Patents

Literature

36results about How to "Reduce strong impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming artificial vascular stent through 4D printing

ActiveCN104116578AFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

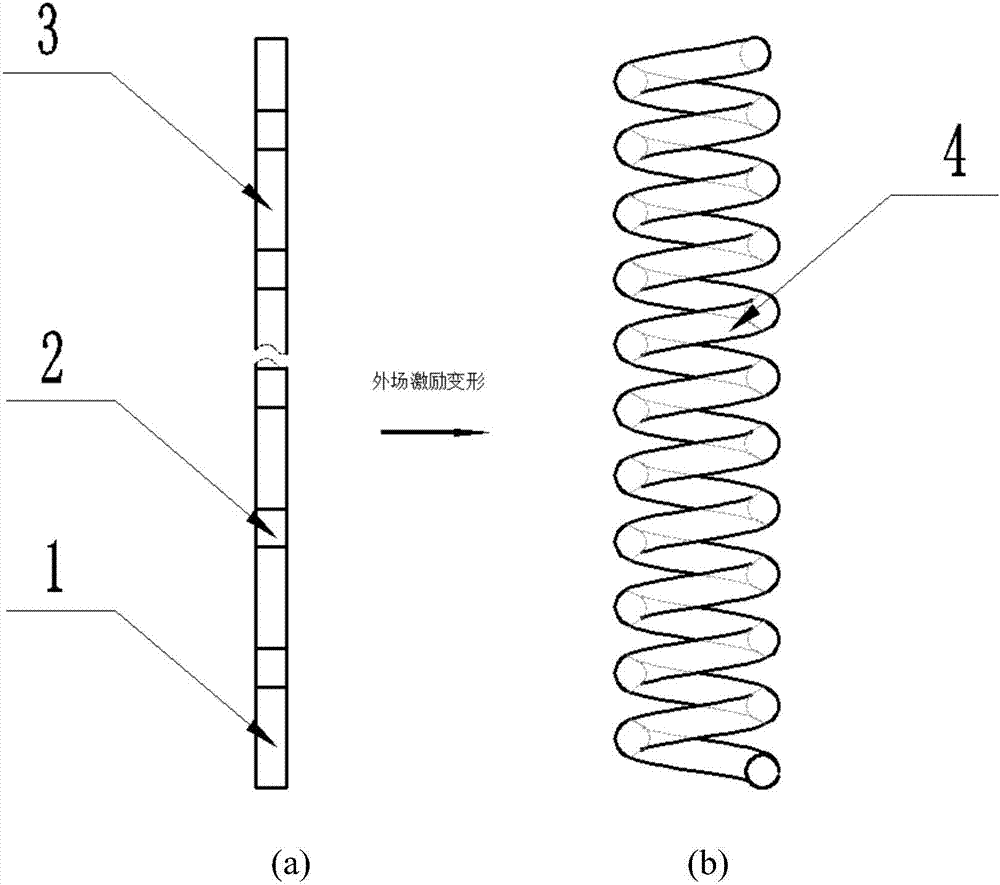

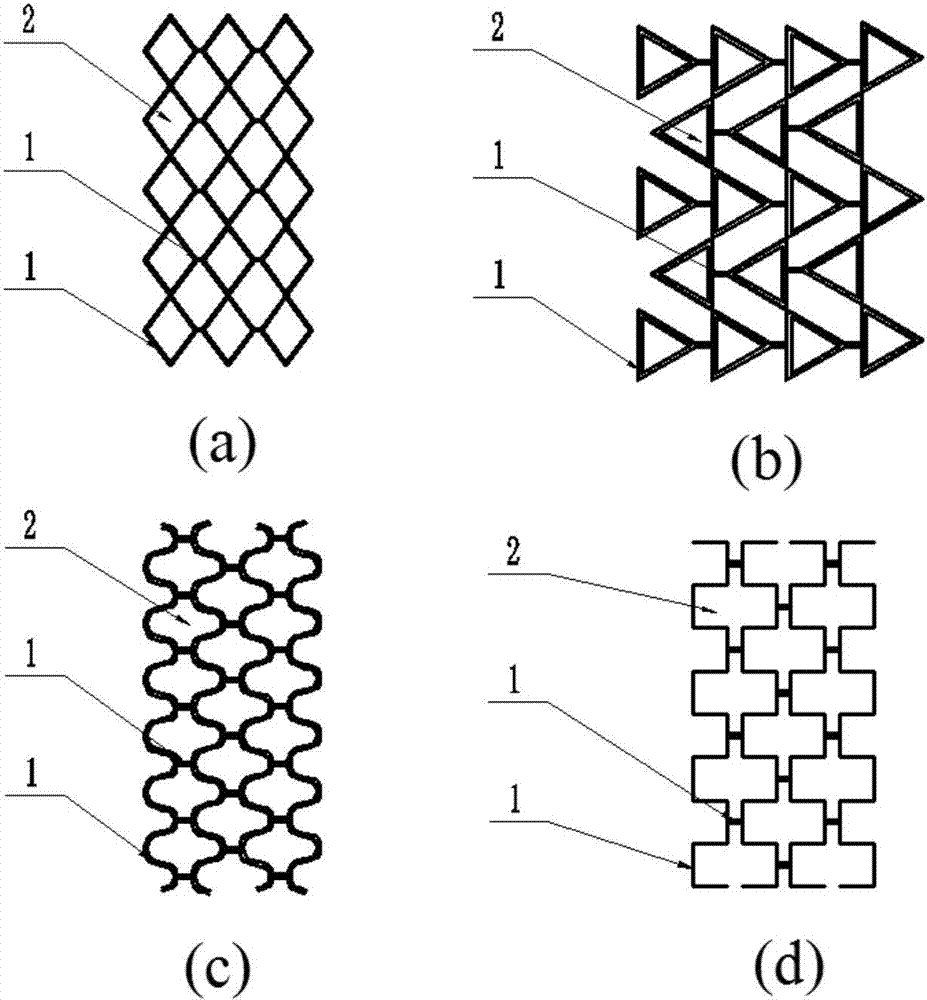

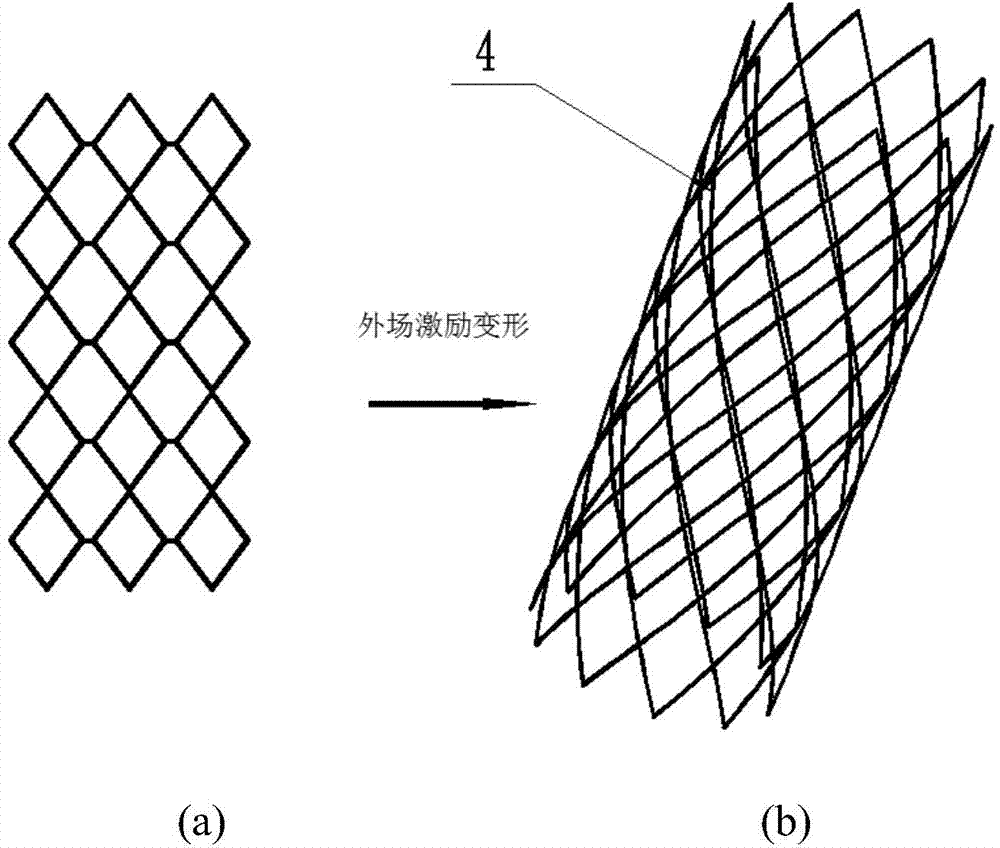

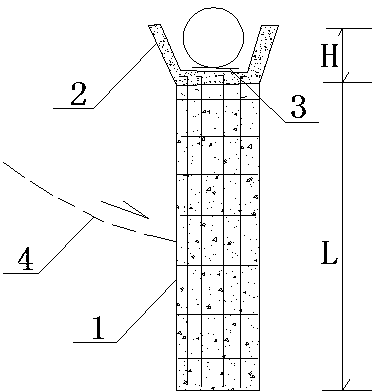

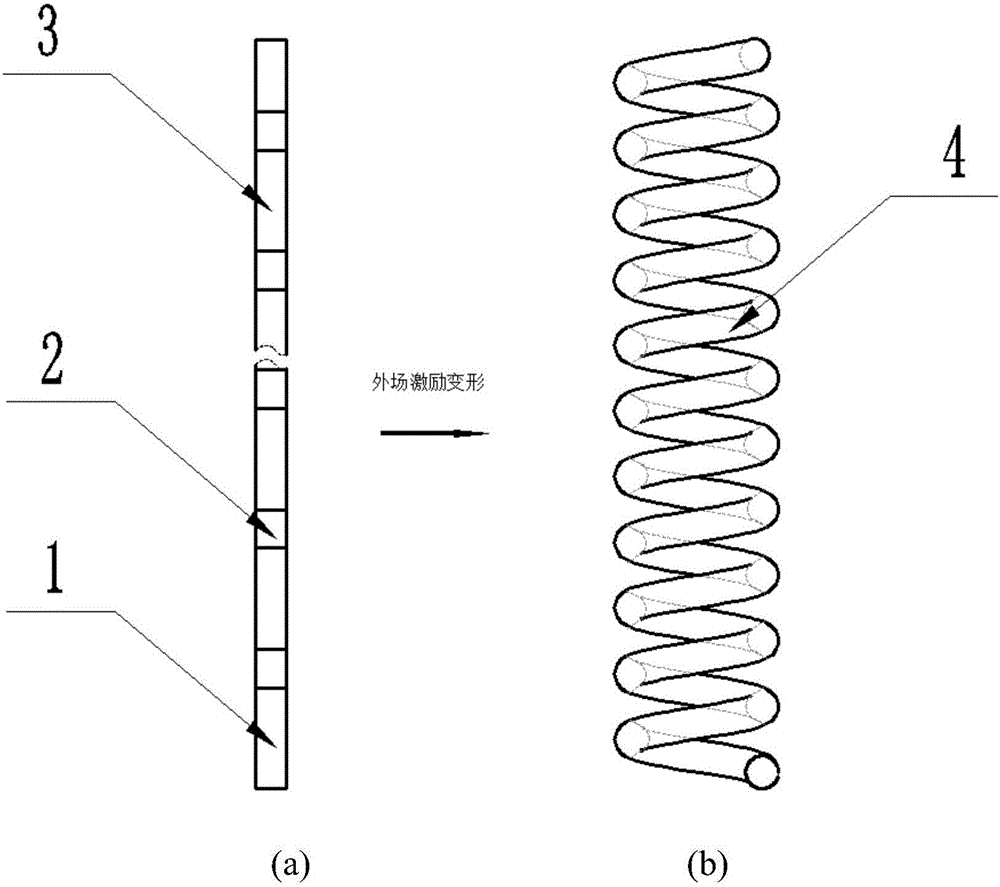

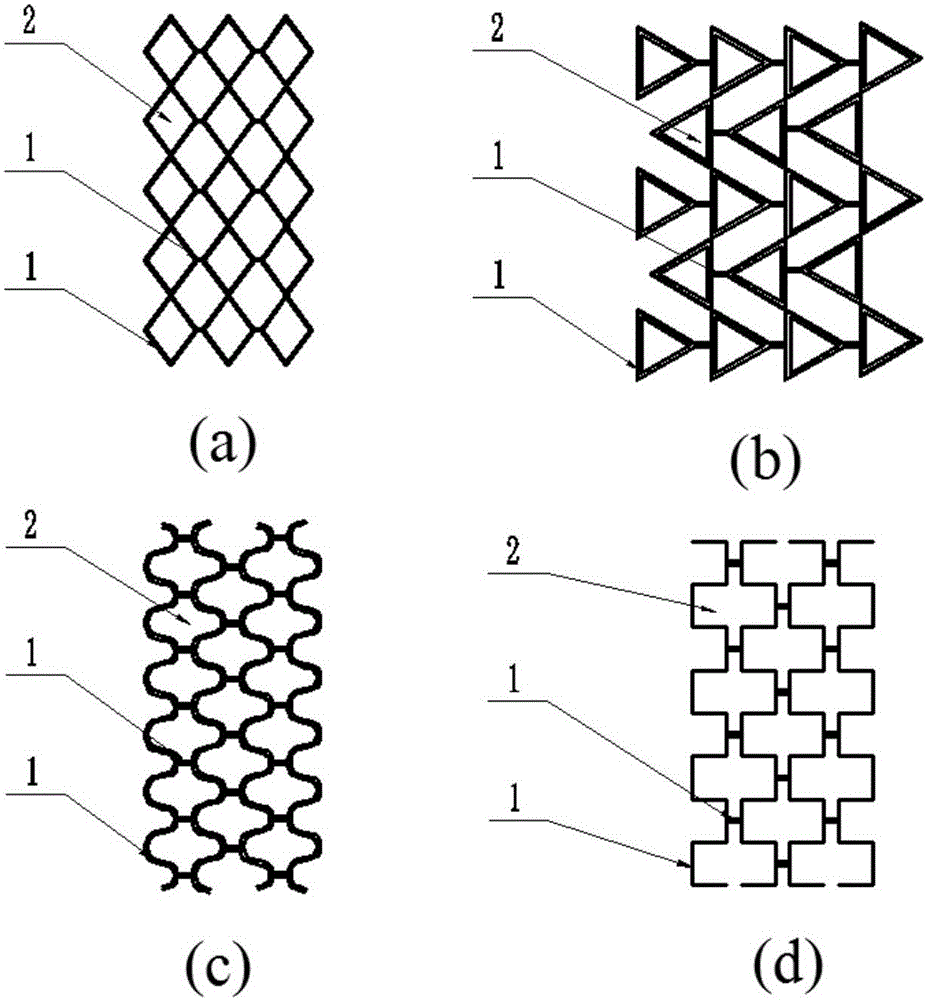

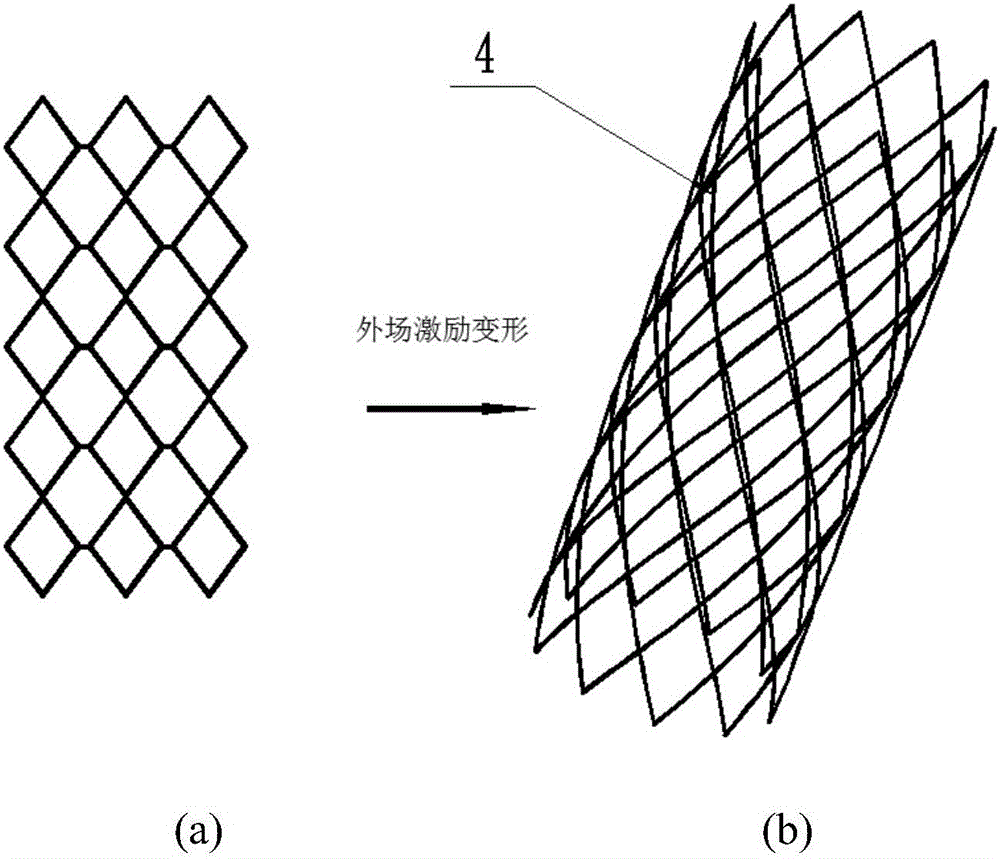

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

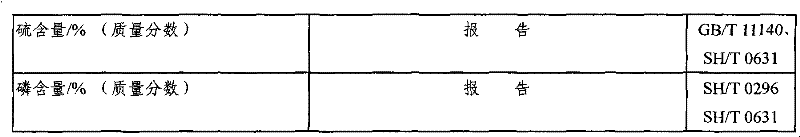

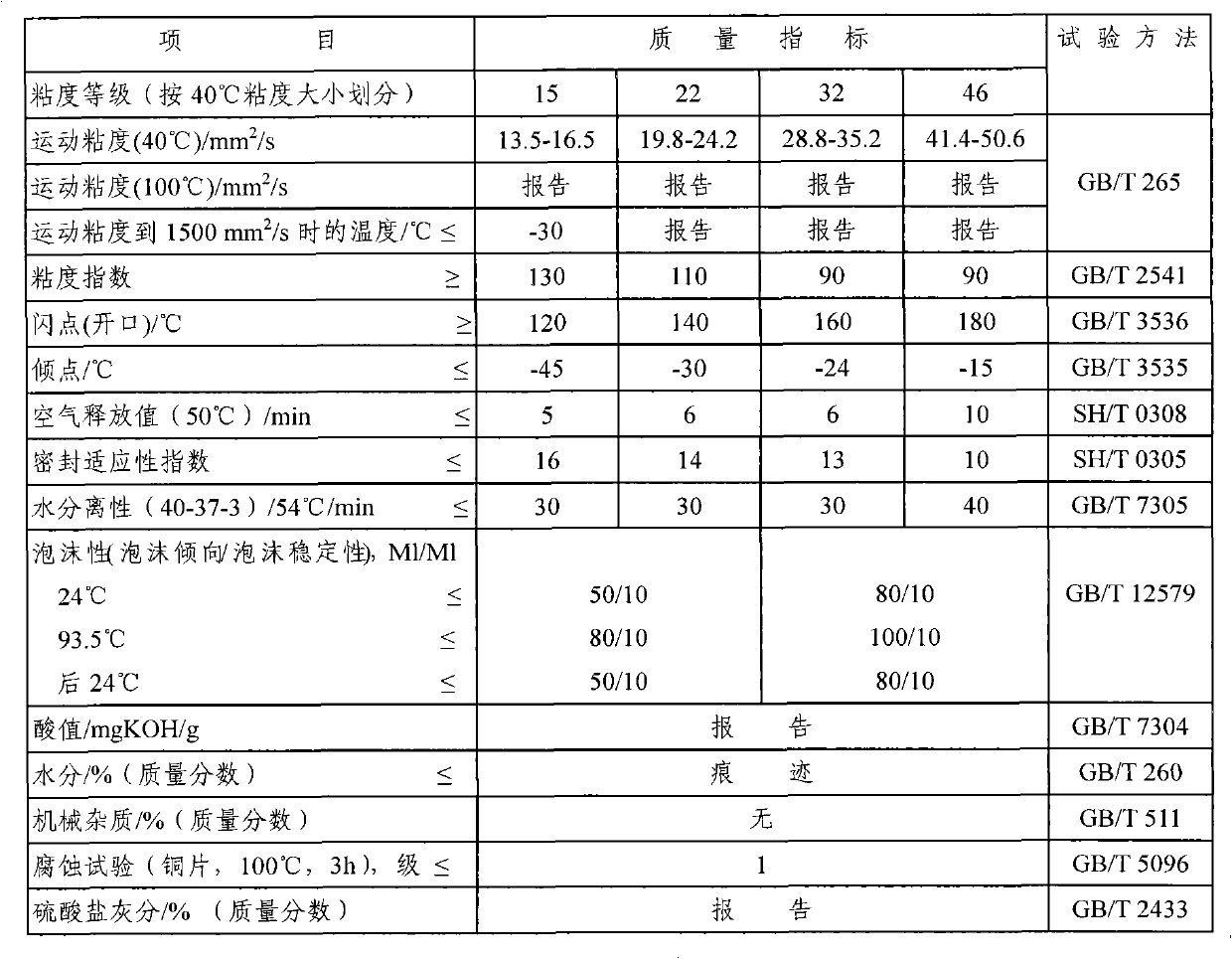

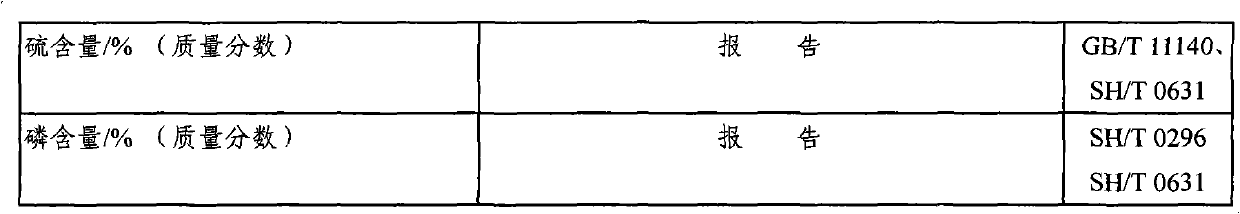

Lubricating oil composition for motorcycle shock absorber

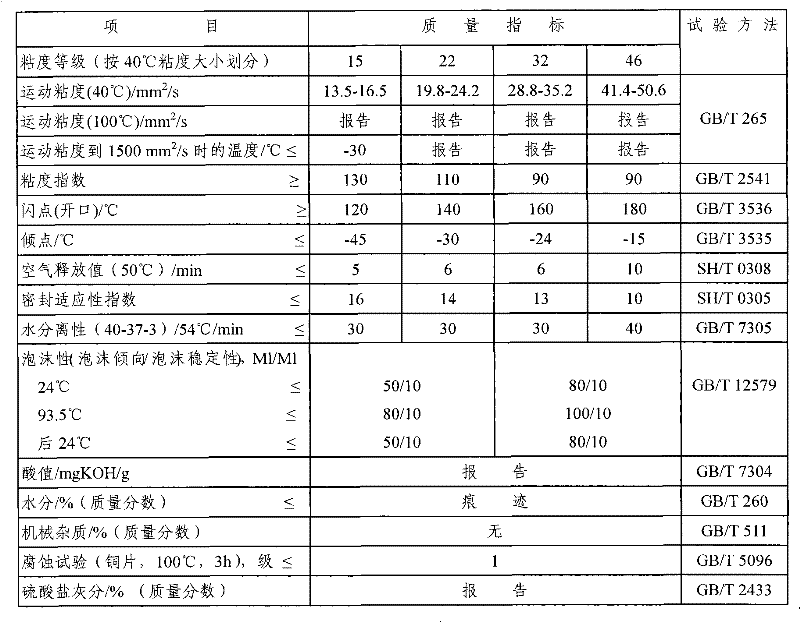

The invention provides a lubricating oil composition for a motorcycle shock absorber. The lubricating oil composition comprises the following components in percentage by weight: 1-20% of viscosity index improver, 0-1.0% of extreme-pressure antiwear agent, 0.05-1.0% of antioxidant and antiwear agent, 0.001-0.01% of demulsifier, 0.0001-0.01% of antifoaming agent, 0.05-1.4% of pour point depressant and the balance of base oil. According to the invention, the lubricating oil composition has the advantages of proper viscosity index, good viscosity-temperature performance, good low-temperature property, excellent rubber compatibility, and good corrosion resistance and oxidation resistance, and can be also used for lubricating a bicycle saddle shock absorber.

