Patents

Literature

82results about How to "Reduced risk of tearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

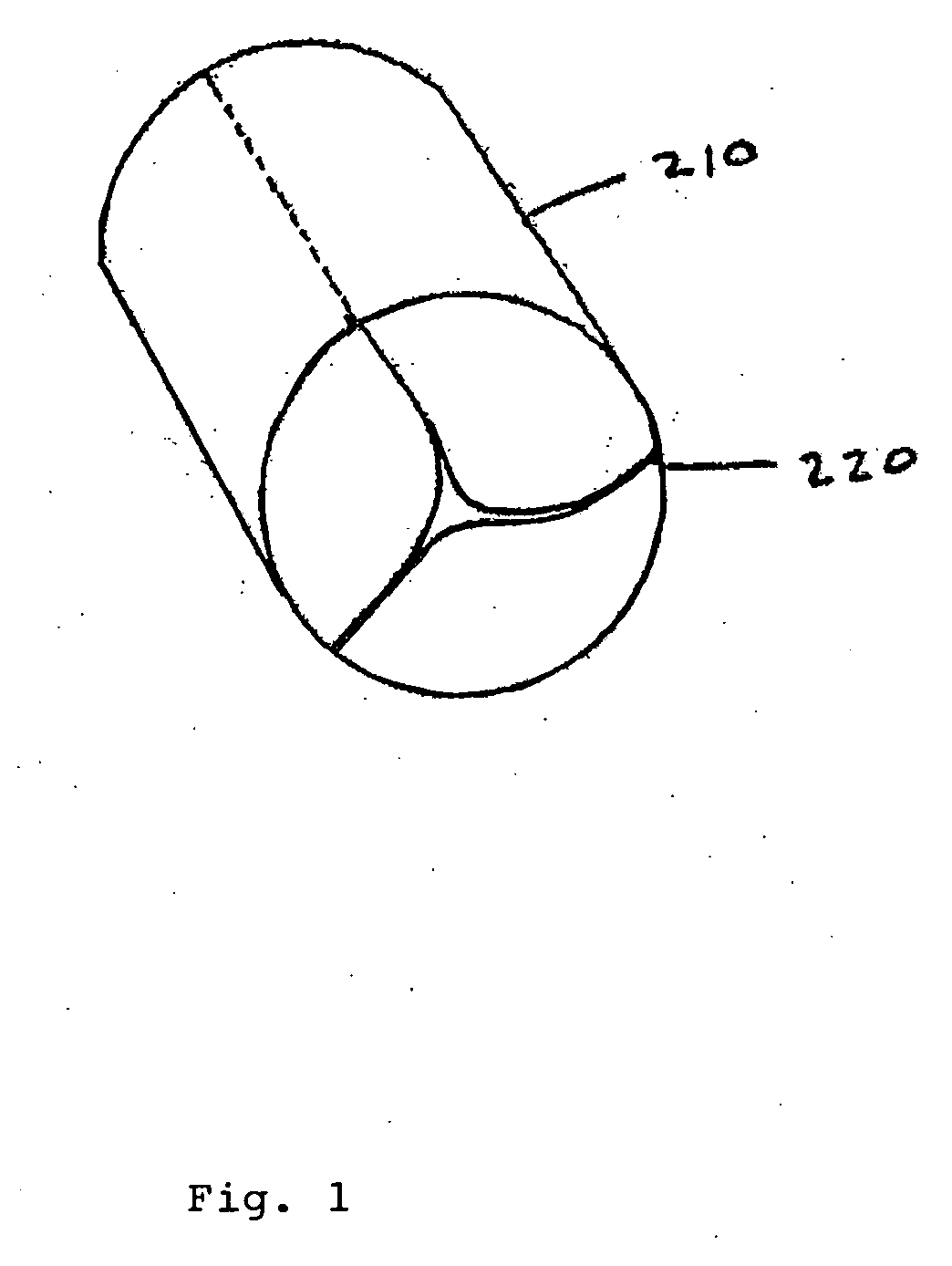

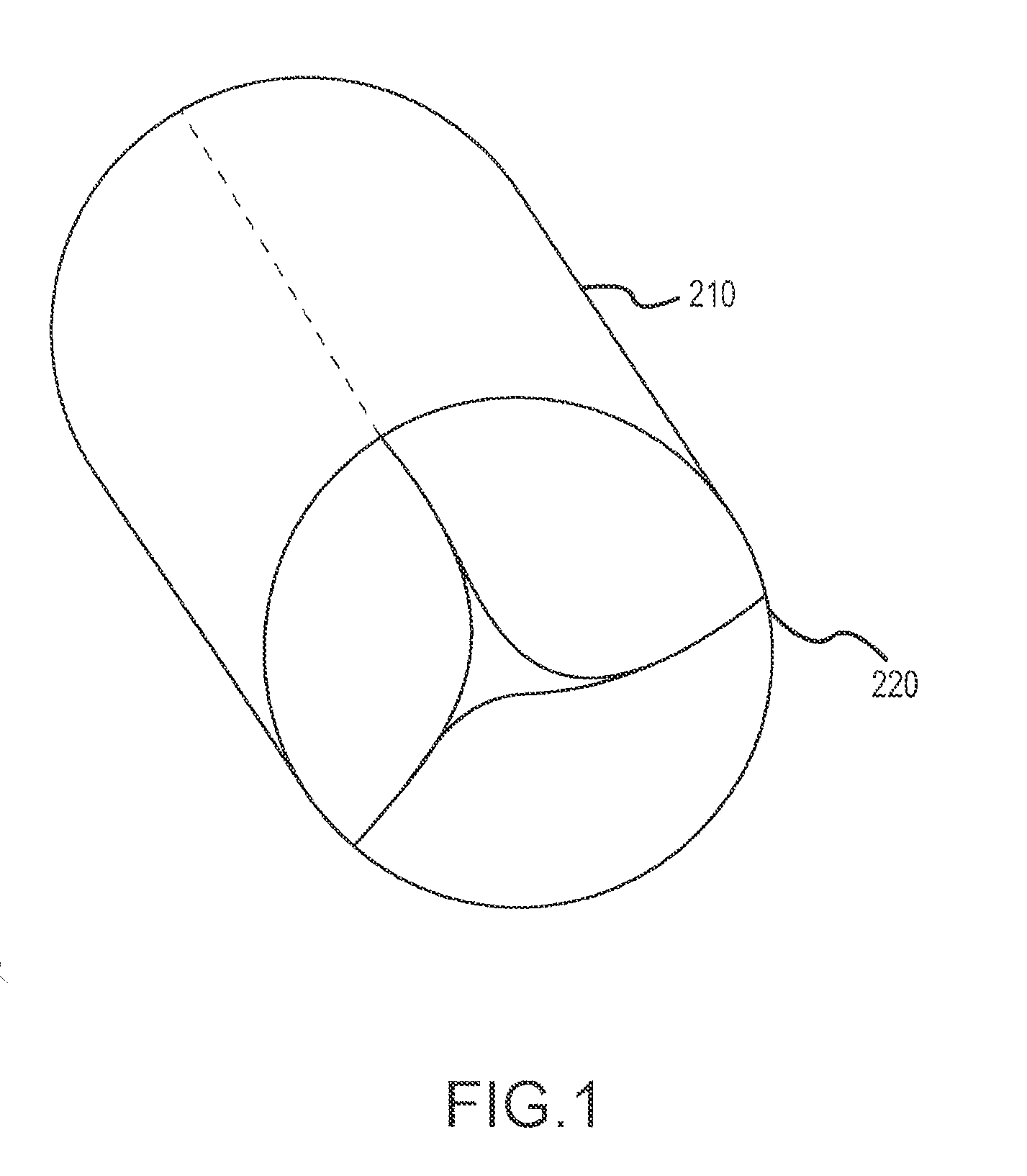

