Pneumatic constant pressure valve

A technology of constant pressure valve and valve body, which is applied to valve details, safety valves, balance valves, etc., and can solve problems such as poor pressure stabilization effect and fluctuating range of the liquid outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

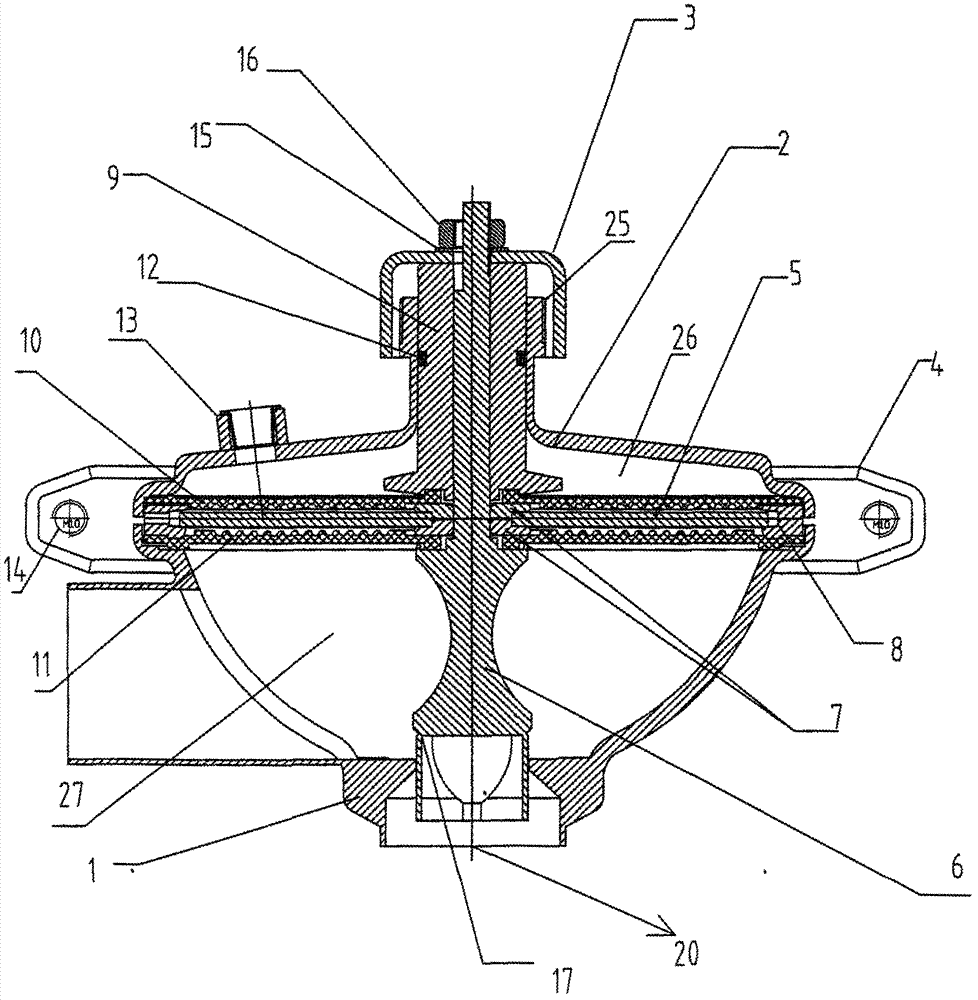

[0031] see figure 1 , the pneumatic constant pressure valve in this embodiment includes: a concave valve body 1, the valve body 1 has a mounting edge, and a liquid outlet is provided at the center of the bottom of the valve body 1, and the liquid outlet is connected with a pressure detection device 20 The side wall of the valve body 1 has a liquid inlet in the horizontal direction; the installation edge of the valve body 1 passes through two semicircular clamps 4 with a U-shaped cross-section and an inner groove and a concave The mounting edge of the bonnet 2 is sealed and fixed, wherein two semicircular clamps 4 are fixedly connected by hexagon socket nuts 14; an air inlet is provided on the bonnet 2, and the air inlet is connected to an air source control The device 13 is connected; between the mounting edge of the valve body 1 and the valve cover 2, the edge of a sealing diaphragm is sealed and fixed, and an elastic sealing air cavity 26 is formed between the sealing diaphr...