Owner:CHINA PETROLEUM & CHEM CORP

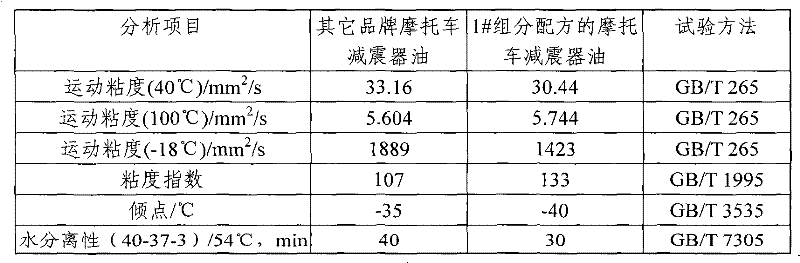

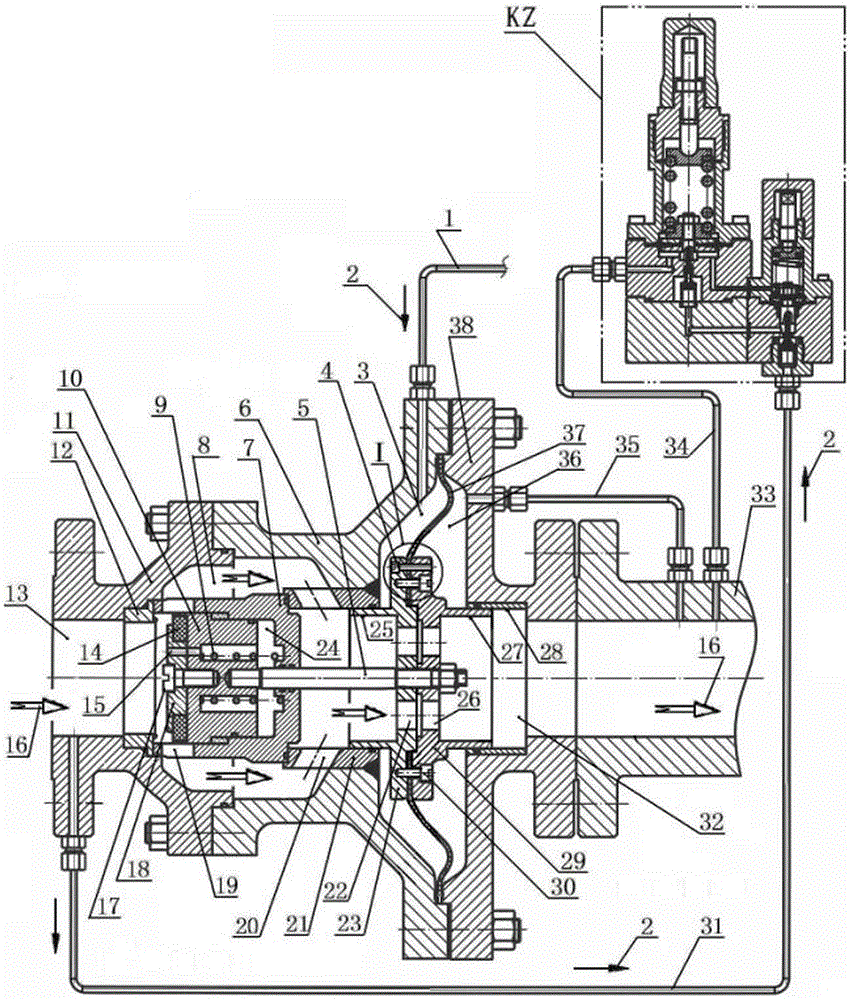

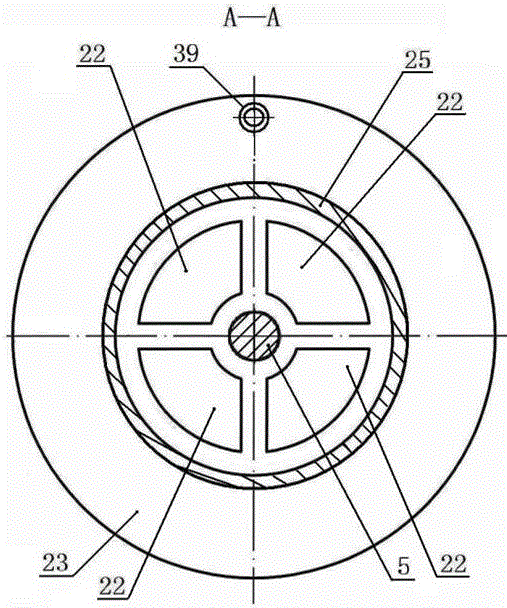

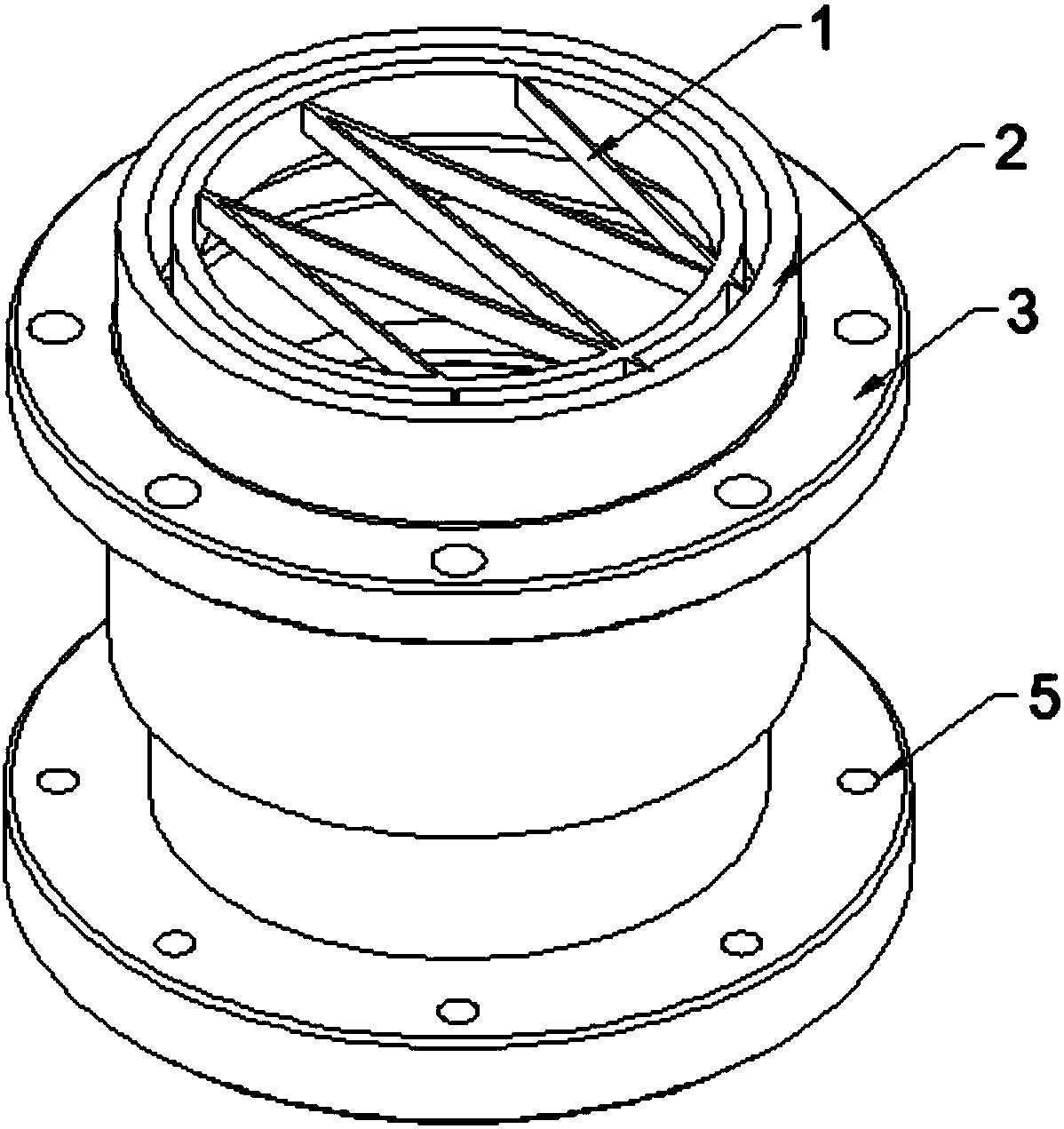

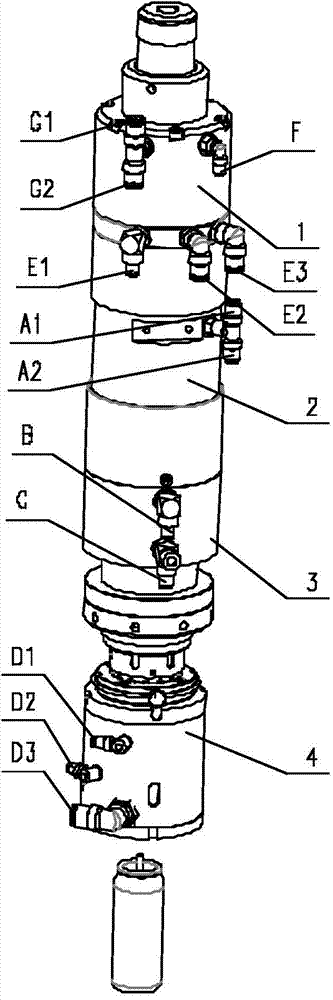

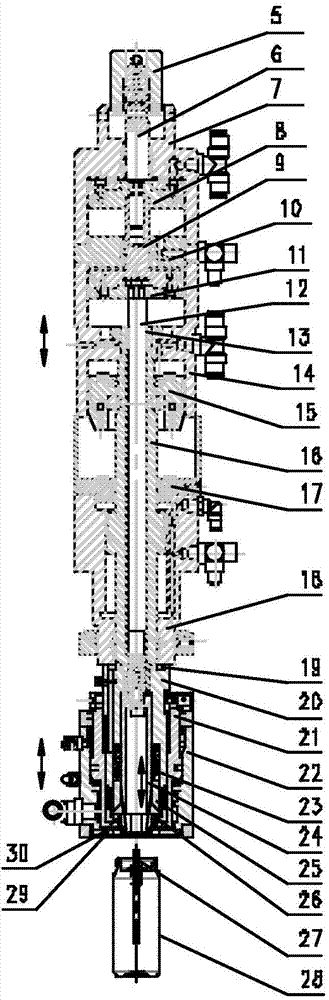

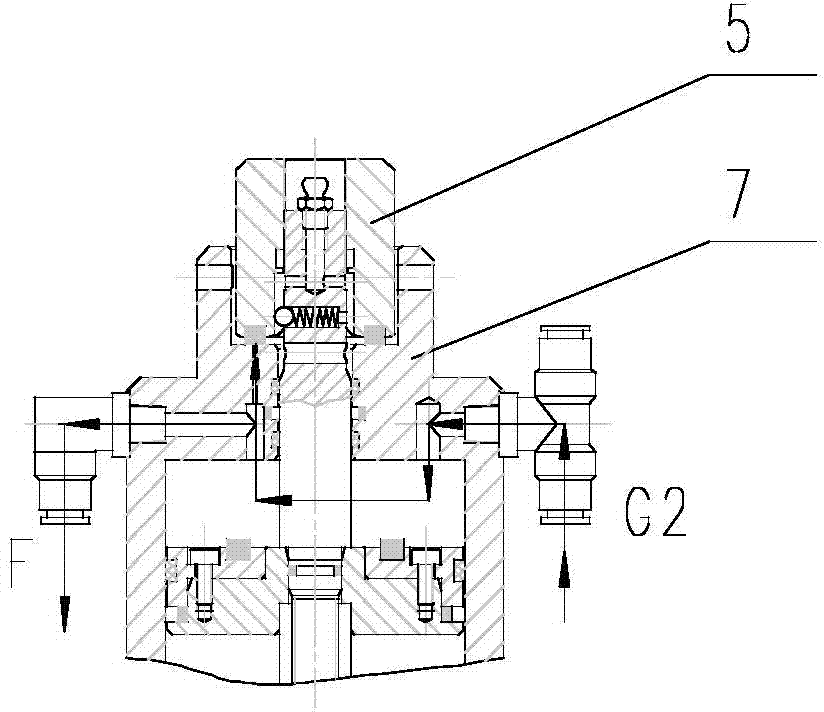

Piston type axial flow pressure regulator

ActiveCN106763960AReduce strong impactExtend working lifeOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringHigh pressure

The invention discloses a piston type axial flow pressure regulator which mainly comprises an axial flow regulation valve, a pressure regulation controller and a group of signal tubes connected with the pressure regulation controller and has the remarkable structure characteristics that separate flow passage, throttling and depressurizing functional component and guide mechanism functional component are designed in the axial flow regulation valve according to the separation principle. A cylinder sleeve is embedded between a valve seat and a valve sleeve to form an annular flow channel, and a piston is matched in the cylinder sleeve in a sliding manner to carry out pressure regulation and stabilization operation, so that the piston is guaranteed to be applied by the pushing and pulling action force in the axial direction only when sliding in the cylinder sleeve, the defects of large flow resistance, large vibration and high noise as the a turbulent flow is easily generated due to a meander flow passage with lower inlet and upper outlet of the traditional regulation valve are well overcome, and the technical effects of further improving the pressure regulation accuracy and pressure regulation stability are very obvious. The piston type axial flow pressure regulator has the outstanding advantages of simple and rapid structure, liability in production, low manufacturing cost, high pressure regulation accuracy, good stability of output pressure, safety and reliability in running and long service life and has very good popularization and application prospect.

Owner:四川长仪油气集输设备股份有限公司

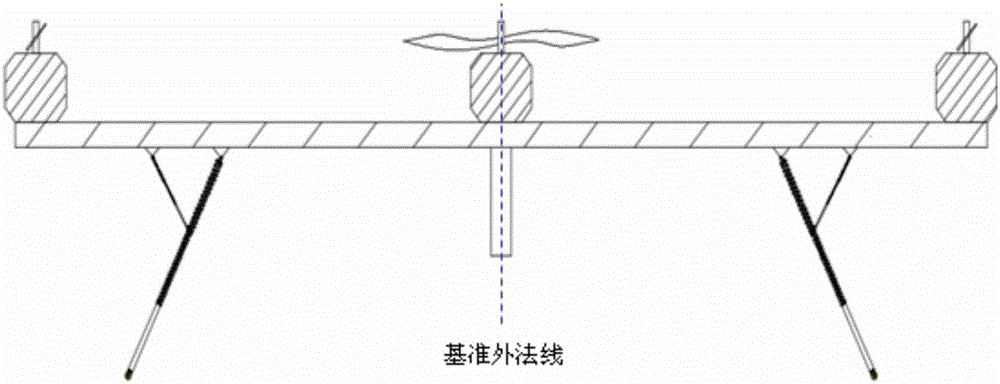

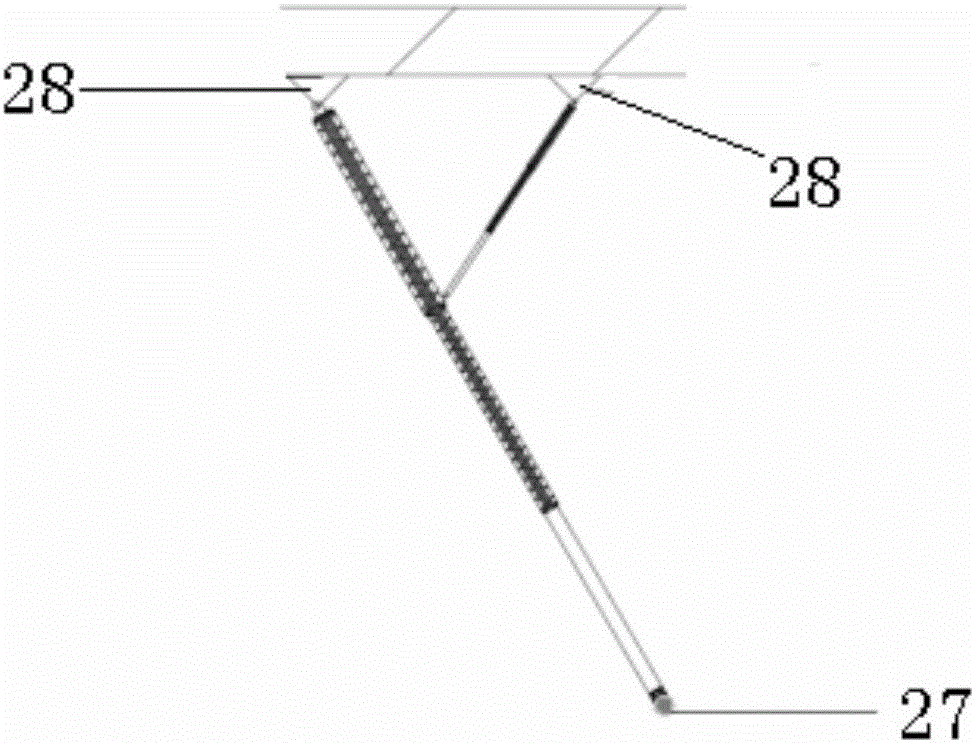

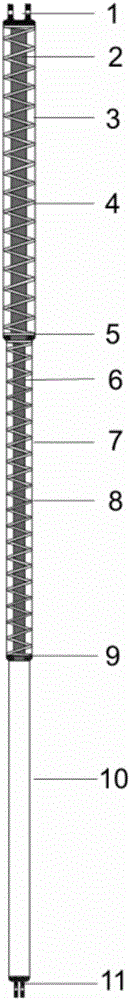

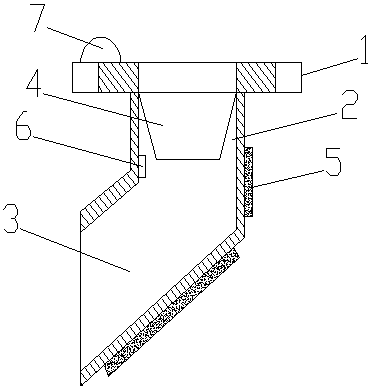

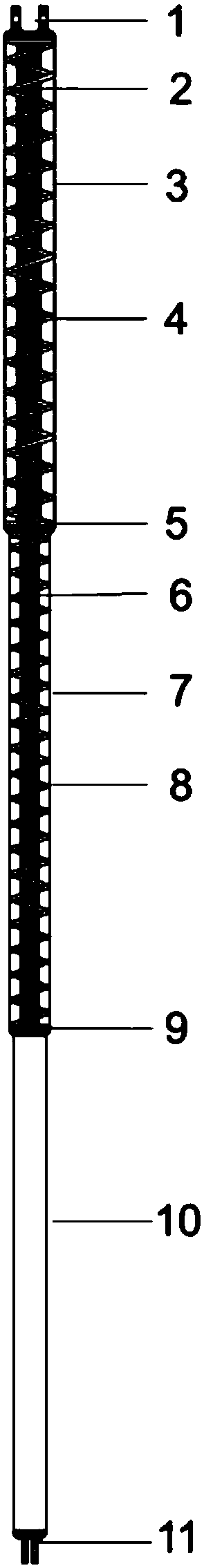

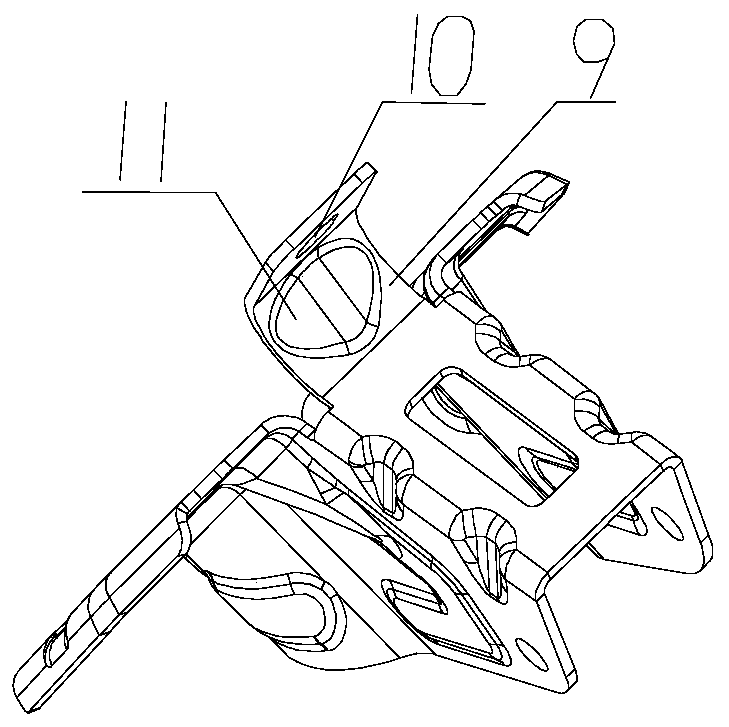

Roller type multistage damping reed pipe anti-falling device for unmanned aerial vehicle

The invention discloses a roller type multistage damping reed pipe anti-falling device for an unmanned aerial vehicle. A three-level damping reed pipe telescopic structure is adopted, damping reed pipes are in a thin-shell cylinder shape, and magnetic rods and springs are installed in the damping reed pipes. The two damping reed pipes have unequal lengths, and the length of the short reed pipe is one-third that of the long reed pipe. The long reed pipe and the short reed pipe are connected to a hinge support of a fuselage base plate, and the tail end of the short reed pipe is connected to the side wall of a first stage of the long reed pipe. A universal wheel support is connected with the long reed pipe, a rubber wheel is installed below the support, and a pressure ball bearing rotates to achieve 360-degree rotation of the rubber wheel. When the rotor unmanned aerial vehicle lands, the anti-falling device delays ground contact time by compressing the springs to reduce impact force and converts kinetic energy into elastic potential energy, magnetic damping can alleviate vibration, and energy is dissipated. The universal wheel support is matched with the rubber wheel to prevent rollover caused by a horizontal speed, and the goal of protecting the unmanned aerial vehicle is achieved. The anti-falling device can also serve as an undercarriage to make the unmanned aerial vehicle capable of landing directly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

