Method for forming artificial vascular stent through 4D printing

A technology of artificial blood vessels and vascular stents, which is applied in the field of additive manufacturing, can solve the problems of limited material complexity and mechanical properties, inability to realize processing, and difficult clamping, so as to reduce the risk of tearing, simplify molding manufacturing equipment, Realize the effect of rapid manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

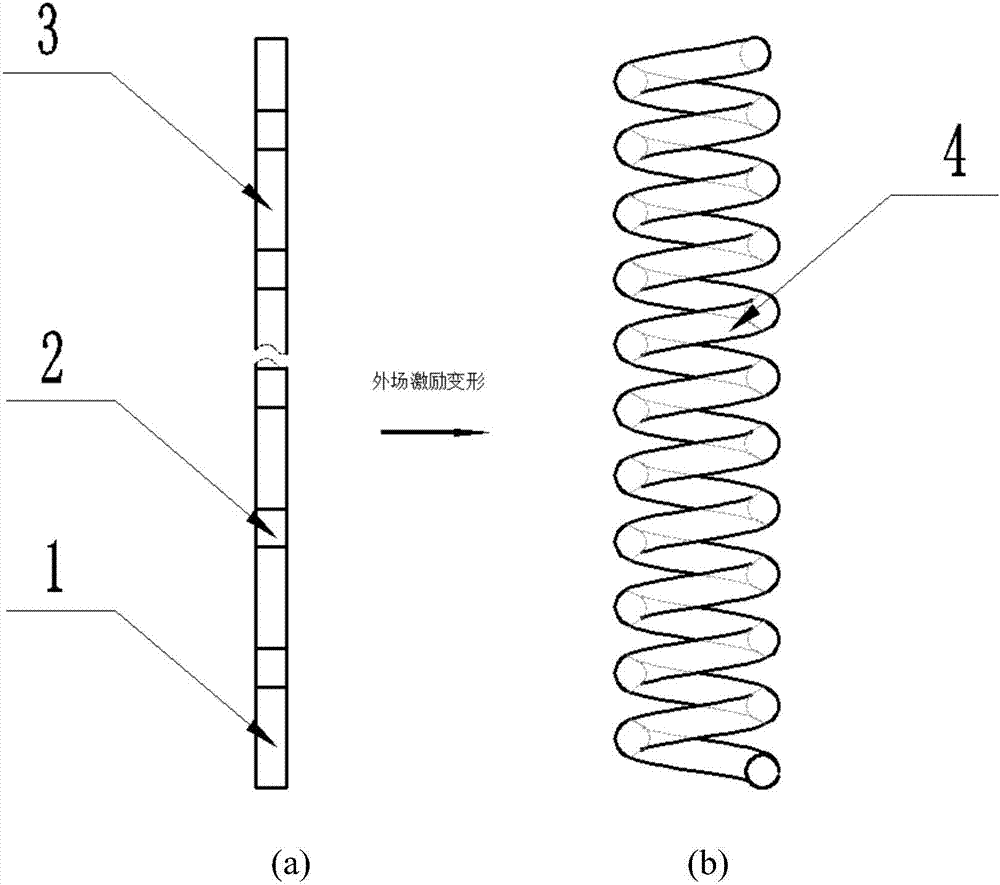

[0035] see figure 1 , a method for 4D printing and forming artificial vascular stents of the present invention, comprising the following steps:

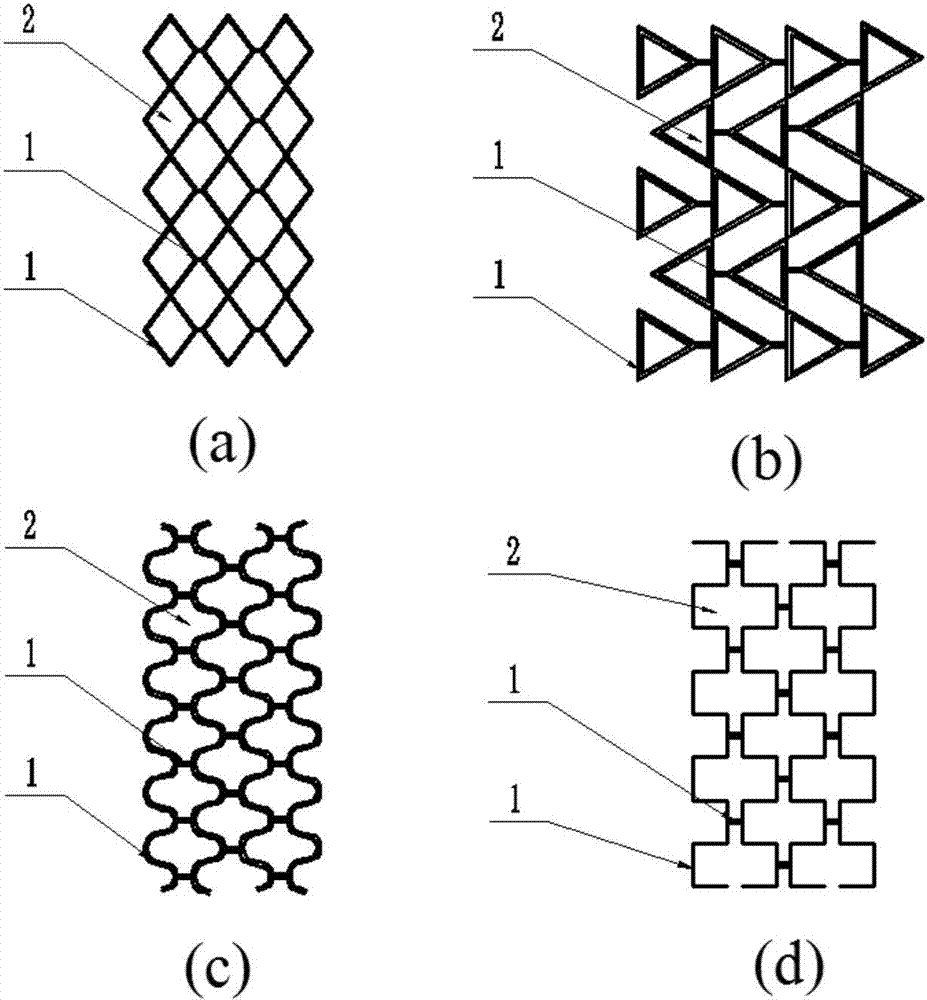

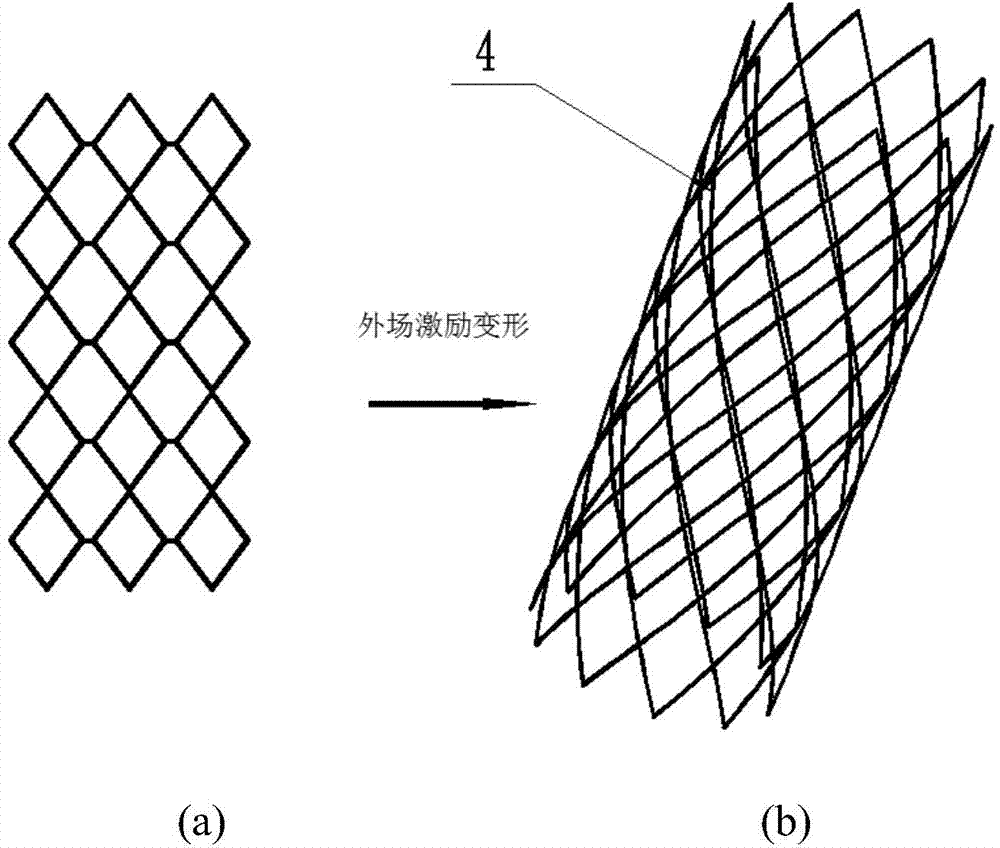

[0036]1) The shape memory polymer is used as the deformable material unit 2, and the polymer material is used as the matrix material unit 1 to design the initial configuration 3 of the stent. The initial configuration 3 of the stent is a spiral ring structure, wherein the matrix material unit 1 and The deformable material units 2 are arranged at intervals, and both ends of the initial configuration 3 of the vascular stent are matrix material units 1, the volume of the matrix material unit 1 and the deformable material unit 2 is 1: (3-5), the designed vascular stent The diameter of the initial configuration 3 is 2 mm to 6 mm, and the wall thickness is 0.09 mm to 0.4 mm;

[0037] 2) Print the base material unit 1 and the deformab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com