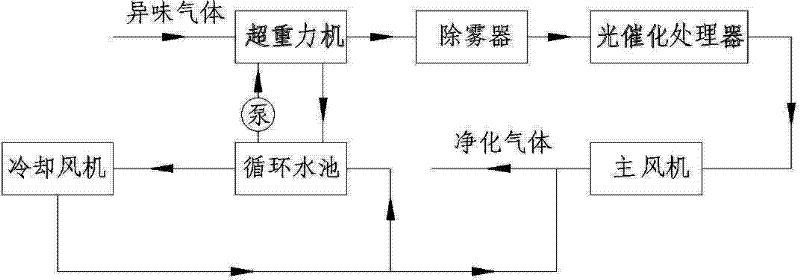

Process for removing tobacco odour

InactiveCN102335539AIncrease flow rateIncrease the effective specific surface areaCombination devicesHypergravityHazardous substance

The invention discloses a process for removing tobacco odour, which comprises the following steps of: removing dust and watersoluble harmful substances or constituents in gas to be treated by using a wet scrubber, removing water mist in the gas by using a demister, oxidizing the harmful substances or constituents in the gas by using a photocatalytic odour processor, and discharging the processed gas to the air by using a main air blower. The wet scrubber is a hypergravity gas dust-removing and sulphur-removing integrated machine, the gas to be treated is washed with circulating water, and the circulating water is cooled by a cooling air blower. The photocatalytic odour processor is a tube self-cleaning photocatalytic odour processor. The hypergravity gas dust-removing and sulphur-removing integrated machine and the photocatalytic odour processor can be used independently and combined for use. Both the hypergravity gas dust-removing and sulphur-removing integrated machine (Patent No. ZL200920233065.5) and the tube self-cleaning photocatalytic odour processor (Patent No. 201010273561.0) are inventions of the applicant, have applied the national patent, and are batch-produced, and are put on the market and gained public praise.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

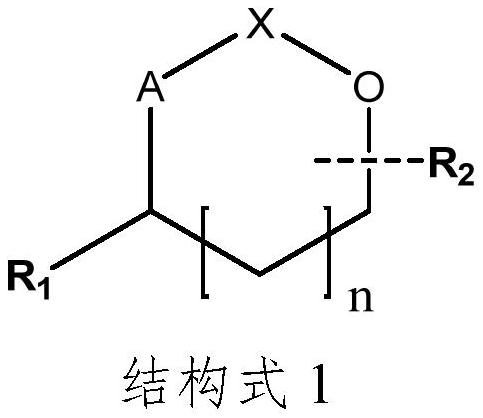

Lithium ion battery

PendingCN114447295AImprove cycle performanceInhibit side effectsSecondary cellsPositive electrodesCarbon coatingElectrolytic agent

In order to solve the problem of power reduction in long-term circulation of the existing lithium iron phosphate battery, the invention provides a lithium ion battery which comprises a positive electrode, a negative electrode and a non-aqueous electrolyte, the positive electrode comprises a positive electrode material layer containing a positive electrode active material, and the negative electrode comprises a negative electrode material layer containing a negative electrode active material; the positive electrode active material comprises a lithium iron phosphate composite material consisting of lithium iron phosphate and a carbon coating layer coated on the surface of the lithium iron phosphate, and the non-aqueous electrolyte comprises a solvent, an electrolyte salt and an additive, the additive comprises a compound as shown in a structural formula 1 and vinylene carbonate; and the lithium ion battery meets the following condition: (W1 / W2) * (Ma + Mb) / 100 is more than or equal to 0.1 and less than or equal to 4. According to the lithium ion battery provided by the invention, a relatively stable passive film is formed on the positive electrode material layer, so that the side reaction of the non-aqueous electrolyte on the surface of the positive electrode active material with strong oxidizing property can be inhibited, and the cycle performance is improved.

Owner:SHENZHEN CAPCHEM TECH

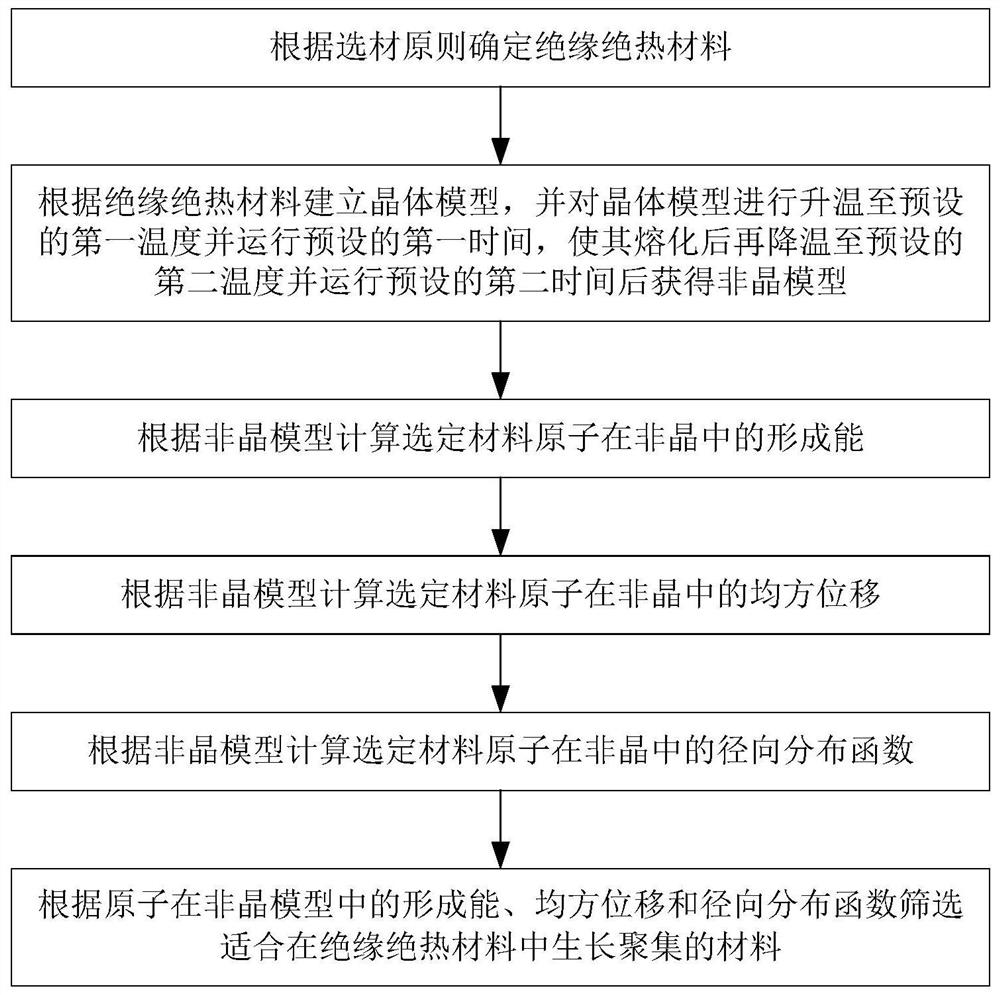

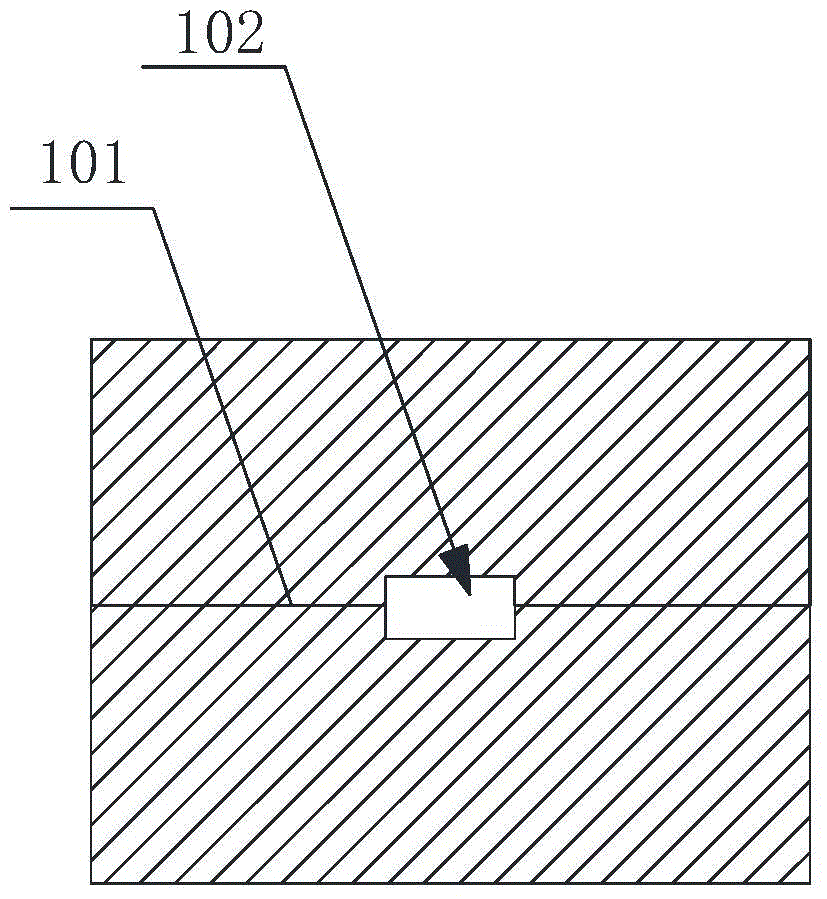

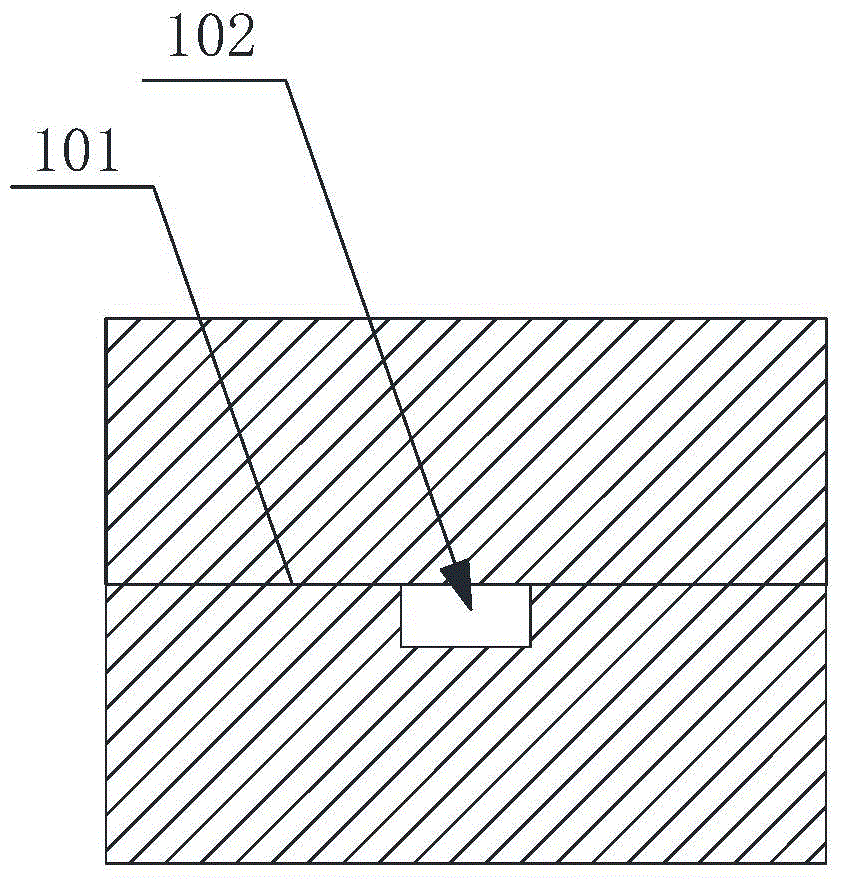

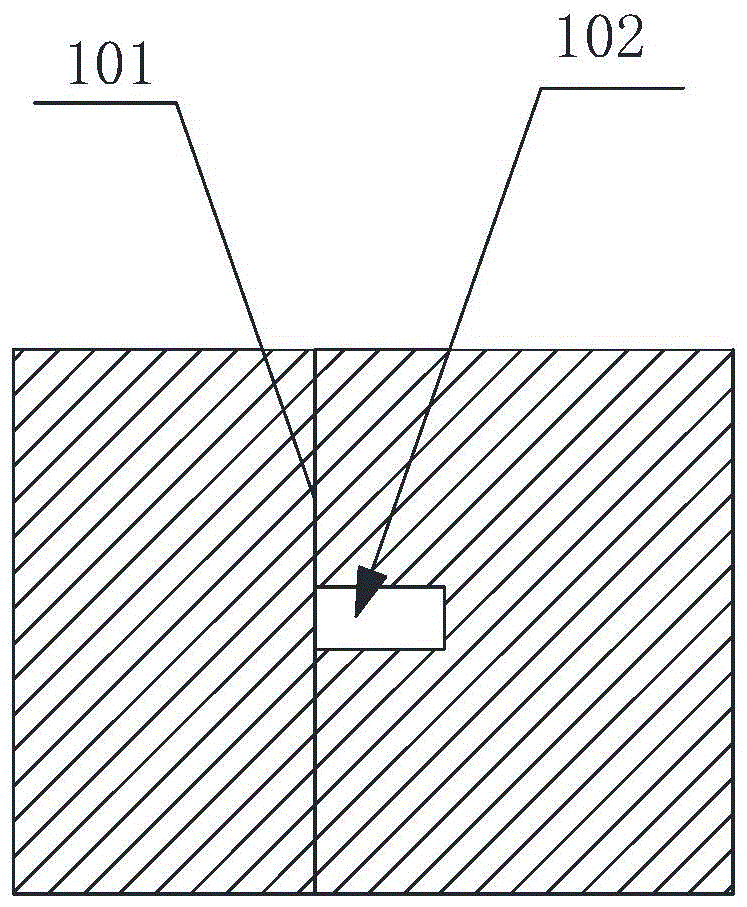

Method for screening and matching insulating and heat-insulating material and nano-crystalline metal material in nano current channel layer

