Engine transmission mechanism capable of replacing crankshafts and connecting rods and linkage power transmission mechanism

A power transmission mechanism, crankshaft and connecting rod technology, applied in the direction of transmission elements, transmission devices, fluid transmission devices, etc., can solve the problem of increasing the lateral friction between the piston and the cylinder wall, affecting the output power of the engine, and reducing the working efficiency of the piston and other issues to achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

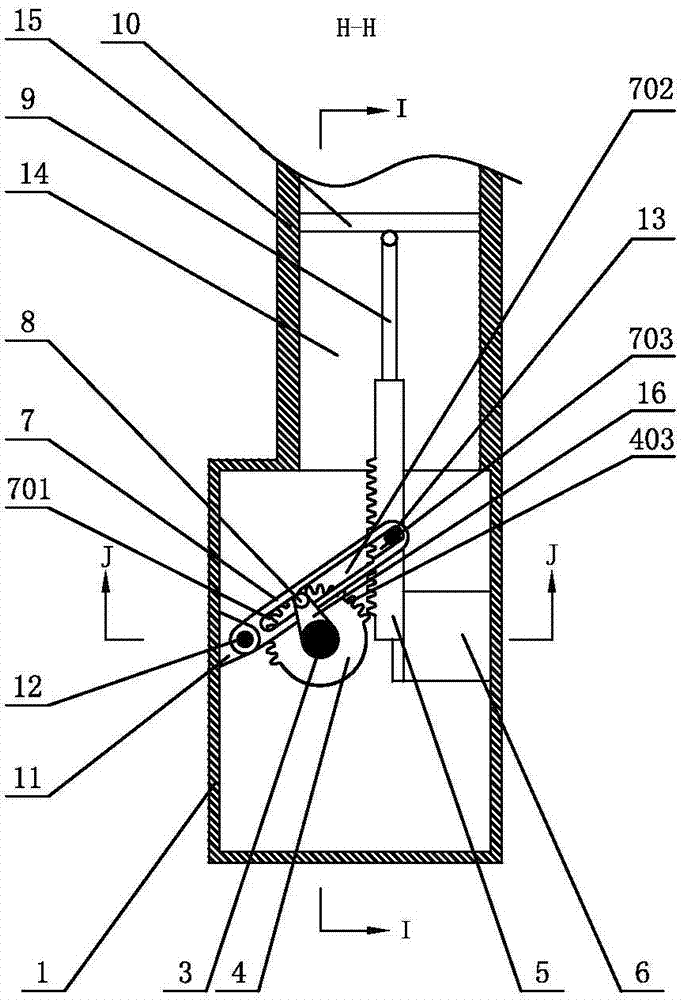

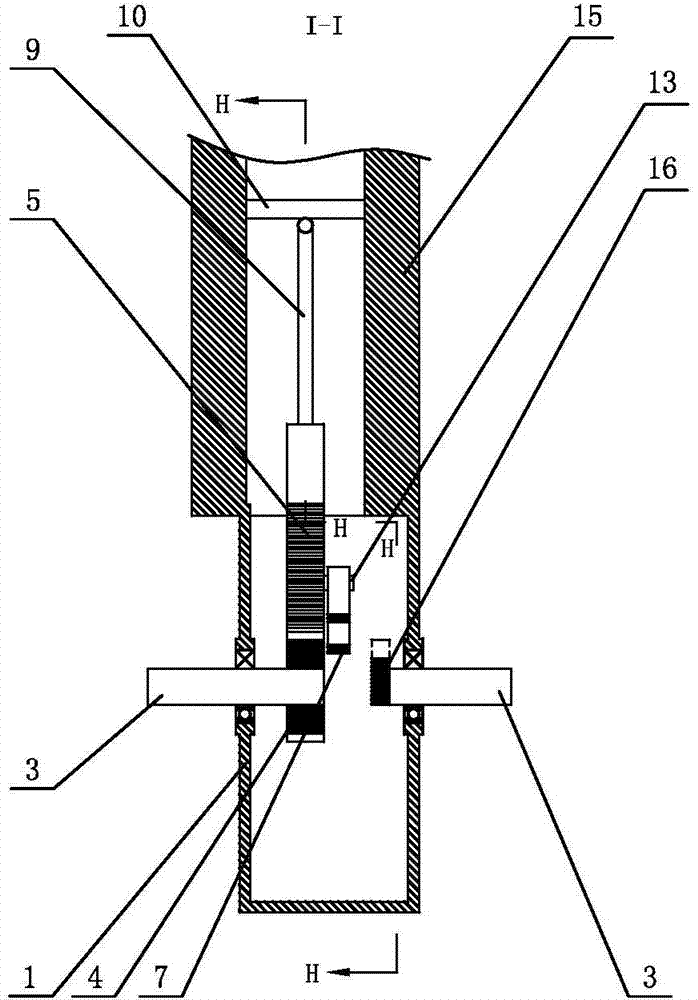

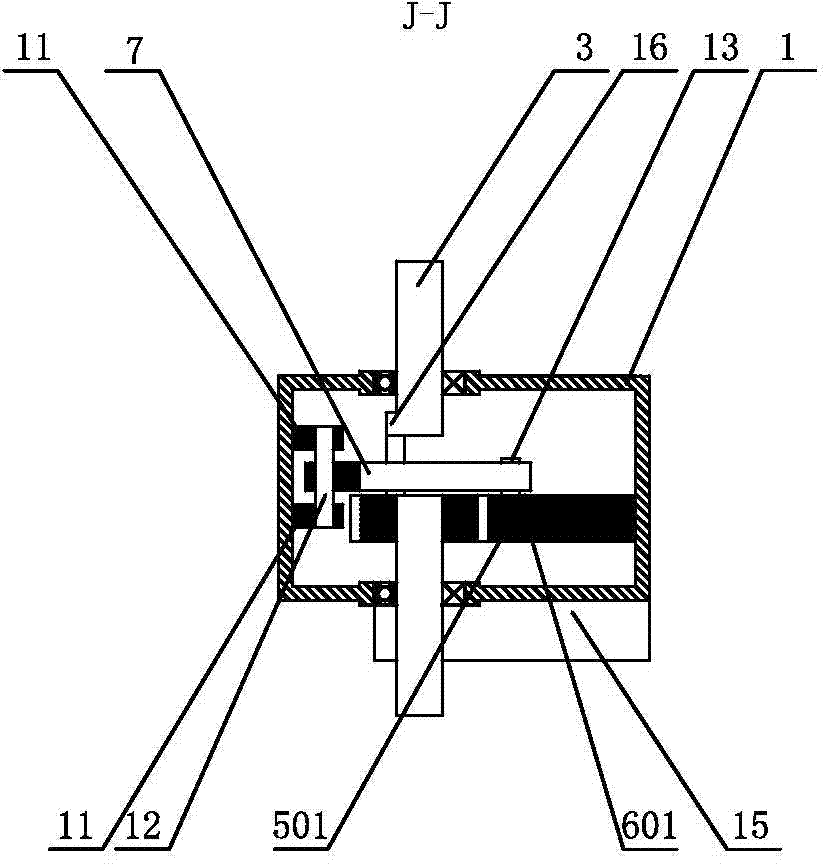

[0040] Such as figure 1 and 2 as shown, figure 1 yes figure 2 The H-H direction sectional view of the engine transmission mechanism that replaces the crankshaft connecting rod in the present embodiment, the engine transmission mechanism that replaces the crankshaft connecting rod includes a housing 1 and a conversion mechanism installed in the housing 1 through two main shafts 3. The conversion mechanism includes a fixed The sector gear 4 at one end of one of the main shafts 3 and the rack 5 installed in the housing 1 through the guide plate 6 and the reset device for driving the rack 5 to reset, the rack 5 alternately meshes with the sector gear 4 and drives the sector gear 4 Rotate, the end of rack 5 is connected with piston 10 through connecting rod 9, and piston 10 is placed in the cylinder 14 of cylinder block 15 to form single-cylinder engine.

[0041] Such as Figure 1-5 As shown, the sector gear 4 is orthogonal to the main shaft 3, the central axis of the sector g...

Embodiment 2

