Lubricating oil composition for motorcycle shock absorber

A technology of lubricating oil composition and shock absorber, which is applied in the field of lubricating oil composition and lubricating oil composition of motorcycle shock absorber, which can solve the problems of poor oxidation resistance, short working life of shock absorber oil and impact on shock absorption The service life of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The lubricating oil composition for motorcycle shock absorbers includes: 930g mineral oil type mixed base oil, 60g containing 35% polymethacrylate concentrate as viscosity index improver, 0.2g ethylene oxide homopolymer as demulsifier 5g of alkyl zinc thiophosphate and 1g of p-cresol are used as antioxidant and anticorrosion agent, 4g of fumaric acid ester is used as pour point depressant, and 0.001g of polymethyl silicone oil is used as antifoaming agent , the total amount is about 1000g.

[0058] The lubricating oil composition of the motorcycle shock absorber of the present embodiment is prepared according to the following process steps.

[0059] 1) Place the viscosity index improver in a drying room from room temperature to 60°C for heating. After the temperature of the drying room reaches 60°C, control the heating time for 6 hours. After the viscosity index improver flows freely, place it for use.

[0060] 2) Dilute the pour point depressant with the lightest base...

Embodiment 2

[0075] The motorcycle shock absorber oil composition comprises: 950g mineral oil type mixed base oil, 40g containing 45% polymethacrylate concentrate as a viscosity index improver using 6g of zinc alkylthiophosphate and 1g of p-cresol It is used as anti-oxidant and anti-corrosion agent, 0.008g of polyol ester is used as demulsifier, 3g of fumarate is used as pour point depressant, and 0.005g of polymethicone is used as antifoaming agent, the total amount is about 1000g. The preparation method is the same as in Example 1.

[0076] The mixed base oil is produced by hydrogenation process with a kinematic viscosity of 8.237mm at 40°C 2 / s base oil, the kinematic viscosity at 40°C produced by solvent refining process is 56.30mm 2 / s base oil, the kinematic viscosity at 40°C produced by solvent refining process is 30.56mm 2 / s base oil mixture, the mixing ratio is 2:1:4, and the kinematic viscosity of the mixed base oil at 40°C is 22.81mm 2 / s, the viscosity index is 92, and the ...

Embodiment 3

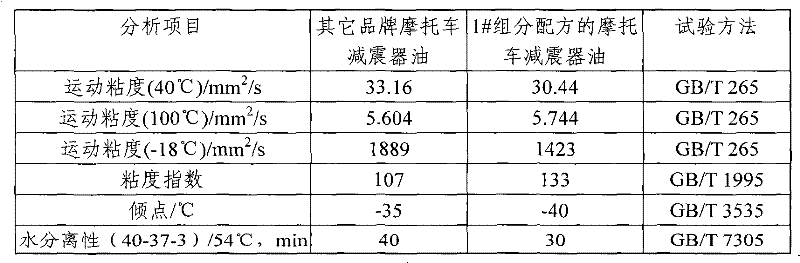

[0081] In the performance of motorcycle shock absorber oil, the low temperature fluidity of the oil is the key factor. Select polymethacrylate VX1-248 from Roman and Haas Additives, polymethacrylate VX1-156 from Roman and Haas Additives, fumarate pour point depressant INF-382 from Infineum Additives, Infineum Additives Company INF-385, China Petroleum & Chemical Co., Ltd. Keweisheng Company T882, Wuxi Nanfang Additive Co., Ltd. alkylnaphthalene T801, Lanlian-Lubrizol Additive Co., Ltd. polyα-olefin T803, investigated the base oil and The relationship between the amount of pour point depressant is shown in Table 5. The data in table 5 shows that the optimum amount of pour point depressant added to the base oil selected by the motorcycle shock absorber in this embodiment is between 0.3% and 0.6%. The preparation method is the same as in Example 1. Other each component consumption is added according to the ratio in embodiment 1.

[0082] The adding amount of the pour point depr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com