PendingCN112687359AReduce the effective contact areaIncrease current densityDesign optimisation/simulationComputational theoretical chemistryPhase-change memoryMetallic materials

The invention discloses a method for screening and matching an insulating and heat-insulating material and a nano-crystalline metal material in a nano current channel layer. The method comprises the following steps: determining the insulating and heat-insulating material according to a material selection principle; establishing a crystal model according to the insulating material, heating the crystal model to melt the crystal model, cooling the crystal model to a preset first temperature, and operating the crystal model for a preset first time to obtain an amorphous model; calculating the formation energy, mean square displacement and radial distribution function of selected nano current channel material atoms in the model according to the amorphous model; and screening a material suitable for growing and gathering in the insulating and heat-insulating material according to the formation energy, the mean square displacement and the radial distribution function. The nano current channel layer prepared from the material screened by the method is an insulating layer containing metal nano crystal grains penetrating through the film thickness of the nano current channel layer, and the current only flows between the electrode layer and the phase change layer through a nano current channel formed by the metal nano crystal grains; and the power consumption of the phase-change memory can be obviously reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

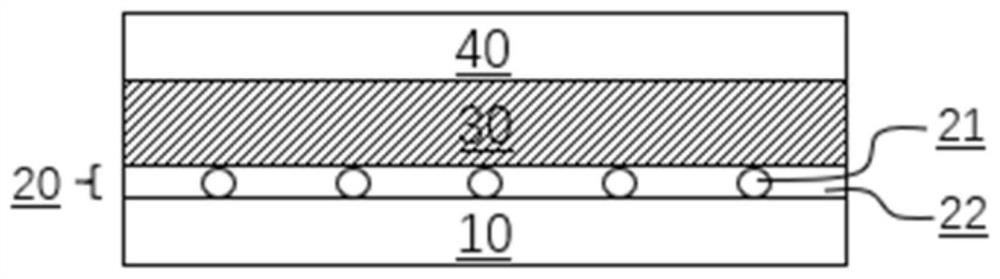

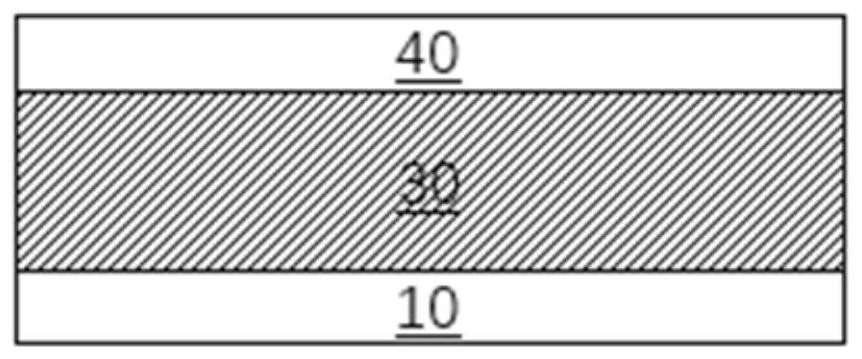

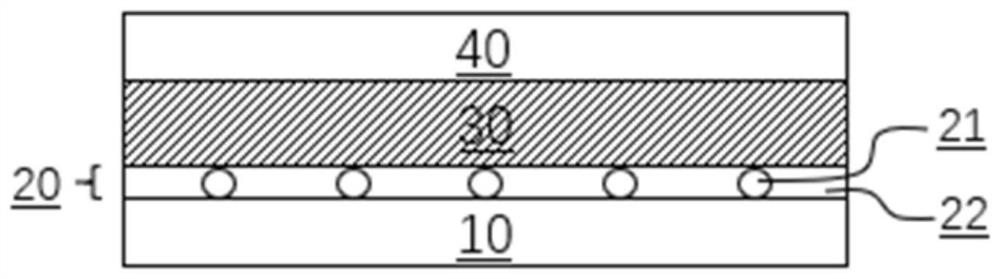

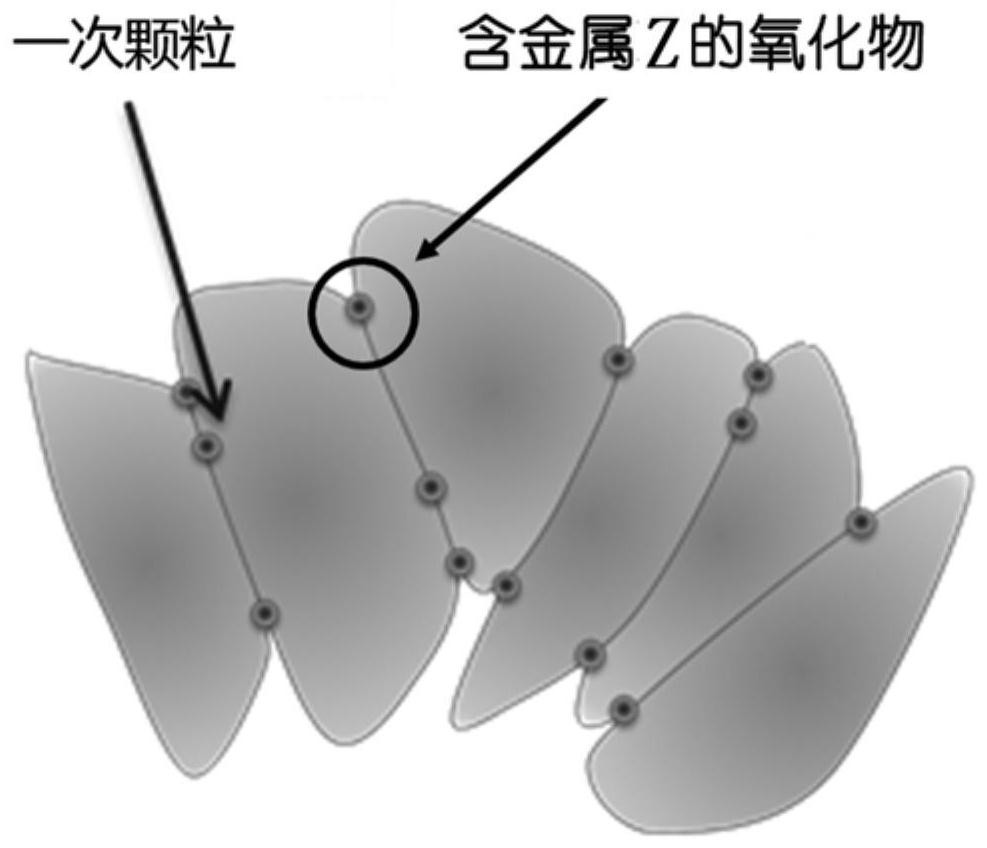

Phase change memory based on nano current channel

ActiveCN112701221AReduce the effective contact areaIncrease current densityElectrical apparatusPhase-change memoryElectro conductivity

The invention discloses a phase change memory based on a nano current channel. A used nano current channel layer structure is used for limiting the path of a current, so that the current enters a phase change layer from a high-conductivity nano crystal grain when flowing through the layer, and the current is limited in the nano current channel. According to the nanoscale conductive channel, the contact area between the phase change layer and the electrode layer is greatly reduced, the current density of a local contact part is greatly improved, and the heat production efficiency of current in the phase change layer is improved. And meanwhile, the insulating heat-insulating material with low conductivity and low heat conductivity prevents heat in the phase change layer from being dissipated to the electrode layer, so that the electric heat utilization efficiency of the phase change layer is improved. Compared with a phase change unit which is as small as possible and manufactured by adopting a more advanced manufacturing process, the phase change memory can break through the process limitation, further reduces the effective contact area of the electrode and the phase change material, and is simple in process, so the phase change memory easily realizes the reduction of operation power consumption.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of producing porous sheet and porous sheet obtained by the production method

InactiveUS20110052872A1Improve permeabilityImprove smoothnessLayered productsRecord information storagePorous sheetSolvent

Owner:IIDA HIROYUKI +4

Efficient inorganic additive for lowering contact resistance of back electrode of solar cell

ActiveCN103000246AReduce the effective contact areaLow activity efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesTin dioxideSolar cell

The invention relates to efficient inorganic additive for lowering contact resistance of a back electrode of a solar cell. The efficient inorganic additive comprises, by weight percent, 50-88% of bismuth trioxide nanotube, 9-20% of manganese dioxide nanotube, 1-20% of tin oxide nanotube, 1-20% of zinc oxide nanotube and 1-20% of titanium oxide nanotube. The nanotubes are summed up to 100% by weight percent. Compared with the prior art, the efficient inorganic additive has the components which are highly flexural and can wind on surfaces of glass powder and silver powder in sliver paste so as to allow the sliver powder to contact with the glass powder in multi-point manner, so that actions of the components are given to fuller play. In addition, the nanotube inorganic additive forms gaps, excessive sintering of the sliver powder can be avoided while formation of conductive path of the sliver powder is not broken, and accordingly the contact resistance of the back electrode of the solar cell can be lowered.

Owner:JIANGSU RUIDE NEW ENERGY TECH

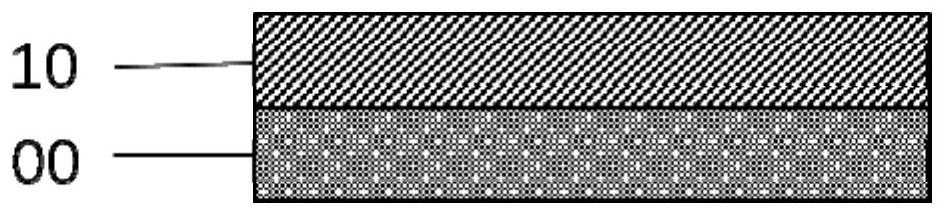

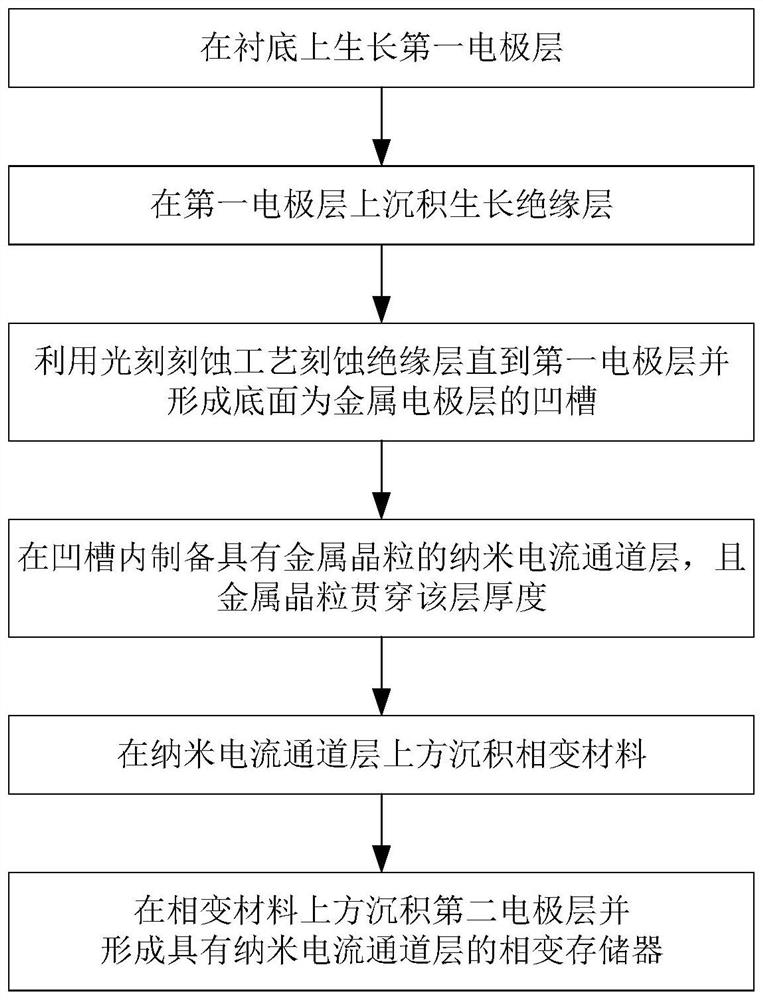

Preparation method of phase change memory based on nano current channel

ActiveCN112713242AReduce the effective contact areaIncrease current densityElectrical apparatusEnergy efficient computingElectrically conductiveElectric heating

The invention discloses a preparation method of a phase change memory based on a nano current channel. The preparation method comprises the following steps of growing a first electrode layer on a substrate; depositing and growing an insulating layer on the first electrode layer; etching the insulating layer to the first electrode layer by using a photoetching process, and forming a groove of which the bottom surface is a metal electrode layer; preparing a nano current channel layer with metal crystal grains in the groove, wherein the metal crystal grains penetrate through the thickness of the layer; depositing a phase change material above the nano current channel layer; and depositing a second electrode layer above the phase change material to form the phase change memory with the nano current channel layer. According to the method, the contact area between the phase change layer and the electrode layer is greatly reduced through the nanoscale conductive channel, the current density of a local contact part is greatly improved, and heat production efficiency of current in the phase change layer is improved; electric heating utilization efficiency of the phase change layer is improved; and the process is simple, so operation power consumption of the phase change memory can be easily reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