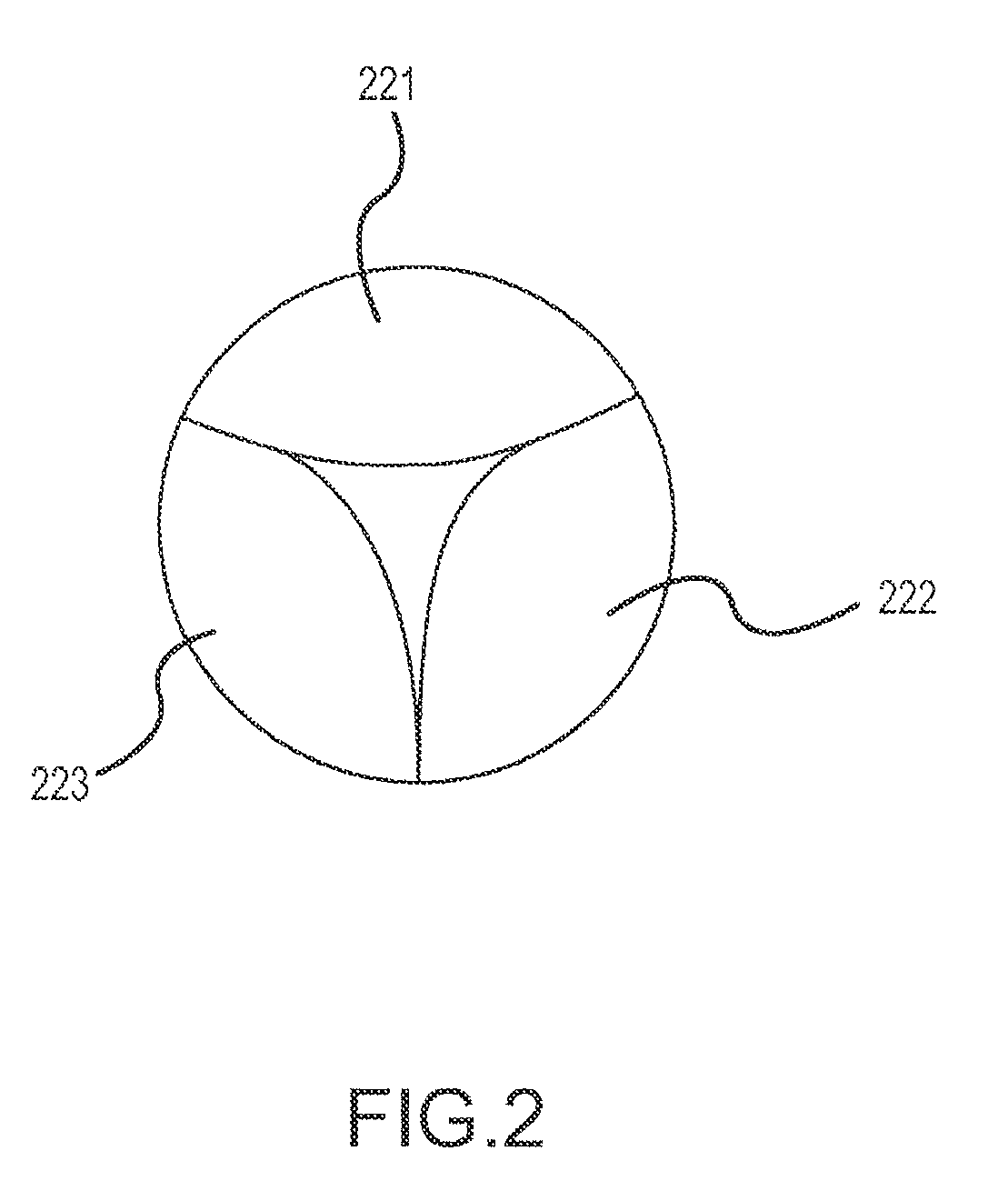

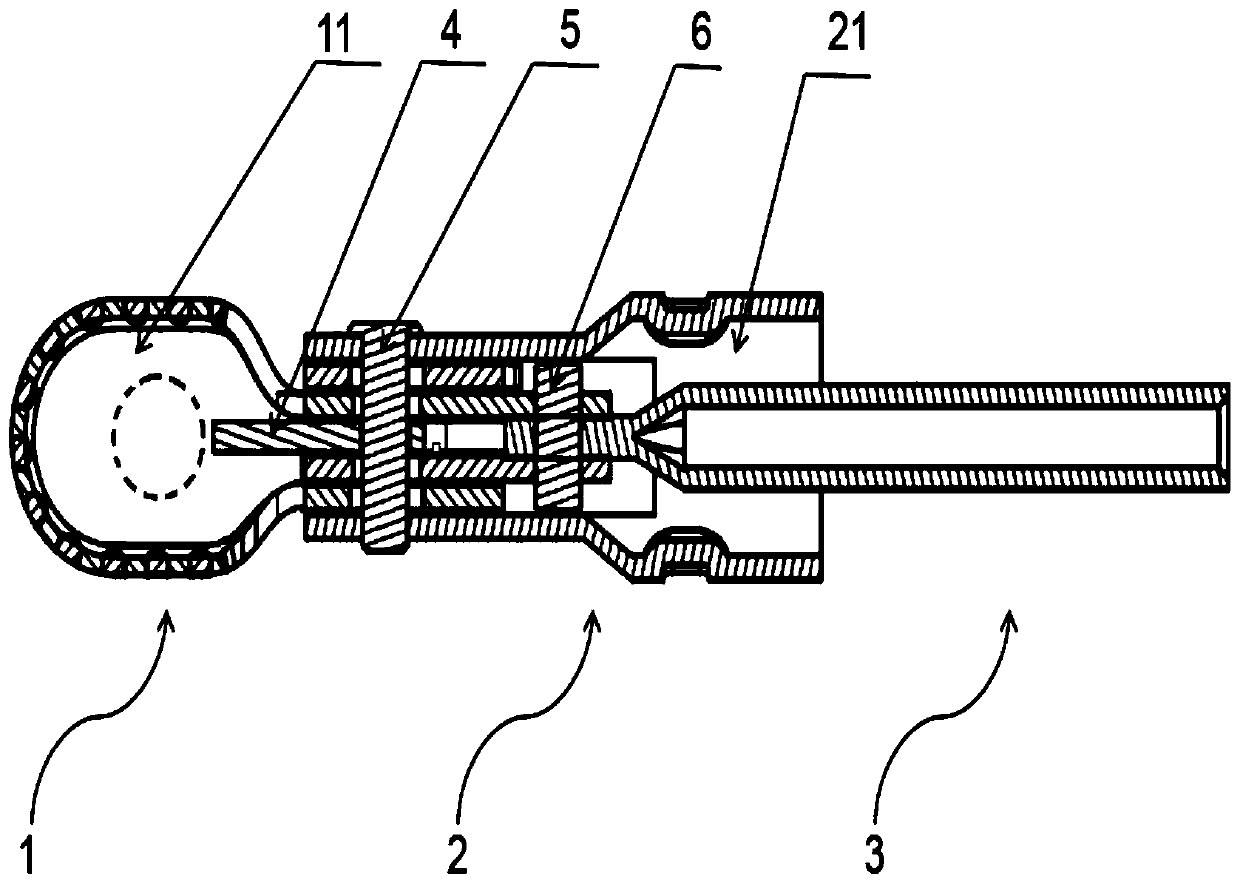

Percutaneously implantable replacement heart valve device and method of making same

