Automatic grabbing and transferring device for multi-size flexible raw tires

A transfer device and multi-size technology, applied in tires, household appliances, and other household appliances, can solve problems such as easy deformation, high work intensity, and reduced production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

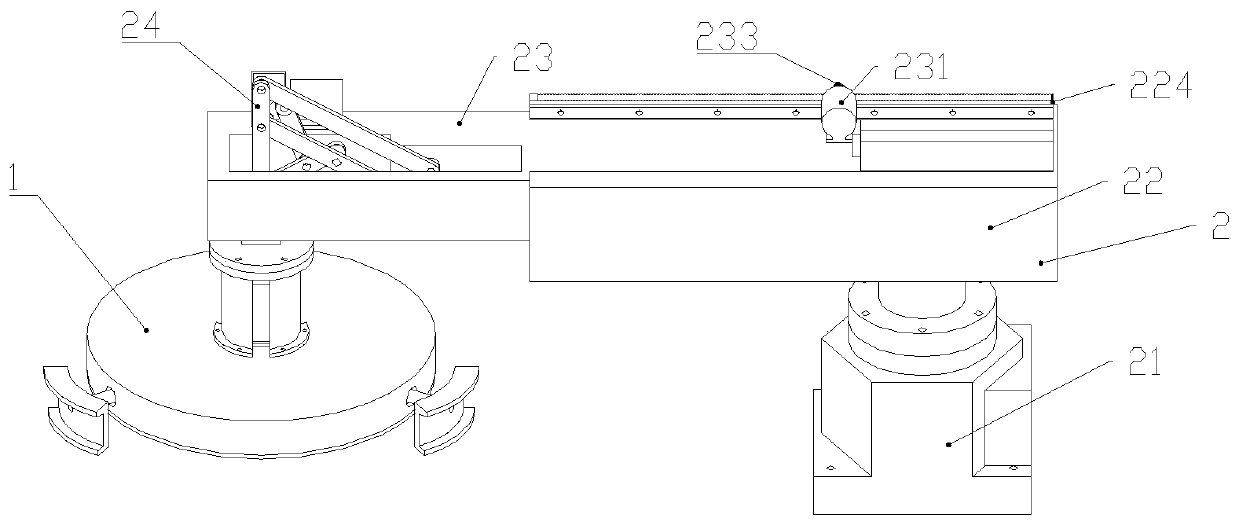

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

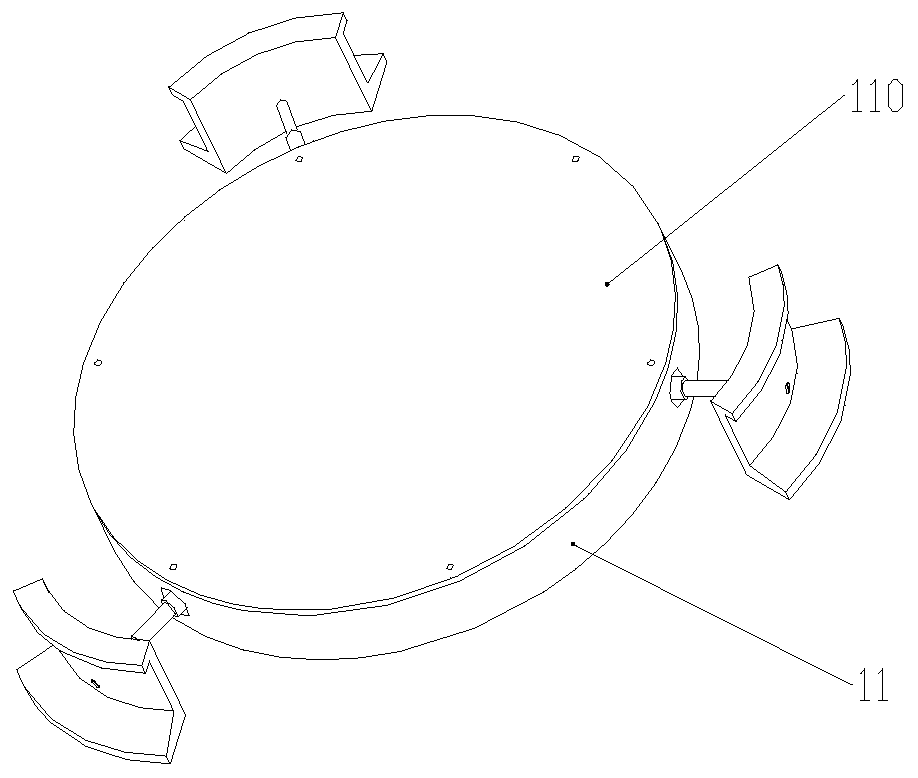

[0033] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12, a multi-size flexible embryo automatic grabbing transfer device, including: a clamping device 1, a transfer device 2; Three clamping plates are installed on the side of the holding device 1, and the three clamping plates are automatically stretched out to act on the inner side of the embryo, and the embryo is clamped through the expansion and contraction of the clamping plates; the transfer device 2 has three degrees of freedom. The clamping device 1 is installed on the lifting device 24 of the transfer device 2. After the clamping device 1 clamps the green tire, the transfer device 2 drives the clamping device 1 to move in a three-dimensional space. Thereby realizing the grasping work of embryonic embryo.

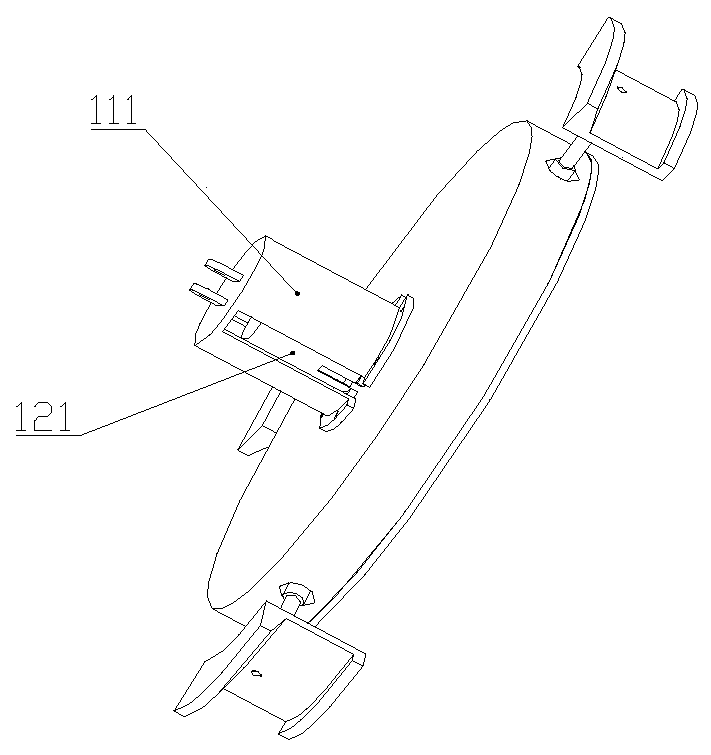

[0034]The clamping device 1 includes: a clamping frame assembly 11, a transmission device 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com