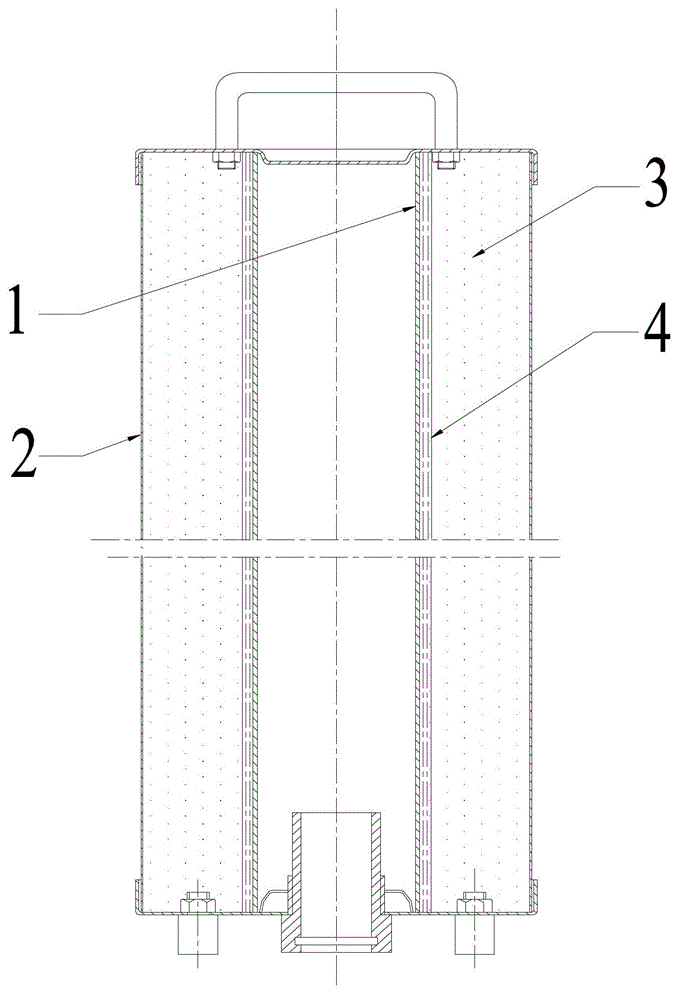

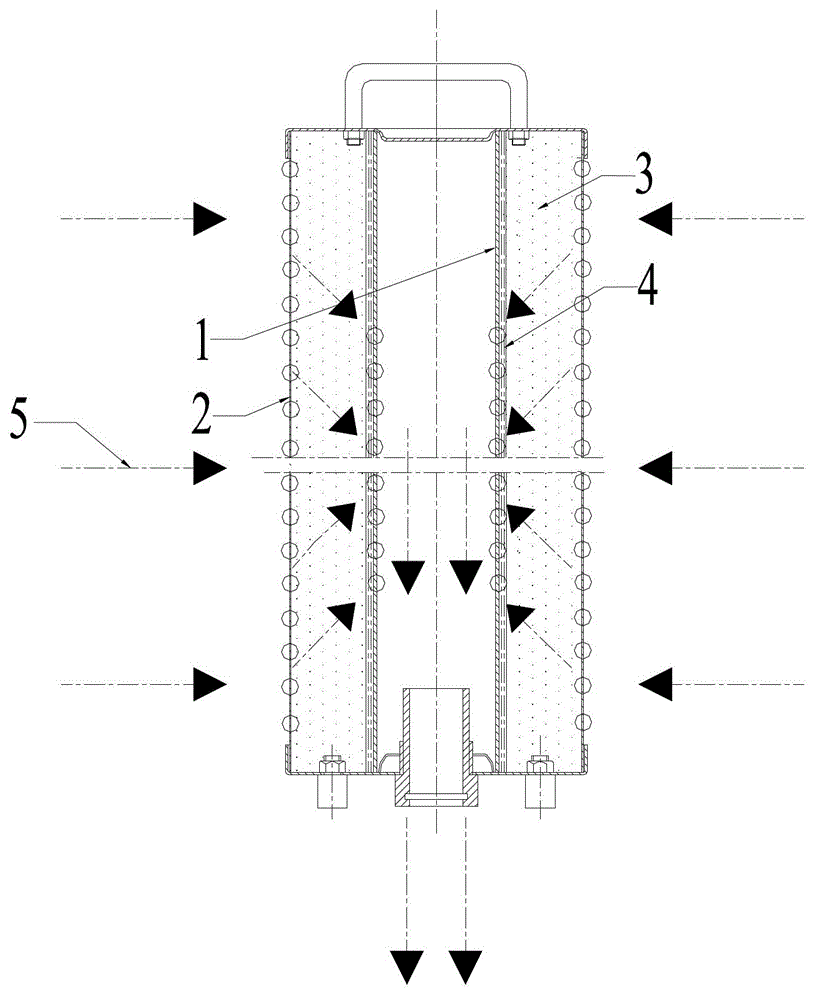

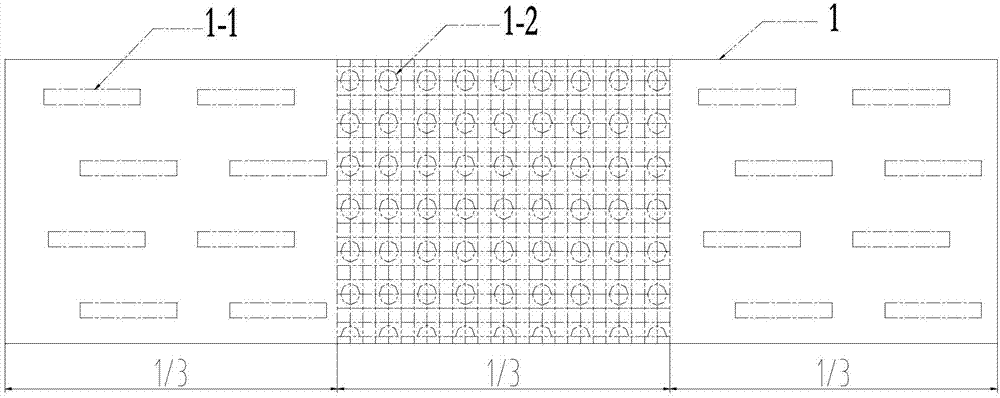

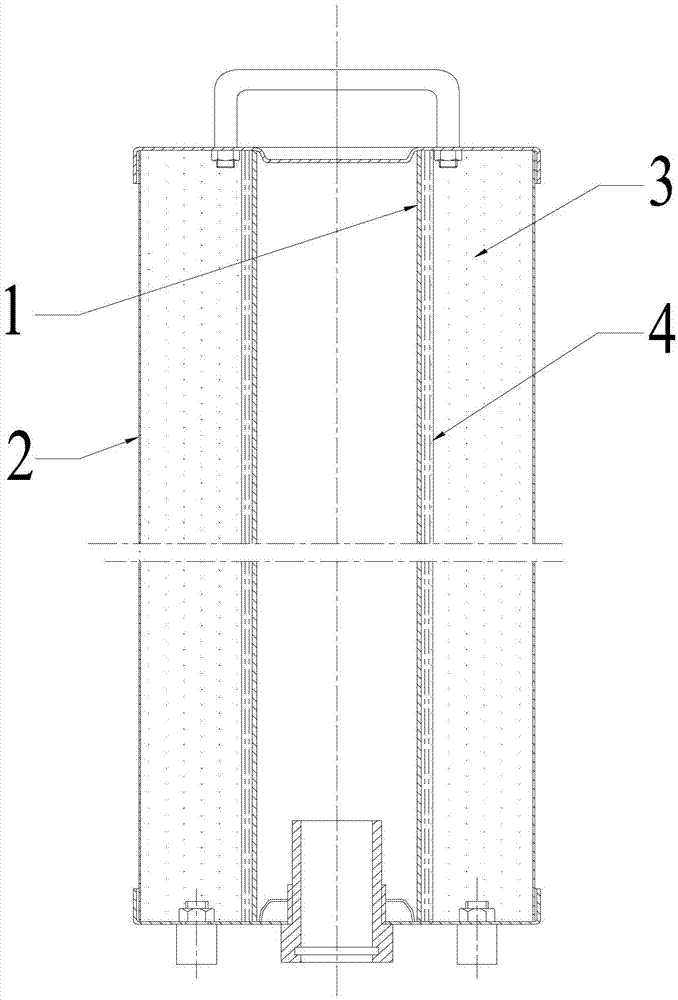

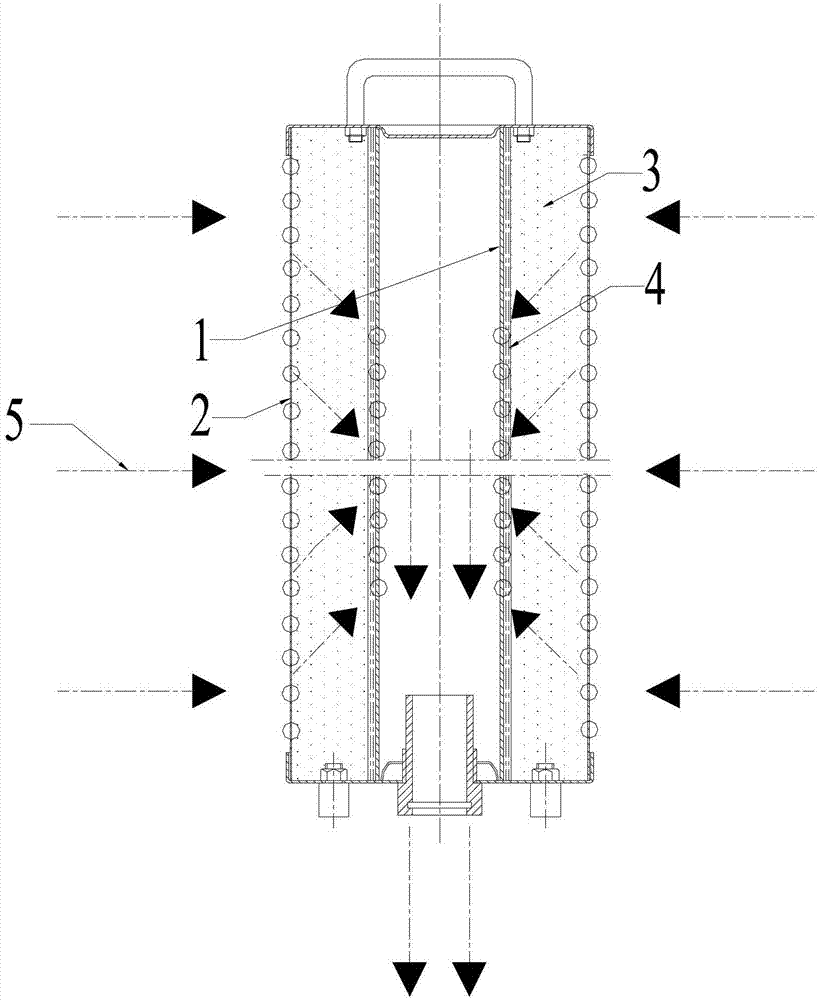

Regeneration filter element and novel hole-layout filter element inner barrel for electric oil

InactiveCN102908826AIncrease contact areaGuaranteed regeneration effectSolid sorbent liquid separationFiltration circuitsBiochemical engineeringFilter material

Provided are a regeneration filter element and a novel hole-layout filter element inner barrel for electric oil. Guide grooves are uniformly and axially arranged on the outer surface of the filter element inner barrel, and filter holes are uniformly arranged in the middle of one third of the length of the filter element inner barrel. The regeneration filter element for the electric oil comprises the novel hole-layout filter element inner barrel for the electric oil, a filter element outer barrel arranged outside the filter element inner barrel, adsorbent stuffed in a cavity between the filter element inner barrel and the filter element outer barrel, and a filter material layer between the adsorbent and the filter element inner barrel. By the aid of the regeneration filter element and the novel hole-layout filter element inner barrel for the electric oil, the problems of adsorbent leakage and oil flow interruption due to poor gluing of an upper end and a lower end of the filter element inner barrel are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