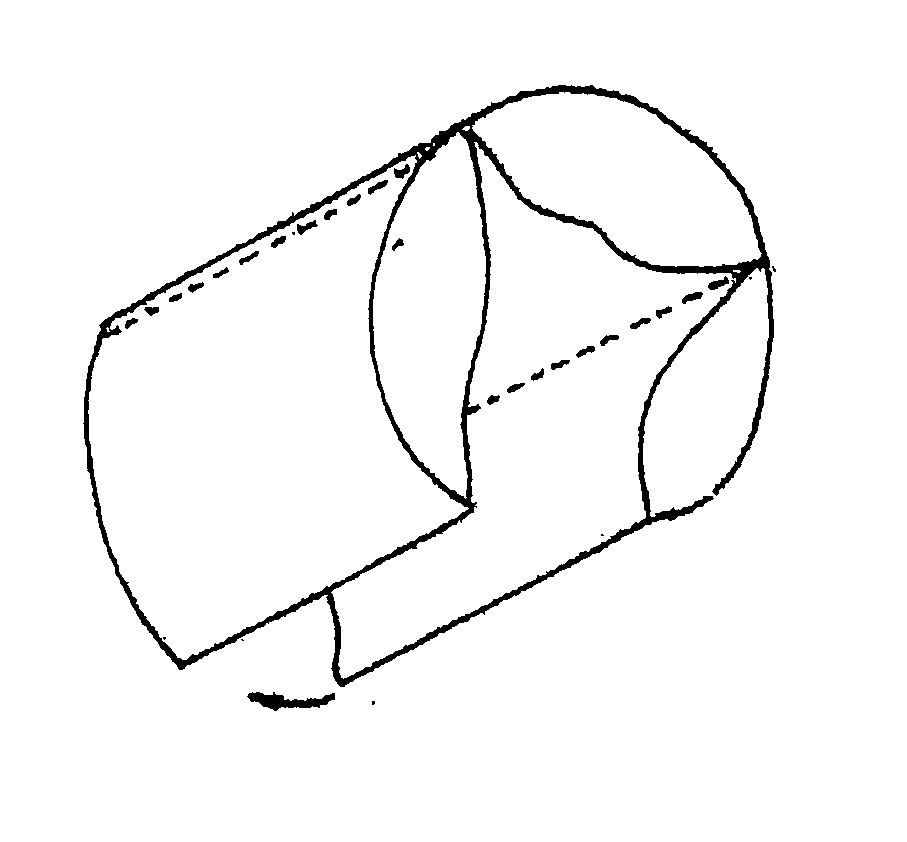

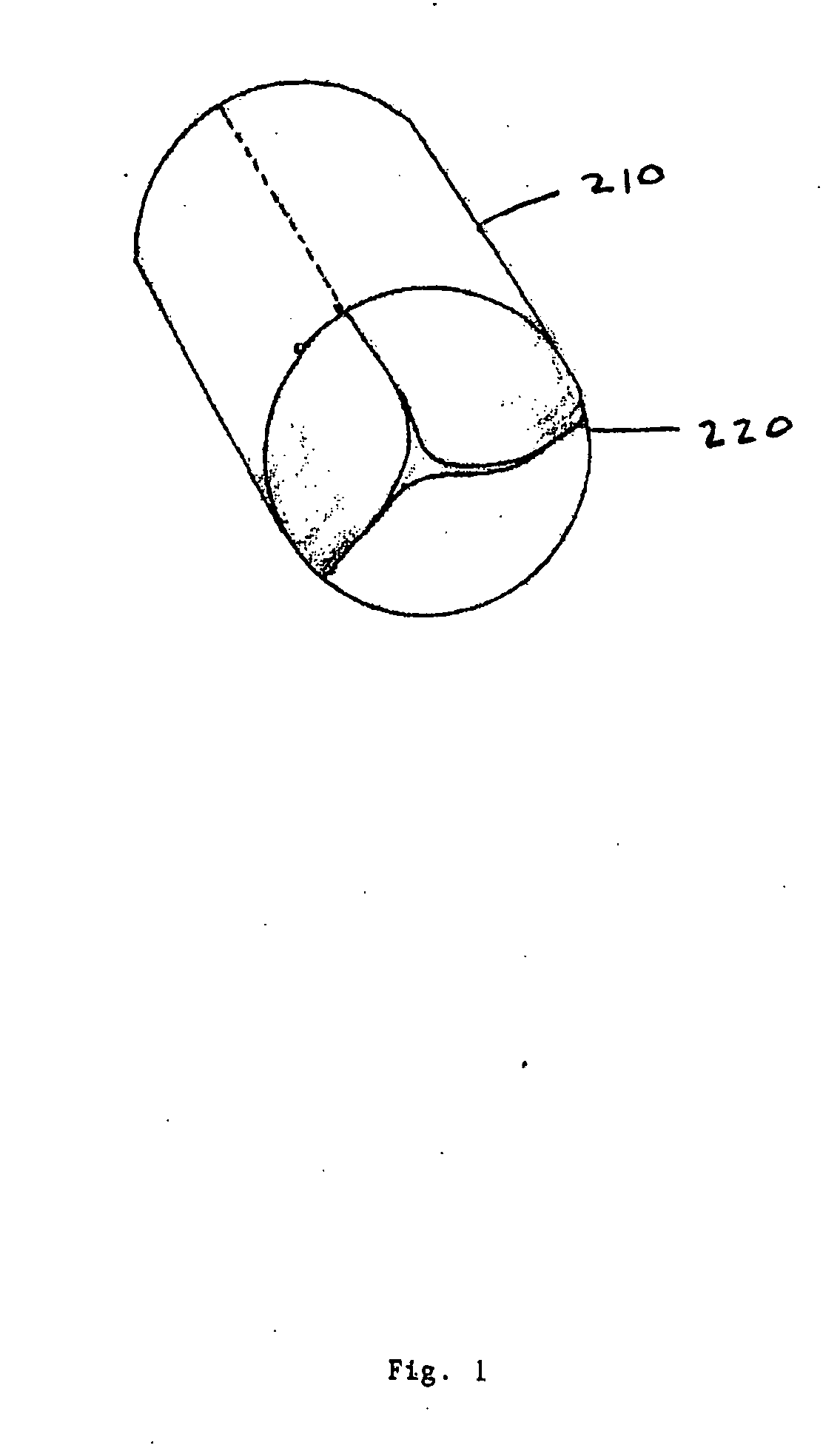

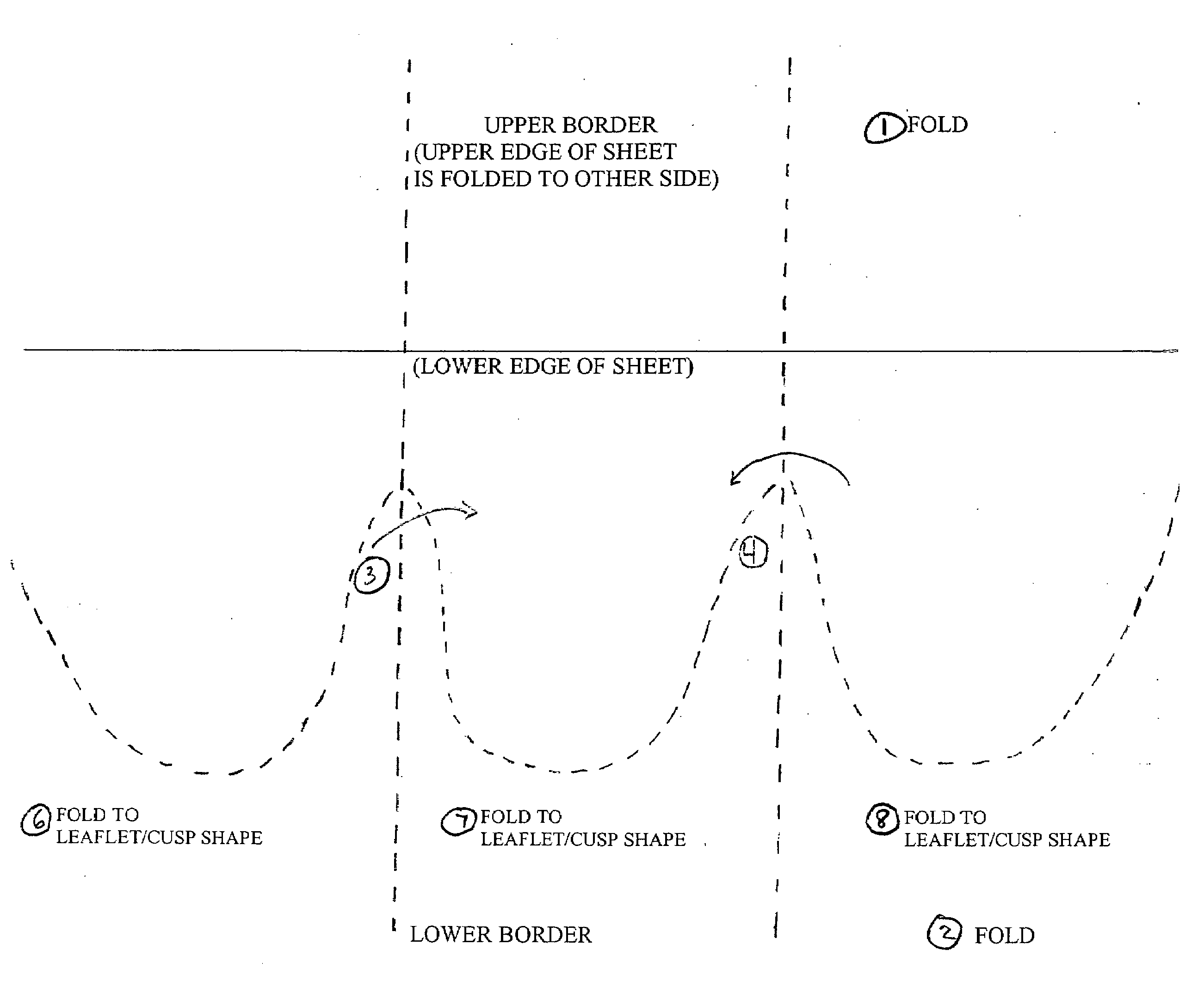

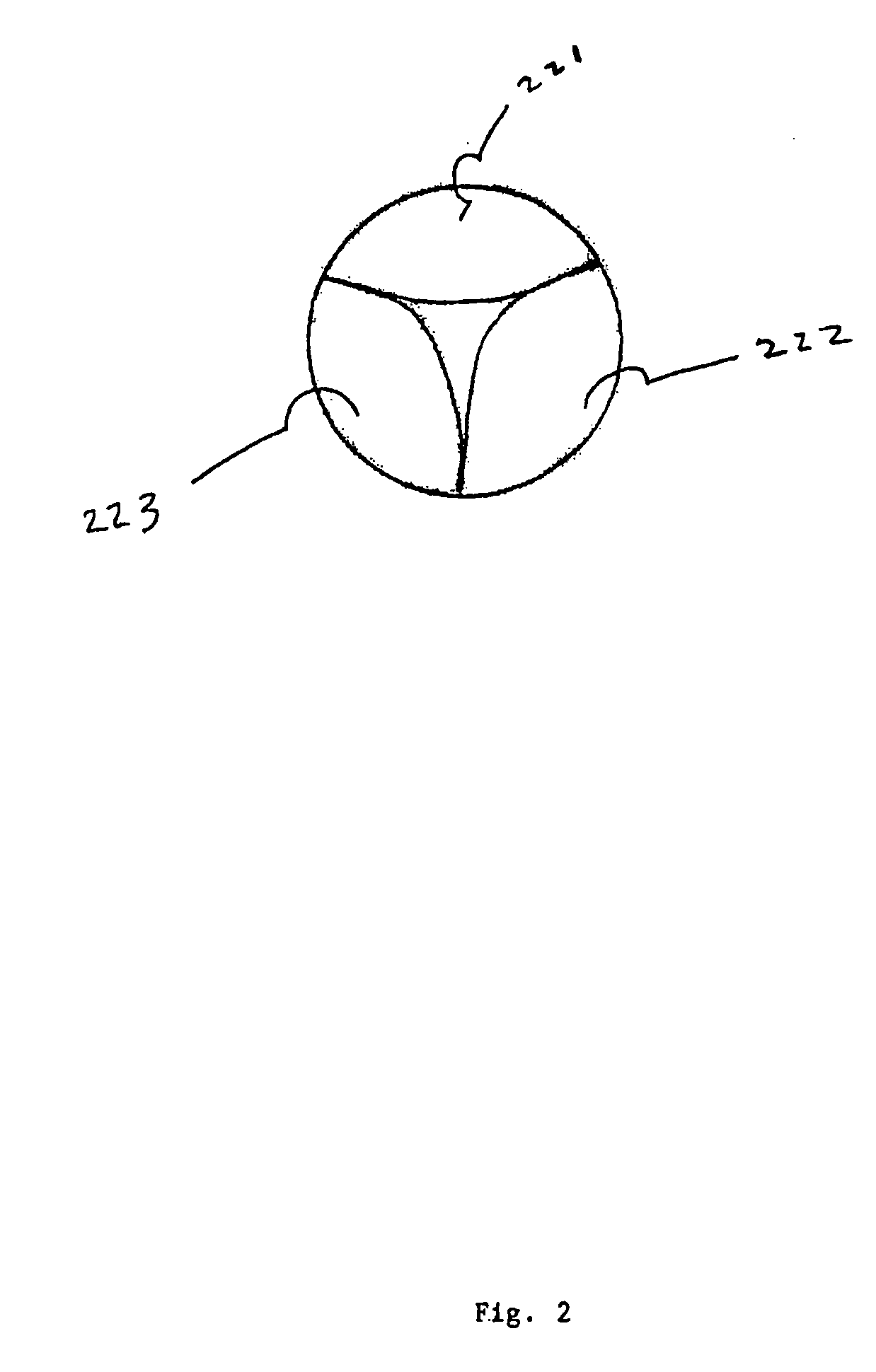

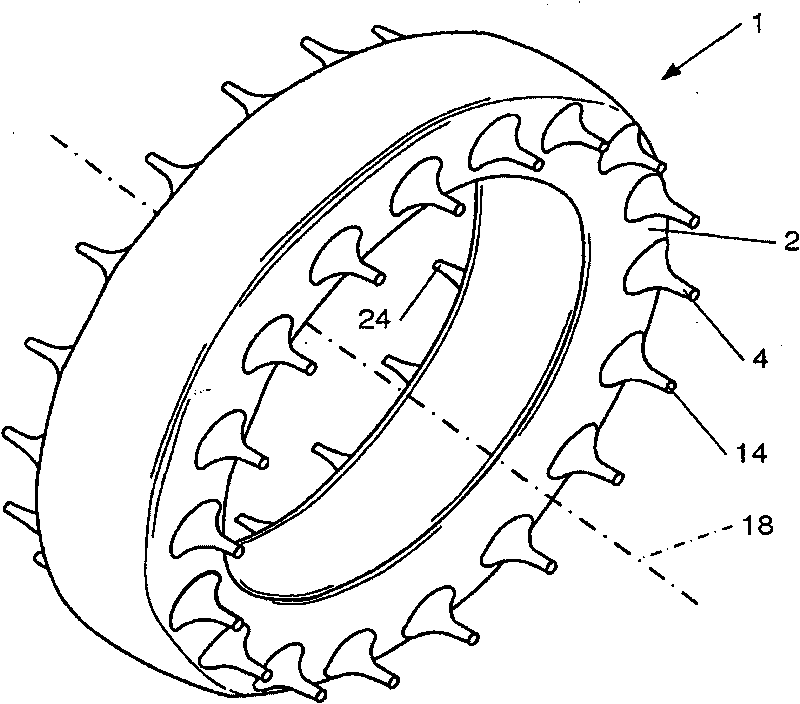

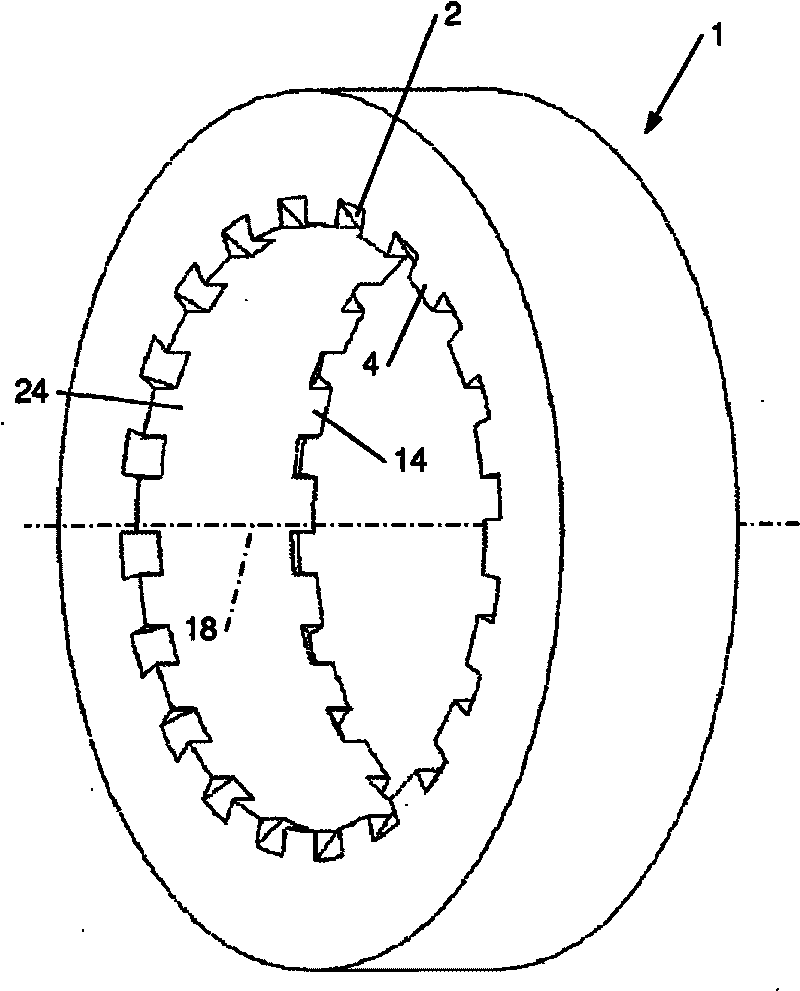

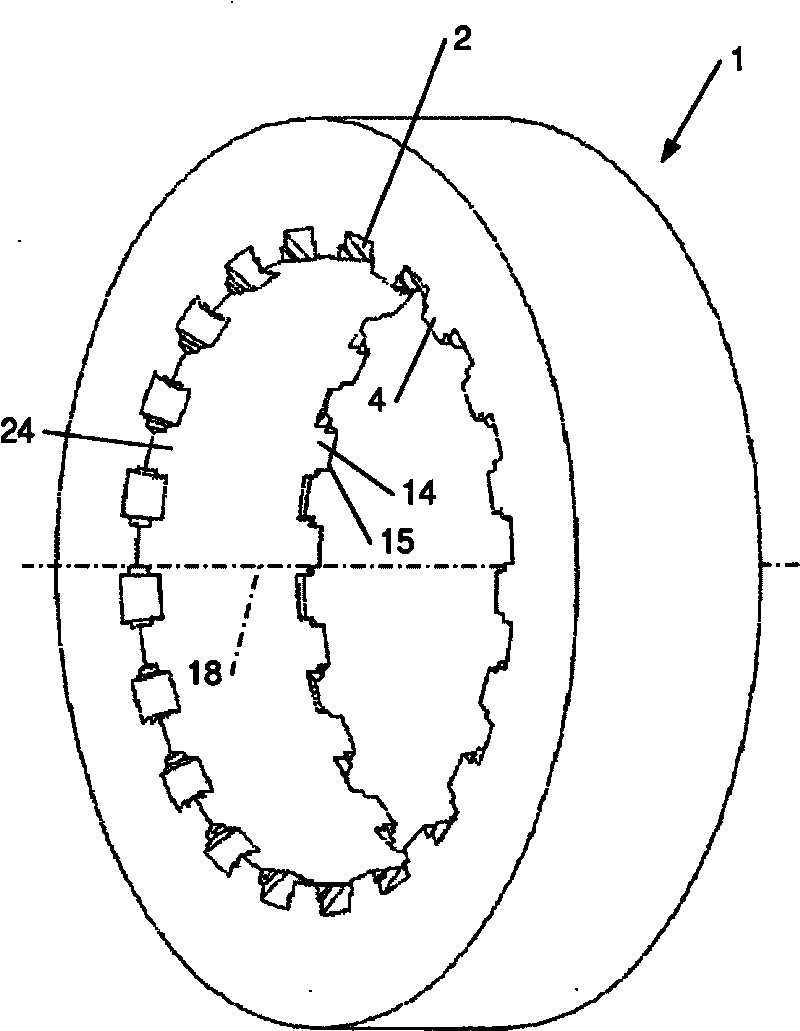

The present invention comprises a percutaneously implantable replacement heart valve device and a method of making same. The replacement heart valve device comprises a stent member made of stainless steel or self-expanding nitinol, a biological tissue artificial valve means disposed within the inner space of the stent member. An implantation and delivery system having a central part which consists of a flexible hollow tube catheter that allows a metallic wire guide to be advanced inside it. The endovascular stented-valve is created from a glutaraldehyde fixed biocompatible tissue material which has two or three cusps that open distally to permit unidirectional blood flow. The present invention also comprises a novel method of making a replacement heart valve by taking a fragment of biocompatible tissue material and treating, drying, folding and rehydrating it in such a way that forms a two- or three-leaflet / cusp valve with the leaflets / cusps formed by folding, thereby eliminating the extent of suturing required, providing improved durability and function.