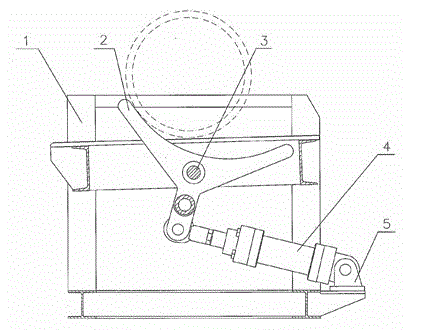

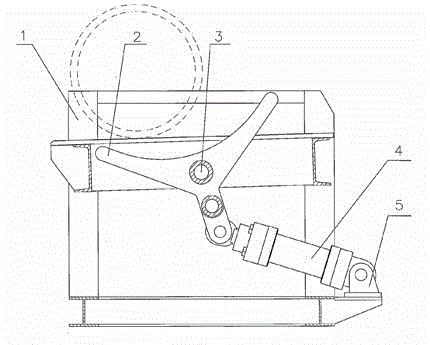

Sleeve-removing shifting fork mechanism and method

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

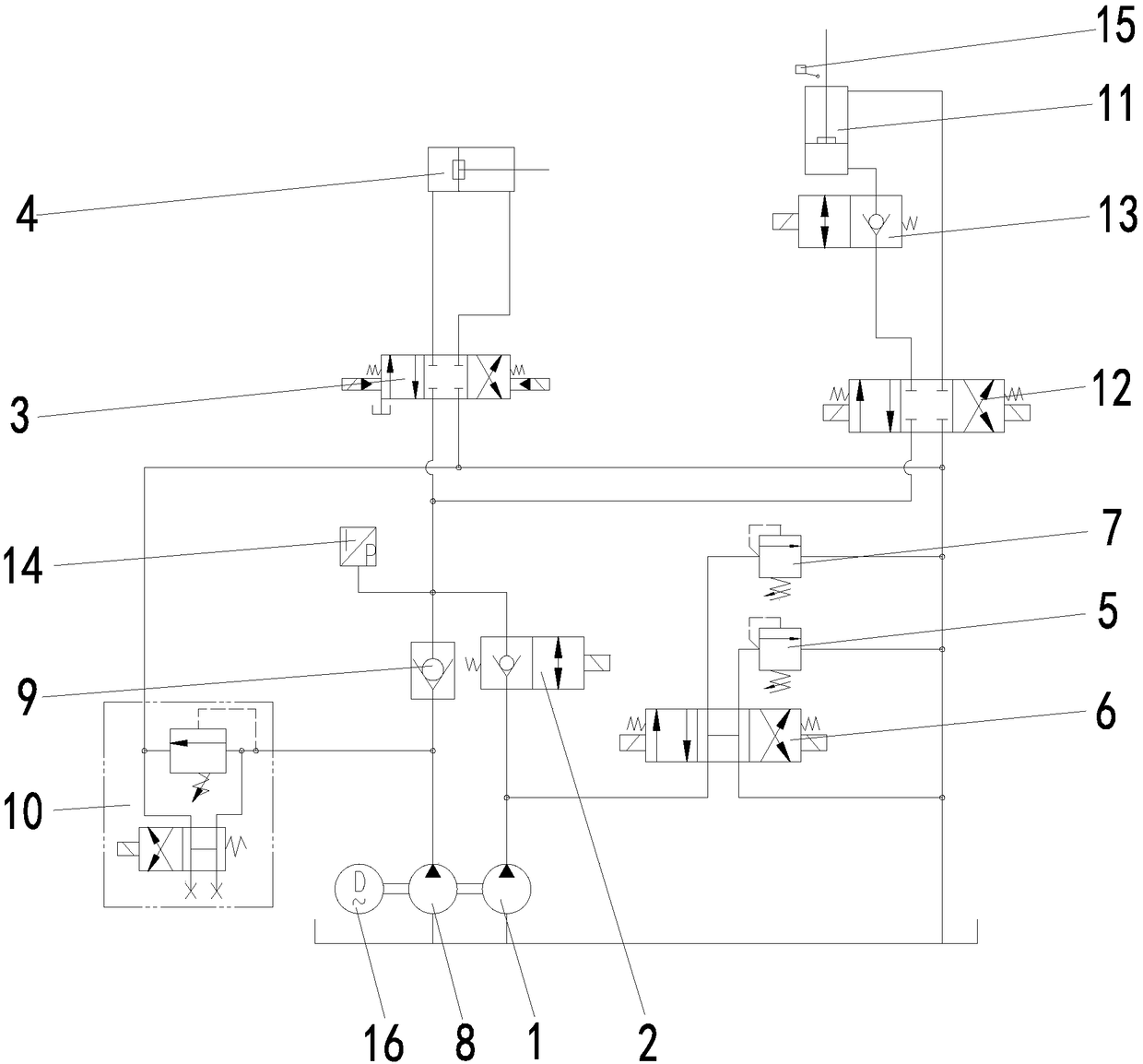

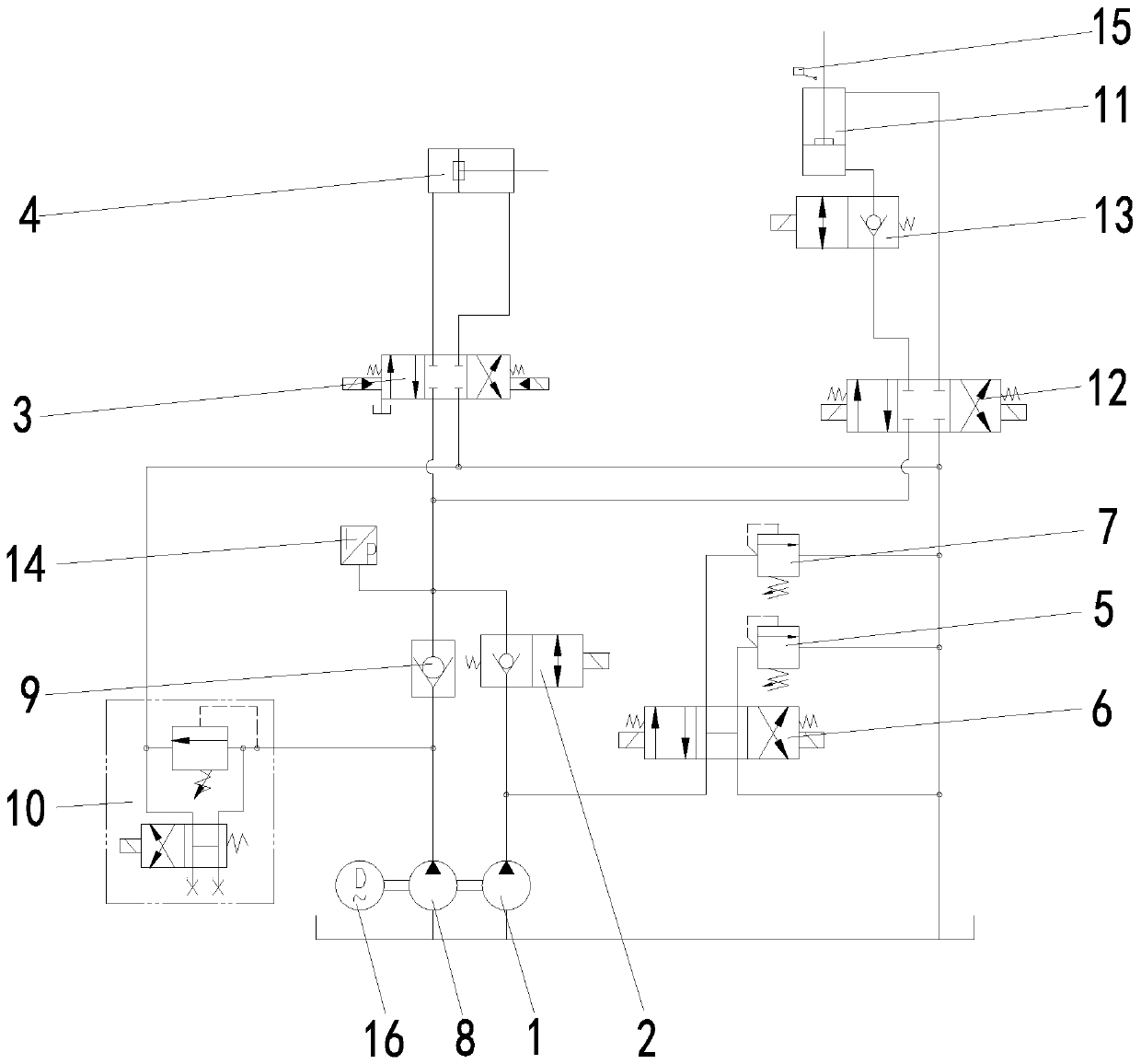

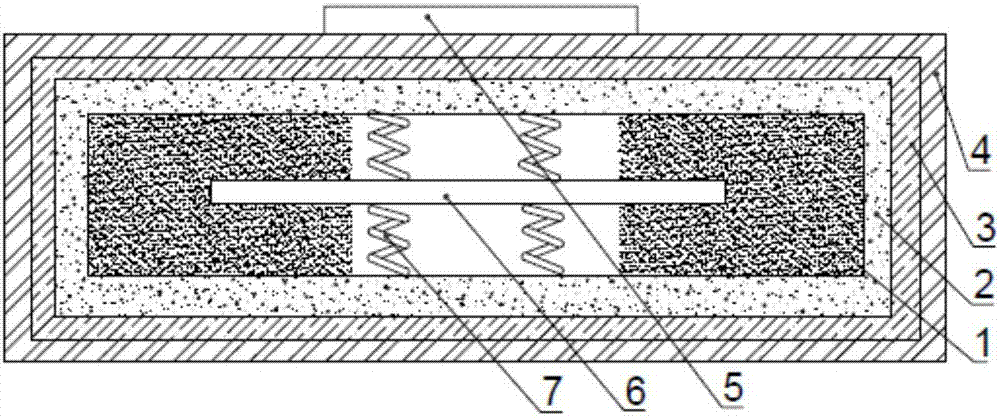

Unloading buffer hydraulic system

ActiveCN109058187AAvoid breakingImprove securityServomotor componentsServomotorsFuel tankHigh pressure

The invention relates to the technical field of hydraulic control, in particular to an unloading buffer hydraulic system. The system comprises a first pump body, a first reversing valve, a second reversing valve, a pushing plate oil cylinder and a first pump body low-pressure overflow valve; the first pump body is in communication with a hydraulic oil tank and the second reversing valve through amain pressure oil way, two oil outlets of the second reversing valve are connected to a rod cavity and a rodless cavity of the pushing plate oil cylinder respectively, and an oil return port of the second reversing valve is in communication with the hydraulic oil tank through an oil return pipeline; the first reversing valve is arranged between the first pump body and the second reversing valve, one end of the first pump body low-pressure overflow valve is connected to a pipeline between the first pump body and the first reversing valve, and the other end of the first pump body low-pressure overflow valve is in communication with the oil return pipeline; and before the second reversing valve carries out the reversing operation, the high-pressure oil unloading is carried out by the pushingplate oil cylinder. According to the unloading buffer hydraulic system of a rubbish compression box, unloading buffer of the pushing plate oil cylinder can be well achieved, the strong impact problemof a water hammer phenomenon is effectively solved, and the safety of an oil supply pipeline of the pushing plate oil cylinder is greatly improved.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

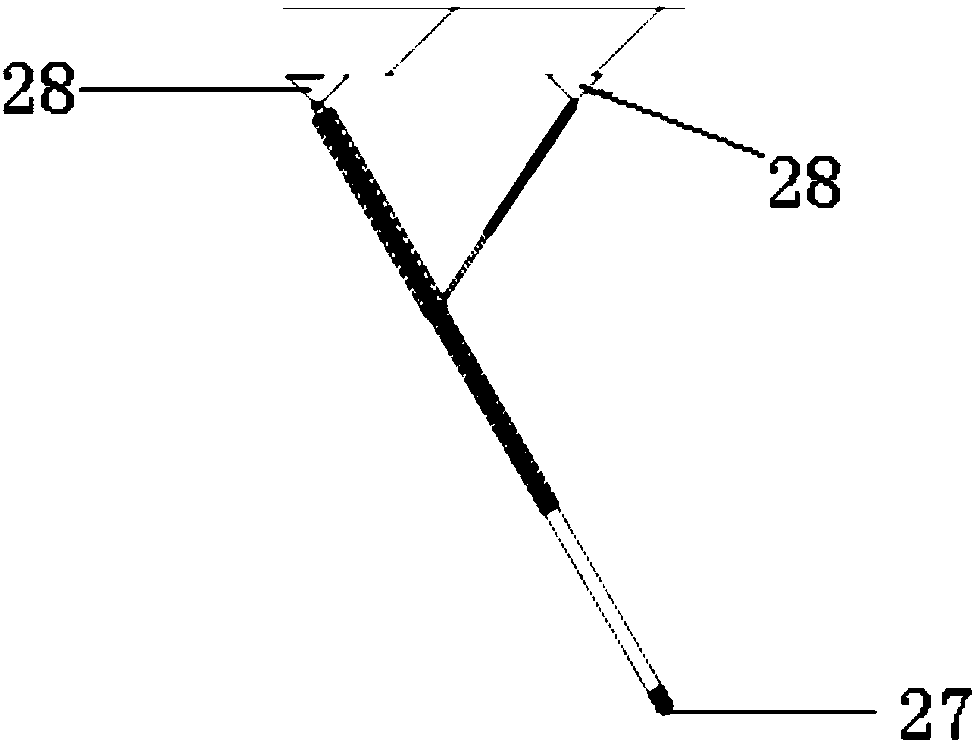

Skid resistance supporting straining protection method for passing through topsoil of landslide area of oil and gas conveying pipeline

The invention discloses a skid resistance supporting straining protection method for passing through a topsoil of the landslide area of an oil and gas conveying pipeline. The method comprises the following steps: a skid resistance and supporting pier, a trapezoidal groove reinforced concrete cushion cap and a pipeline transformation adjusting device are constructed; the pipeline transformation adjusting device capable of sliding freely is arranged on the groove-shaped cushion cap at the top of the pipeline and the skid resistance and supporting pier, and when the pipeline is subjected to the thrust effect of the landslide, the pipeline can perform self adjusting through the pipeline transformation adjusting device, so that the stress of the pipeline is reduced, the straining design is realized, and the purpose of protecting the pipeline is achieved. Besides, in consideration of the anti-seismic requirement, the filler material with better elasticity is filled between the pipeline in the groove and the two side walls of the groove through adopting the method, so that when a strong earthquake occurs, the pipeline in the trapezoidal groove is enabled to slightly move to left or right along with the shaking of the earthquake to relieve strong impact brought by the earthquake, and the purpose of protecting the pipeline is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A 4D printing method for artificial vascular stents

ActiveCN104116578BFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

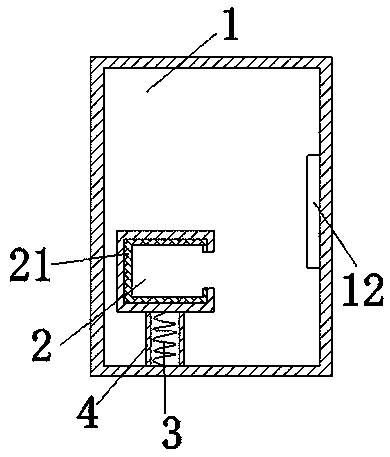

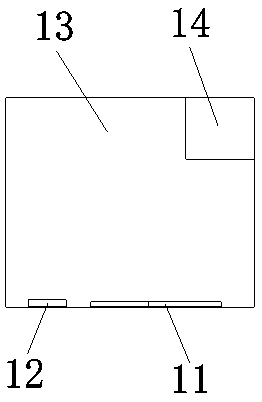

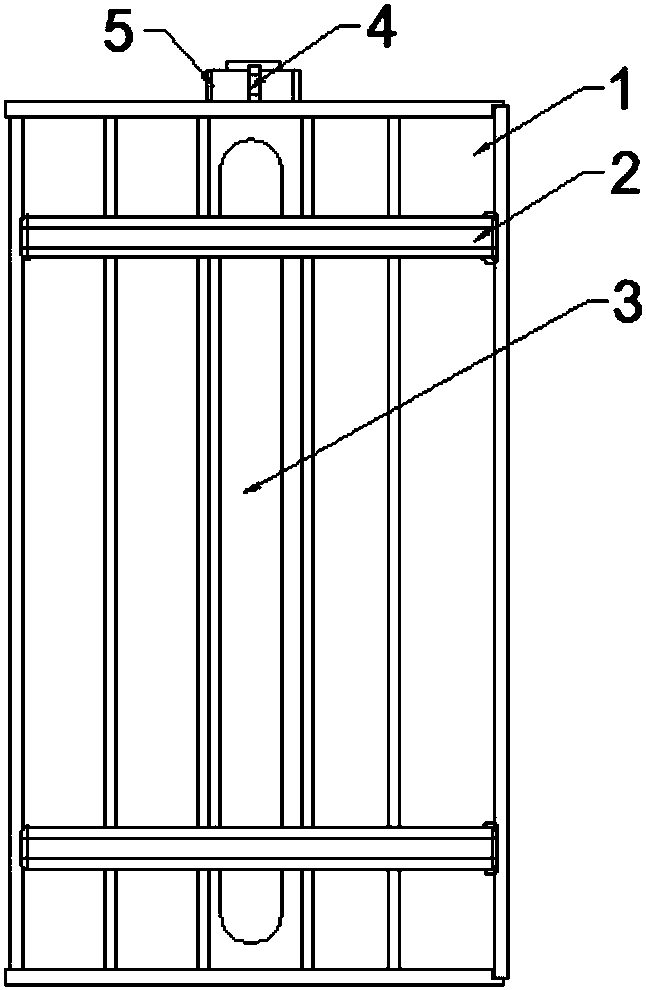

A child safety elevator

ActiveCN106219353BReduce harmReduce strong impactElevatorsBuilding liftsEngineeringMechanical engineering

The invention discloses a safety elevator for children. The safety elevator comprises a lift car and a safety seat arranged in the lift car. The safety seat is shaped like a shell. An opening is formed in the side face of the safety seat. The safety seat is arranged on a floor of the lift car. An elastic part is arranged between the safety seat and the floor of the lift car. The safety seat can rotate by 360 degrees. The safety elevator is adopted, the elastic part is arranged between the floor of the lift car and the safety seat, in the process during which the elevator falls and suddenly stops, the strong impact force generated in the process is greatly reduced by conducting buffering through the elastic part, and therefore injuries caused by elevator falling accidents to children are greatly reduced.

Owner:HOMEFRIEND & FUJI ELEVATOR CO LTD

Box type polyurethane ceramic liner plate preparing method and liner plate manufactured through box type polyurethane ceramic liner plate preparing method

InactiveCN109592242AReduce strong impactIncrease contact areaLarge containersFastening meansManufacturing technologyWear resistance

The invention provides a box type polyurethane ceramic liner plate preparing method and a liner plate manufactured through the box type polyurethane ceramic liner plate preparing method. The liner plate comprises a steel shell. A glue injection hole is formed in a bottom face steel plate of the steel shell and formed in the bottom face steel plate. Corundum ceramic blocks are tightly placed on theupper surface of the steel shell at equal intervals. Cavities between the bottoms of the corundum ceramic blocks and the inner side wall of the bottom face steel plate are filled with a polyurethanematerial layer for fixedly connecting the corundum ceramic blocks with the steel shell. The manufacturing technology is simple, the structure is reasonable, the liner plate is high in abrasion resistance and can bear powerful impacts for a long term, the production cost is low, and the comprehensive usage expense can be reduced for users.