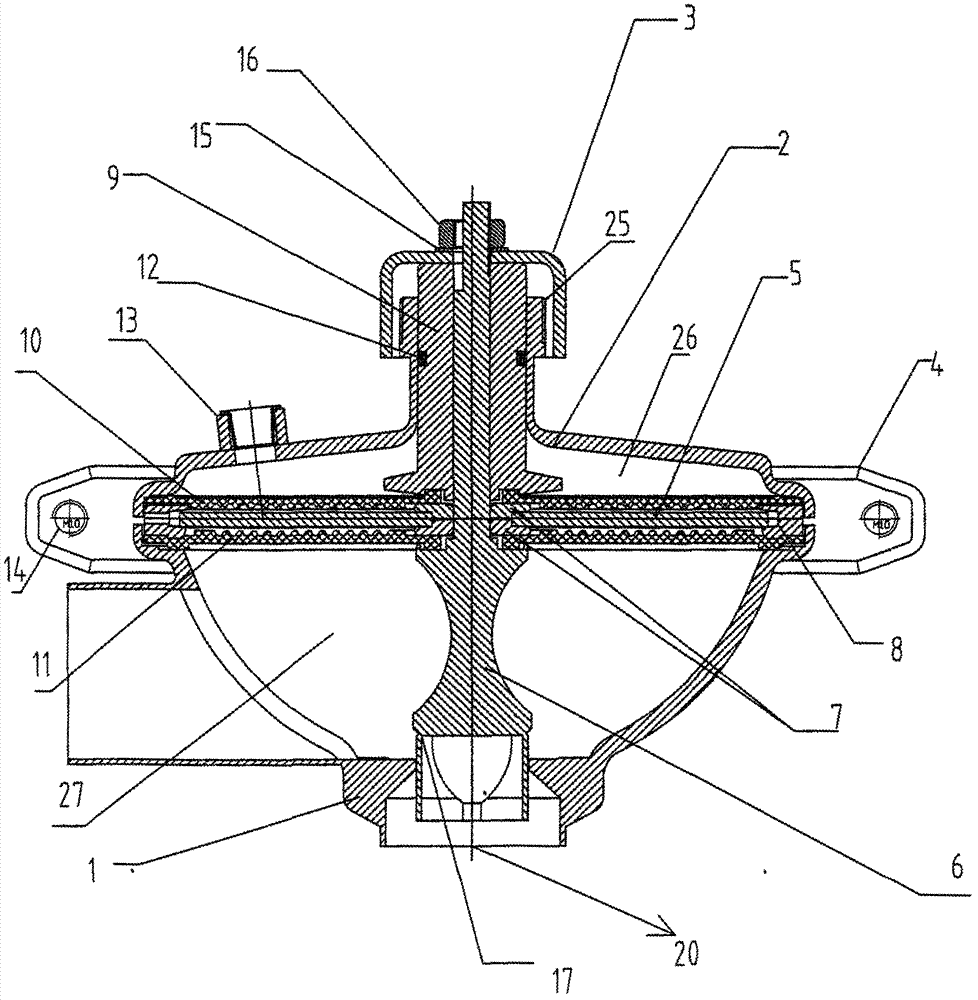

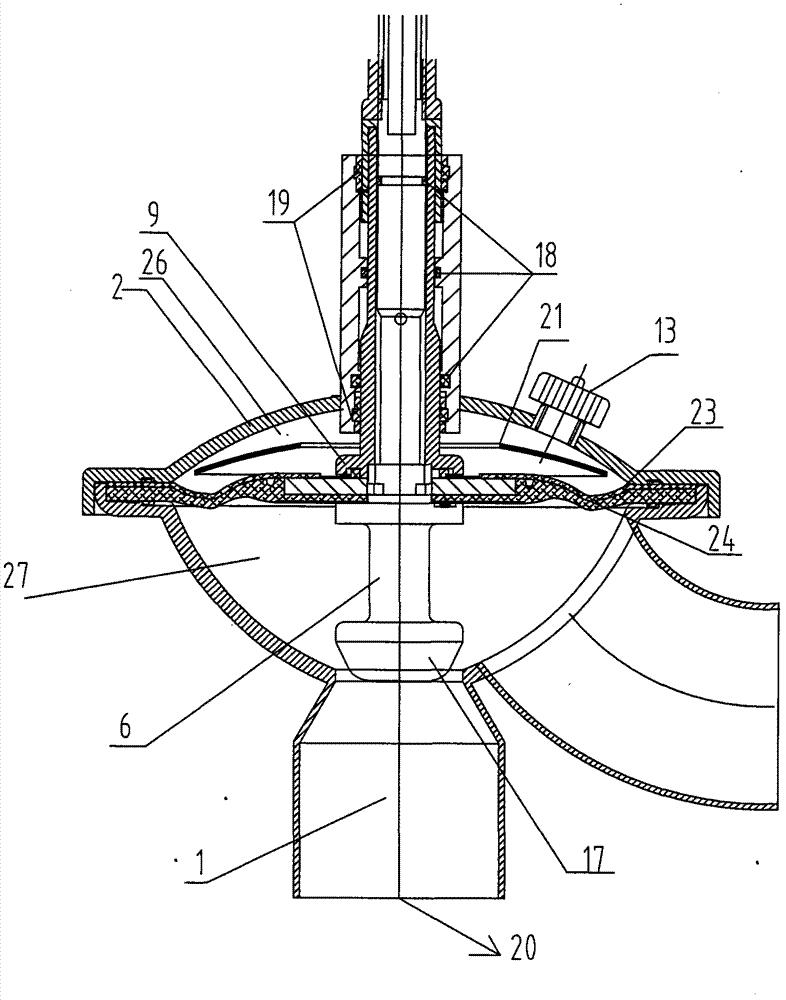

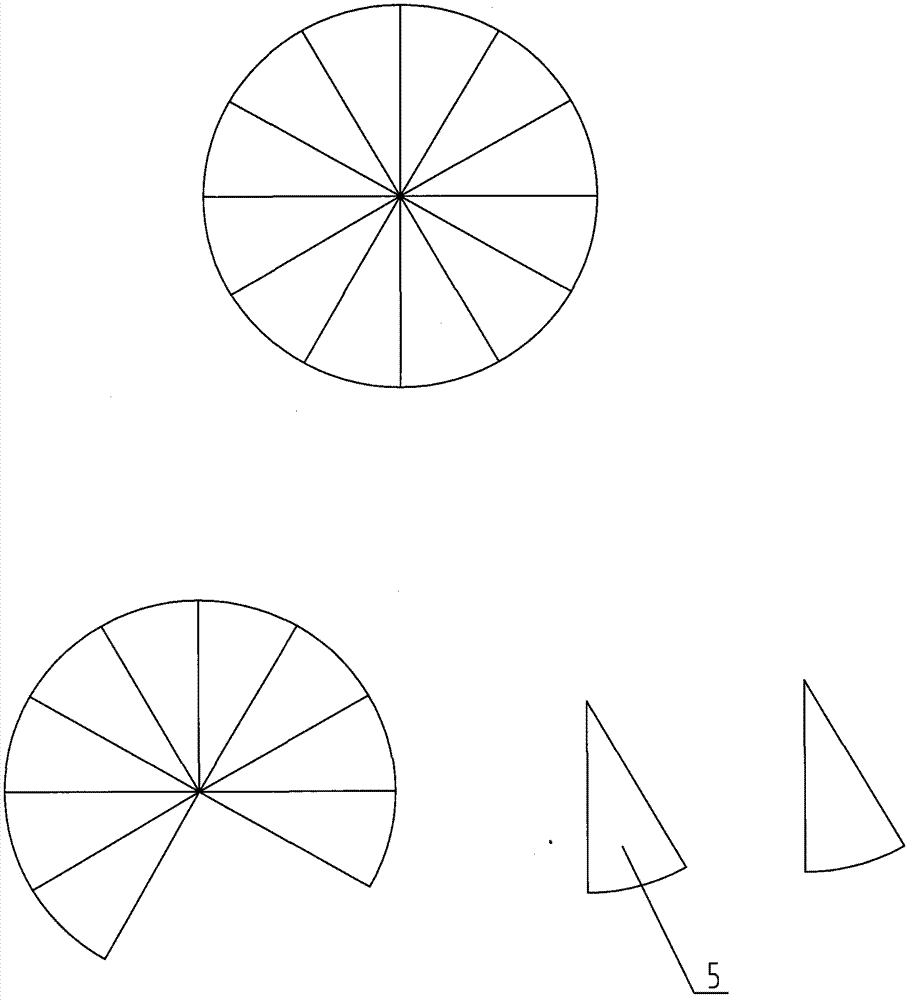

Pneumatic constant pressure valve

ActiveCN101929572BGood voltage stabilization effectAvoid adjustment pitfallsOperating means/releasing devices for valvesEqualizing valvesLiquid pressureConstant pressure

The invention relates to a pneumatic constant pressure valve which comprises a valve body and a valve cap, wherein the valve cap is hermetically matched with the valve body; a sealing diaphragm is arranged between the valve body and the valve cap, the outer edge of the sealing diaphragm is clamped between the valve body and the valve cap, the rest part of the sealing diaphragm can move up and down in the working state, and a through hole is arranged in the middle of the sealing diaphragm; an air inlet and an air inlet standard part 1 for sealing the air inlet are arranged on the valve cap; a through hole is arranged in the middle of the valve cap; a liquid inlet on the side wall and a liquid outlet on the bottom are arranged on the valve body; a valve spool rod hermetically passes through the through hole of the valve cap and the through hole of the sealing diaphragm and extends into the valve body; a valve plug hermetically matched with the liquid outlet is arranged at the lower end of the valve spool rod; and when the sealing diaphragm moves upwards, the valve spool rod is driven by a link mechanism to move upwards to separate the valve plug from the liquid outlet. The pneumatic constant pressure valve of the invention adapts to the requirements of large scale production, can realize opening of the valve and control of the liquid flow and liquid pressure at the outlet under the working state of the valve without frequently replacing components, simultaneously has good pressure stabilizing effect, and can adapt to different liquid environments.