Owner:COLIBRI HEART VALVE

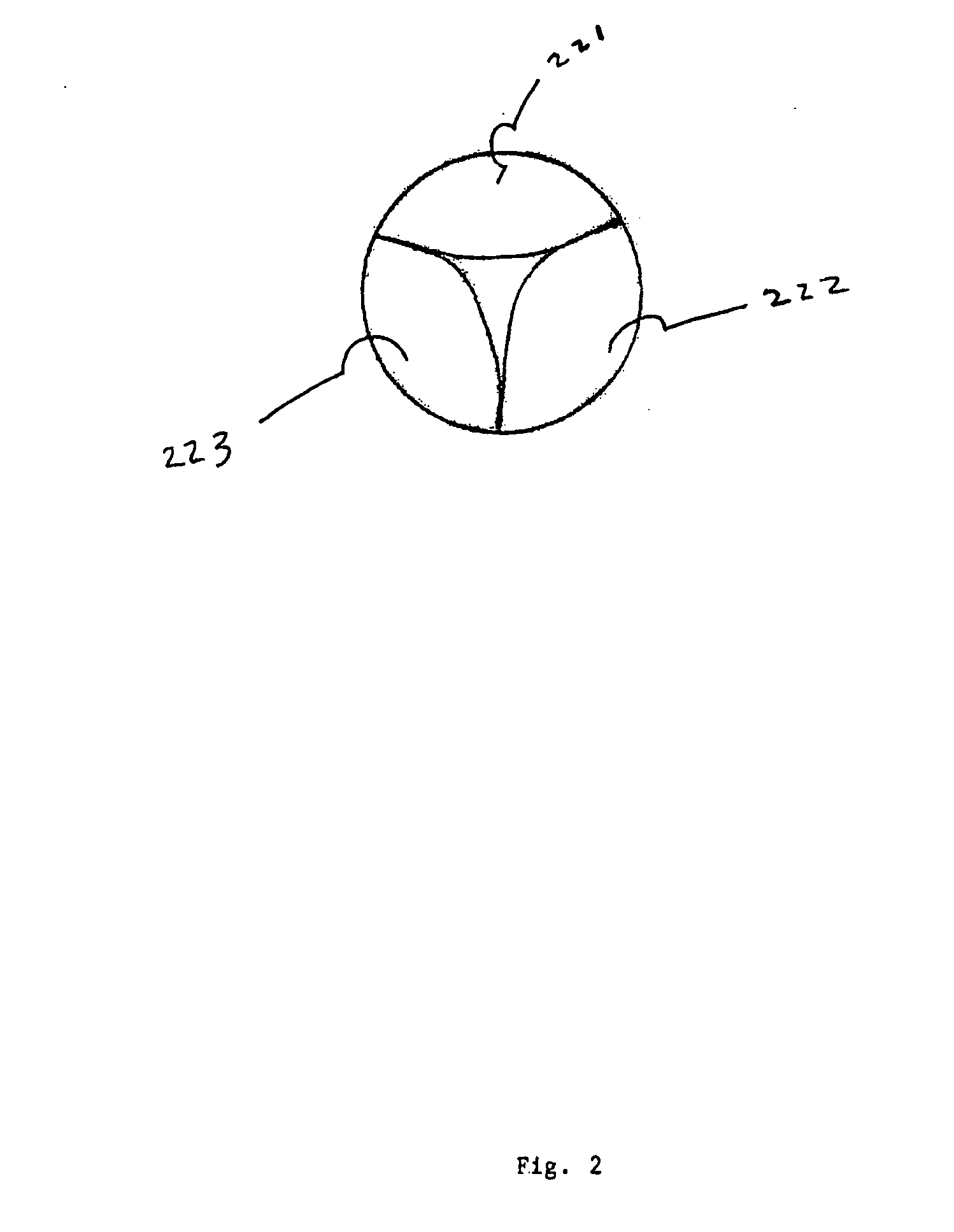

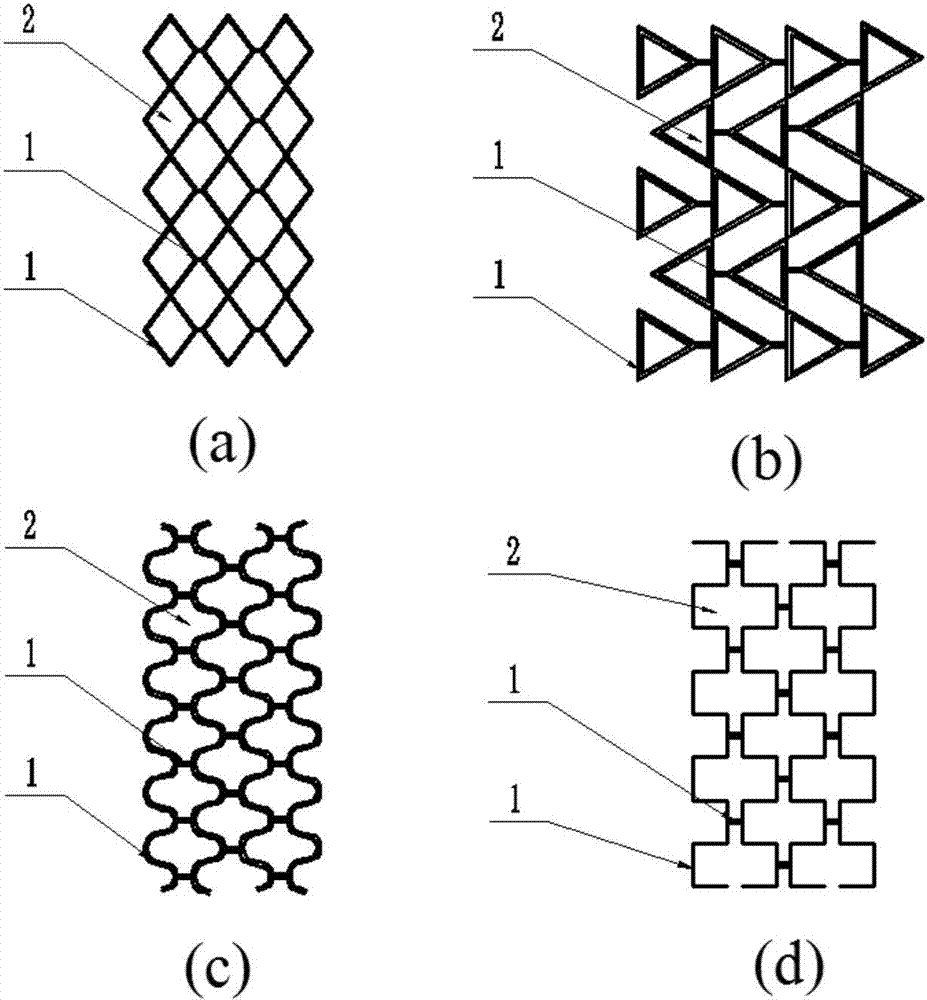

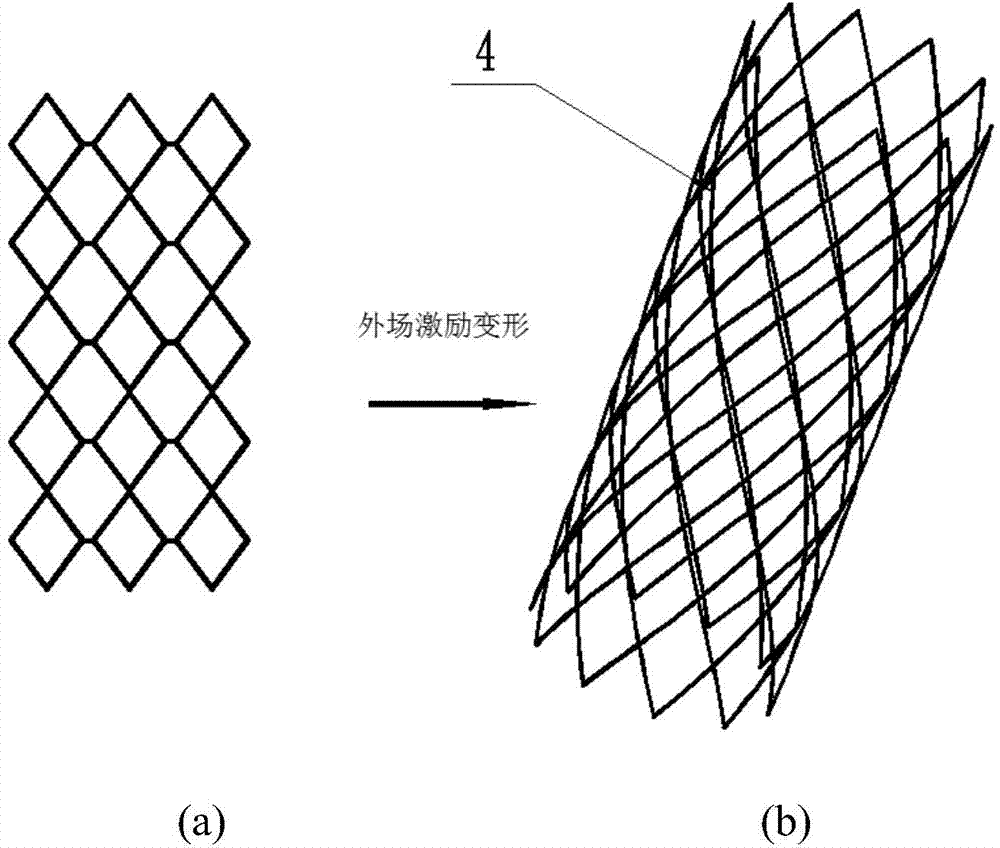

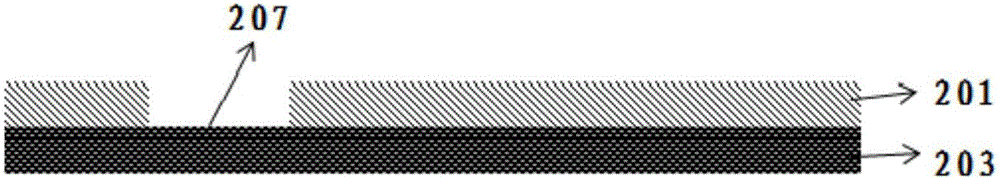

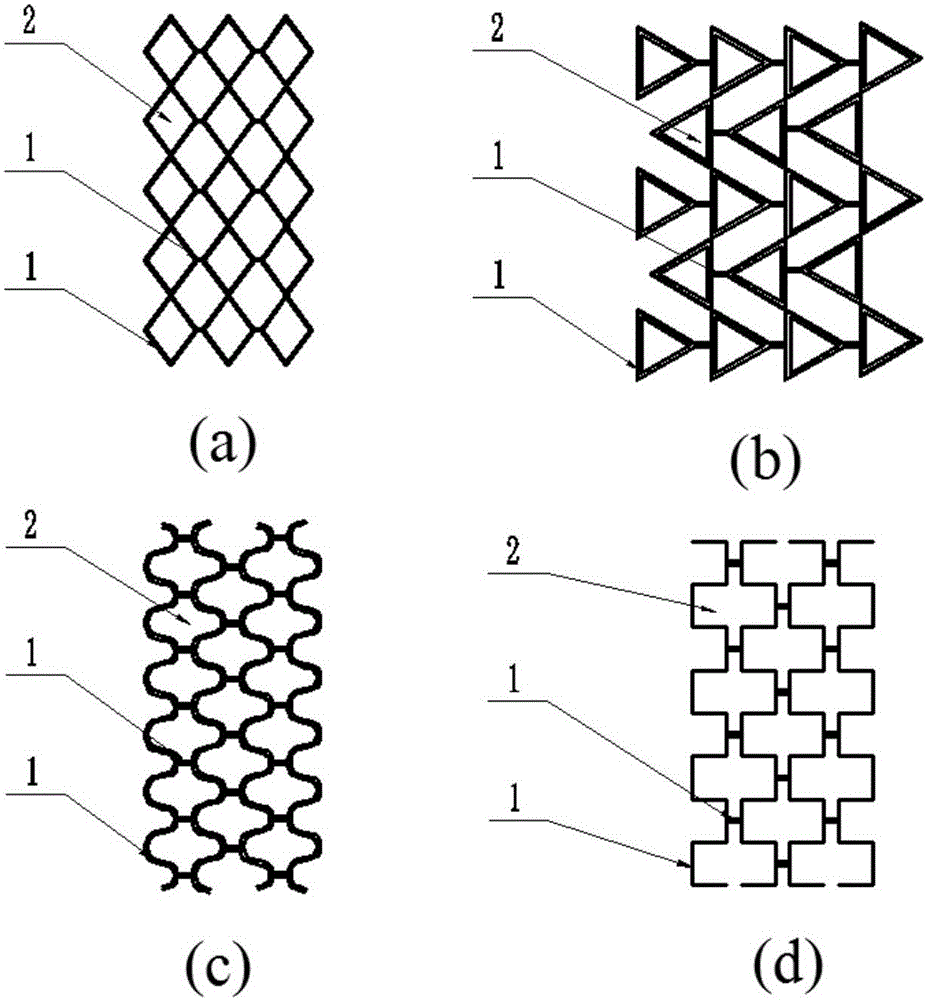

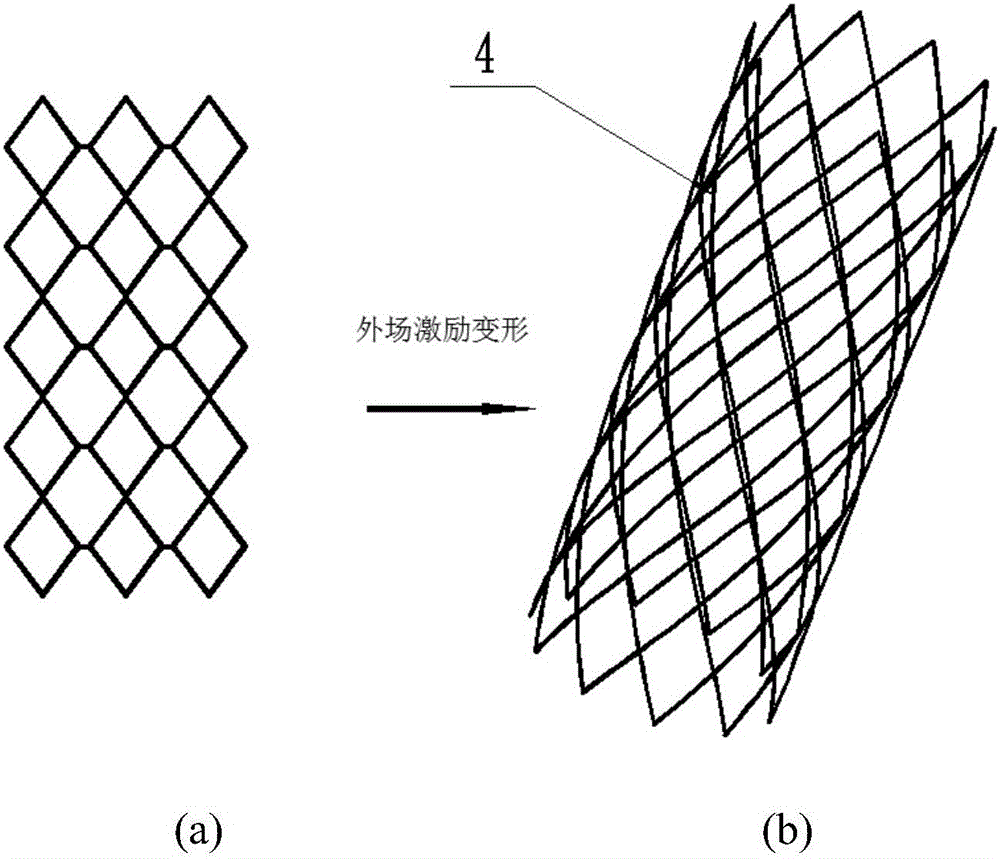

Method for forming artificial vascular stent through 4D printing

ActiveCN104116578AFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

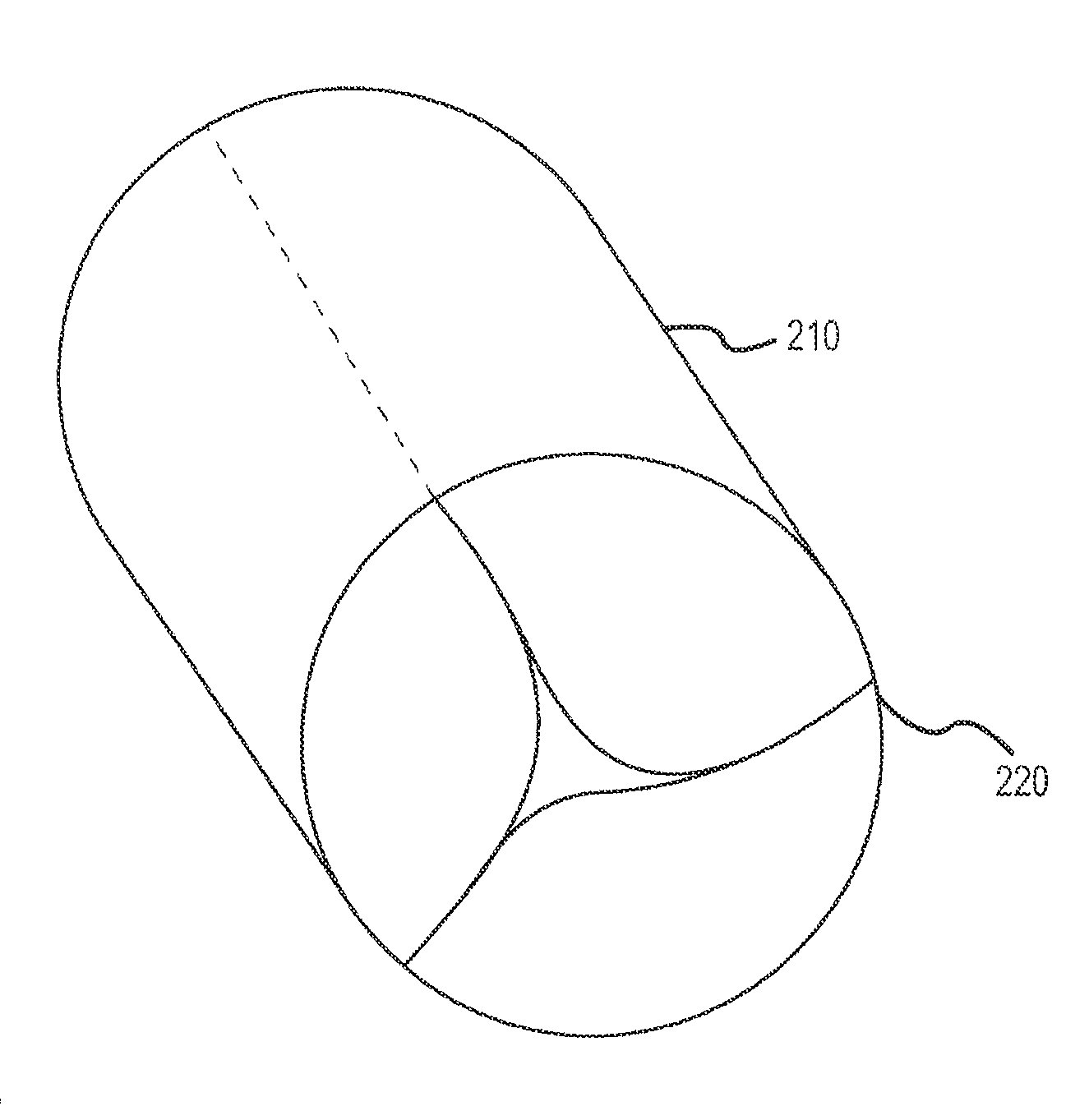

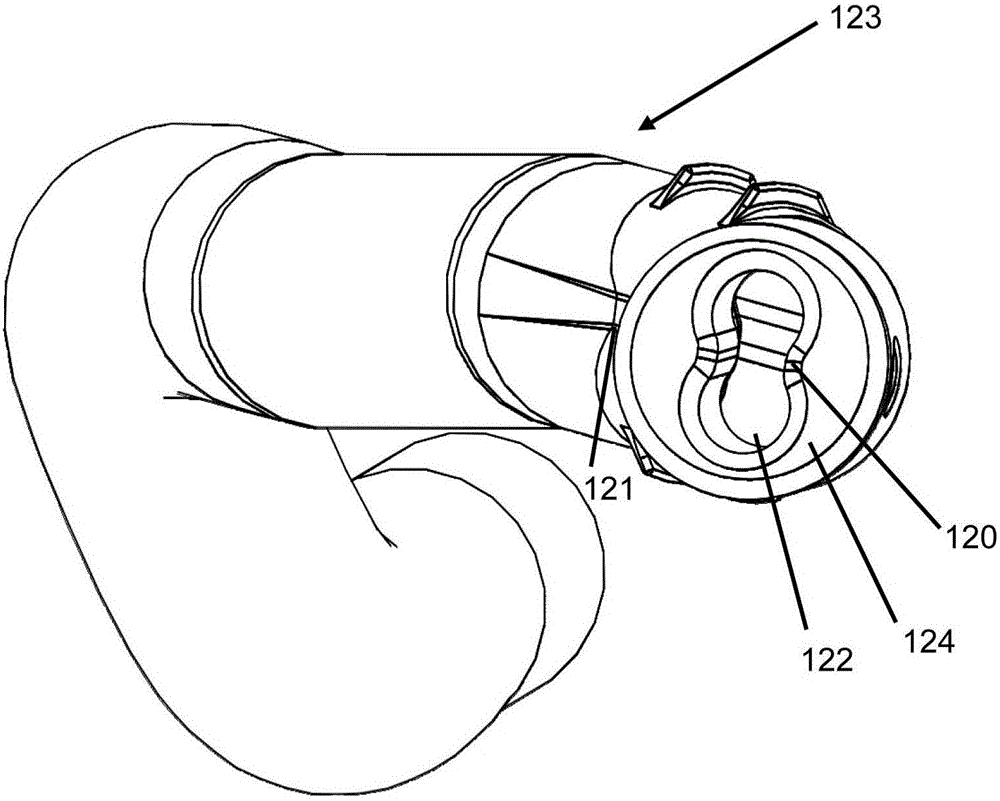

Percutaneously implantable replacement heart valve device and method of making same

InactiveUS20090030511A1Improve the immunityReduced risk of tearingStentsBalloon catheterTissue materialVALVE PORT

A method of making a replacement heart valve device whereby a fragment of biocompatible tissue material is treated and soaked in one or more alcohol solutions and a solution of gluteraldehyde. The dried biocompatible tissue material is folded and rehydrated in such a way that forms a two- or three-leaflet / cusp valve without affixing of separate cusps or leaflets or cutting slits into the biocompatible tissue material to form the cusps or leaflets. After the biocompatible tissue material is folded, it is affixed at one or more points on the outer surface to the inner cavity or a stent.