[0052] Such as Figure 10-12 As shown, two sets of power transmission mechanisms with the same structure are arranged in the housing 1, the main shaft 3 connected with the crank arm 16 in the two sets of power transmission mechanisms is coaxially connected, and the side of the sector gear 4 in the two power transmission mechanisms is fixedly connected The main shaft 3 is respectively installed on the two side walls of the housing 1 through the bearing seat and is connected with the external power output mechanism, wherein, when the piston 10 in the engine transmission mechanism of the first set replaces the crankshaft connecting rod and runs to the top dead center of the stroke , the second set of pistons 10 in the engine transmission mechanism replacing the crankshaft and connecting rod just runs to the bottom dead center of the stroke, and the two sets of pistons 10 in the engine transmission mechanism replacing the crankshaft and connecting rod are respectively placed in the...

Embodiment 3

[0055] Such as Figure 13 As shown, in this embodiment, a first power transmission mechanism, a second power transmission mechanism, a third power transmission mechanism and a fourth power transmission mechanism are arranged in the casing 1, and the main shaft 3 installed close to the side wall of the casing 1 passes through the bearing seat respectively. Installed on the two side walls of the housing 1, and respectively connected with the power output mechanism, the adjacent main shaft 3 in the housing 1 is coaxially connected, the first power transmission mechanism and the rotating arm 7 of the third power transmission mechanism, The rack 5, the connecting rod 9 and the piston 10 move in the same direction, the rotating arm 7, the rack 5, the connecting rod 9 and the piston 10 move in the same direction as the second power transmission mechanism and the fourth power transmission mechanism, and the first power transmission mechanism and the piston 10 move in the same direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com