Owner:上海远安流体设备科技有限公司

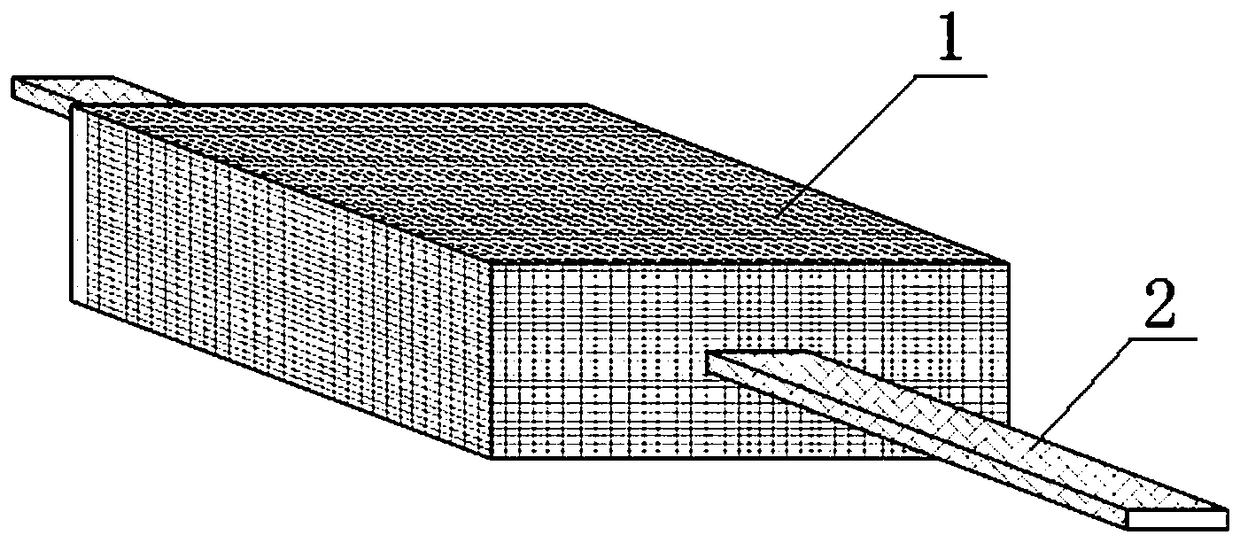

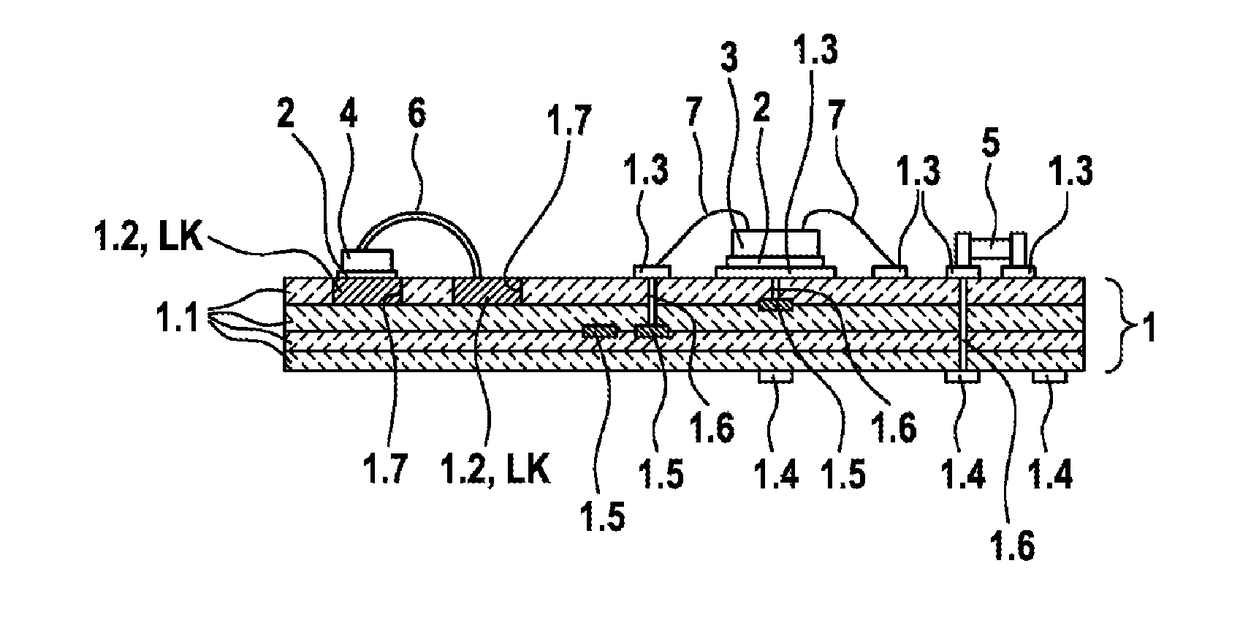

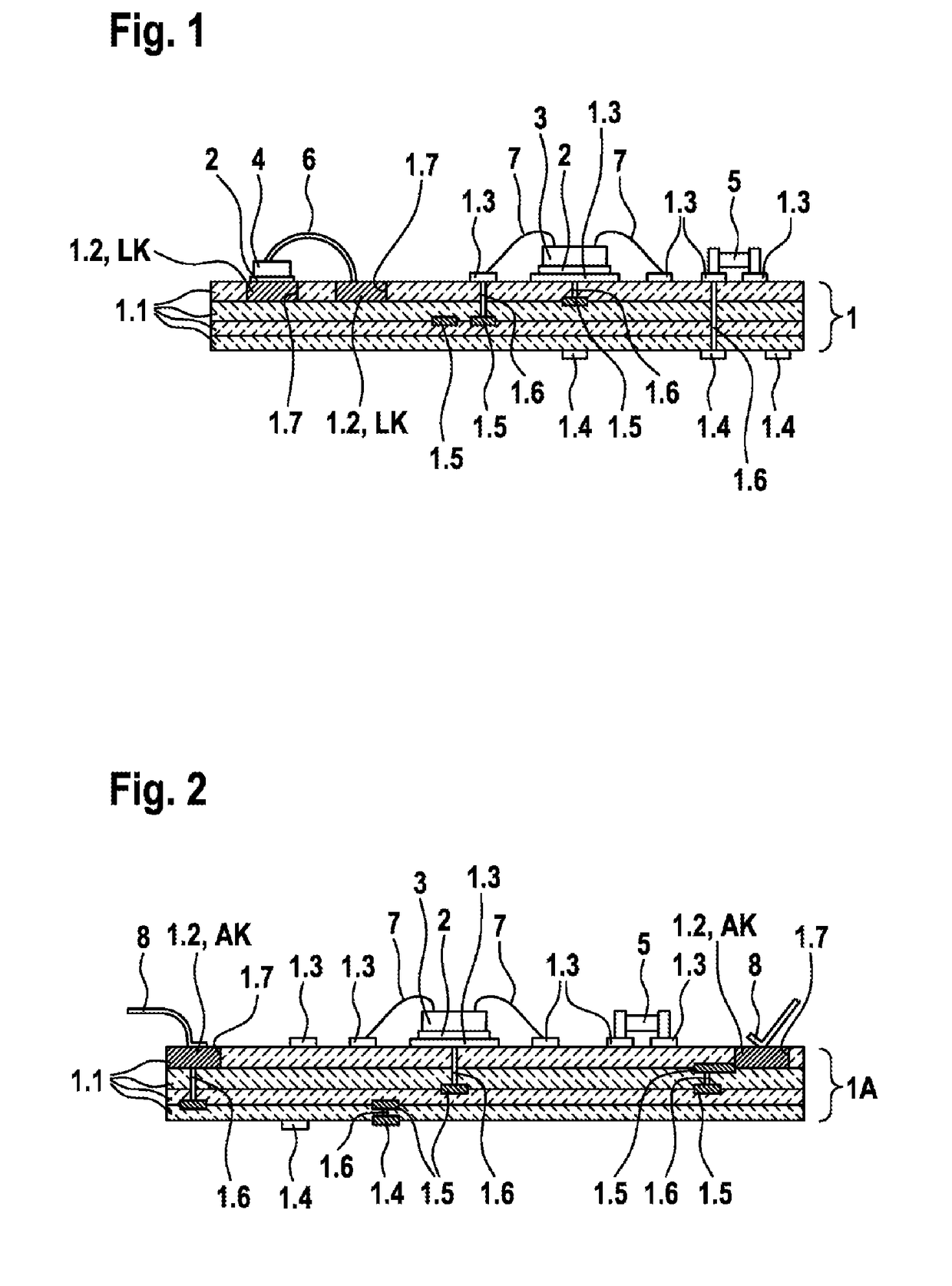

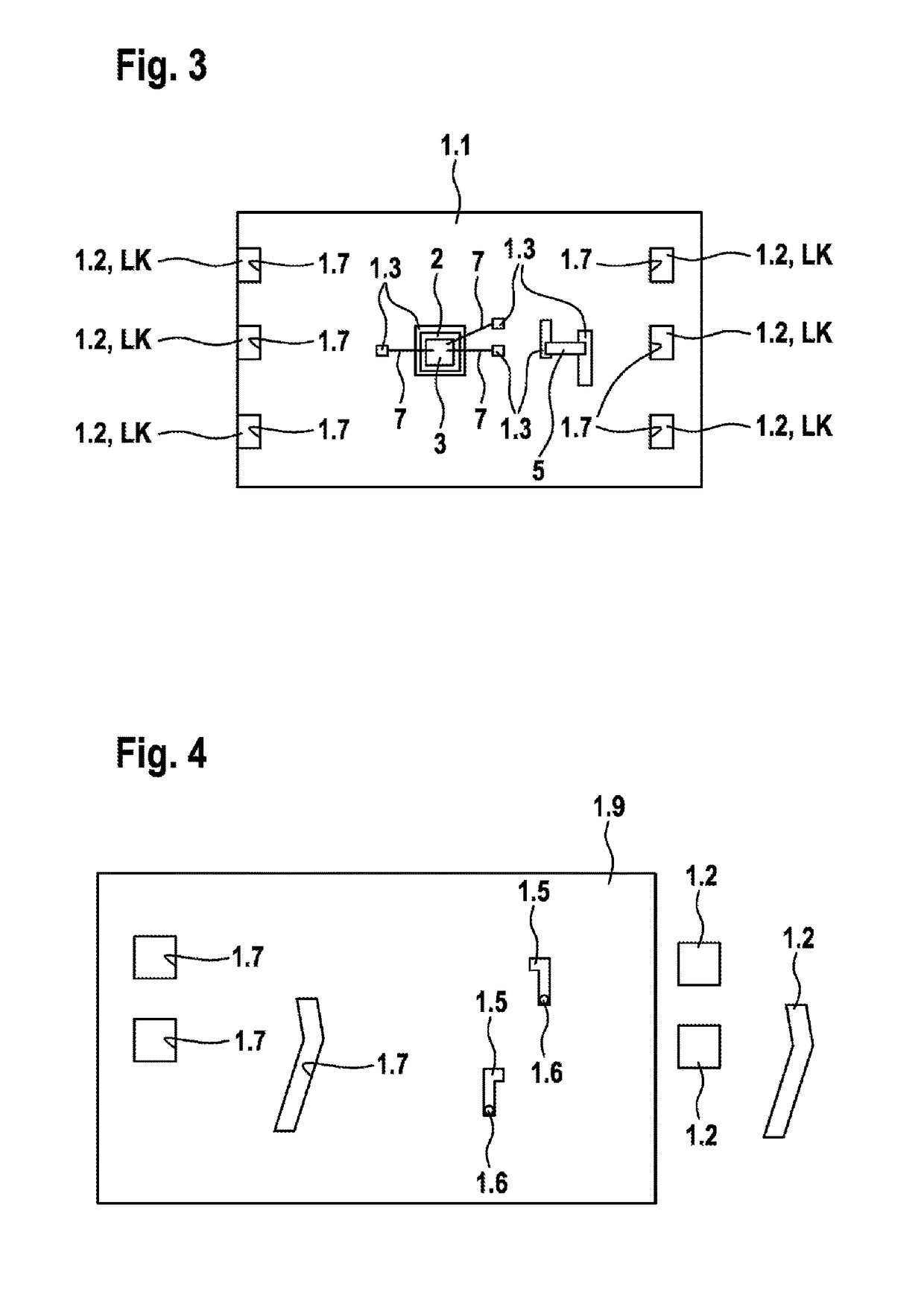

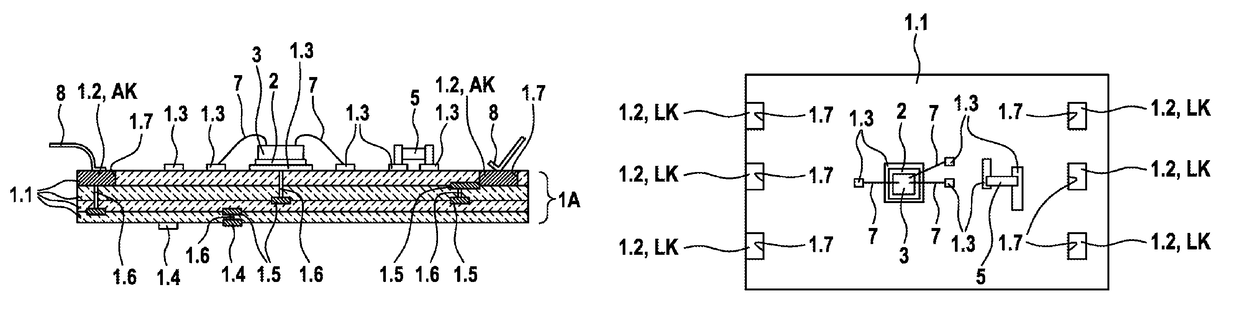

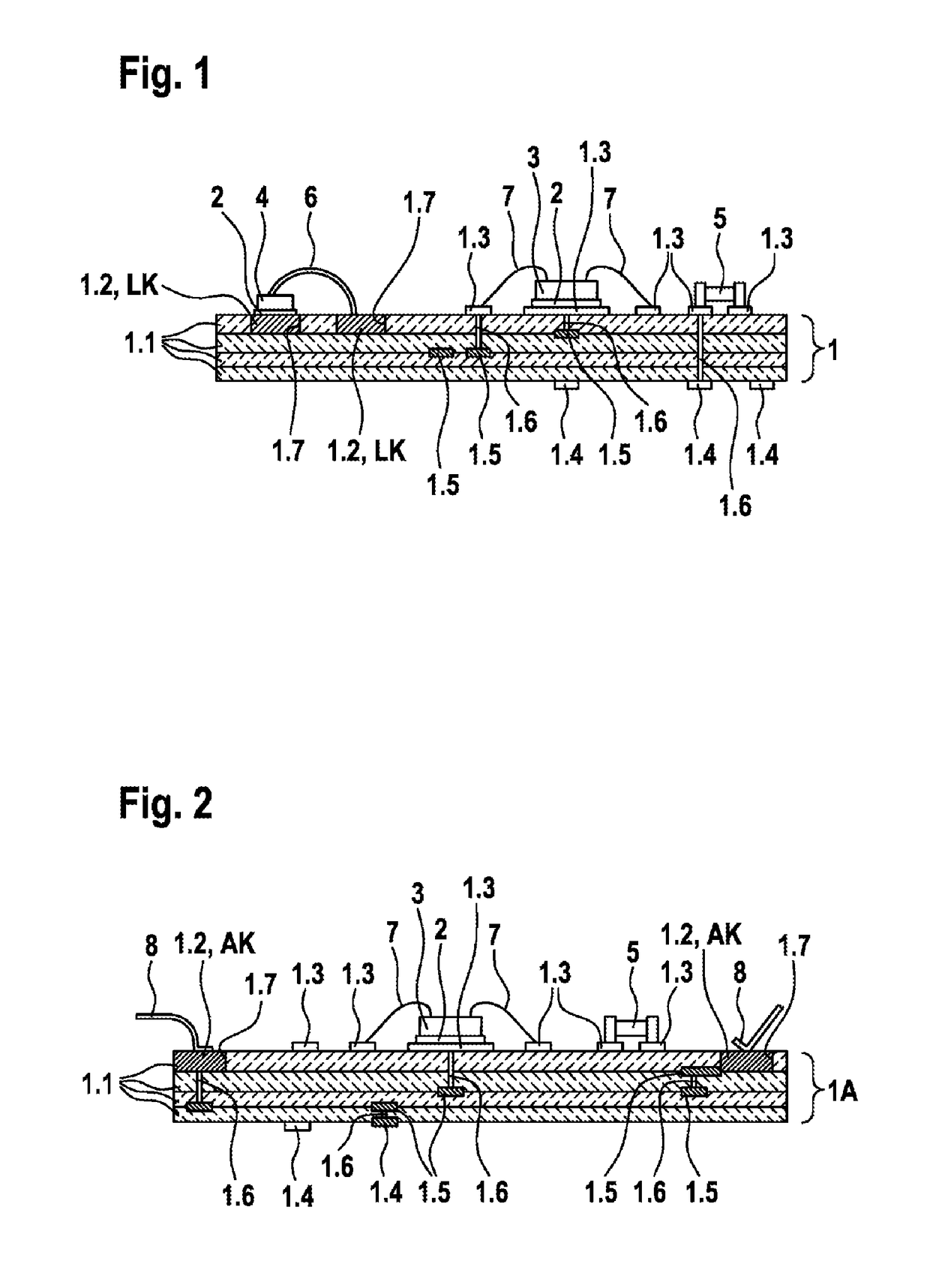

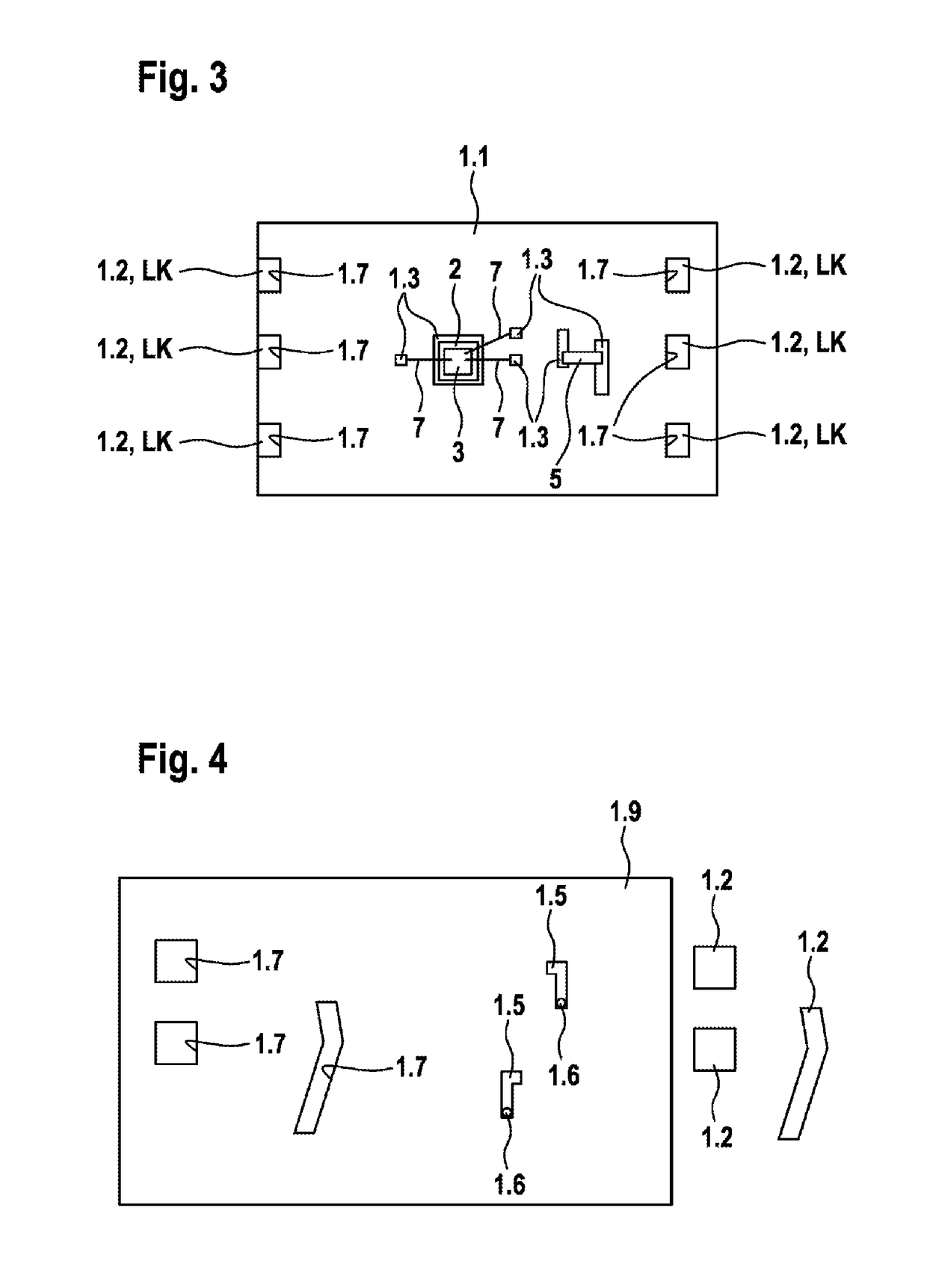

Circuit carrier and a method for producing a circuit carrier

ActiveUS20180027667A1Prevent materialReduce the effective contact areaElectrical connection printed elementsMultilayer circuit manufactureElectricityEngineering

The invention relates to a circuit carrier (1) comprising a plurality of inorganic substrate layers (1.1) that have partial metallisations (1.2, 1.3, 1.4, 1.5, 1.6) for the purpose of electrical and / or thermal conduction, and to a corresponding method for producing such a circuit carrier (1). According to the invention, at least one partial metallisation is made in the form of an insert (1.2) that fills a corresponding shaped hole (1.7) introduced into one of said inorganic substrate layers (1.1).

Owner:ROBERT BOSCH GMBH

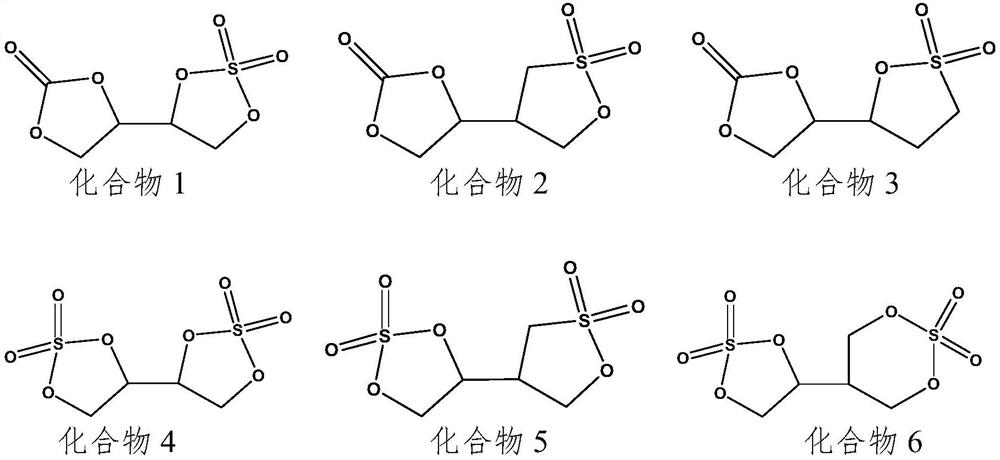

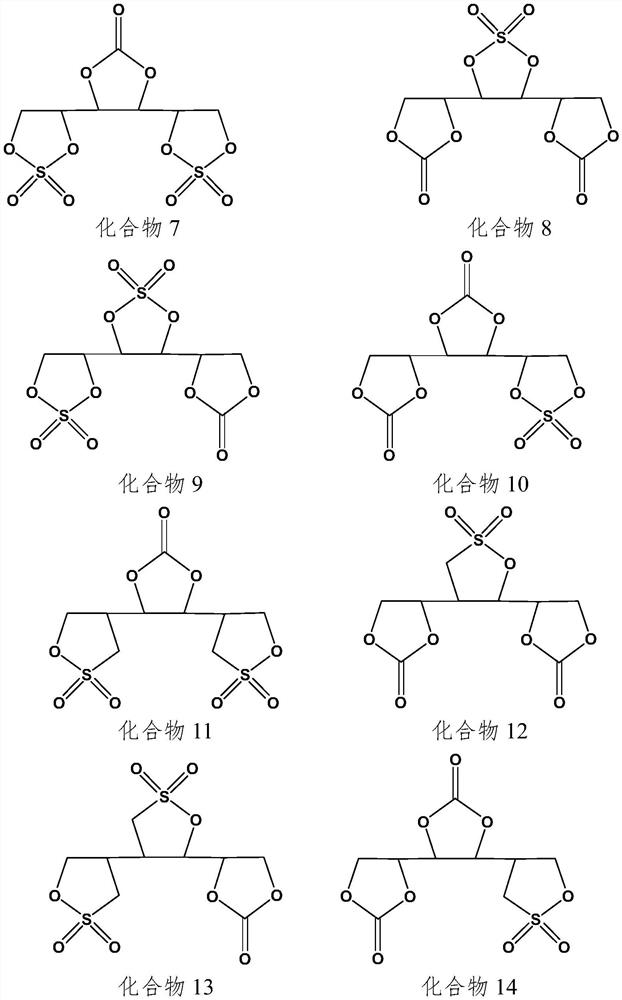

Lithium ion battery, preparation method thereof and electric automobile comprising lithium ion battery

ActiveCN113130997AReduce gas productionImprove cycle lifeSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a lithium ion battery, a preparation method thereof and an electric vehicle comprising the lithium ion battery. The lithium ion battery comprises a positive pole piece, a negative pole piece, an isolating membrane and electrolyte. The positive pole piece comprises a positive active material; the positive active material comprises a substrate, a first coating layer and a second coating layer; the first coating layer coats the surface of the substrate in a discrete island form; the second coating layer coats the surfaces of the first coating layer and the substrate in a continuous layered form; and the electrolyte comprises an additive A and an additive B, the additive A is selected from one or more of cyclic sulfate compounds as shown in a formula 1 and a formula 2, and the additive B is selected from