Embodiment 2

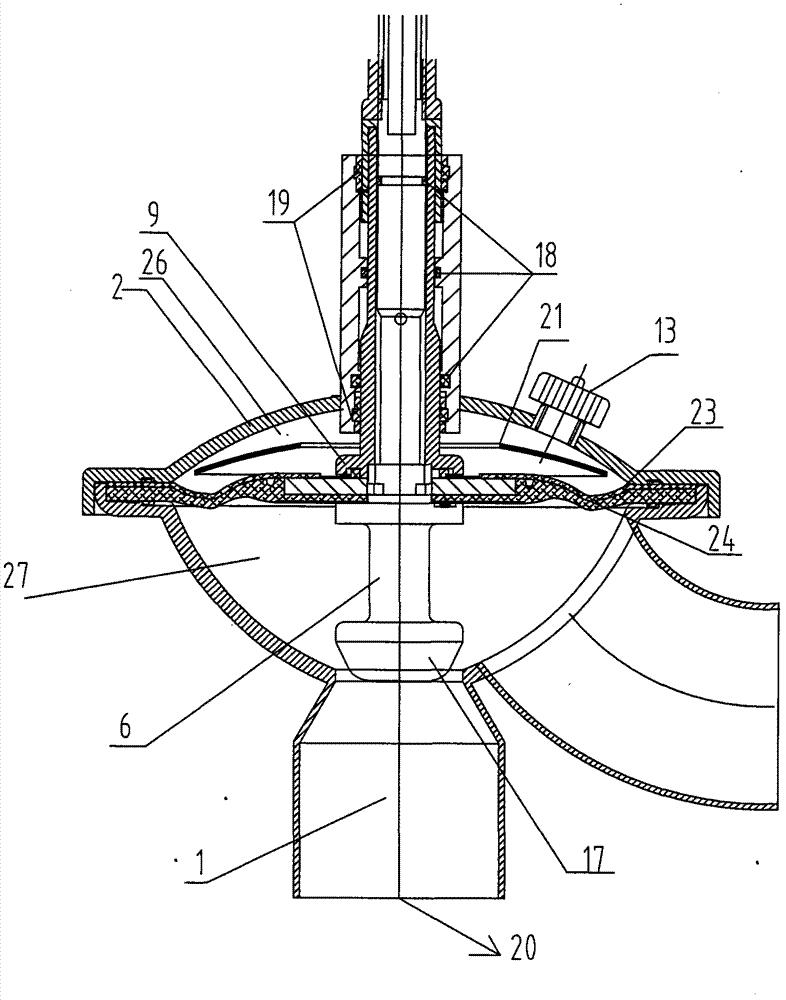

[0037] see figure 2 . The pneumatic constant pressure valve of the present invention includes a valve body 1 , which is concave, and the cross section of the valve body 1 is circular here, and may also be set as an ellipse. The valve body 1 has a valve body installation edge, a liquid outlet is provided at the center, and a liquid inlet is arranged next to the liquid outlet, and the liquid inlet here is arc-shaped; the valve cover 2 is concave , with the installation edge of the valve cover 2 matching with the connection structure of the installation edge of the valve body 1, a hollow installation pipe 25 is fixedly arranged in the center of the valve cover 2 at a position corresponding to the liquid outlet, and the hollow The installation pipe 25 passes through the middle of the valve cover 2, and is axially aligned with the center of the liquid outlet; the valve cover 2 is also provided with an air source control device 13 connected to the air inlet, sealing the diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com