Owner:余博

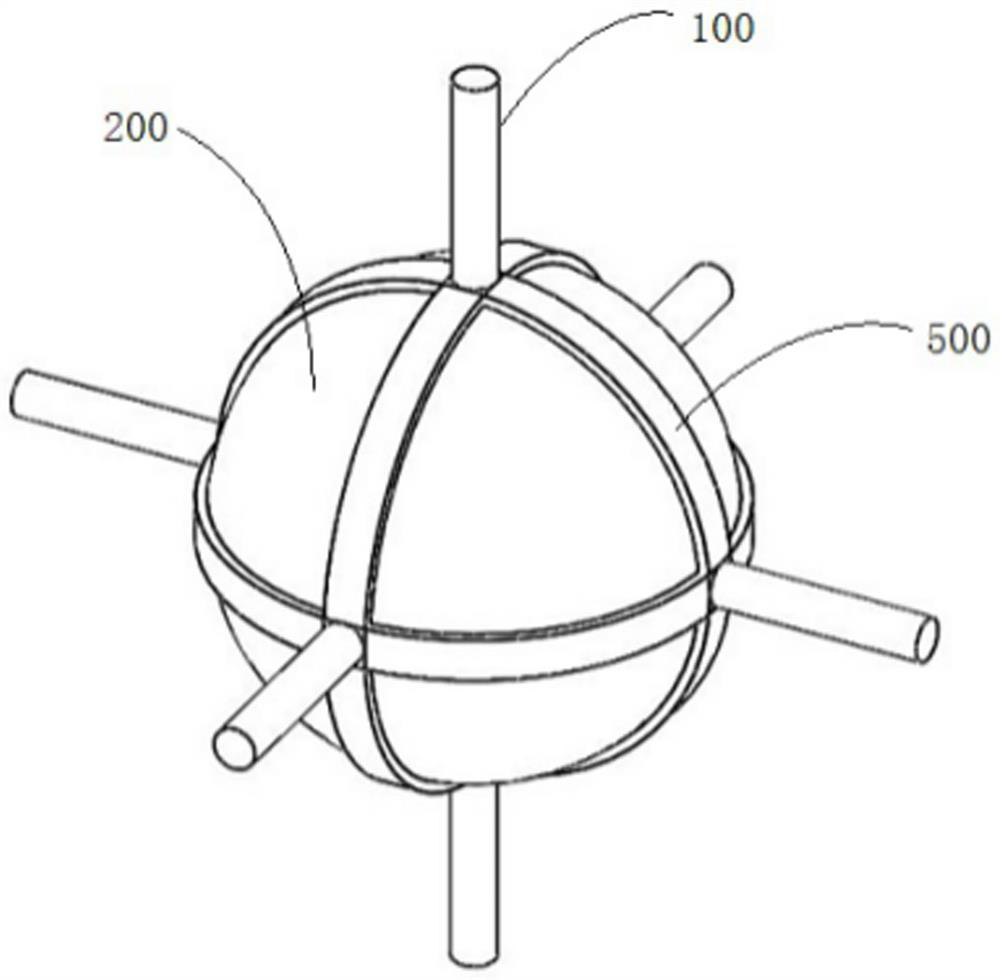

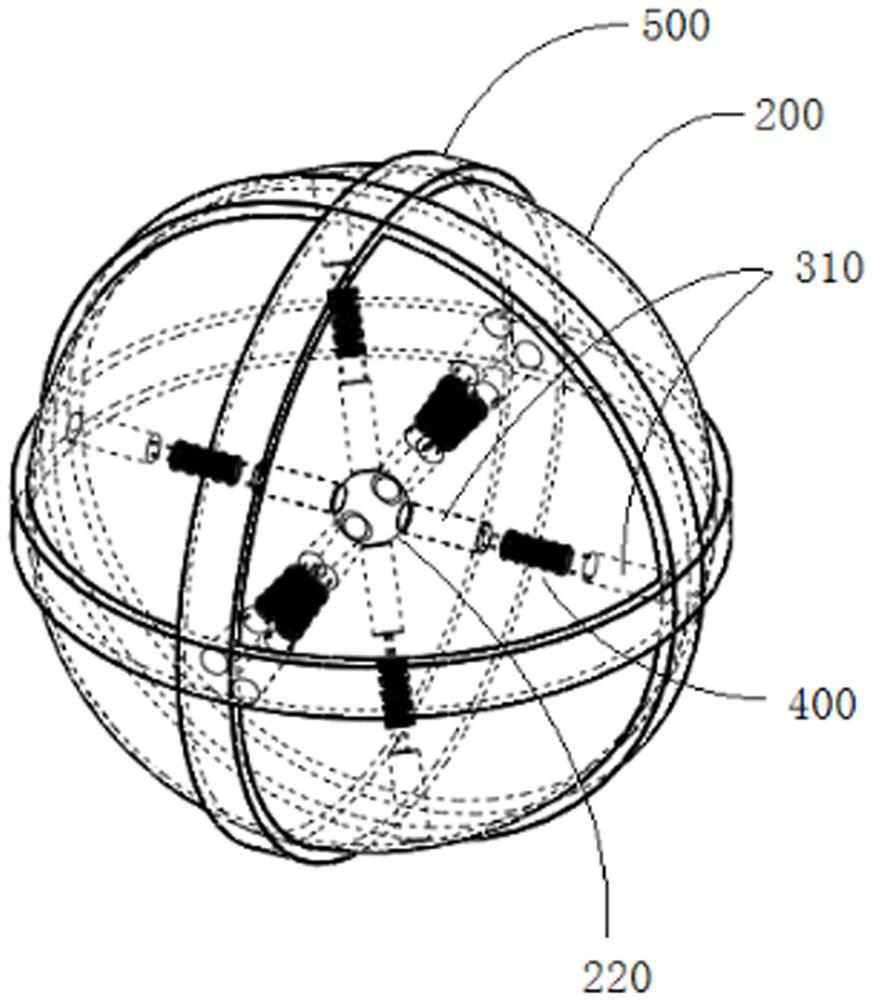

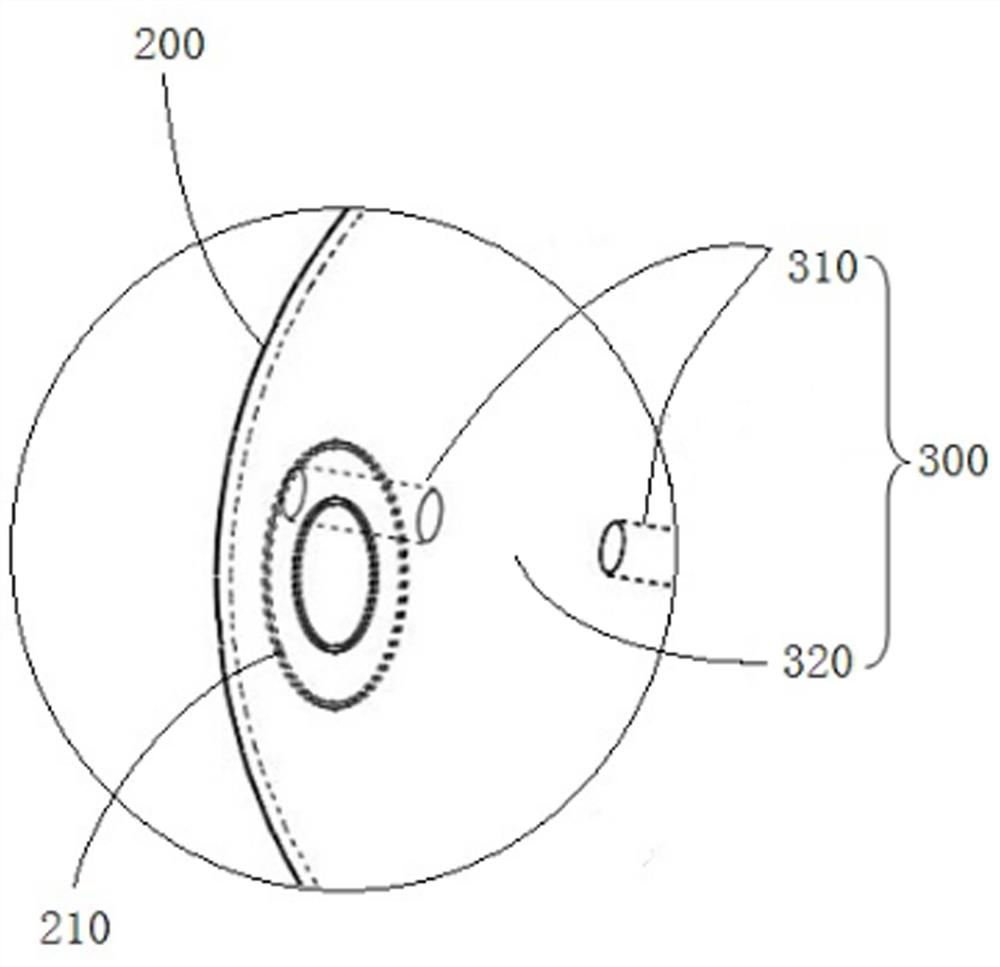

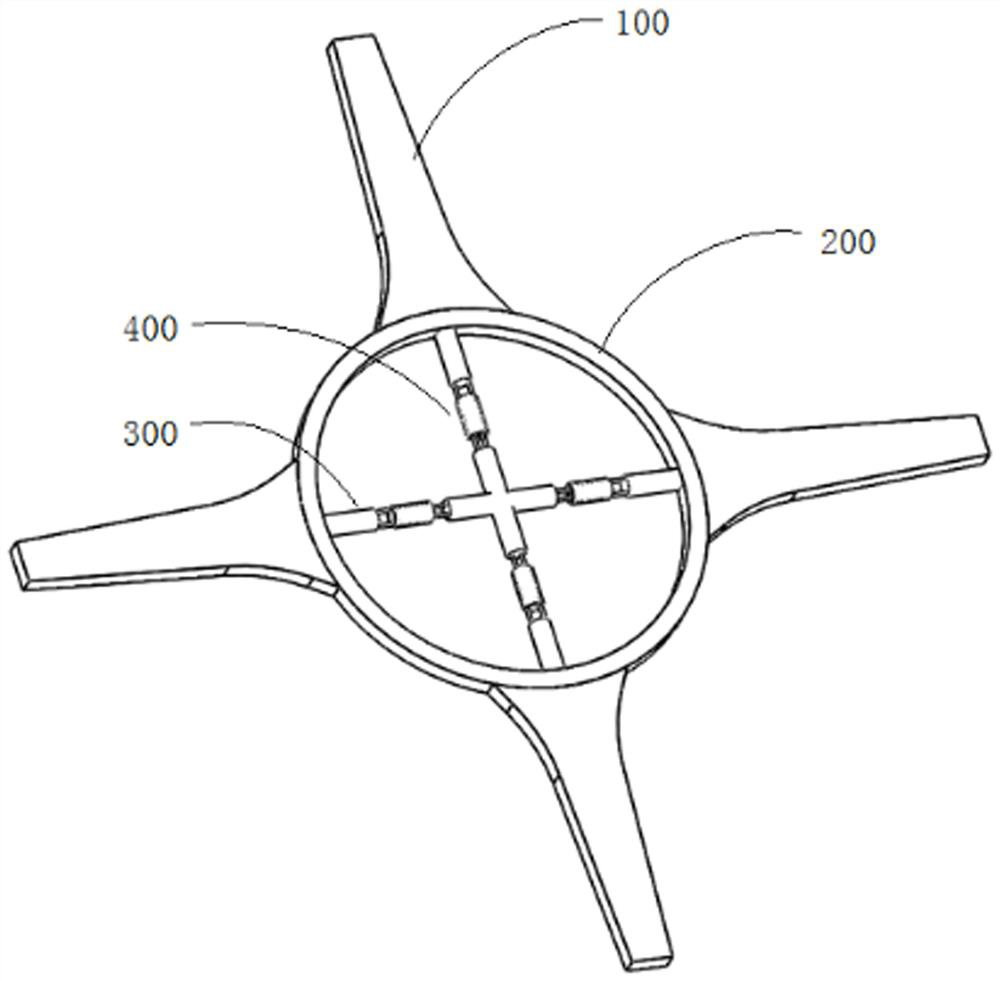

Sphere elastic buffering part

ActiveCN111911575AExtended service lifeGood buffer protectionLow internal friction springsClassical mechanicsStructural engineering

The invention discloses a sphere elastic buffering part which comprises a sphere shell, multiple reinforcing rings, multiple connecting rods and multiple elastic elements. The multiple reinforcing rings are arranged on the exterior of the sphere shell in an attached manner. The multiple connecting rods and the multiple elastic elements are arranged in the sphere shell. The ends of the multiple connecting rods are fixedly connected to the center point of the sphere shell. The other ends of the connecting rods are connected with the side wall of the sphere shell. Each connecting rod comprises atleast two coaxial supporting rods. An installing distance is spaced between the adjacent supporting rods. The length of the elastic elements is the same as the installing distance. The elastic elements are arranged between the adjacent supporting rods. The multiple reinforcing rings are at least arranged in the manner of intersecting in pairs. The sphere shell, the reinforcing rings and the connecting rods all have elasticity. According to the buffering part, strong impact on a machine from external loads can be weakened in a full-angle and all-dimensional manner, a good buffering protectionfunction can be achieved for the whole interior of a machine, the service life of the machine is prolonged, and stability and accuracy of operation and use are improved.

Owner:芜湖市聚晶新材料有限公司

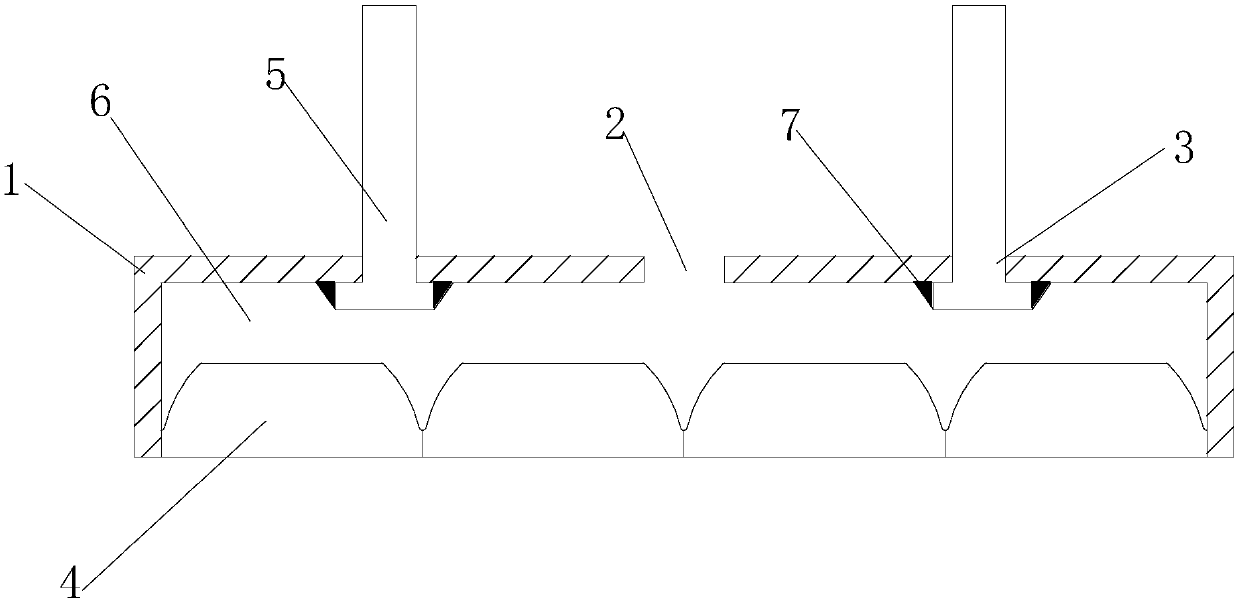

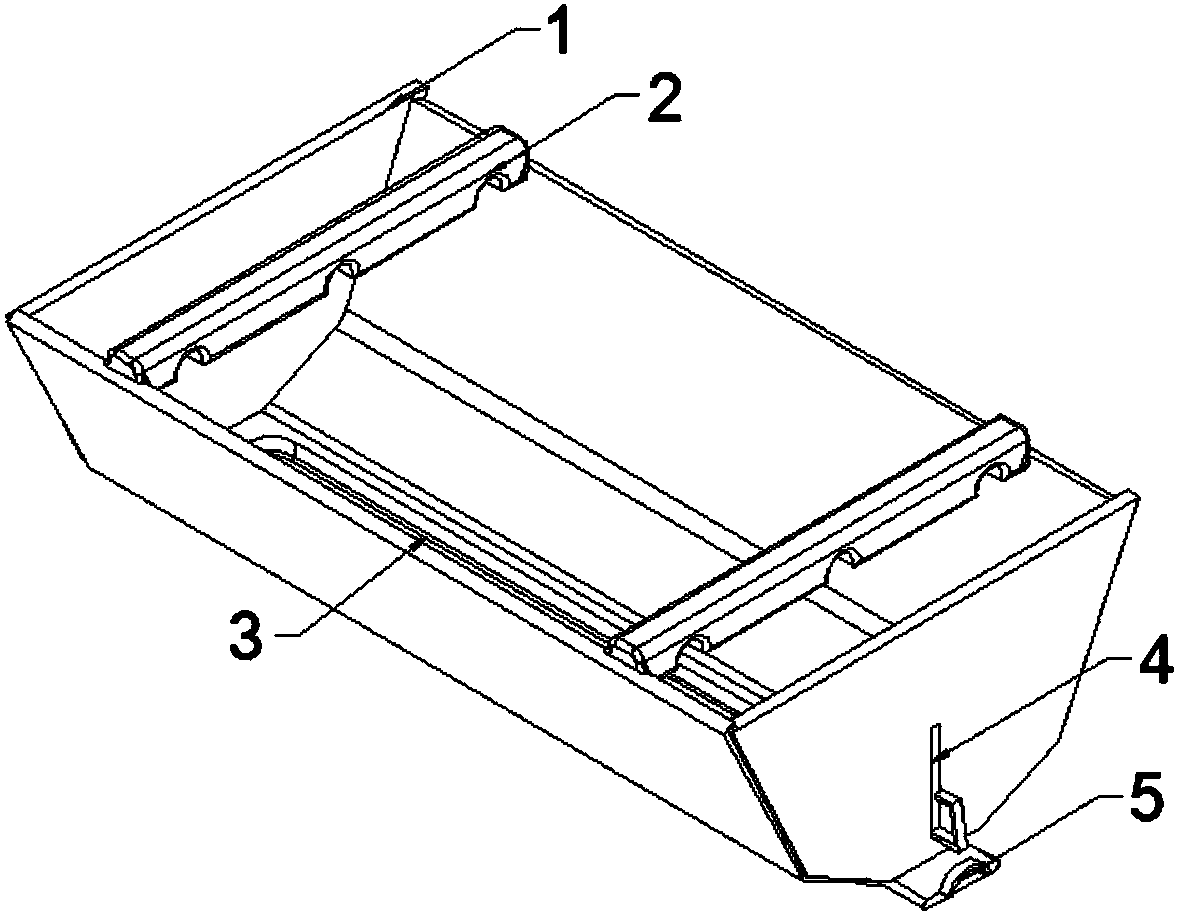

Ore conveying hopper based on the reinforcing plates

The invention discloses an ore conveying hopper based on the reinforcing plates. The conveying hopper comprises a hopper body, the hopper body comprises a hopper wall and connecting rods, wherein theconnecting rods are fixedly connected with the upper end of the hopper wall; the hopper wall comprises a bottom plate and side plates, the side plates are connected with the bottom plate, the longitudinal section profile of each side plate is in a fold line shape with an included angle of an obtuse angle, and the included angle between the upper end of each side plate and the vertical direction issmaller than the included angle between the lower end of each side plate and the vertical direction; grooves are formed in the connecting rods, and round angles are formed in the edges of the grooves; a discharging opening is formed in the bottom plate, an inserting plate sliding groove is formed in the lower end of the discharging opening, and the inserting plate sliding groove is internally andslidably connected with an inserting plate. The conveying hopper has the beneficial effects that ore containing is more convenient due to the wide inlet design, the design of the side plates enablesores to be buffered through the side plates when entering the bottom plate, so that the strong impact of the ores to the bottom plate is reduced, and the service life of the hopper is prolonged; and the whole process of discharging can be completed by virtue of the gravity action of the ores, so that the advantages of saving manpower and saving energy are achieved.

Owner:TIANJIN SANXIN SUNSHINE

Novel connecting flange

InactiveCN108253212AFlexible assembly and disassemblyReduce use costFlanged jointsPipe elementsEngineeringScrew thread

The invention provides a novel connecting flange. The novel connecting flange comprises a first connecting end and a second connecting end. The first connecting end and the second connecting end eachinclude a flange plate and a connecting pipe welded and fixed to the flange plate. The two connecting pipes are connected and fixed together through threads. Connecting end surfaces of the two connecting pipes are provided with sealing pads. Center pipe openings of the flange plates of the first connecting end and the second connecting end are provided with a first connecting ring and a second connecting ring in sealed and sleeving mode correspondingly. A buffering net plate is further connected in the first connecting ring in a clamped mode. The buffering net plate includes a mounting frame body and a mansard blocking bar welded and fixed to the mounting frame body. The novel connecting flange has the beneficial effects that the two connecting ends are designed to be a threaded connectingstructure, so that the novel connecting flange has the ability to be disassembled so that the two connecting ends can be disassembled when the situation that one connecting end of the flange is damaged and cannot be applied and the other connecting end is structurally intact is encountered, the flange is assembled with a new connecting end into a whole to be used, so that a repairable characteristic is given to the flange, and the using cost of the flange is reduced accordingly.