one or two of lithium difluoro bis (oxalate) phosphate and lithium tetrafluoro (oxalate) phosphate. According to the lithium ion battery, preparation method thereof and the electric automobile comprising lithium ion battery of the invention, the gas production rate of a lithium ion battery can be reduced, the cycle life and storage life of the lithium ion battery can be prolonged, and the increase of direct-current internal resistance of the lithium ion battery in cycle and storage processes can be remarkably inhibited.

Owner:CONTEMPORARY AMPEREX TECH CO

A cast polypropylene straight composite film

InactiveCN103182820BReduce the effective contact areaAvoid stickingSynthetic resin layered productsSandwich likeEnvironmental resistance

An CPP (casting polypropylene) direct response membrane comprises an anti-sticking layer, a sandwich layer and a thermosensitive functional layer, wherein the sandwich layer is positioned between the anti-sticking layer and the thermosensitive functional layer, the thickness of the anti-sticking layer accounts for 10 to 20 percent of the total thickness, the thickness of the sandwich layer accounts for 40 to 60 percent of the total thickness, and the thickness of the thermosensitive functional layer accounts for 10 to 30 percent of the total thickness; the anti-sticking layer provided by the invention is made of propylene binary random copolymer with better temperature resisting performance and can provide better temperature endurance, so that a thin film is prevented from causing thermal contraction during direct response; the sandwich layer ensures that the stiffness and the temperature endurance of material are improved, the thermosensitive functional layer adopts a vinyl-type copolymer with higher hot sticking performance and ethylene-acrylic acid copolymer, the hot sticking problems of the material are reduced greatly, the material is enabled to have a better direct response performance, and adhesive is not required to be used when the material is combined with BOPP, BOPET thin film and print film. Therefore, the cost is lowered and the CPP straight complex membrane is beneficial to environmental protection.

