Self-pressure-loading type pressure regulator

A technology of self-pressure and pressure regulator, which is applied in the direction of fluid pressure control, fluid pressure control without auxiliary power, instruments, etc. It can solve the problems of shortened working life of the main diaphragm, safety production problems, and reduced sealing performance. Achieve the effects of improving smoothness and stability of pressure change, obvious pressure regulation and stabilization performance, and improving closing and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

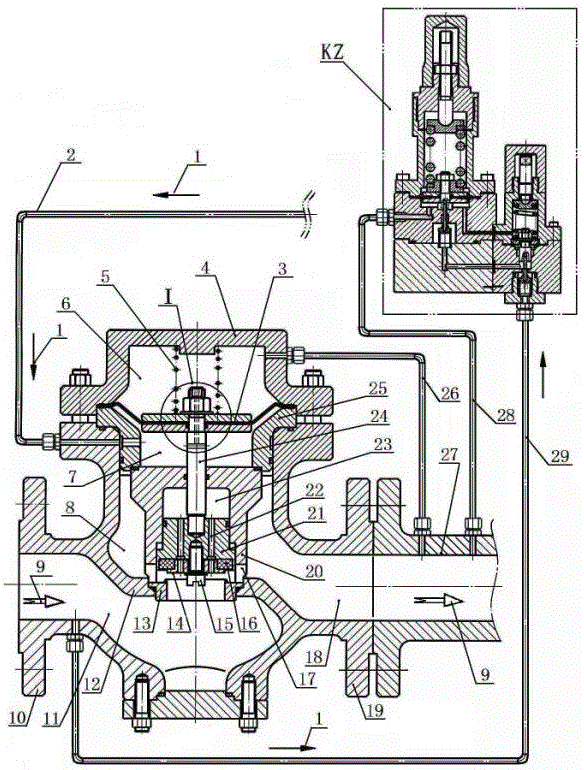

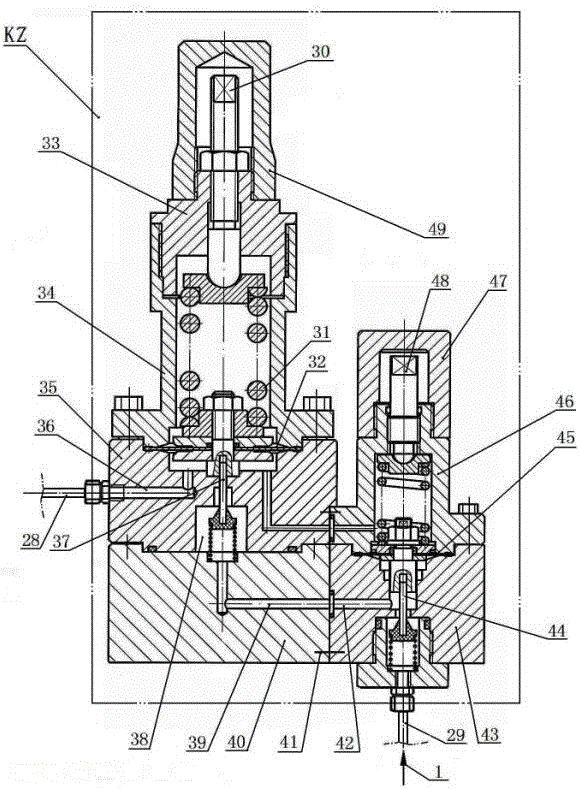

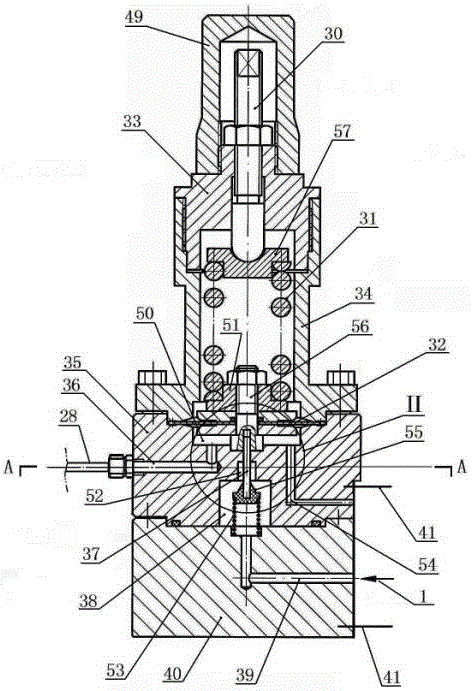

[0028]A self-pressure loaded pressure regulator proposed by the present invention is mainly composed of a pressure regulating main valve, a pressure regulating controller KZ and a main regulating signal tube 2 connected thereto, a front pressure signal tube 29 and a rear pressure signal tube 28 , Back pressure return pipe 26 is formed. The pressure regulating main valve is mainly composed of a main valve body 12, a main valve cover 4 installed on the main valve body 12, a film backing ring 25, a main valve port 13 fitted in the valve cavity 8, a main valve sleeve 20, a main The adjusting valve core 21 and the main adjusting valve stem 24 are composed of the main adjusting membrane assembly 3 between the membrane backing ring 25 and the main valve cover 4 to separate the main adjusting membrane cavity 6 and the main adjusting lower membrane cavity 7. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com