Owner:TIANJIN YUEFENG TECH

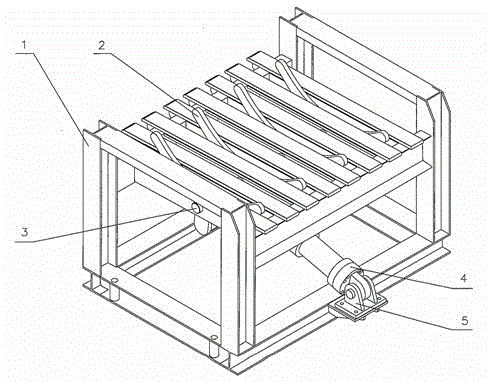

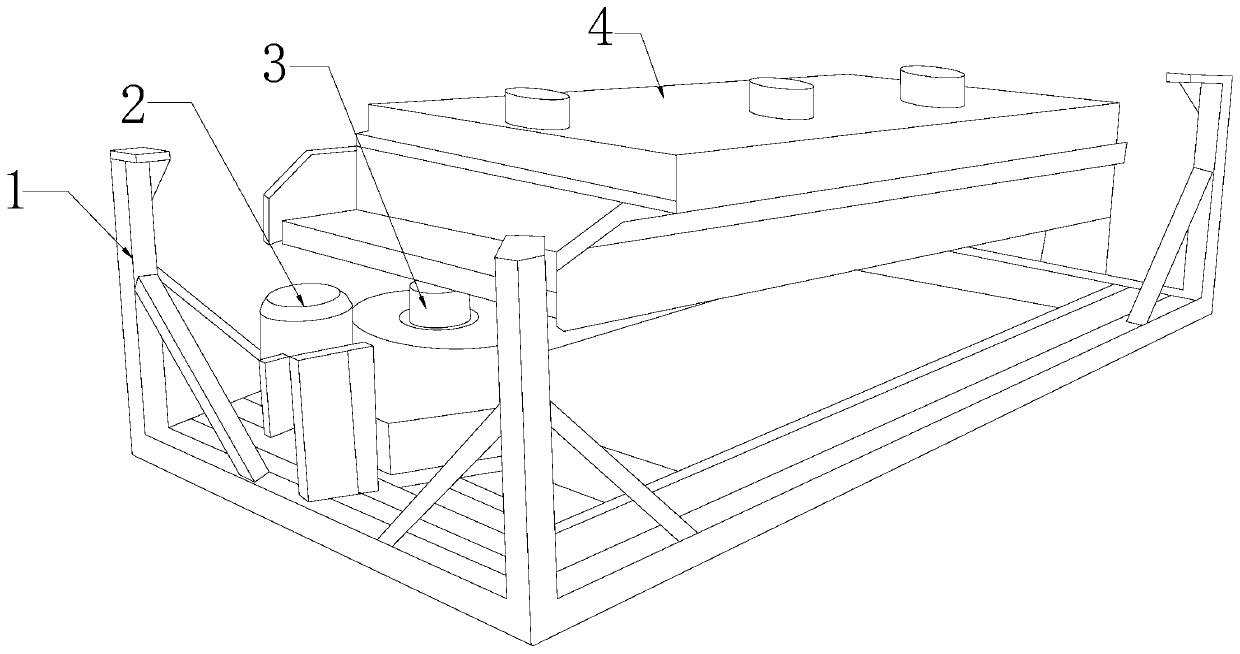

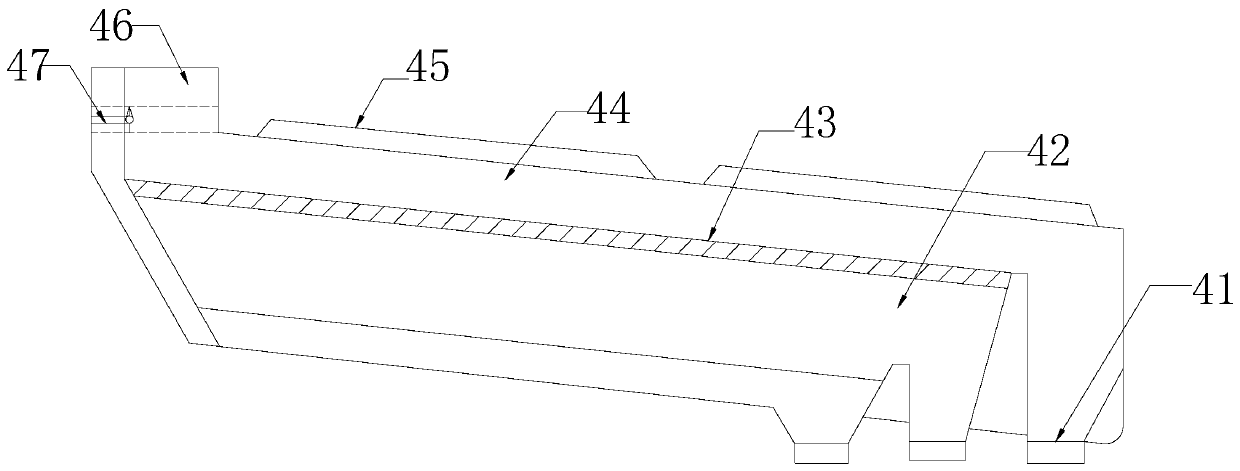

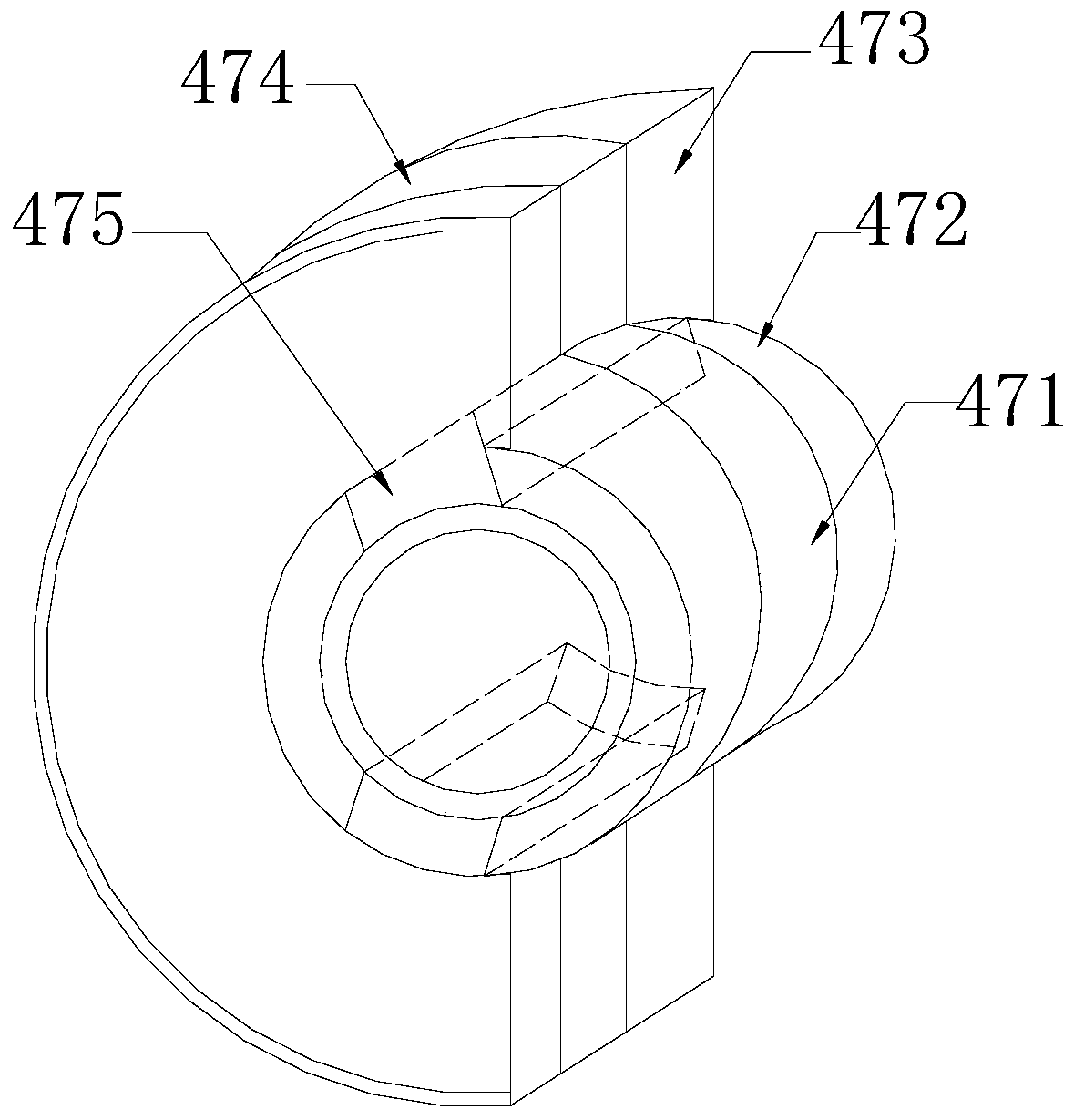

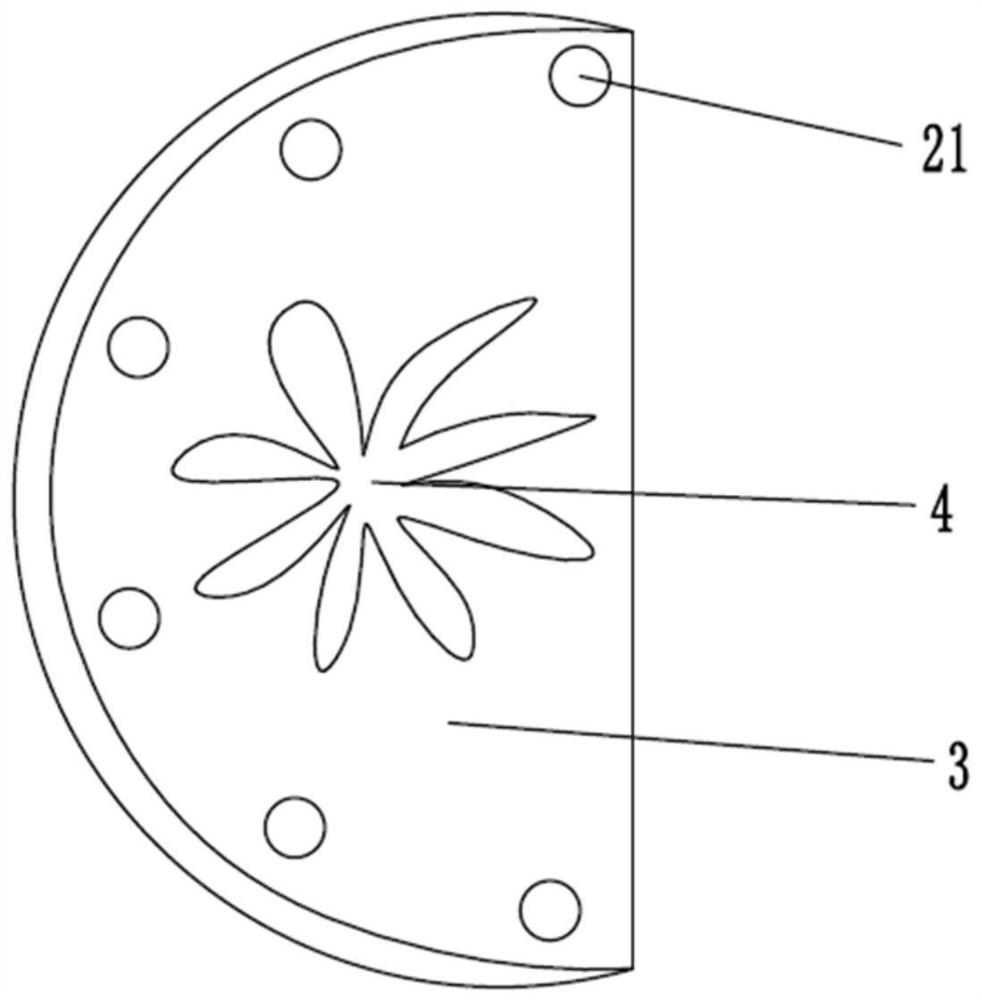

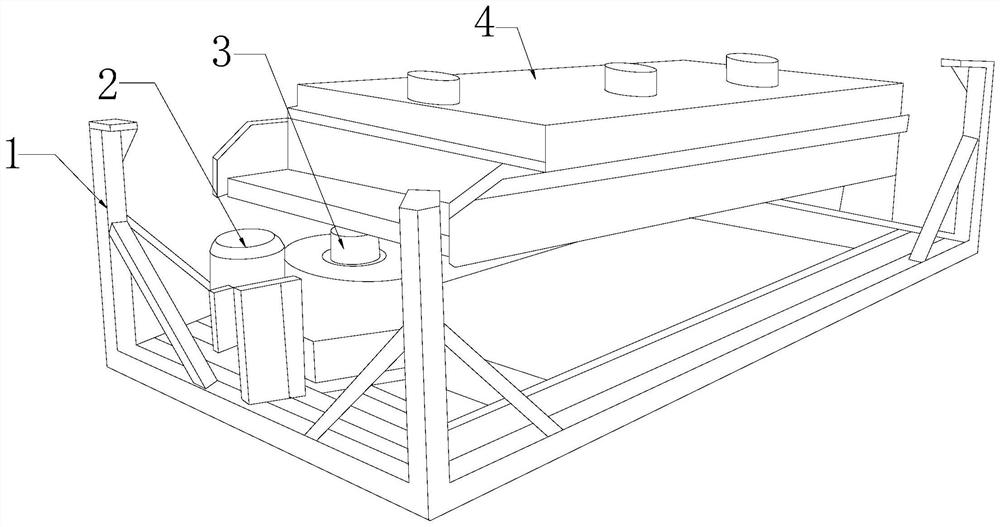

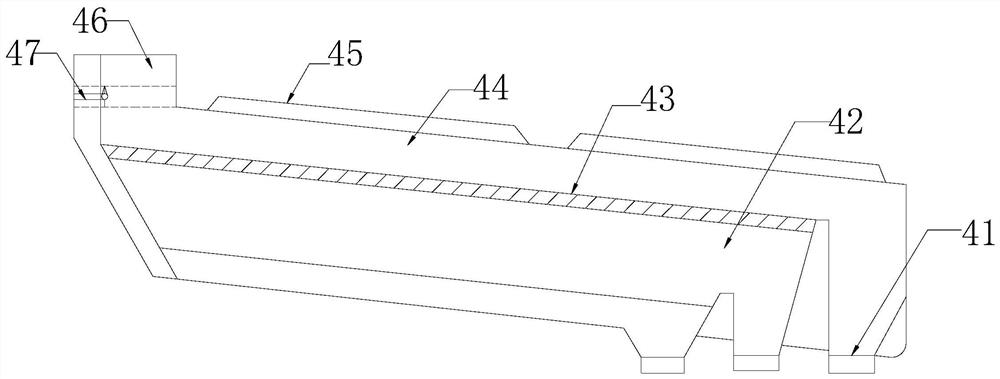

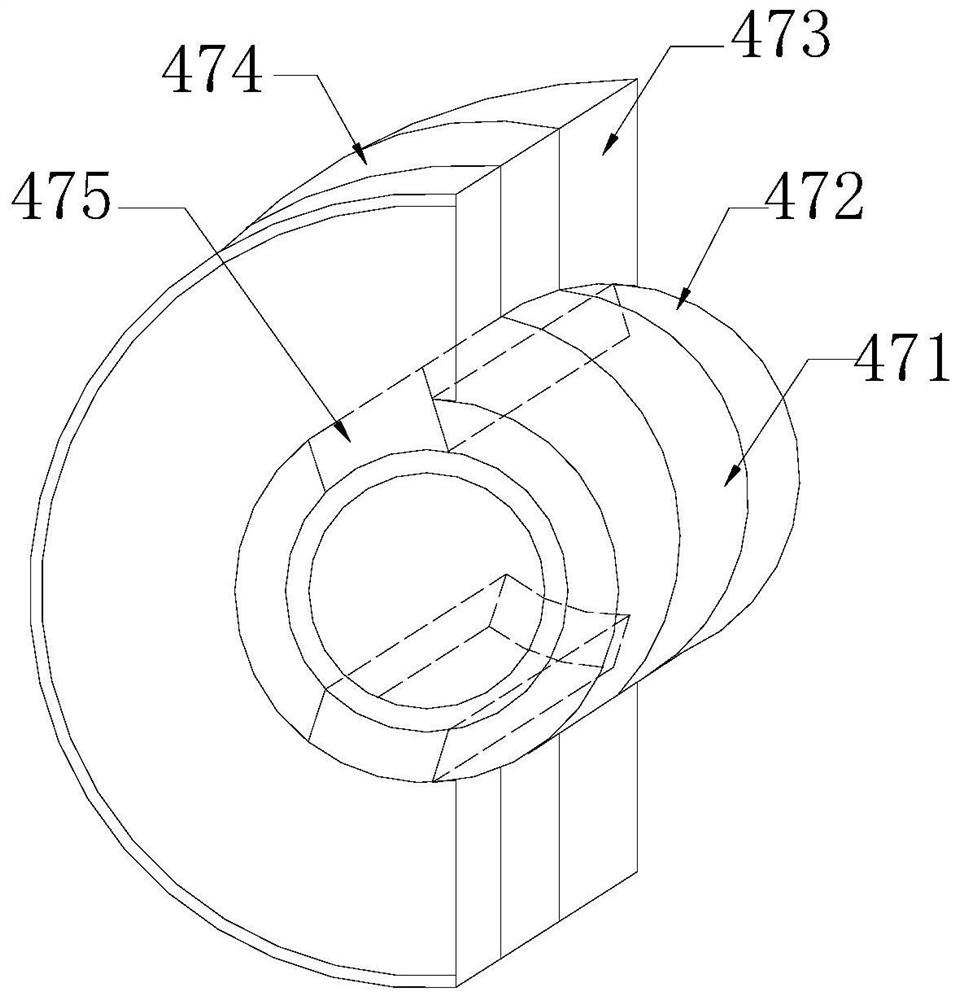

Refined screening machine for metallurgical machining non-ferrous metals

ActiveCN111589693AReduce strong impactGuaranteed Steering EffectivenessSievingScreeningNonferrous metalEngineering

The invention discloses a refined screening machine for metallurgical machining non-ferrous metals. The refined screening machine structurally includes a supporting frame, a driving device, a transmission device and a screen box. The supporting frame is equipped with the driving device and the transmission device, and the driving device and the transmission device are matched in the screen box ina transmission mode. The screen box is internally provided with discharge ports, a first material distribution groove, a screening plate, a second material distribution groove, a shell, a feed port, and a buffer mechanism. The feed port is internally provided with a buffer mechanism, and a screen plate is horizontally installed between the first material distribution groove and the second materialdistribution groove, the transmission end of the screen plate is electrically connected to the driving device, and the discharge ports are fixed to the first material distribution groove and the second material distribution groove correspondingly. According to the buffer mechanism, when a material is fed at the feed port, through a method that the circular high-speed turning movement formed by aturntable matched by a supporting shaft is in contact matching with a material, the turntable cuts into the material continuously, the problem of strong impact force due to the excessive concentrationon the screening plate during feeding is further solved, and a spring is arranged in the supporting shaft to cooperate with the turntable so as to buffer the turntable.

Owner:娄底市涟钢振兴冶金材料有限公司

Skid resistance supporting straining protection method for passing through topsoil of landslide area of oil and gas conveying pipeline

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

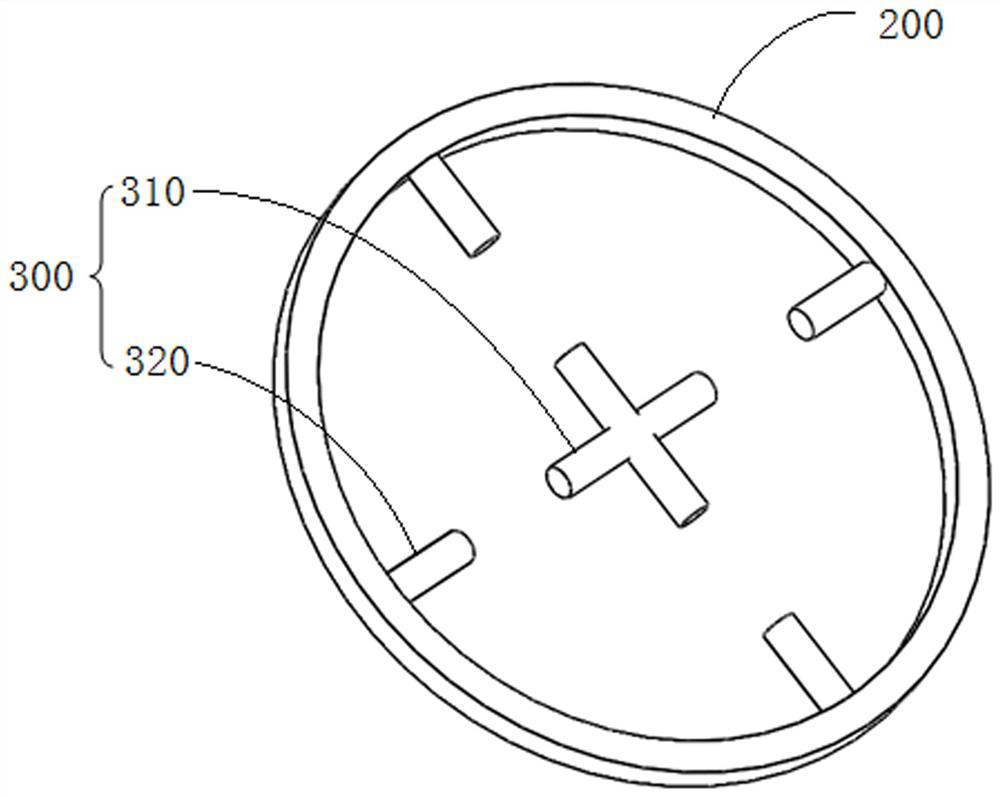

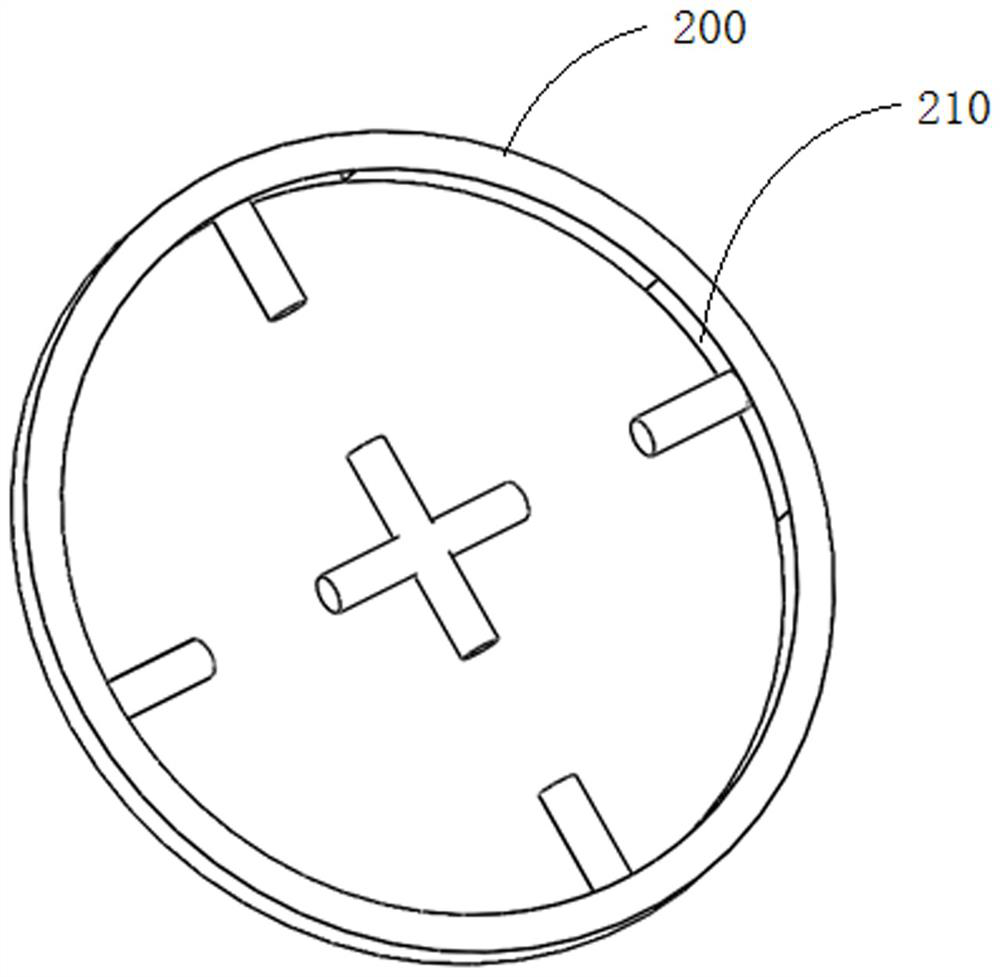

Ring elastic buffer piece

ActiveCN111911590AExtended service lifeImprove structural simplicityNon-rotating vibration suppressionMachine partsEngineering

The invention discloses a ring elastic buffer piece. The ring elastic buffer piece comprises an elastic ring, and a plurality of connecting rods and a plurality of elastic elements are arranged in theelastic ring; the ends of the connecting rods are connected with the side wall of the elastic ring, and each connecting rod comprises a first rod body and a second rod body which are spaced by a certain distance; the elastic elements are arranged between the first rod bodies and the second rod bodies, and each elastic element comprises a first shell, a first spring body, a second shell, a secondspring body, a first abutting piece and a second abutting piece, wherein the first shell, the first spring body, the second shell and the second spring body are sequentially connected in a sleeved mode from outside to inside, and each first abutting piece and each second abutting piece are fixedly connected with each first rod body and each second shell respectively; the axes of the first rod bodies, the second rod bodies and the elastic elements coincide. The ring elastic buffer piece is suitable for the joints of various machine parts, mechanisms and equipment, the strong impact of externalloads on the elastic ring is weakened, the accurate and multi-directional differential buffer protection effect on the whole interior of a machine can be achieved, the service life of the machine is prolonged, and the stability and accuracy of operation and use are improved.

Owner:重庆翔越机械有限公司

An unloading buffer hydraulic system

ActiveCN109058187BAvoid breakingImprove securityServomotor componentsServomotorsEngineeringWater hammer

The invention relates to the technical field of hydraulic control, in particular to an unloading buffer hydraulic system. The system comprises a first pump body, a first reversing valve, a second reversing valve, a pushing plate oil cylinder and a first pump body low-pressure overflow valve; the first pump body is in communication with a hydraulic oil tank and the second reversing valve through amain pressure oil way, two oil outlets of the second reversing valve are connected to a rod cavity and a rodless cavity of the pushing plate oil cylinder respectively, and an oil return port of the second reversing valve is in communication with the hydraulic oil tank through an oil return pipeline; the first reversing valve is arranged between the first pump body and the second reversing valve, one end of the first pump body low-pressure overflow valve is connected to a pipeline between the first pump body and the first reversing valve, and the other end of the first pump body low-pressure overflow valve is in communication with the oil return pipeline; and before the second reversing valve carries out the reversing operation, the high-pressure oil unloading is carried out by the pushingplate oil cylinder. According to the unloading buffer hydraulic system of a rubbish compression box, unloading buffer of the pushing plate oil cylinder can be well achieved, the strong impact problemof a water hammer phenomenon is effectively solved, and the safety of an oil supply pipeline of the pushing plate oil cylinder is greatly improved.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

