Cavitation roller capable of continuously making caves to plant cotton nutritive bowls by rotation

A nutrient bowl and cotton technology, applied in planting methods, excavation/covering of trenches, applications, etc., can solve the problems of inaccurate control of hole spacing, row spacing, large inertial force of hole-forming equipment, uneven hole depth, etc. Improve the efficiency of hole making, small inertial force and uniform hole depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

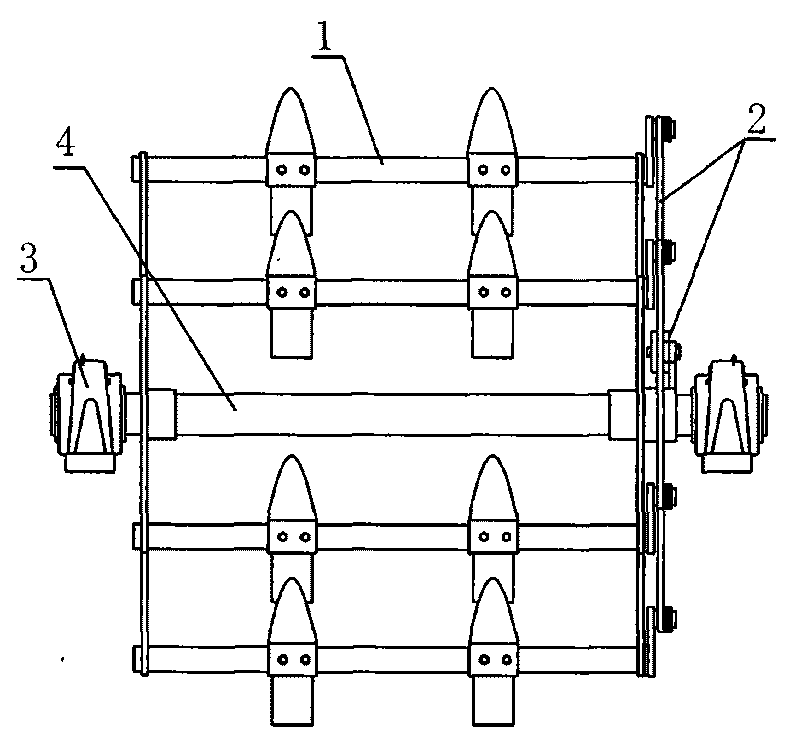

[0025] The cavitation roller includes a knife roller assembly 1, an eccentric adjustment device 2, a bearing seat 3 and a mandrel 4, the knife roller assembly 1 is installed on the mandrel 4, and the eccentric adjustment device 2 is installed on one side of the knife roller assembly 1, The two ends of the mandrel 4 are equipped with bearing blocks 3 connected with the frame.