Owner:湖北慧狮塑业股份有限公司

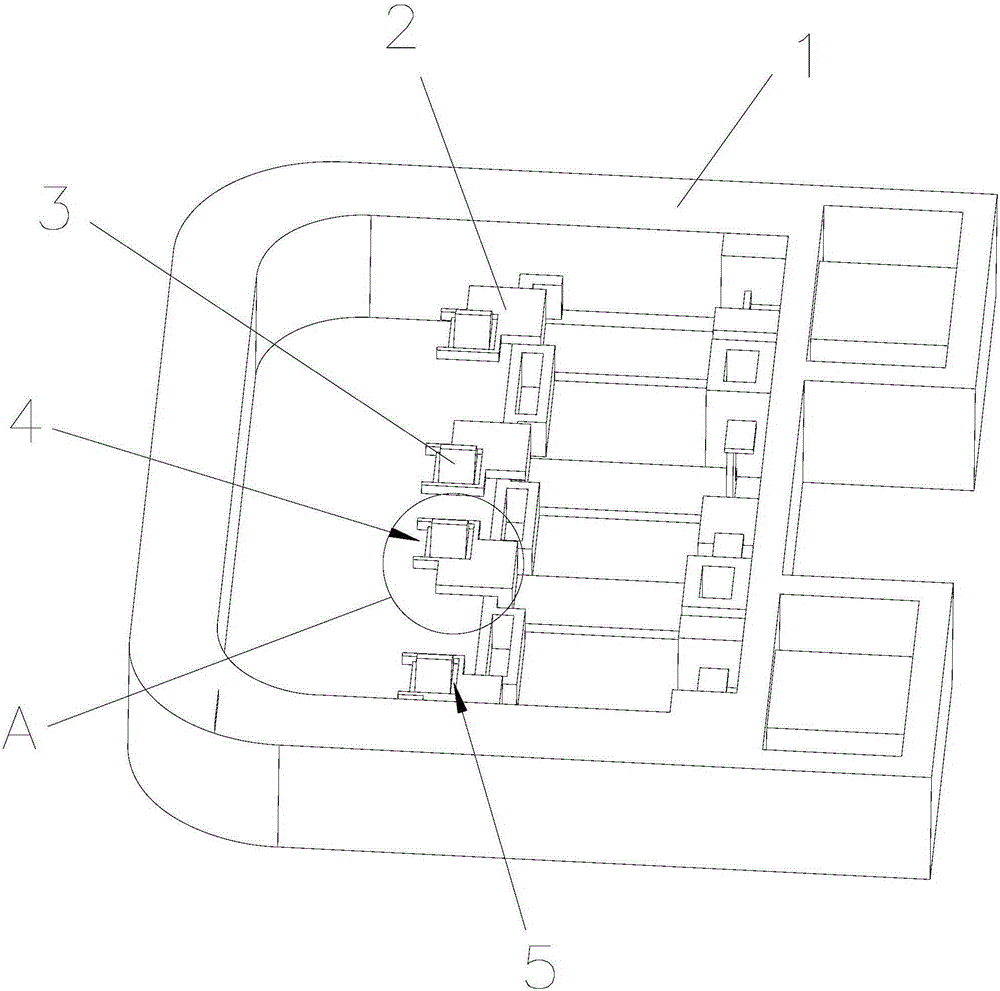

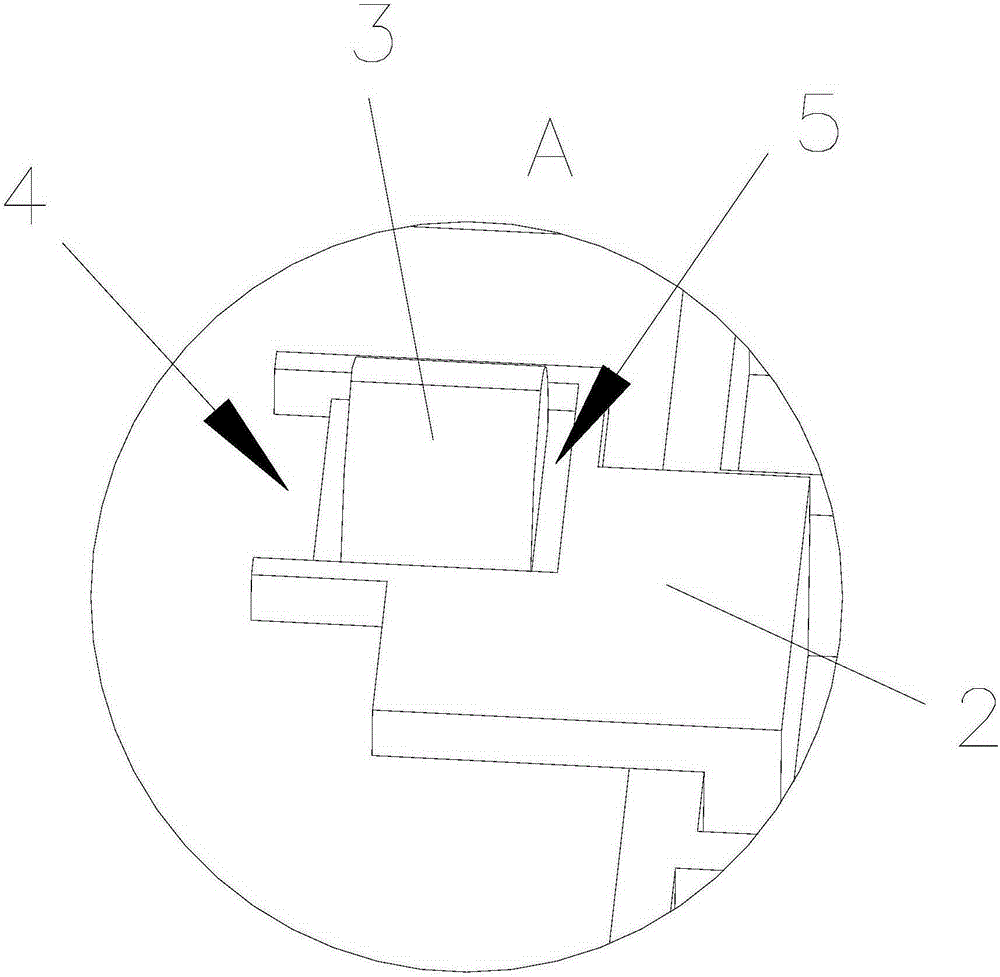

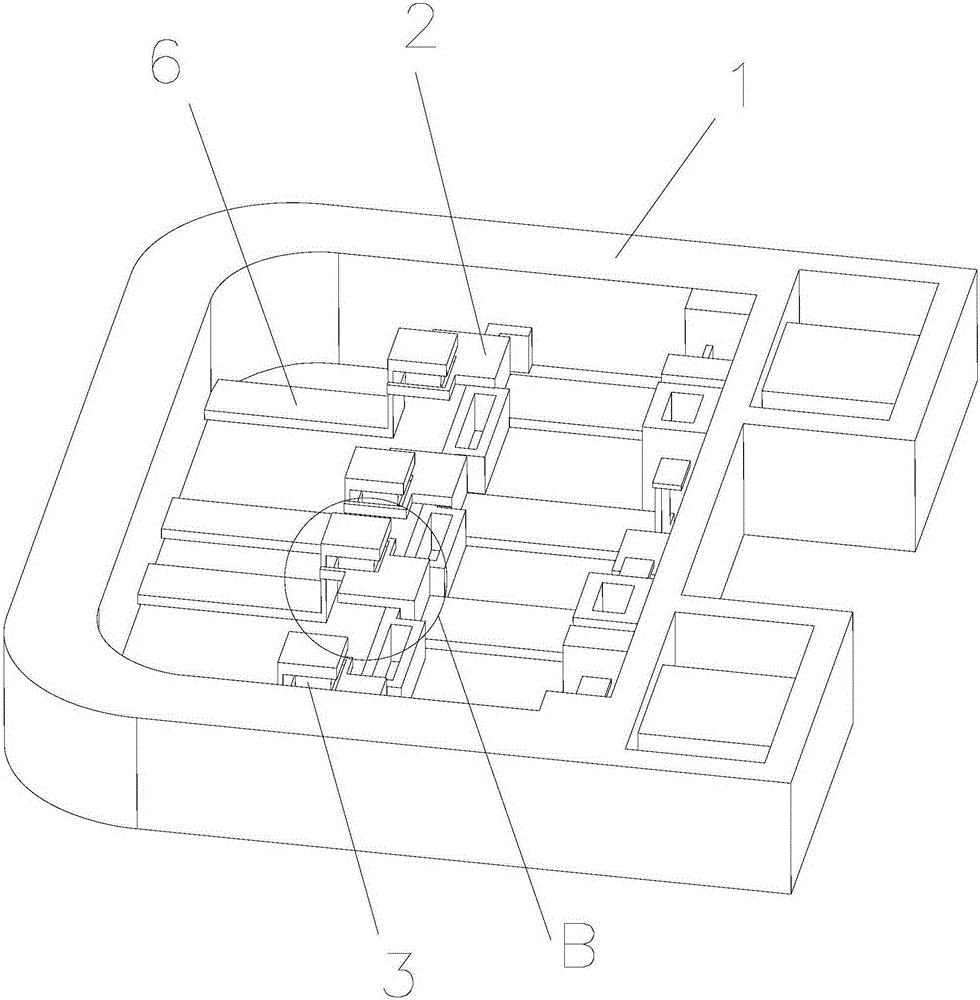

Solar photovoltaic assembly wiring box convenient to fix and reliable to weld

InactiveCN105187008AReduce the effective contact areaAvoid Welding PhenomenonPhotovoltaicsPhotovoltaic energy generationEngineeringTin

The invention relates to a solar photovoltaic assembly wiring box convenient to fix and reliable to weld. The solar photovoltaic assembly wiring box convenient to fix and reliable to weld comprises a wiring box body, wherein a metal piece leading-out wire is arranged in the wiring box body; the front end of the metal piece leading-out wire is provided with a groove and an opening; the opening is formed in the front end of the groove. The solar photovoltaic assembly wiring box convenient to fix and reliable to weld can be used for conveniently and fast clamping a welding belt at the opening of the metal piece leading-out wire for fixing the welding belt, so that the reduction of the effective contact area of the metal piece leading-out wire, caused by left-ring skewing of welding belt during welding, can be limited, and the rate that the welding belt breaks away from the metal piece leading-out wire is reduced; melt welding tin is encircled in the groove, and an insufficient welding phenomenon generated by a fact that the welding tin is melt to flow out from the periphery of the plane of the metal piece leading-out wire is avoided; one edge of the groove is communicated with the opening, the melt tin only can flow out from the opening end of the groove to be connected with the welding belt pasted on the opening end, so that the relatively reliable welding is achieved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

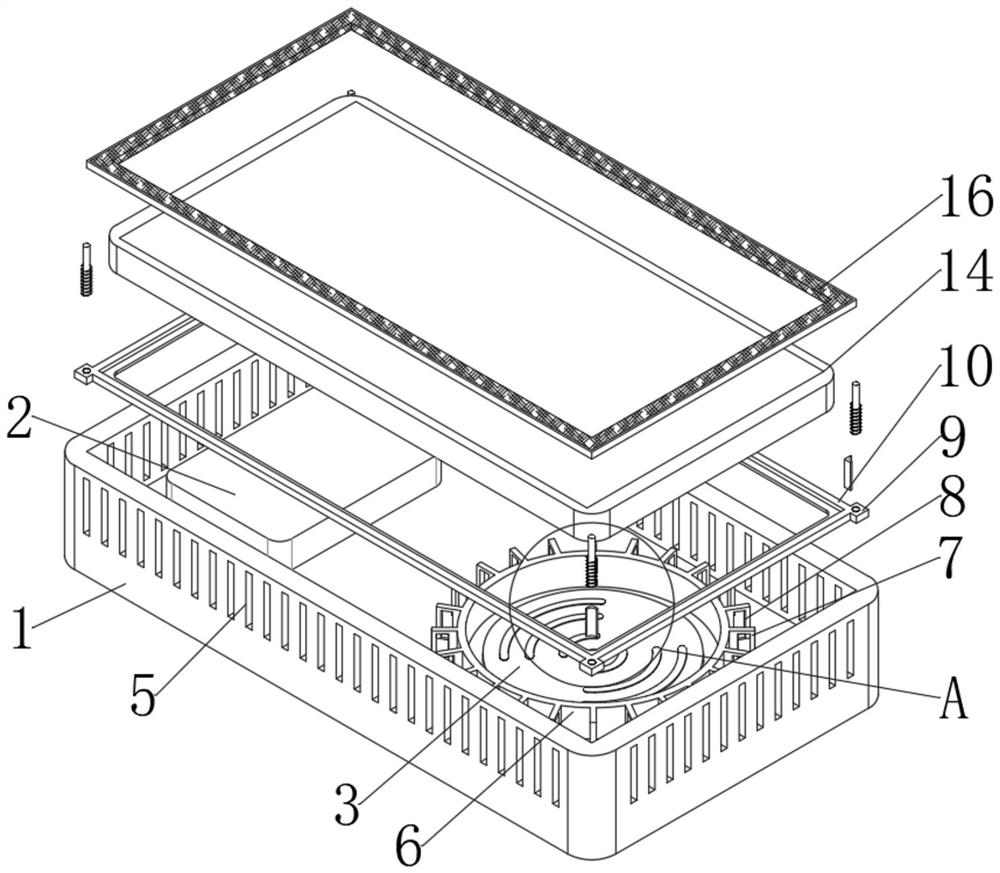

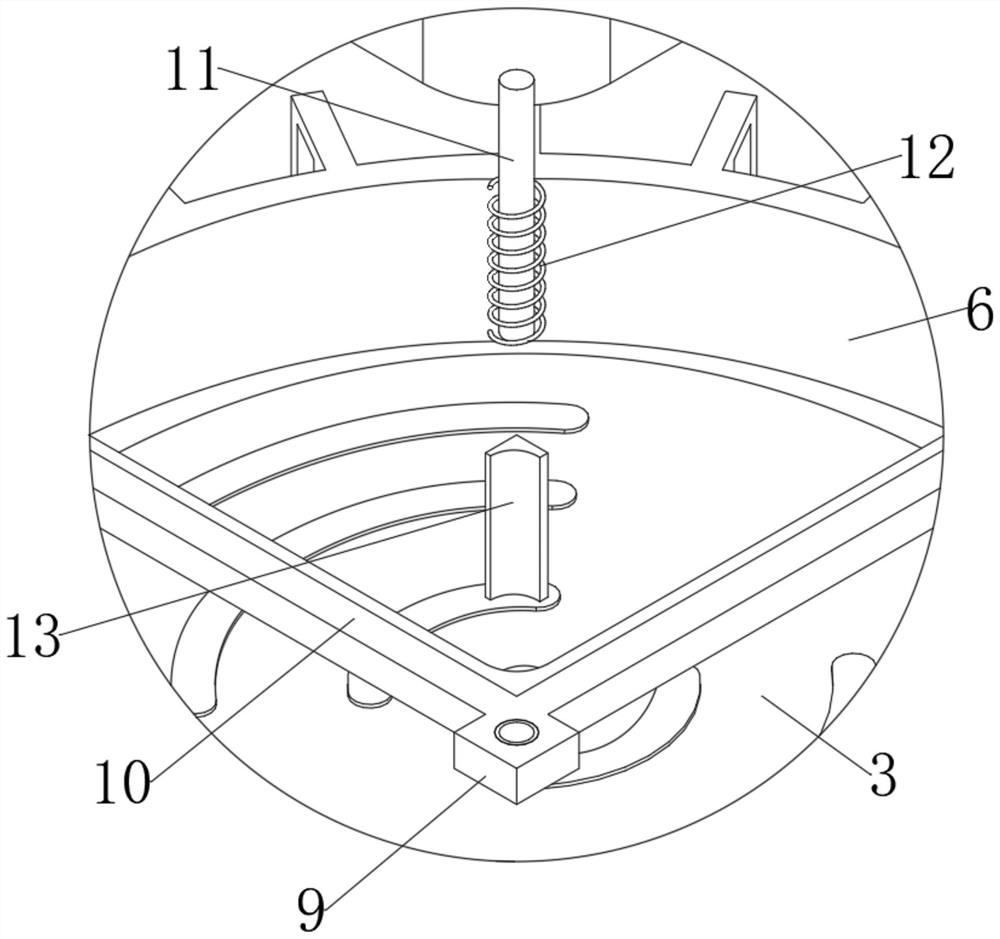

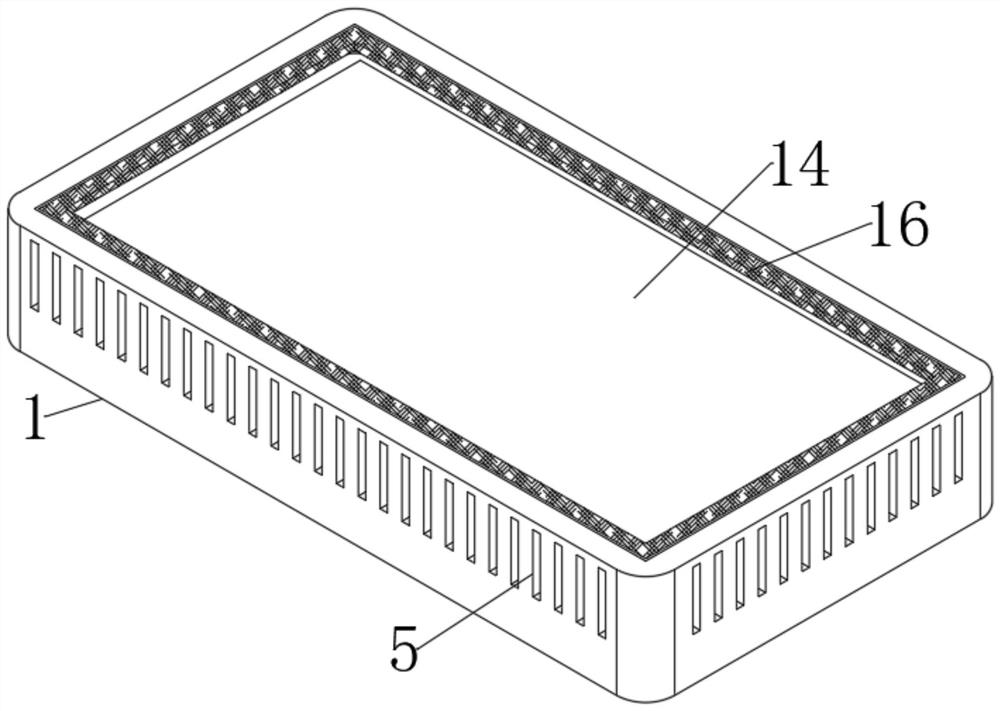

A portable mobile phone wireless charger with an overheating protection device

ActiveCN112350446BAvoid continuous accumulationImprove securityElectromagnets without armaturesBatteries circuit arrangementsMobile phoneBattery cell

The invention discloses a portable mobile phone wireless charger with an overheat protection device, which belongs to the field of mobile phone wireless chargers. A portable mobile phone wireless charger with an overheat protection device cuts off the power supply of the charging module when the temperature at the charging module is too high. This is the first protection of this scheme, and when the first protection fails to work, the control terminal cuts off the power supply circuit of the electromagnet, and under the action of the compression spring in the compressed state, The main body of the mobile phone will be ejected from the main body of the wireless charger. This is the second protection of this scheme. When the first protection and the second protection cannot function normally, the thermally expanded overheating protection pile will The function of placing the frame is to push out the main body of the mobile phone and disconnect the wireless charging. This is the third protection of this solution. Through the three protections, the safety of wireless charger charging is increased, and it is not easy to induce battery safety accidents.