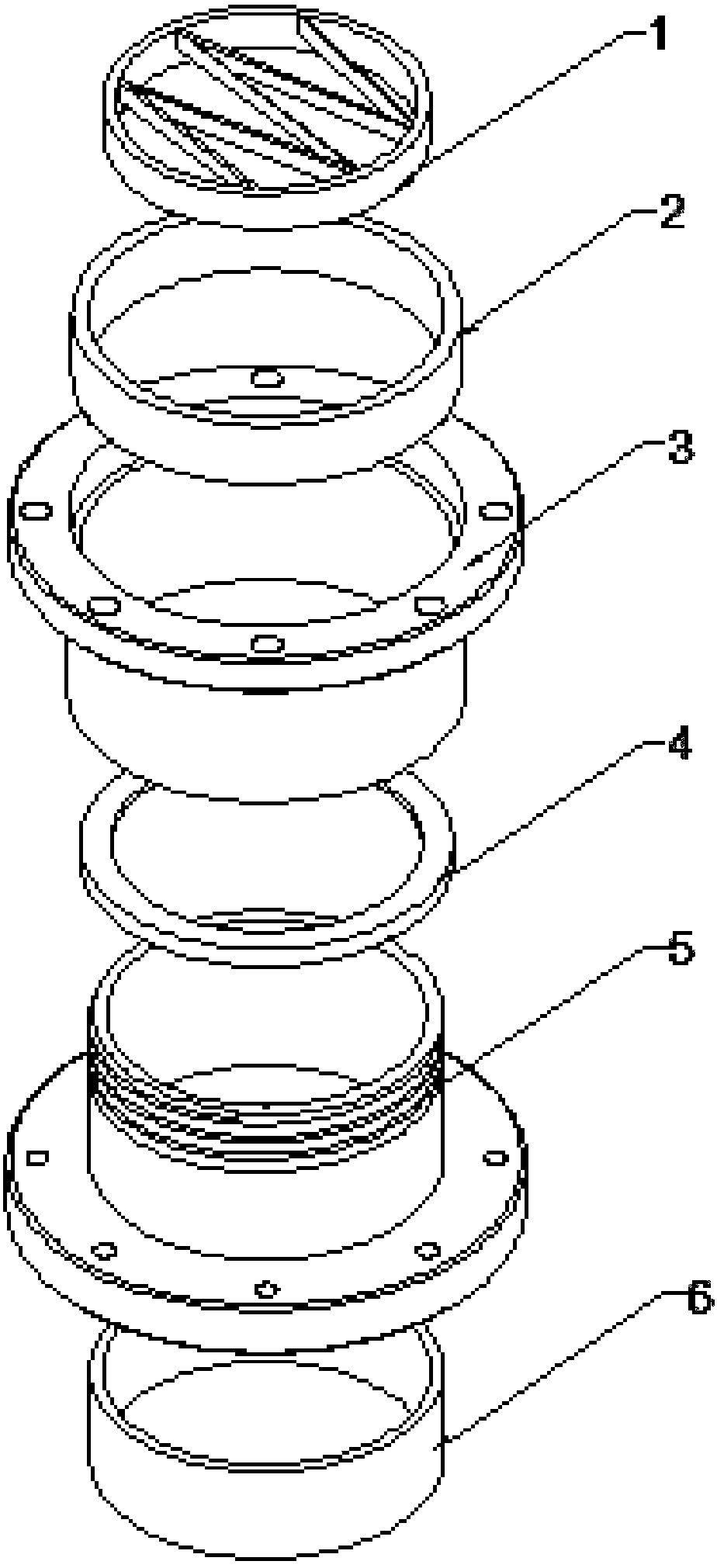

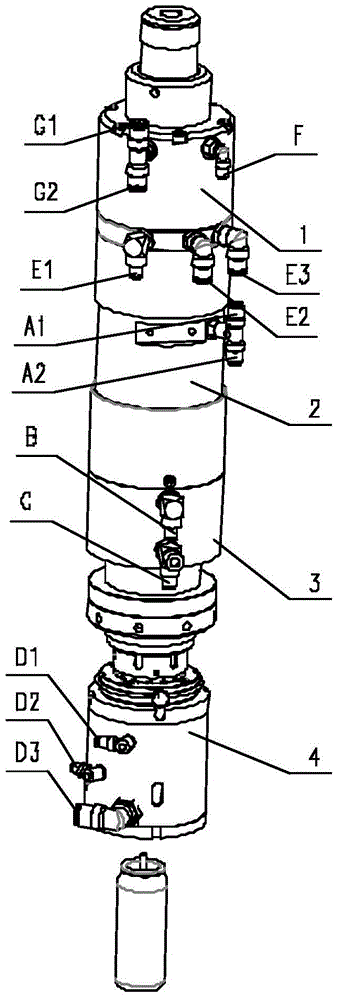

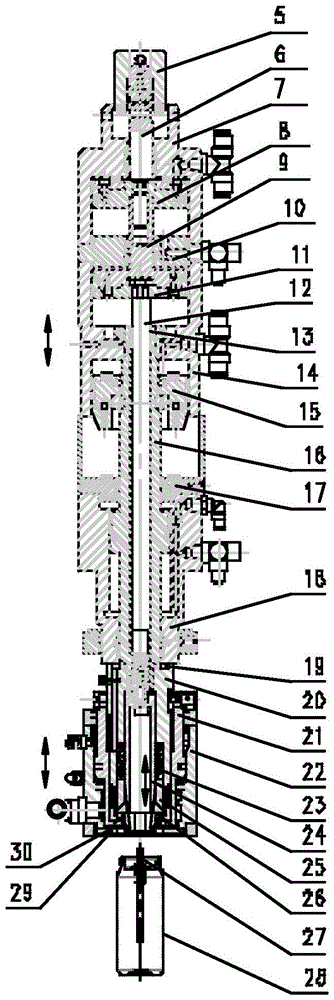

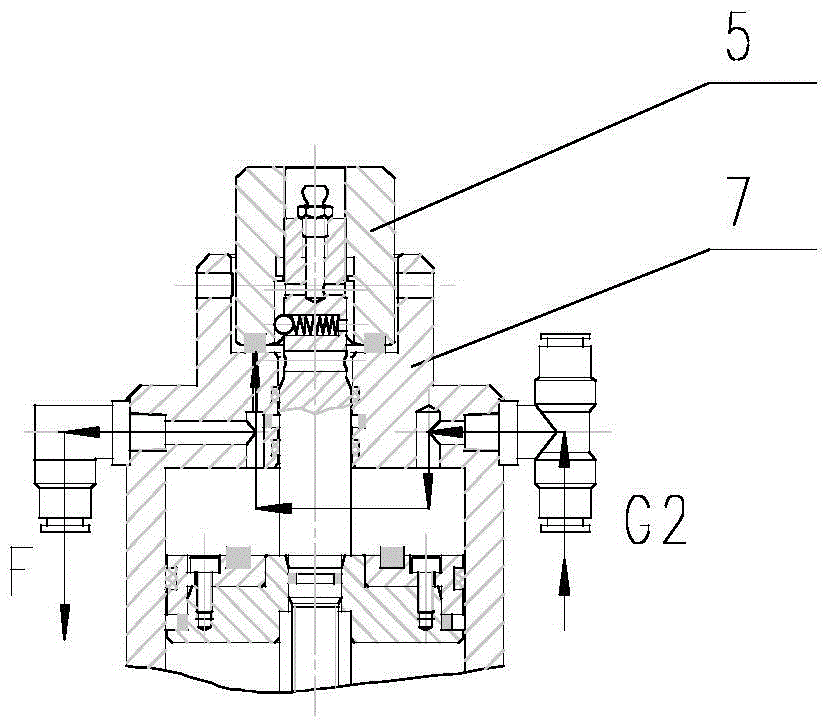

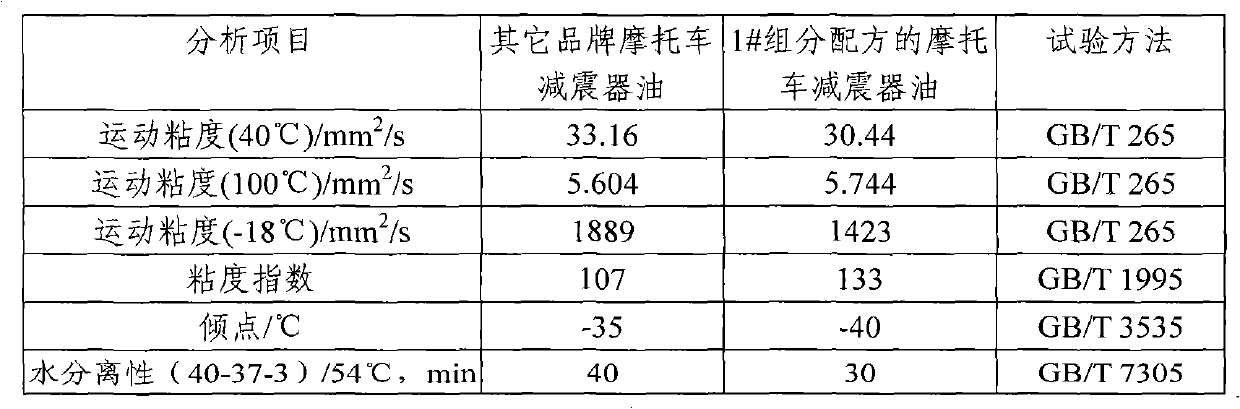

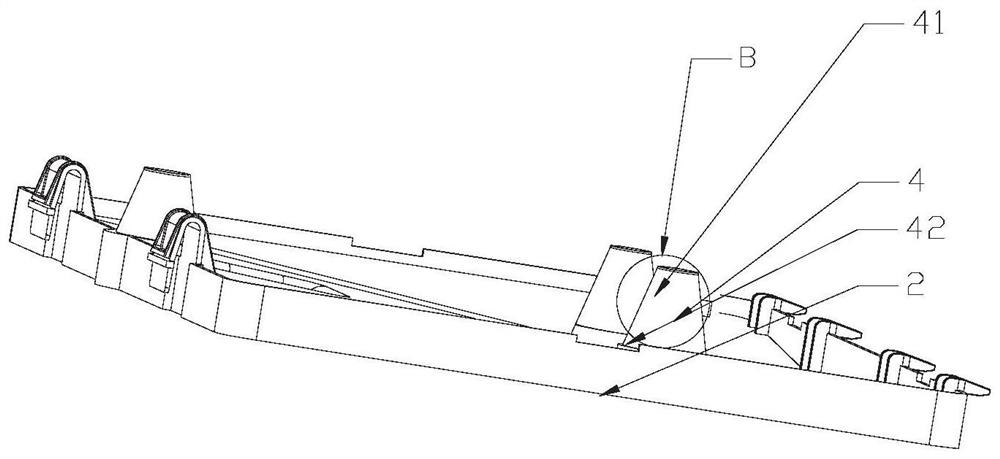

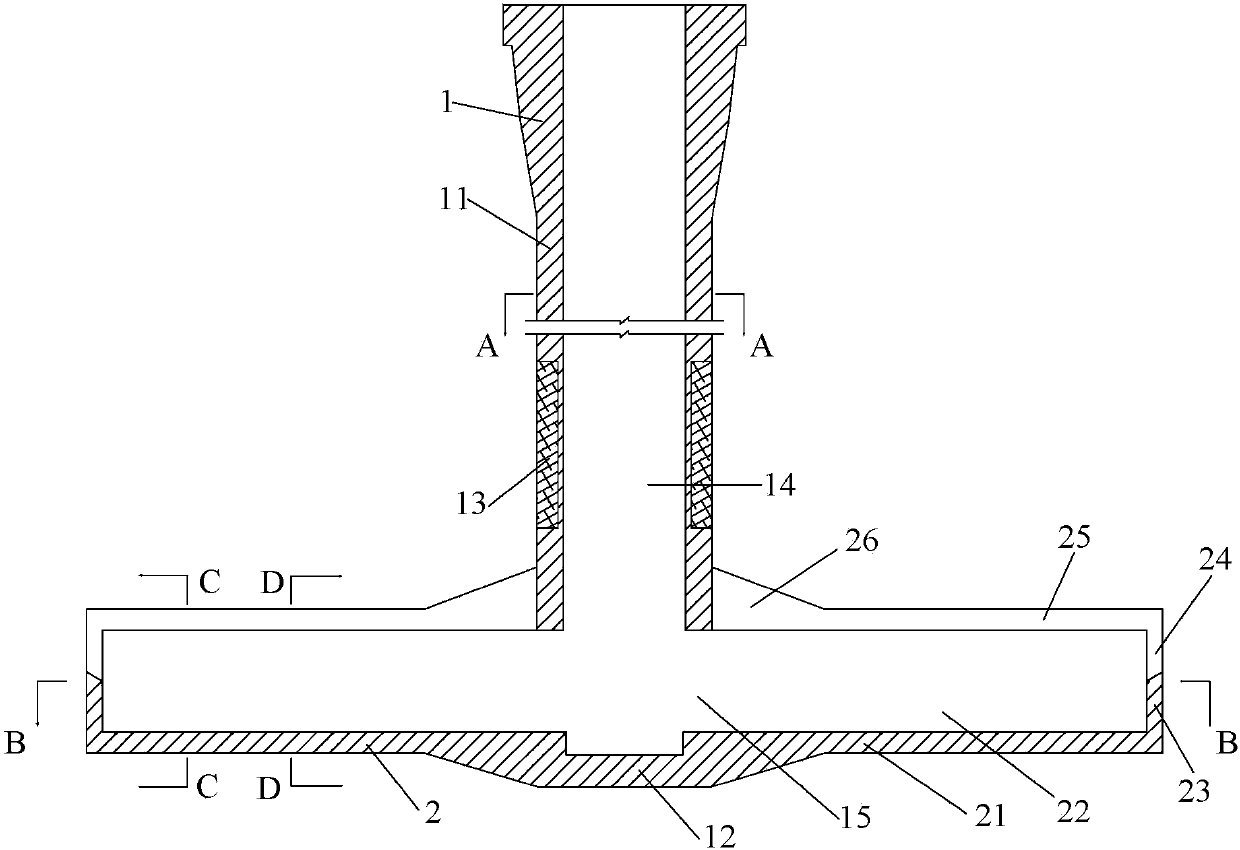

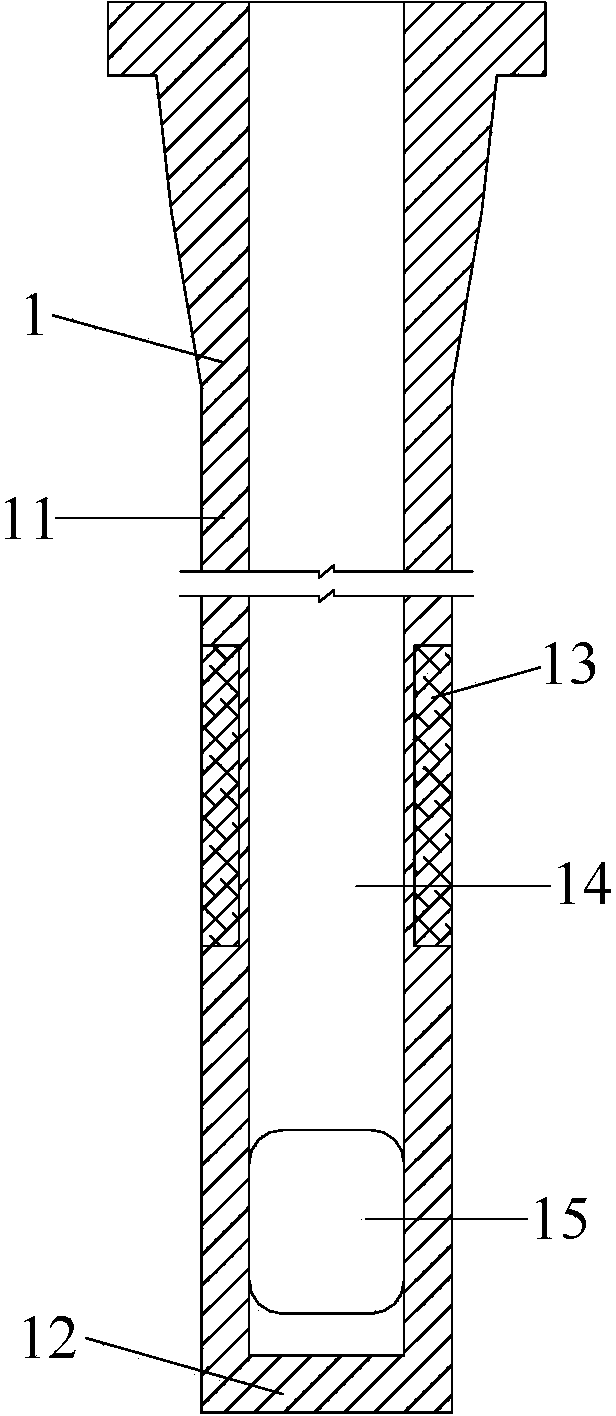

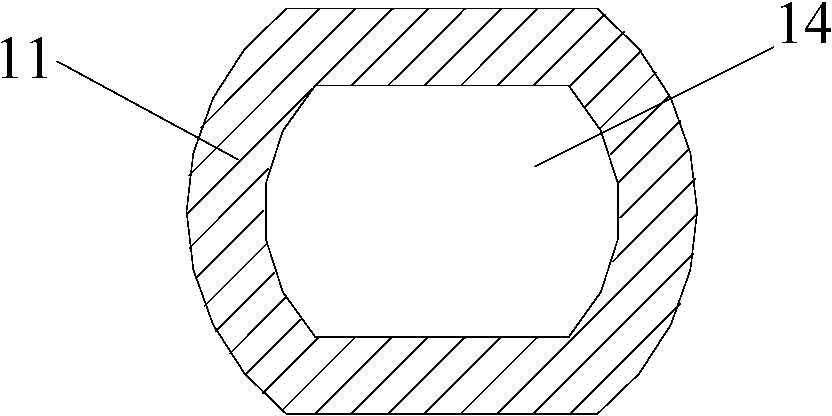

A pneumatic filling head applied to the sealing of aerosol valves

ActiveCN104773690BAchieve airtightReduce strong impactBottle-handling machinesLiquid bottlingAerosol sprayEngineering

The invention discloses a pneumatic encapsulating head applied for enclosing an aerosol valve. The encapsulating head is characterized in that a sealing cylinder (1), a buffer cylinder (2), a positioning pressure cylinder (3), and a vacuumizing cylinder (4) are arranged in the encapsulating head from top to bottom. A pushing pawl mechanism is arranged in the lower part of the vacuumizing cylinder (4). The air pressures in four cylinders in the encapsulating head are controlled by an air control valve so as to make the cylinders operate in steps to finish a complete circle including gas buffering, downward positioning, slow pressurizing, vacummizing to eliminate foams in a stock solution, opening sealing, and encapsulating head resetting, so as to seal the top valve and internal wall of an aerosol tank. The sealing effect is good, the operation speed is quick, and the requirements of high speed and high efficient aerosol production can be fulfilled by the provided pneumatic encapsulating head.