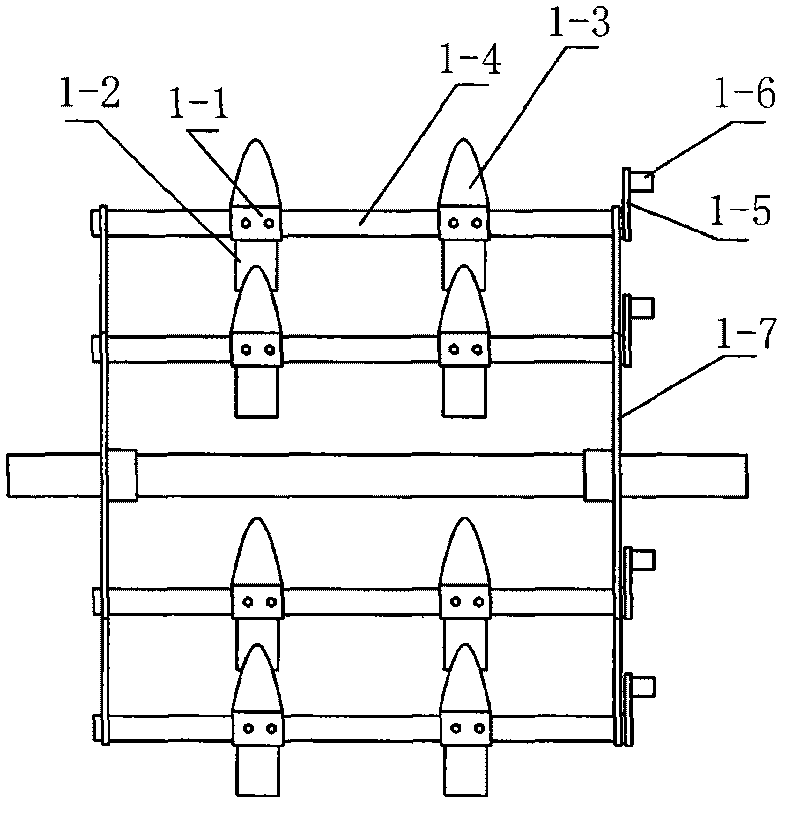

[0026] The cutter roller assembly 1 includes a cutter setter 1-1, a hole forming cutter 1-2, a soil throwing board 1-3, a connecting pipe 1-4, a connecting plate 1-5, a small short shaft 1-6 and a mounting frame 1- 7; The mounting frame 1-7 is a device similar to a "meter" shape in which four knife bars 1-9 are evenly arranged radially outwards from the same circle center. There is a round hole at the top of each knife bar 1-9, and all knife bars 1-9 The round holes on the top are on the same circumference; there are two mounting frames 1-7, and the two mounting frames 1-7 are installed on both sides of ...

Embodiment 2

[0029] The cavitation roller includes a knife roller assembly 1, an eccentric adjustment device 2, a bearing seat 3 and a mandrel 4, the knife roller assembly 1 is installed on the mandrel 4, and the eccentric adjustment device 2 is installed on one side of the knife roller assembly 1, The two ends of the mandrel 4 are equipped with bearing blocks 3 connected with the frame.

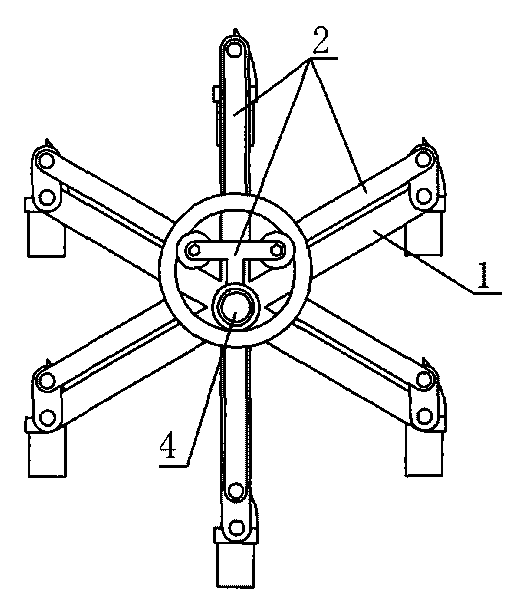

[0030] The cutter roller assembly 1 includes a cutter setter 1-1, a hole forming cutter 1-2, a soil throwing board 1-3, a connecting pipe 1-4, a connecting plate 1-5, a small short shaft 1-6 and a mounting frame 1- 7; The installation frame 1-7 is a device similar to the "meter" shape of eight knife bars 1-9 evenly arranged radially outwards from the same circle center. There is a round hole at the top of each knife bar 1-9, and all knife bars 1-9 The round holes on the top are on the same circumference; there are two mounting frames 1-7, and the two mounting frames 1-7 are installed on both sides of the...

Embodiment 3

[0033] The cavitation roller includes a cutter roller assembly 1, an eccentric adjustment device 2, a bearing seat 3 and a mandrel 4, the cutter roller assembly 1 is installed on the mandrel 4, and the eccentric adjustment device 2 is installed on one side of the cutter roller assembly 1, The two ends of the mandrel 4 are equipped with bearing blocks 3 connected with the frame.

[0034] The cutter roller assembly 1 includes a cutter setter 1-1, a hole forming cutter 1-2, a soil throwing board 1-3, a connecting pipe 1-4, a connecting plate 1-5, a small short shaft 1-6 and a mounting frame 1- 7; The installation frame 1-7 is a device similar to the "meter" shape of six knife bars 1-9 radially arranged outwards from the same circle center, and each knife bar 1-9 has a round hole at the top, and all knife bars 1-9 The round holes on the top are on the same circumference; there are two mounting frames 1-7, and the two mounting frames 1-7 are installed on both sides of the mandrel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com