Owner:SHENZHEN WIRELESS TECH CO LTD

Circuit carrier and a method for producing a circuit carrier

ActiveUS10129987B2Prevent materialReduce the effective contact areaPrinted circuit aspectsConductive pattern formationElectricityEngineering

The invention relates to a circuit carrier (1) comprising a plurality of inorganic substrate layers (1.1) that have partial metallizations (1.2, 1.3, 1.4, 1.5, 1.6) for the purpose of electrical and / or thermal conduction, and to a corresponding method for producing such a circuit carrier (1). According to the invention, at least one partial metallization is made in the form of an insert (1.2) that fills a corresponding shaped hole (1.7) introduced into one of said inorganic substrate layers (1.1).

Owner:ROBERT BOSCH GMBH

Regeneration filter element and novel hole-layout filter element inner barrel for electric oil

InactiveCN102908826BIncrease contact areaGuaranteed regeneration effectSolid sorbent liquid separationFiltration circuitsBiochemical engineeringFilter material

Provided are a regeneration filter element and a novel hole-layout filter element inner barrel for electric oil. Guide grooves are uniformly and axially arranged on the outer surface of the filter element inner barrel, and filter holes are uniformly arranged in the middle of one third of the length of the filter element inner barrel. The regeneration filter element for the electric oil comprises the novel hole-layout filter element inner barrel for the electric oil, a filter element outer barrel arranged outside the filter element inner barrel, adsorbent stuffed in a cavity between the filter element inner barrel and the filter element outer barrel, and a filter material layer between the adsorbent and the filter element inner barrel. By the aid of the regeneration filter element and the novel hole-layout filter element inner barrel for the electric oil, the problems of adsorbent leakage and oil flow interruption due to poor gluing of an upper end and a lower end of the filter element inner barrel are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

A High Performance Combined Rectangular Waveguide

InactiveCN104037483BImprove microwave transmission characteristicsReduce the effective contact areaWaveguidesWaveguideMicrowave signals

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

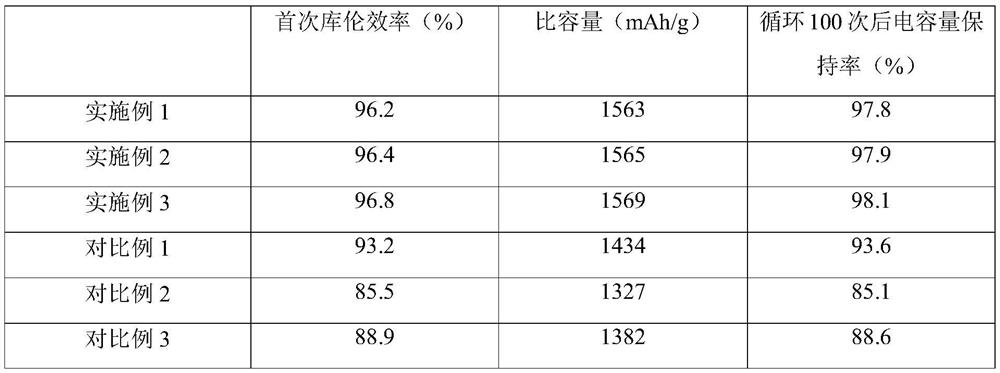

Graphene-based lithium ion battery negative electrode material and preparation method thereof

PendingCN111961170AImprove Coulombic efficiencyHigh specific capacityCarbon compoundsNegative electrodesLithium electrodeChlorosilane

The invention discloses a graphene-based lithium ion battery negative electrode material and a preparation method thereof. The method comprises the steps that niobium and tin doped graphene is modified with 7-octenyl trichlorosilane to obtain silanized graphene, then the silanized graphene is reacted with 4-bromo-2-(2-nitro-1-propenyl) thiophene, and modified graphene is obtained; finally, the modified graphene and 2-vinylthiophene are used as raw materials, a polymerization reaction is performed to obtain the graphene-based lithium ion battery negative electrode material, and the graphene-based lithium ion battery negative electrode material is high in initial coulombic efficiency, high in specific capacity and excellent in cycle performance.

Owner:南京彼洲生物科技有限公司

An inorganic additive that can reduce the contact resistance of the back electrode of solar cells

ActiveCN103000246BReduce the effective contact areaLow activity efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesTin dioxideSolar cell

The invention relates to efficient inorganic additive for lowering contact resistance of a back electrode of a solar cell. The efficient inorganic additive comprises, by weight percent, 50-88% of bismuth trioxide nanotube, 9-20% of manganese dioxide nanotube, 1-20% of tin oxide nanotube, 1-20% of zinc oxide nanotube and 1-20% of titanium oxide nanotube. The nanotubes are summed up to 100% by weight percent. Compared with the prior art, the efficient inorganic additive has the components which are highly flexural and can wind on surfaces of glass powder and silver powder in sliver paste so as to allow the sliver powder to contact with the glass powder in multi-point manner, so that actions of the components are given to fuller play. In addition, the nanotube inorganic additive forms gaps, excessive sintering of the sliver powder can be avoided while formation of conductive path of the sliver powder is not broken, and accordingly the contact resistance of the back electrode of the solar cell can be lowered.

Owner:JIANGSU RUIDE NEW ENERGY TECH

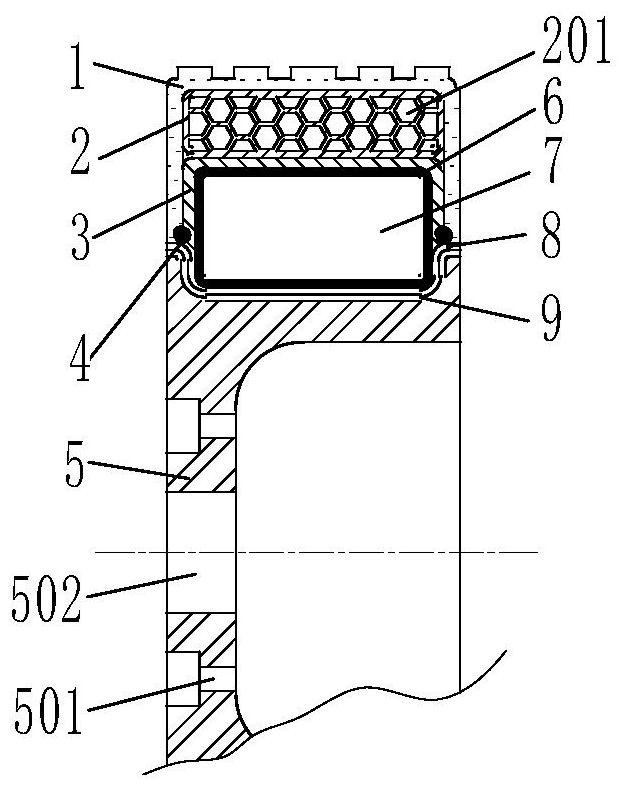

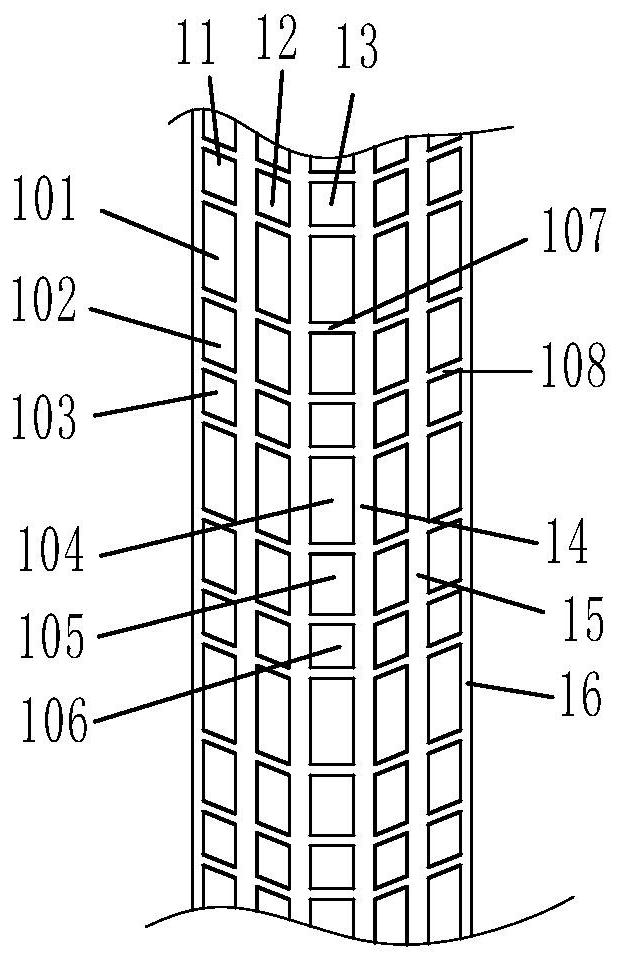

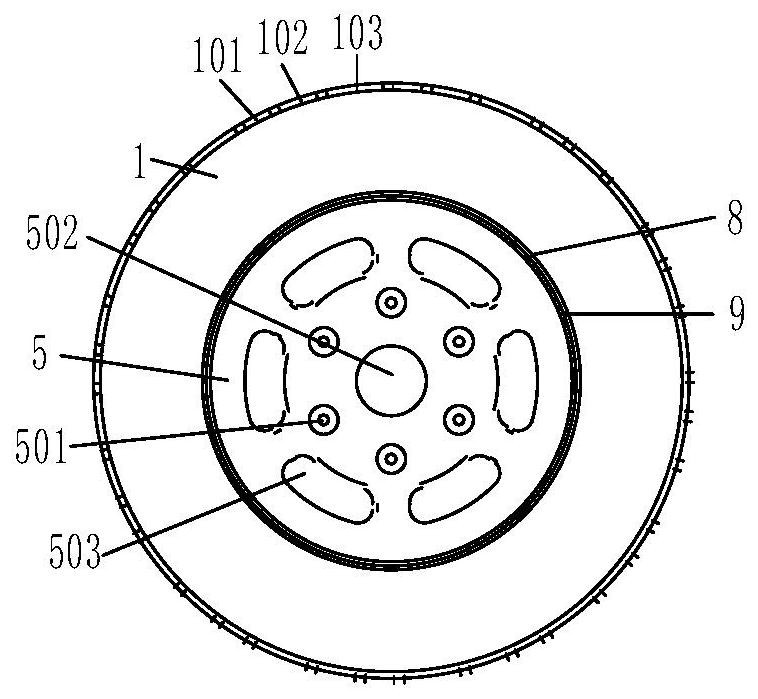

Mute type new energy automobile tire

InactiveCN112046206AAchieve mute effectImprove mute effectTyre tread bands/patternsInsulation layerNew energy

The invention discloses a mute type new energy automobile tire, and relates to the technical field of tires. The mute type new energy automobile tire comprises tire skin, a first inclined protruding belt, a second inclined protruding belt, a square protruding belt, a first circumferential groove, a second circumferential groove, a wheel side groove, a buffer pad, a reinforcing layer, steel rings,a hub, a sealing layer, an inflation layer, a sound absorption layer and a sound insulation layer; the outer side of the hub is sleeved with the sound insulation layer; the outer side of the sound insulation layer is sleeved with the absorption layer; the outer side of the sound absorption layer is sleeved with the sealing layer; the inflation layer is arranged in the sealing layer; the outer sideof the sealing layer is sleeved with the reinforcing layer; the outer side of the reinforcing layer is sleeved with the buffer pad; the outer side of the buffer pad is sleeved with the tire skin; thesteel rings are clamped between two inner sides of the tire skin and two outer sides of the reinforcing layer; and the square protruding belt is arranged in the center of the surface of the tire skin. Through the arrangement of the sound absorption layer and the sound insulation layer, the transmission of noise on the tire is blocked.

Owner:深圳朴坂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com