Owner:YUNNAN BAIYAO GROUP

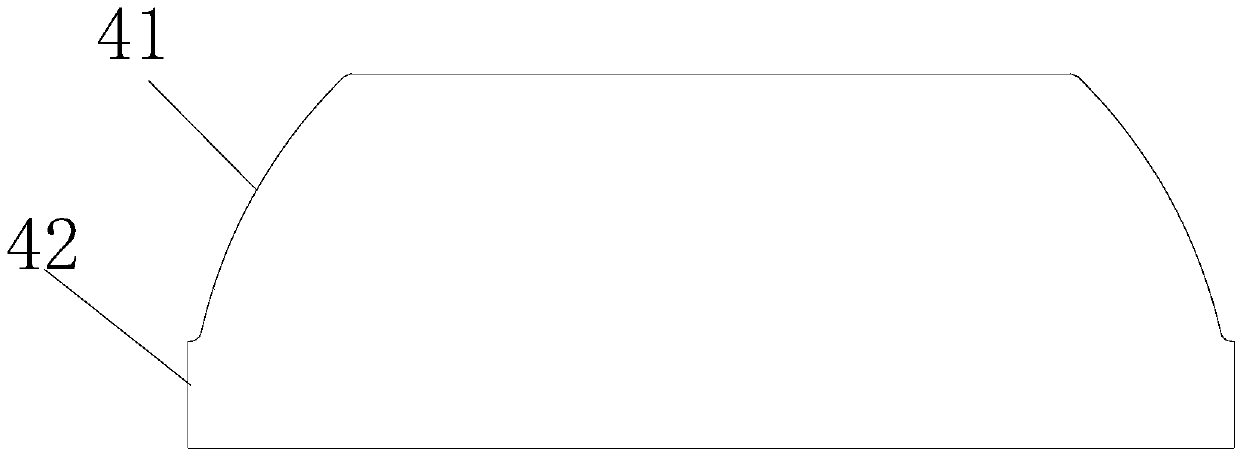

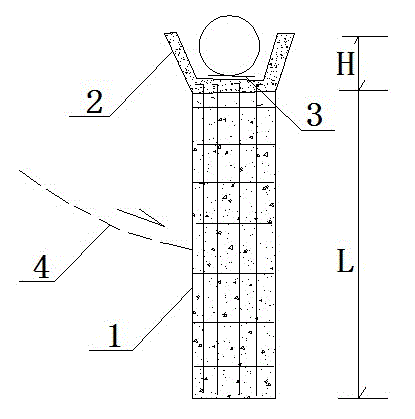

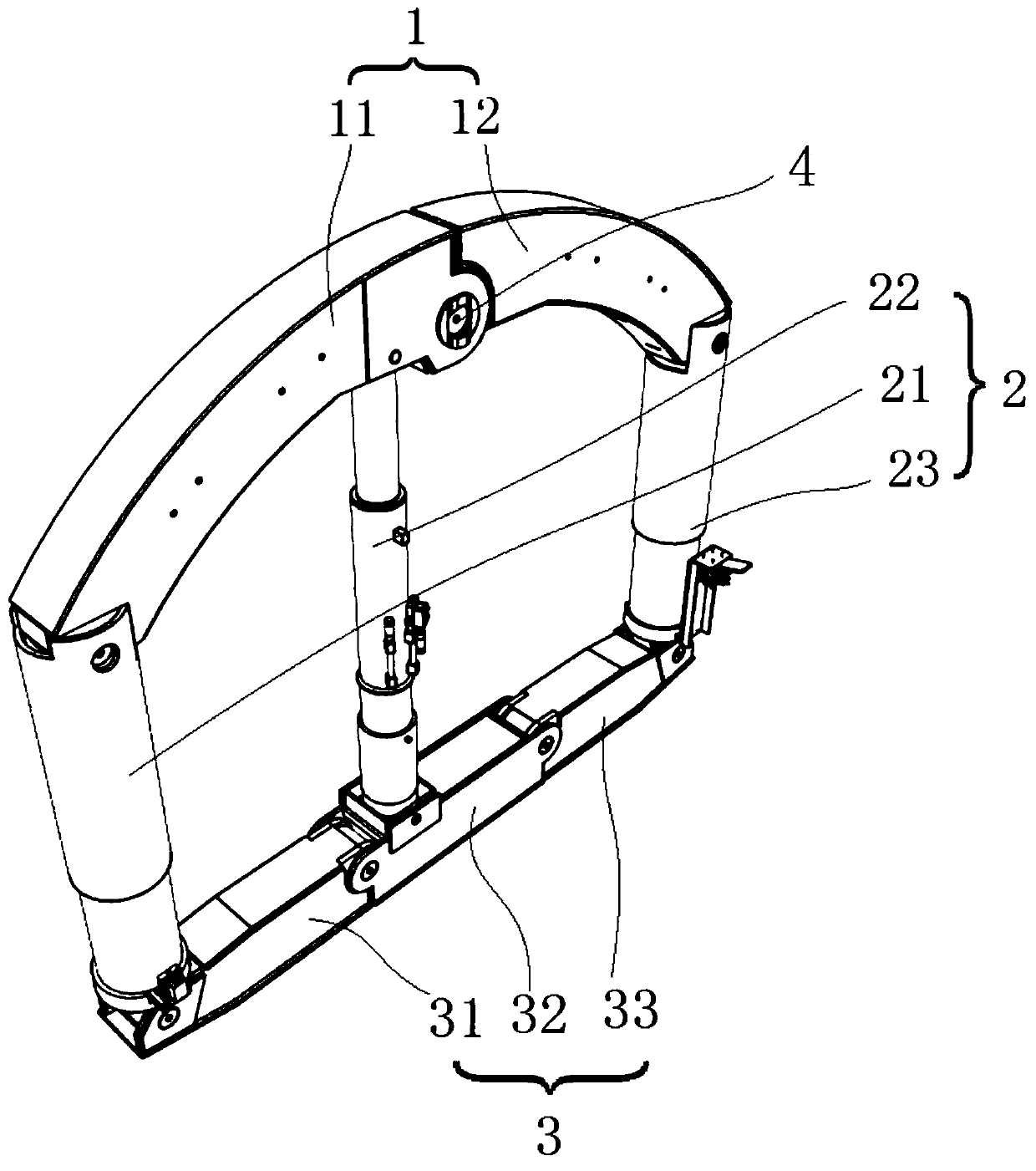

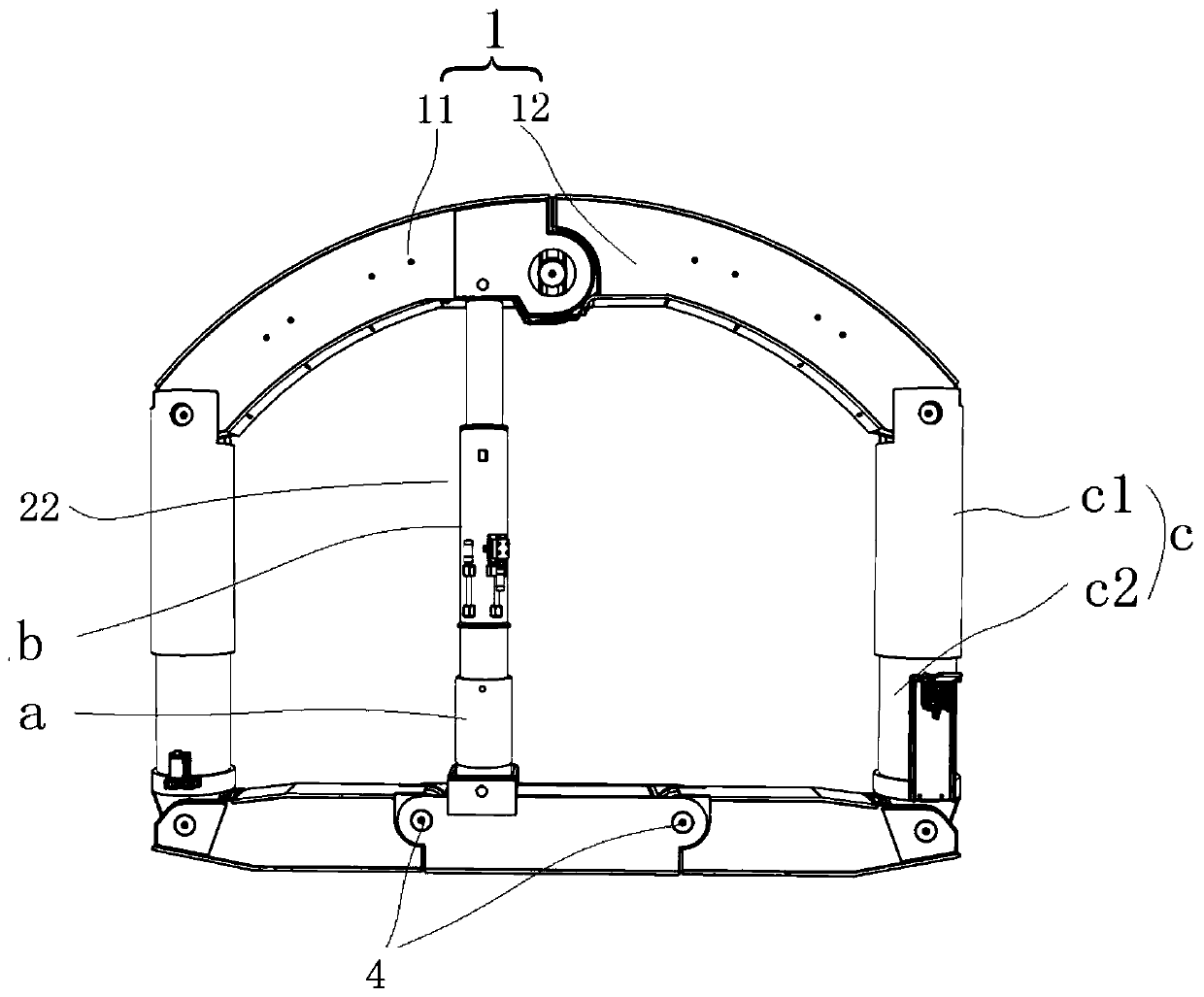

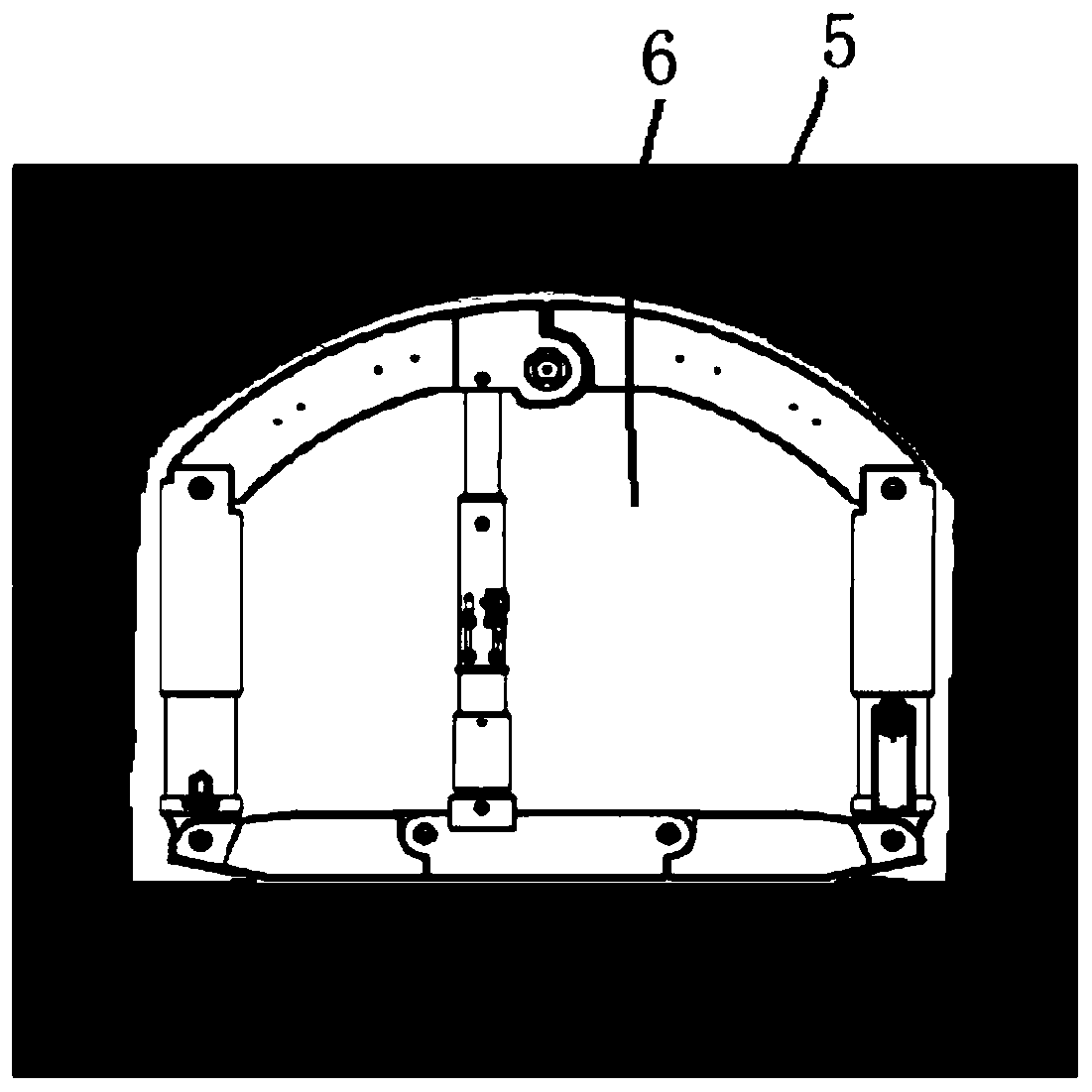

Sleeve connection rod type anti-impact bracket

PendingCN110130955AImprove structural strengthUniform supportMine roof capsProps/chocksEngineeringStructural engineering

The invention discloses a sleeve connection rod type anti-impact bracket. The sleeve connection rod type anti-impact bracket comprises a top beam, a plurality of supporting columns and a bottom beam,two ends of the supporting columns are separately hinged to the top beam and the bottom beam, the top beam is in an arc shape, the supporting columns hinged to the lower part of the top beam are arranged on the top beam in the length direction of the top beam, the supporting columns are of telescopic structures, and the top beam is driven by the supporting columns to enable the top beam move in the limited telescopic direction of the supporting columns. According to the sleeve connection rod type anti-impact bracket, the top beam is arranged as an arc-shaped structure and can better adapt to the sectional shape of an arch roadway, the top beam is supported by depending on the supporting columns with the telescopic structures below the top beam, so that supporting force of the bracket is more balance. Meanwhile, the top beam with the arc structure has good structural strength, optimal structural design of a beam body is facilitated, and the material utilization rate is improved.

Owner:BEIJING CHENGTIAN HENGYE COAL MINE EQUIP CO LTD +2

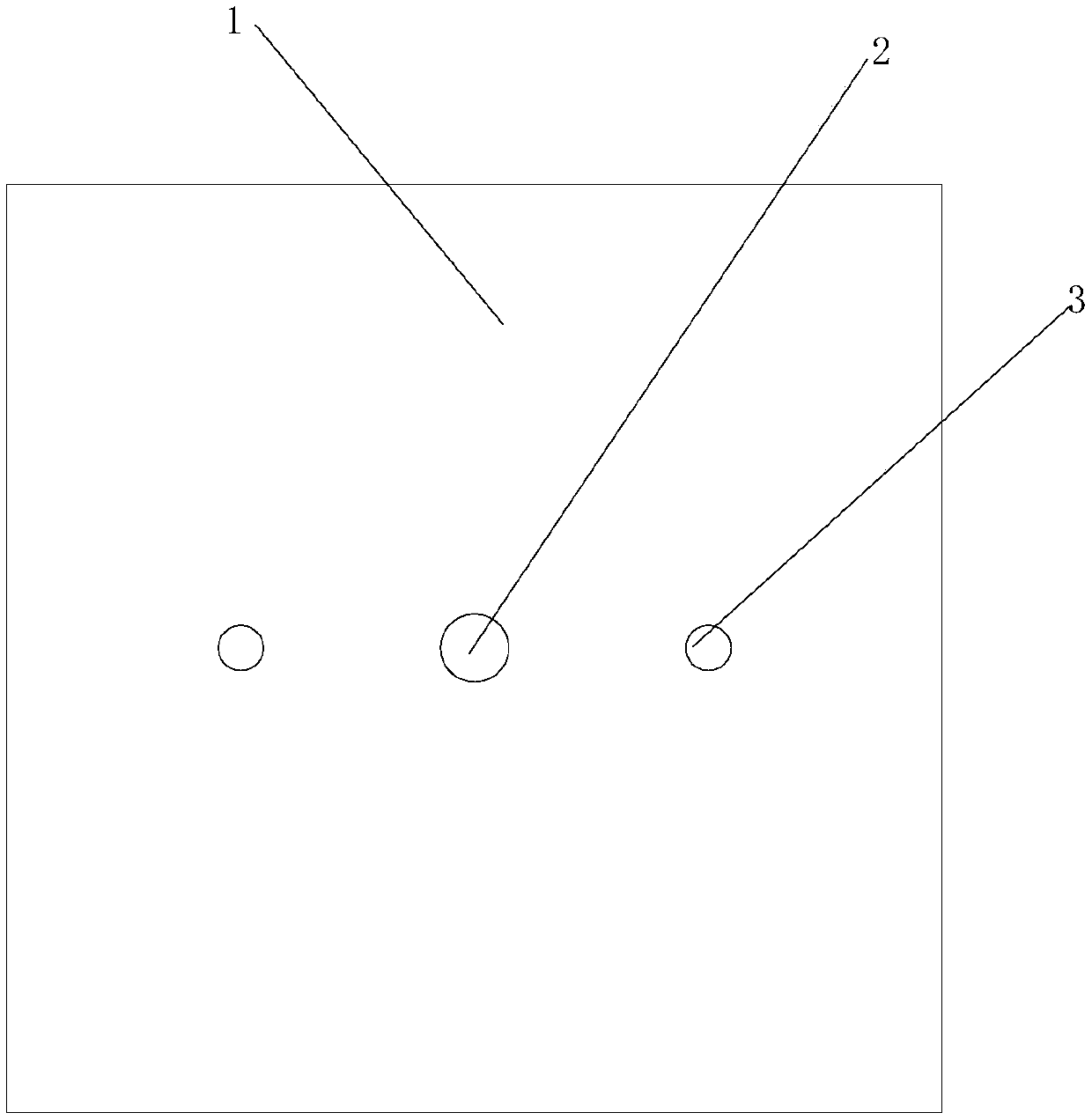

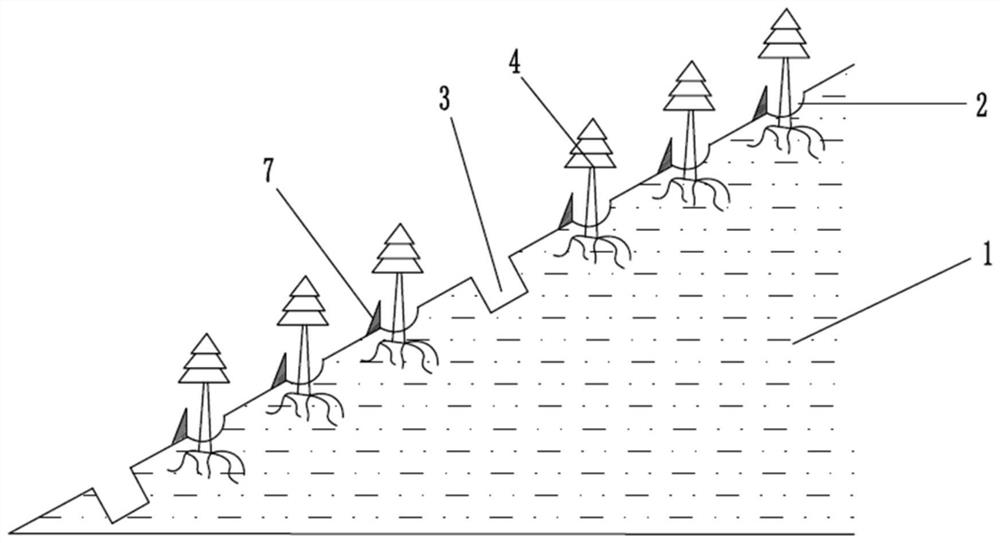

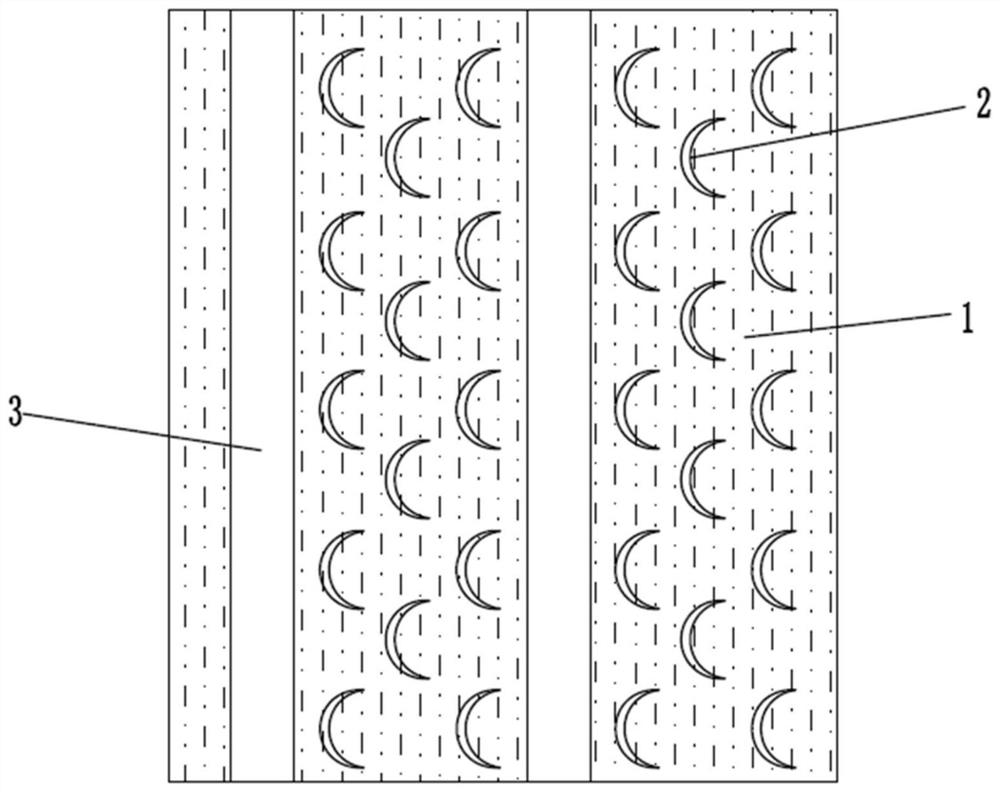

A comprehensive runoff storage system of fish scale pit and intercepting ditch and its construction method

ActiveCN111236275BThe effect of blocking is goodReduce washoutSewerage structuresExcavationsCapillary TubingRainwater harvesting

The invention discloses a fish scale pit and intercepting ditch comprehensive runoff storage system and a construction method thereof. A fish scale pit is arranged on a mountain body along a contour line or close to the contour line, and an intercepting ditch is arranged below the fish scale pit. Plants are planted in the fish scale pit, and the fish scale pit collects rainwater into the underground sump through the water collection pipe, and the capillary is also provided in the sump, and the top of the capillary is in contact with the root system of the plant; The sump is connected through a drainage pipe, and the bottom of the drainage pipe is directly connected with the intercepting ditch; the end of the intercepting ditch close to the natural channel is provided with a flood outlet, and the flood outlet is provided with a water retaining valve that can be opened and closed automatically. plate. When it rains, the rainwater is collected into the sump through the water collection pipe and used to water the plants through the capillary; when the water level in the sump reaches a certain height, it is discharged into the intercepting ditch through the drain pipe, and when the water level in the intercepting ditch exceeds the safe height, The water baffle is automatically opened to drain water and prevent floods from happening.

Owner:黄河水利科学研究院引黄灌溉工程技术研究中心

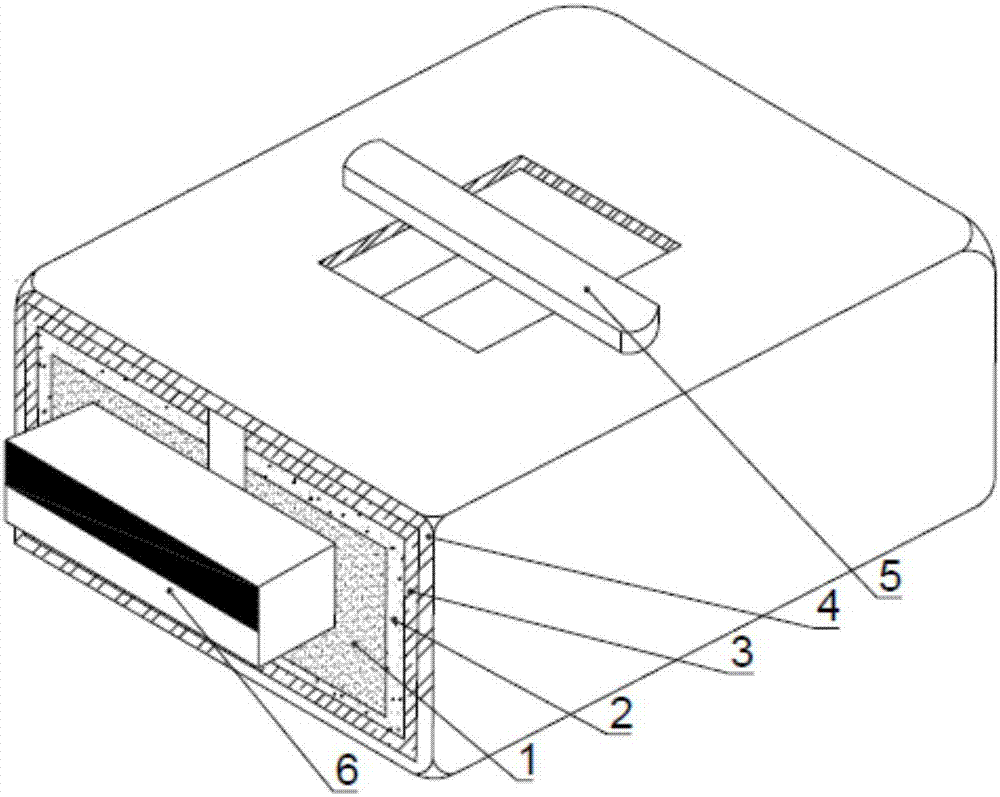

Anti-falling mobile memory

InactiveCN107886977AIncrease elasticityHigh strengthCarrier constructional parts dispositionUndesired vibrations/sounds insulation/absorptionFiberEngineering

The invention discloses an anti-falling mobile memory, which comprises a shell and an internal circuit. The internal circuit is arranged in the shell. A carbon fiber layer, a polyethylene fiber layerand a sponge layer are sequentially arranged in the shell from outside to inside. A spring is arranged in the sponge layer. The internal circuit is adhered to the sponge layer so as to prevent the mobile memory from being damaged during the easy-to-use process. A soft and elastic suction layer is additionally arranged between the shell and the internal circuit. A sufficient moving and staggered space is reserved between the shell and the internal circuit. Even if the shell falls down to be deflected, the soft and elastic suction layer arranged between the shell and the internal circuit is deformed to absorb most of the collision energy. Therefore, impact on the internal circuit is reduced. The internal circuit is prevented from being damaged due to strong impact.

Owner:ZHENGZHOU JINHENG ELECTRONICS TECH CO LTD

Pneumatic encapsulating head applied for enclosing aerosol valve

ActiveCN104773690AReduce strong impactGuaranteed concentricityBottle-handling machinesLiquid bottlingEngineeringControl valves

The invention discloses a pneumatic encapsulating head applied for enclosing an aerosol valve. The encapsulating head is characterized in that a sealing cylinder (1), a buffer cylinder (2), a positioning pressure cylinder (3), and a vacuumizing cylinder (4) are arranged in the encapsulating head from top to bottom. A pushing pawl mechanism is arranged in the lower part of the vacuumizing cylinder (4). The air pressures in four cylinders in the encapsulating head are controlled by an air control valve so as to make the cylinders operate in steps to finish a complete circle including gas buffering, downward positioning, slow pressurizing, vacummizing to eliminate foams in a stock solution, opening sealing, and encapsulating head resetting, so as to seal the top valve and internal wall of an aerosol tank. The sealing effect is good, the operation speed is quick, and the requirements of high speed and high efficient aerosol production can be fulfilled by the provided pneumatic encapsulating head.

Owner:YUNNAN BAIYAO GROUP

Lubricating oil composition for motorcycle shock absorber

ActiveCN102533409BSmall inertia forceImprove steering braking functionAdditivesDemulsifierChemical composition

Owner:CHINA PETROLEUM & CHEM CORP

Special feeding groove for wet coal spiral screening machine

The invention discloses a special feeding groove for a wet coal spiral screening machine. The special feeding groove for the wet coal spiral screening machine comprises a feeding groove body; the feeding groove body consists of a vertical through groove way and an inclined groove way; the vertical through groove way is vertically arranged; the inclined groove way is aslant downwards guided below the vertical through groove way; an internal feed hopper is mounted at an opening end of the upper end of the vertical through groove way; electric heating plates are paved on a back end channel of thevertical through groove way and a lower end channel of the inclined groove way; a coal dust content detector is mounted on the inner wall of a front end channel of the vertical through groove way; analarm device is arranged at the external of the feeding groove body; and the coal dust content detector is in wireless induction connection with the alarm device. Through the mode, the feeding groovecan be special used for the screening work of wet coals; rising moisture can be heated by the electric heating plates to improve the coal quality; the internal feed hopper can prevent coal dust fromflying for discharge; and the coal dust content detector can detect signals of bad coal dust to transfer to the alarm device for alarming.