Owner:COLIBRI HEART VALVE

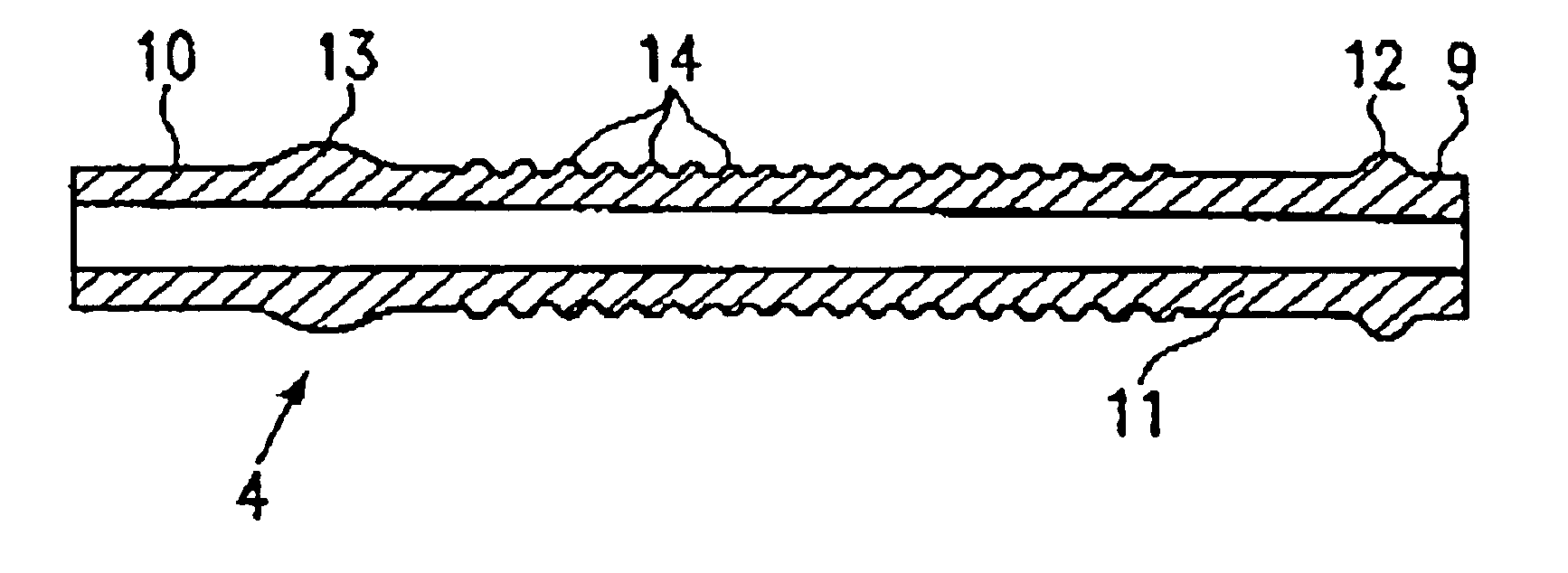

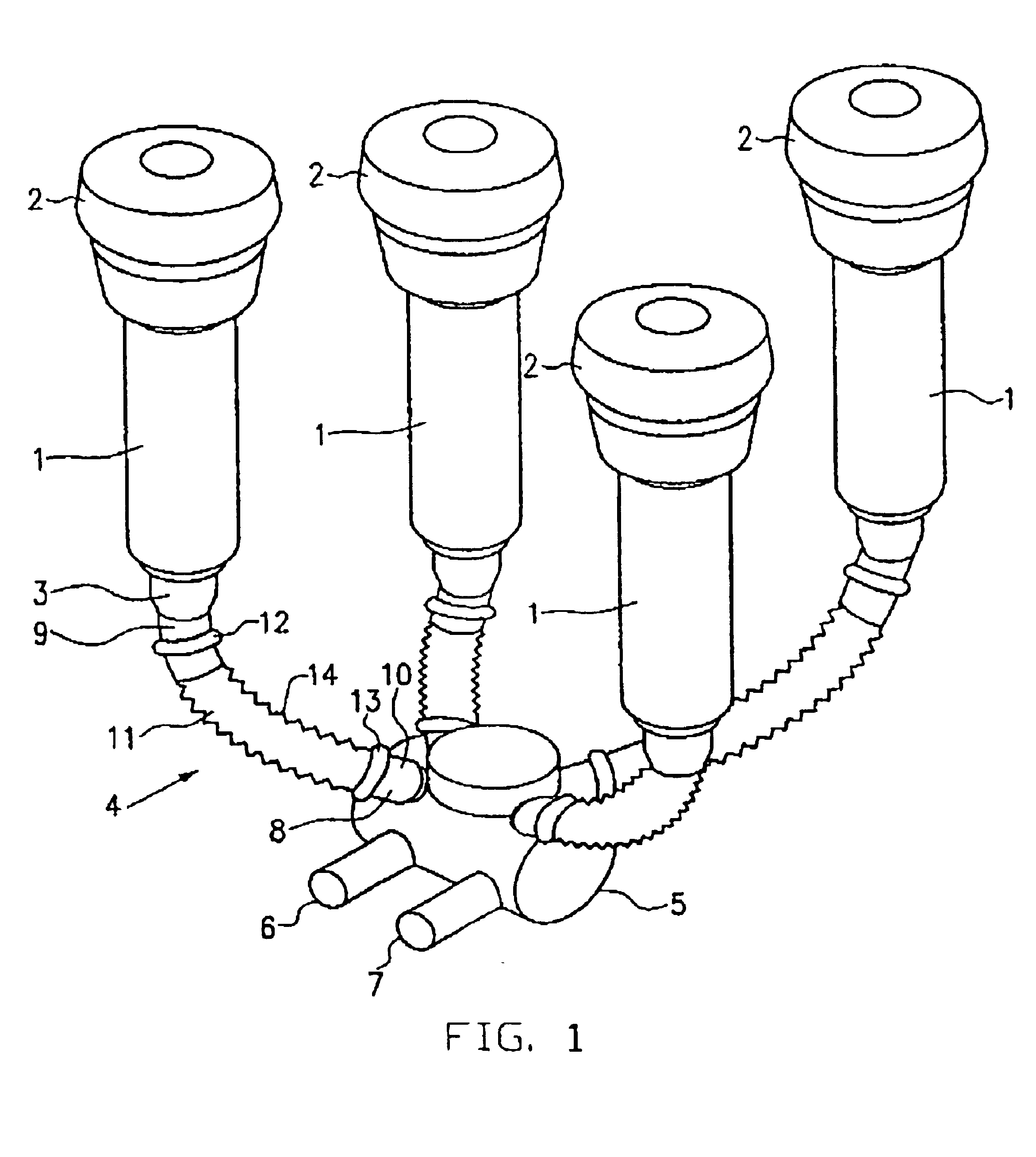

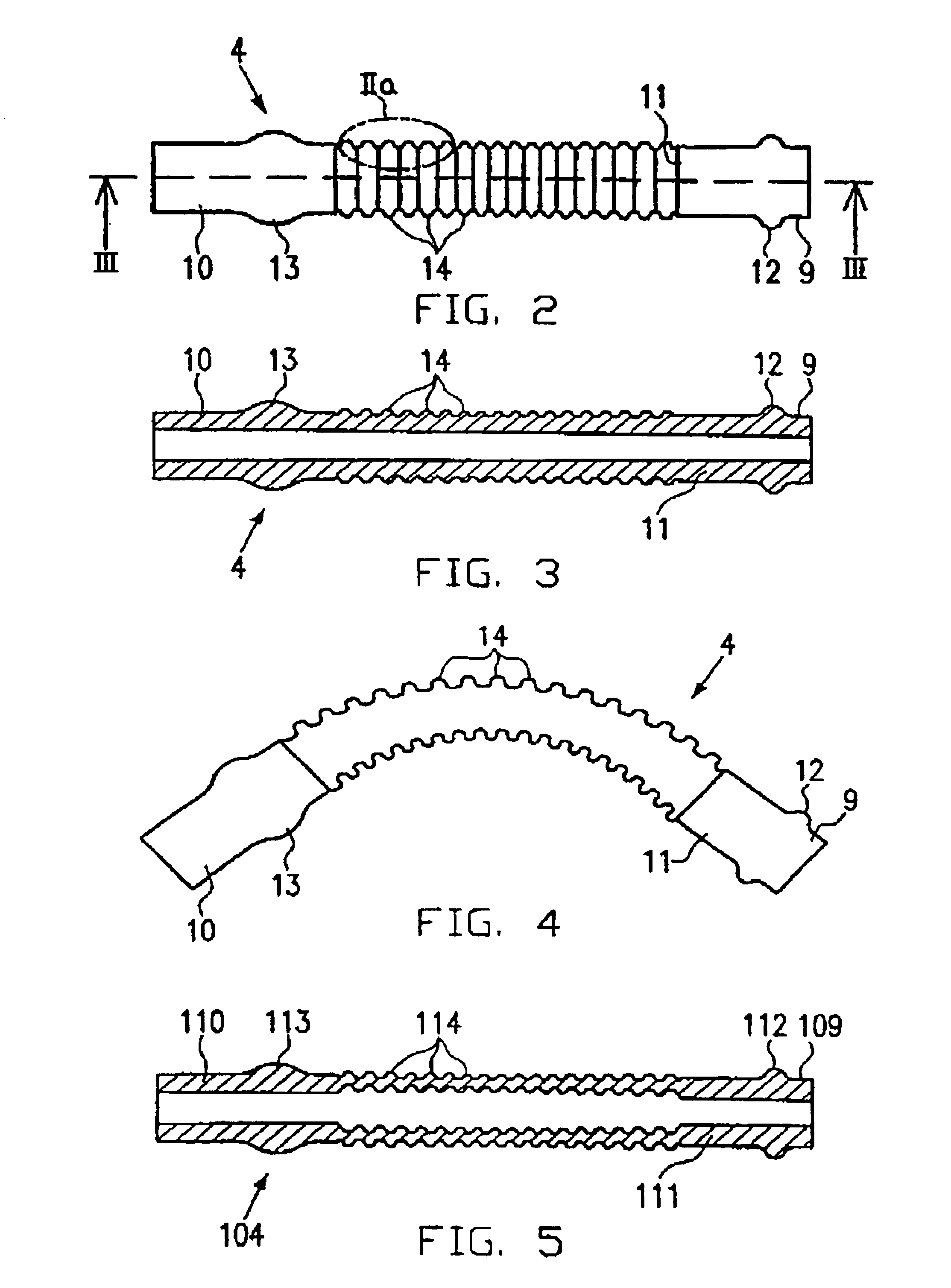

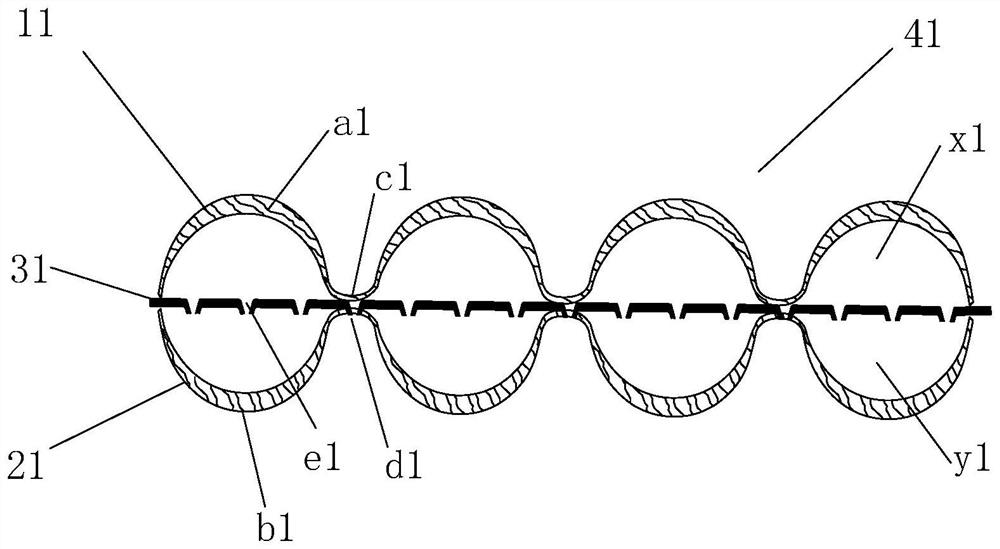

Flexible milk hose for an automatic milking plant

InactiveUS6895890B1Guaranteed mechanical stabilityUniform materialFlexible pipesMilking devicesMechanical stabilityAutomatic milking

An automatic milking plant is provided with a short milk hose, which, due to spaced-apart elevations in its center piece, has sufficient mechanical stability vis-a-vis pressure differences as well as a high flexibility. The use of the short milk hose according to the present invention leads to a reduction of the mechanical strain on the udder and thus also reduces irritations of the animal to be milked.