Owner:WUXI YUNENG COAL DRESSING MACHINERY PLANT

A roller-type multi-stage damping reed pipe UAV anti-drop device

The invention discloses a roller type multistage damping reed pipe anti-falling device for an unmanned aerial vehicle. A three-level damping reed pipe telescopic structure is adopted, damping reed pipes are in a thin-shell cylinder shape, and magnetic rods and springs are installed in the damping reed pipes. The two damping reed pipes have unequal lengths, and the length of the short reed pipe is one-third that of the long reed pipe. The long reed pipe and the short reed pipe are connected to a hinge support of a fuselage base plate, and the tail end of the short reed pipe is connected to the side wall of a first stage of the long reed pipe. A universal wheel support is connected with the long reed pipe, a rubber wheel is installed below the support, and a pressure ball bearing rotates to achieve 360-degree rotation of the rubber wheel. When the rotor unmanned aerial vehicle lands, the anti-falling device delays ground contact time by compressing the springs to reduce impact force and converts kinetic energy into elastic potential energy, magnetic damping can alleviate vibration, and energy is dissipated. The universal wheel support is matched with the rubber wheel to prevent rollover caused by a horizontal speed, and the goal of protecting the unmanned aerial vehicle is achieved. The anti-falling device can also serve as an undercarriage to make the unmanned aerial vehicle capable of landing directly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

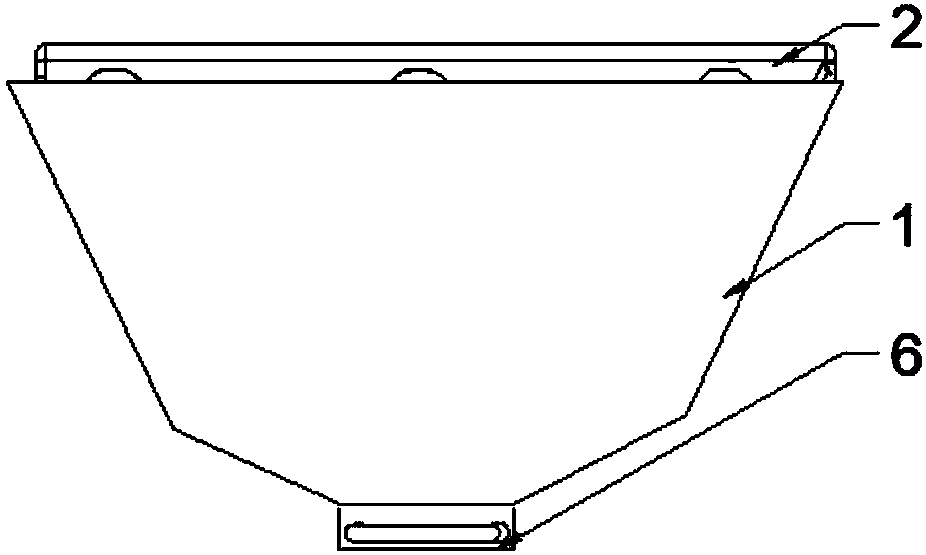

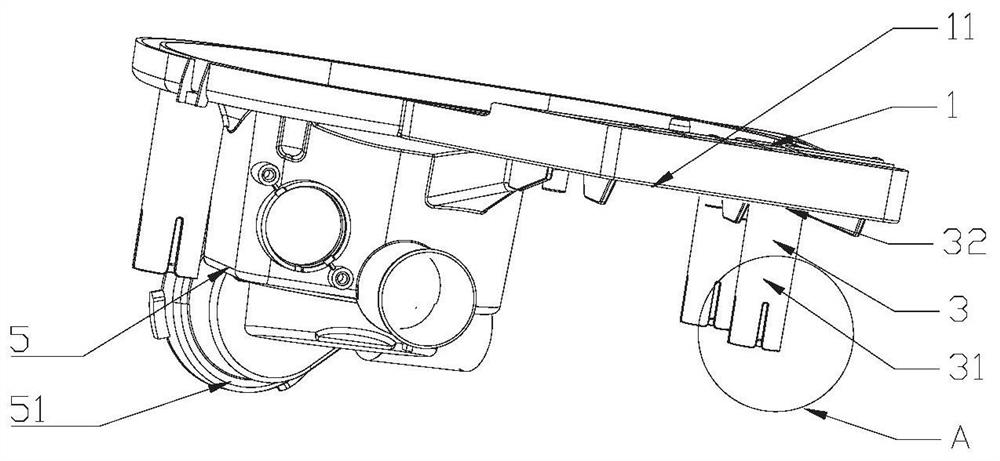

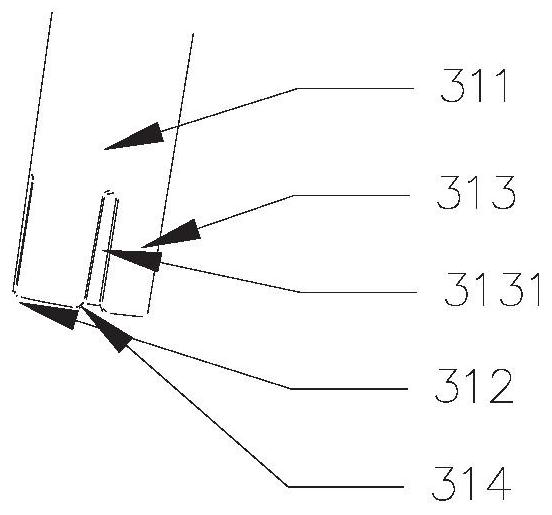

Dish washing machine

PendingCN112568849AAvoid impact damageReduce strong impactTableware washing/rinsing machine detailsProcess engineeringEnvironmental geology

The invention discloses a dish washing machine which comprises a water tank and a base, a supporting structure capable of being supported on the base is arranged at the bottom of the water tank, and / or a supporting structure capable of supporting the bottom of the water tank is arranged on the base. The supporting structure is arranged at the bottom of the water tank and / or on the base, when the water tank structure moves downwards, the water tank and the base are separated through the supporting structure, the base of the dish-washing machine is prevented from being broken by the downwards-moving water tank and components of the water tank, and meanwhile a washing pump or other components at the bottom of the water tank are prevented from being damaged by collision. The supporting structure on the base is used in cooperation with the supporting structure on the water tank, when the water tank structure moves downwards, the supporting structure on the water tank abuts against the supporting structure on the base in a matched mode, the larger the downward moving distance is, the larger the resistance borne by the water tank and the supporting structure on the base is, and the stronger the impact force borne by the supporting structure is weakened through the gradually-changed resistance. Therefore, the supporting effect is better, and the protection effect of the supporting structure on the water tank and the base is further improved.

Owner:QINGDAO HAIER DISHWASHER +1

Slab continuous casting submersed nozzle

ActiveCN102794445BOutflow smoothlyGuaranteed temperature uniformityMelt-holding vesselsNon-metallic inclusionsEngineering

The invention relates to a slab continuous casting submersed nozzle. The slab continuous casting submersed nozzle consists of a vertical section and a horizontal section; a pair of side holes are formed in the side wall close to the upper side of the bottom of the slab continuous casting submersed nozzle; two side holes are communicated with a hollow inner cavity; the wall surfaces around the side holes extend in the horizontal direction to form the horizontal section; the wall surface of the horizontal section forms a tubular pipeline the shape of which is identical to that of the side holes in an encircling manner; one end of the tubular channel is connected with the side holes; the other end of the tubular channel forms the semi-sealed surface; and an elongated opening identical to the length of the horizontal section is formed in the wall surface of the upper end of the tubular channel. According to the technical scheme, a steel liquid flowing channel is enlarged, and the steel liquid can be fully diffused to the cross section of the whole crystallizer, so that the transverse temperature of the crystallizer and the uniformity of components are guaranteed to ensure that the heat center of high-temperature steel liquid subjected to pouring is moved upwards; a reasonable temperature trapezoid is guaranteed; the normal growth of casting blank is facilitated; flotation removal of nonmetallic inclusion and bubbles is facilitated; the remelting and the destroy of a blank shell is avoided; the disturbance of the steel liquid on the liquid level of the crystallizer is reduced; the smoothness of continuous casting process is facilitated; and the quality of the casting blank is improved.

Owner:启东市长江船舶工业投资发展有限公司

A refining screening machine for metallurgical machining of non-ferrous metals

ActiveCN111589693BReduce strong impactGuaranteed Steering EffectivenessSievingScreeningNonferrous metalEngineering

The invention discloses a refined screening machine for metallurgical machining of non-ferrous metals. Its structure includes a support frame, a driver, a driver, and a screen box. The driver and the driver are installed on the support frame, and the driver and the driver are driven and matched with the screen box. The inside of the screen box is equipped with a discharge port, a first distribution chute, a screening plate, a second distribution chute, a shell, a feed port, and a buffer mechanism. The inside of the feed port is provided with a buffer mechanism. A screening plate is installed horizontally between the second material distribution trough, and the transmission end of the screening plate is electrically connected to the actuator. The first material distribution chute and the second material distribution chute are both fixed with discharge ports. When feeding materials at the feed inlet, the circular high-speed steering movement formed by the supporting shaft and the rotating disc is in contact with the material. The rotating disc cuts into the material continuously, further reducing the impact on the screening plate caused by excessive concentration when feeding. There is a strong impact force problem, and the spring in the support shaft cooperates with the turntable to dampen the shock of the turntable.

Owner:娄底市涟钢振兴冶金材料有限公司

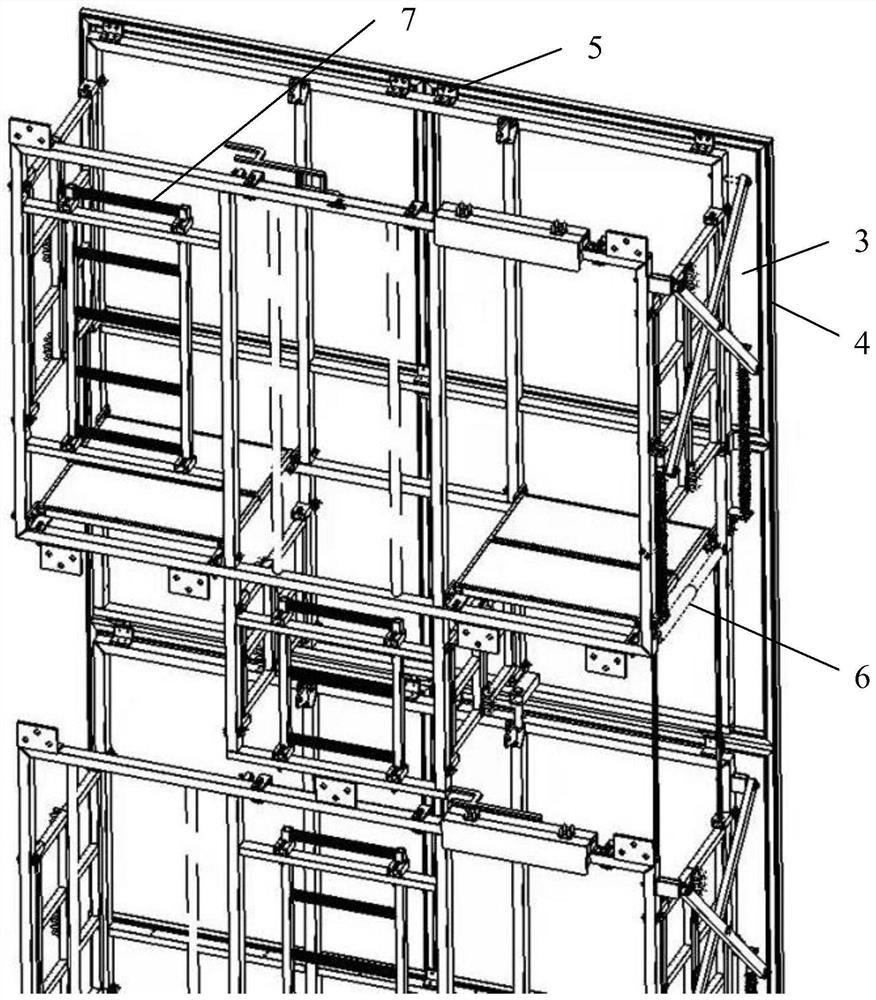

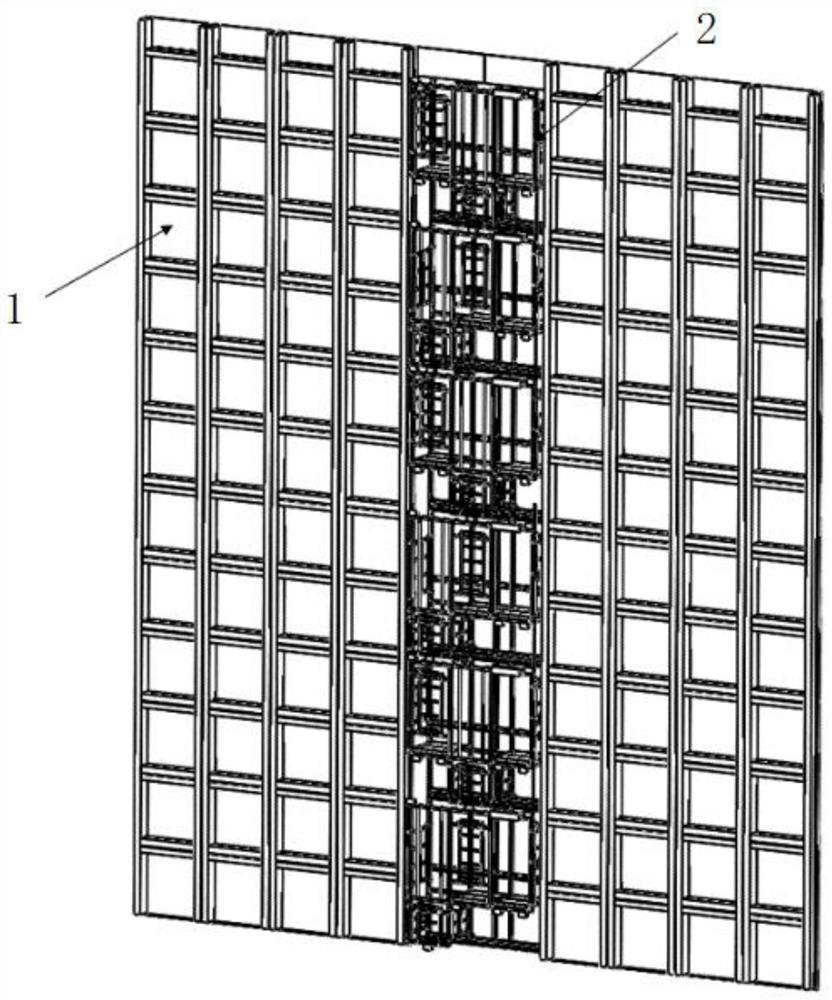

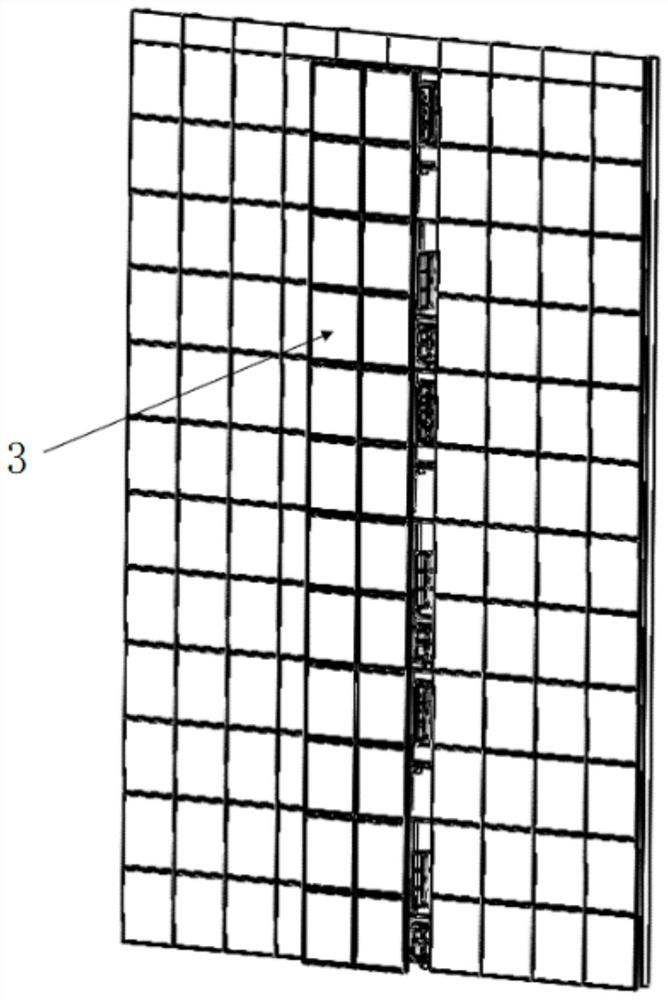

Built-in escape ladder suitable for building curtain wall structure

PendingCN114046132AIt has the function of waterproof and heat preservationImprove securityLaddersFixed frameDamper

The invention relates to a built-in escape ladder suitable for a building curtain wall structure, and belongs to the technical field of escape facilities, the built-in escape ladder comprises an escape ladder body, the escape ladder body is located on the outer side of a window, the escape ladder body comprises a main frame, the main frame comprises a fixed frame close to one side of the window and a movable frame away from one side of the window, and glass is arranged on the movable frame, and when the escape ladder is in a folded state, the glass of the escape ladder is flush with curtain wall glass fixed on the surrounding wall body, so that the escape ladder and the curtain wall are integrated in a closed state, and the appearance and the function of the building curtain wall are not influenced. A sealing strip is further arranged on the periphery of the glass to seal a gap formed between the escape ladder in a folded state and curtain wall glass fixed on a surrounding wall body, so that the escape ladder has waterproof and heat preservation effects; the damper is arranged on the escape ladder body, so that strong impact on curtain wall glass during opening of the escape ladder is reduced, the integrity of a curtain wall structure is protected, and the use safety of the escape ladder is improved.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

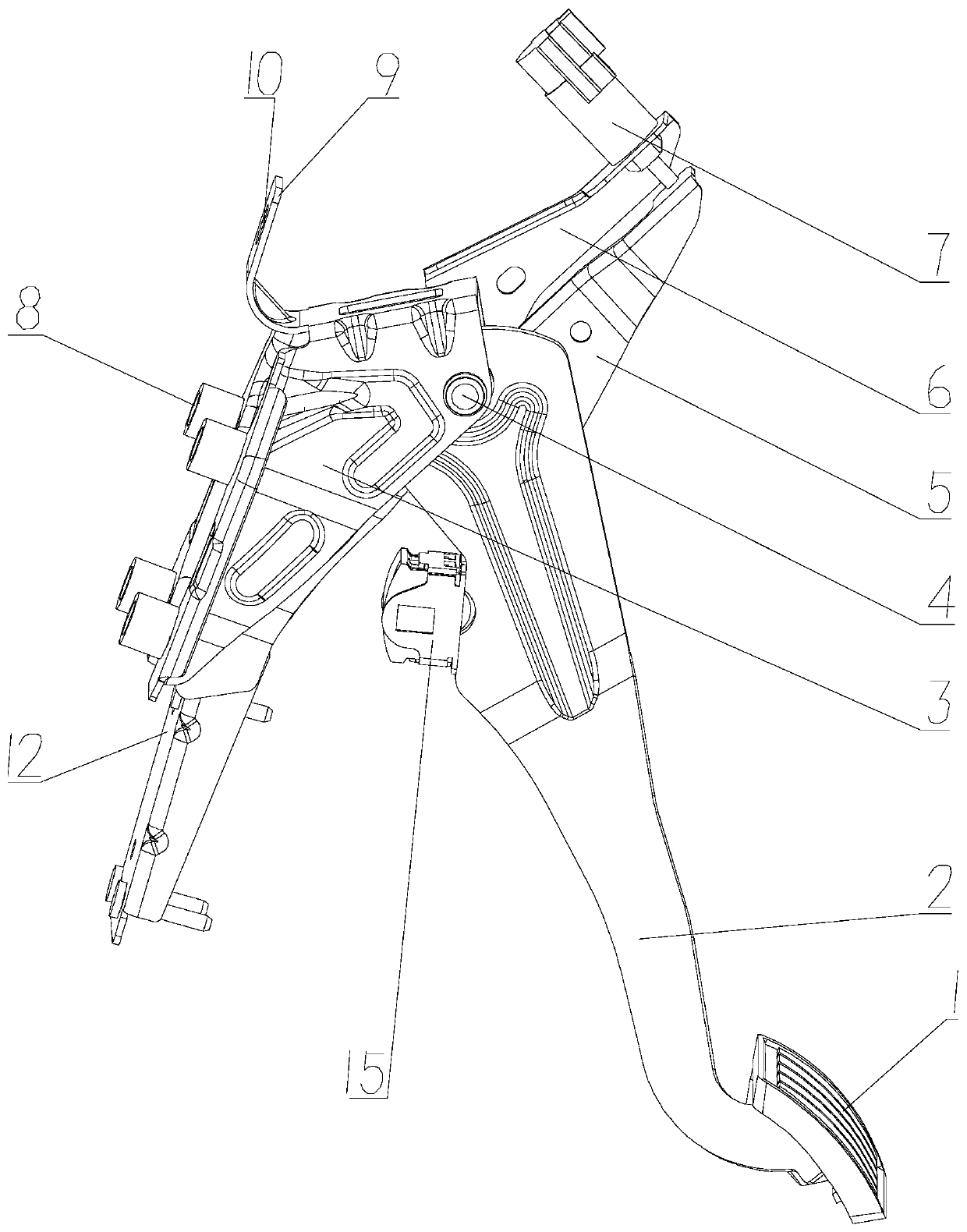

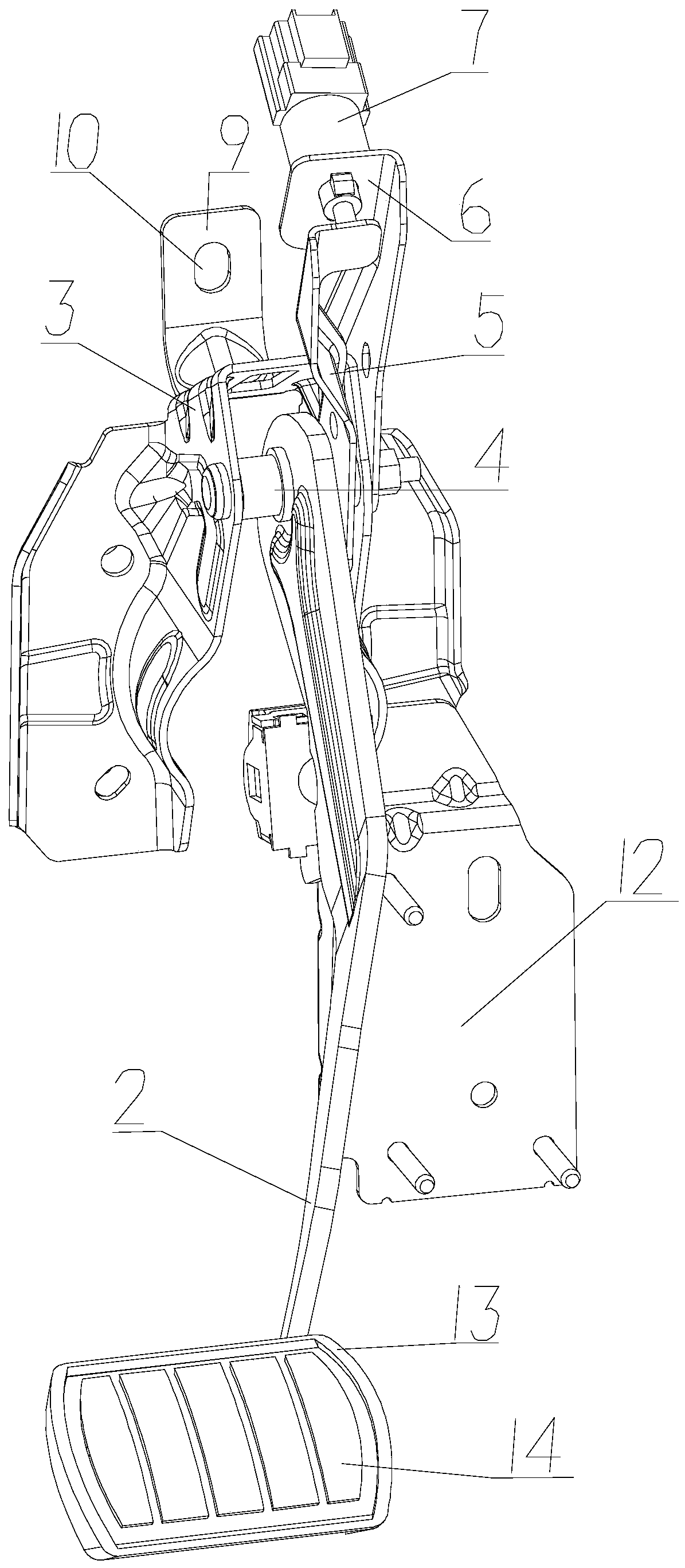

Brake pedal structure capable of protecting shanks and feet of driver

InactiveCN110901607AProtection securityReduce damage rateFoot actuated initiationsHead-on collisionDriver/operator

The invention discloses a brake pedal structure capable of protecting shanks and feet of a driver. The brake pedal structure comprises a brake pedal, a brake pedal arm, a brake pedal support, a brakepedal first upper support, a brake pedal second upper support, a brake lamp assembly and a brake pedal base. The brake pedal support is of a unique wavy structure. When the brake pedal support and thebrake pedal second upper bracket are stressed excessively; the brake pedal support and the brake pedal second upper support are bent from the collapsing holes to be collapsed and deformed, the upwarping amplitude of the brake pedal can be reduced in the head-on collision process of an vehicle, and therefore the shanks and the feet of a driver are protected, the probability that the driver is injured is reduced, the safety performance of the whole vehicle is improved, and the life safety of people is guaranteed.

Owner:SHAANXI TONGJIA AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com