Owner:MAIER JR JAKOB

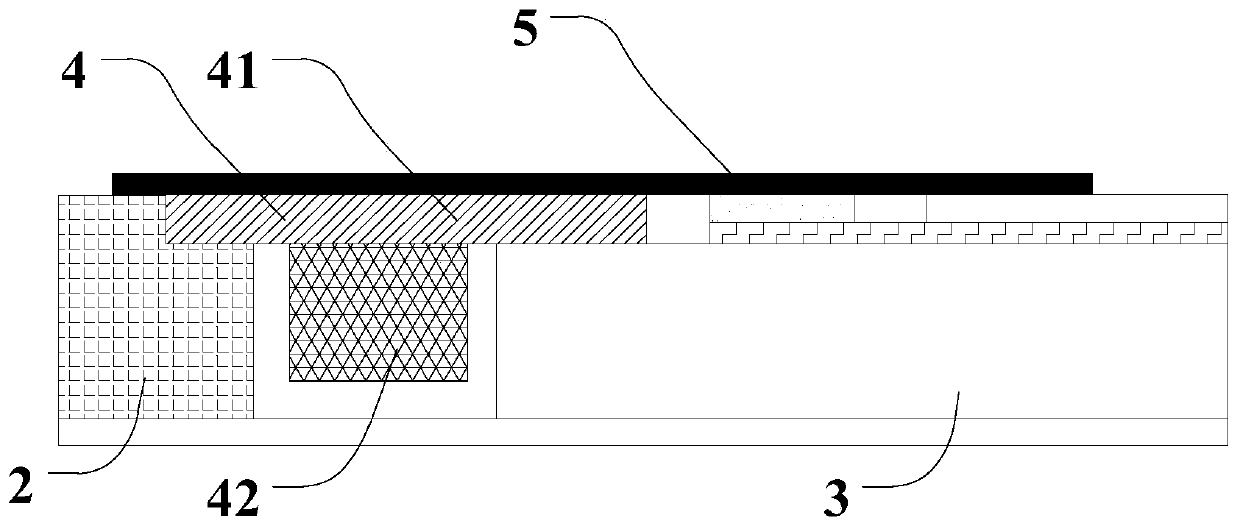

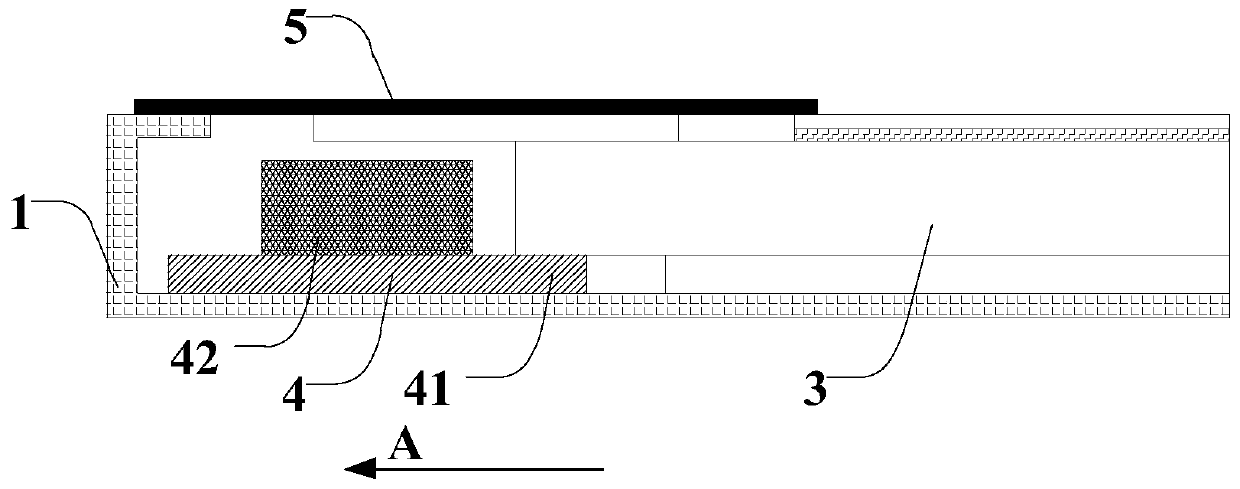

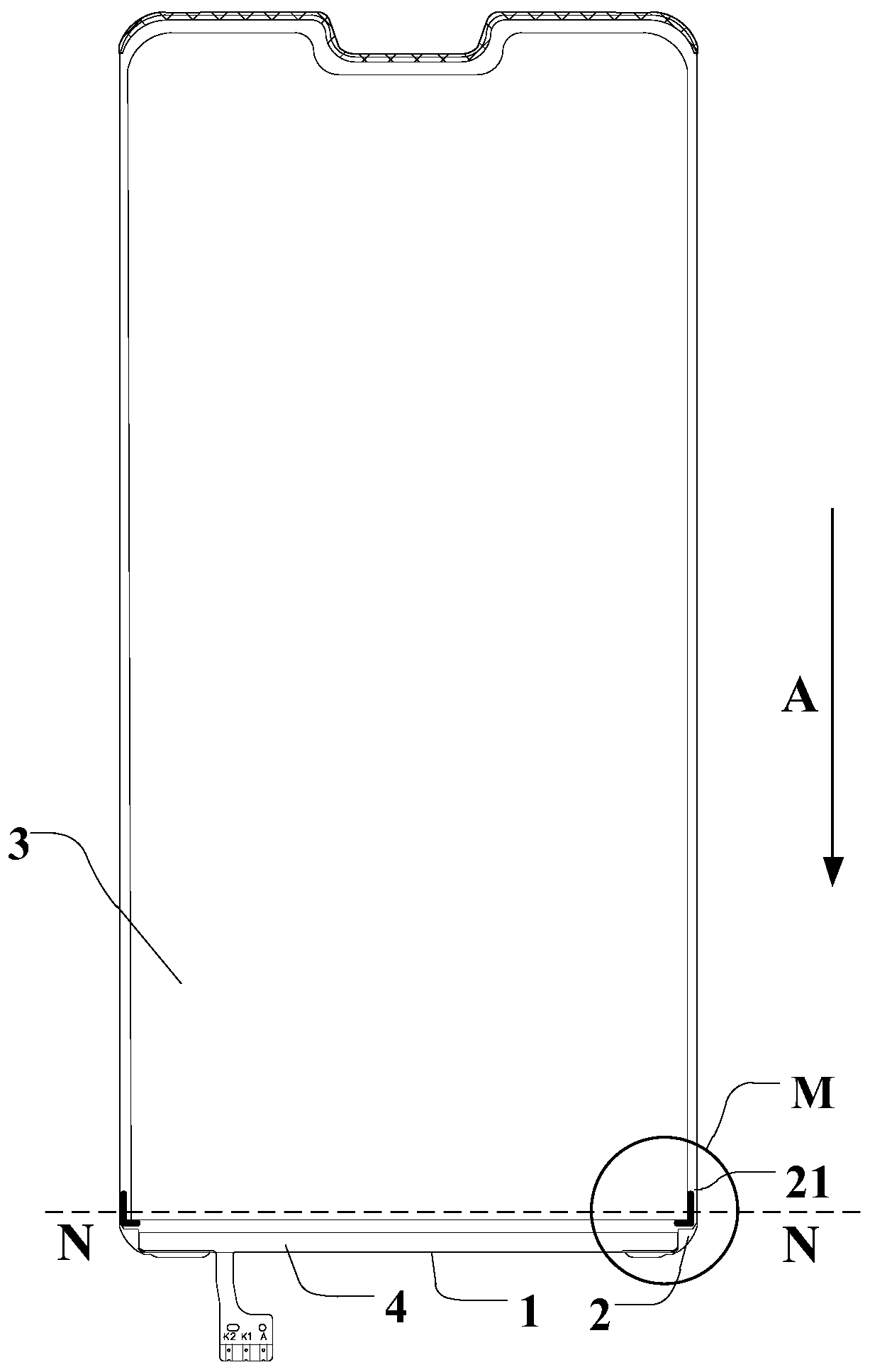

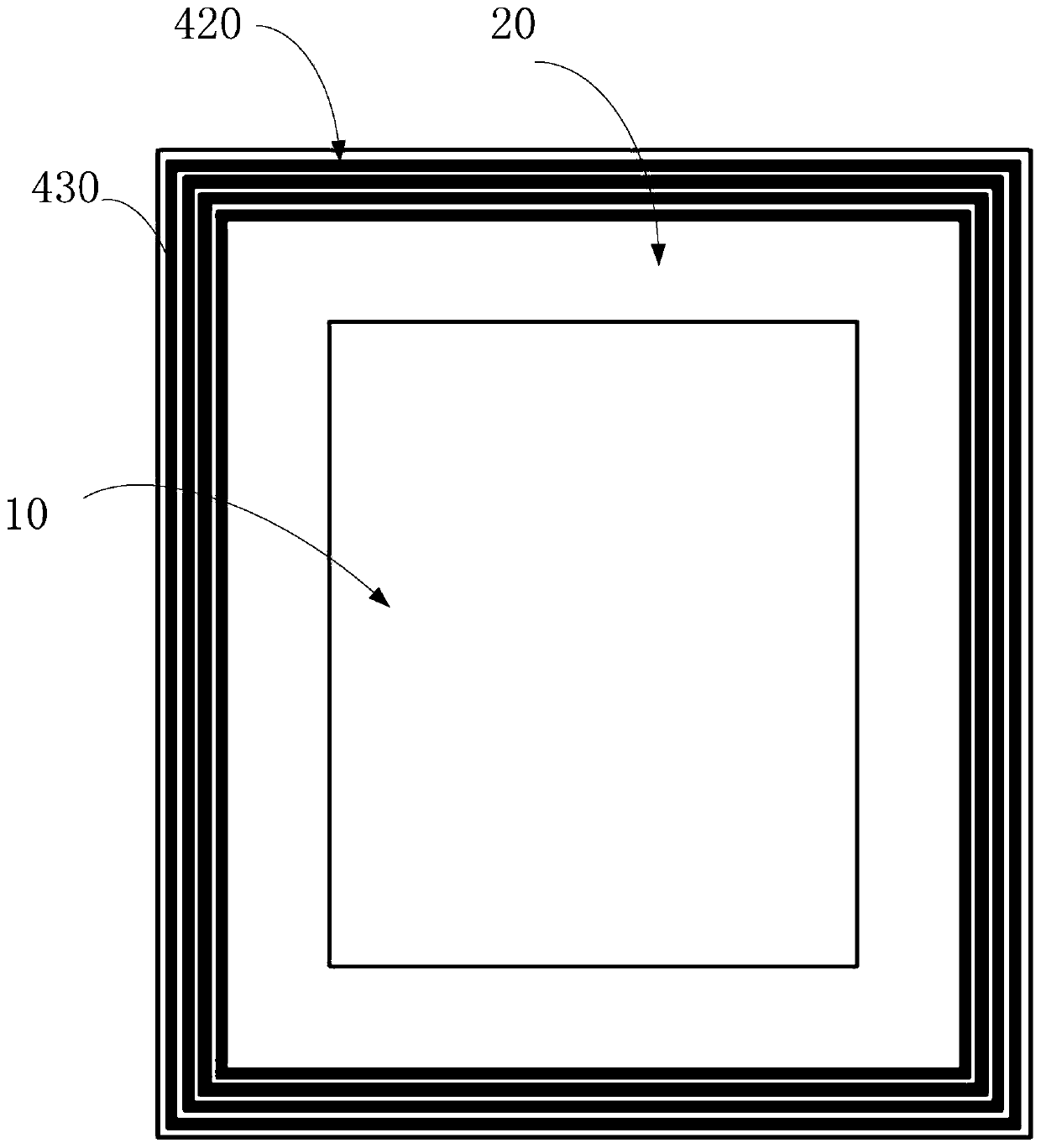

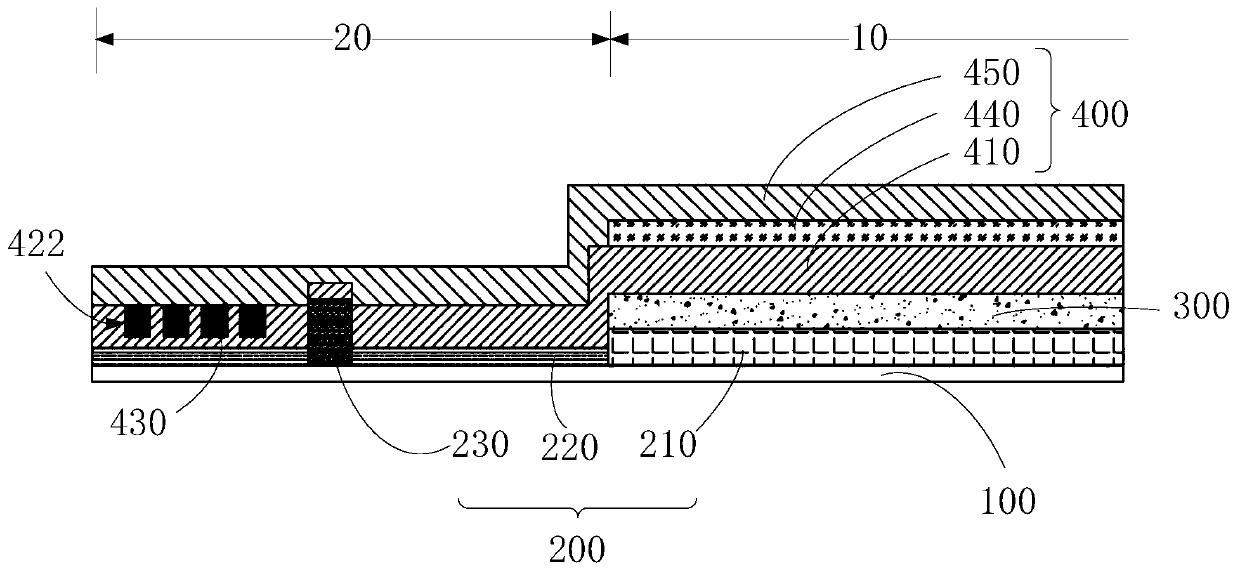

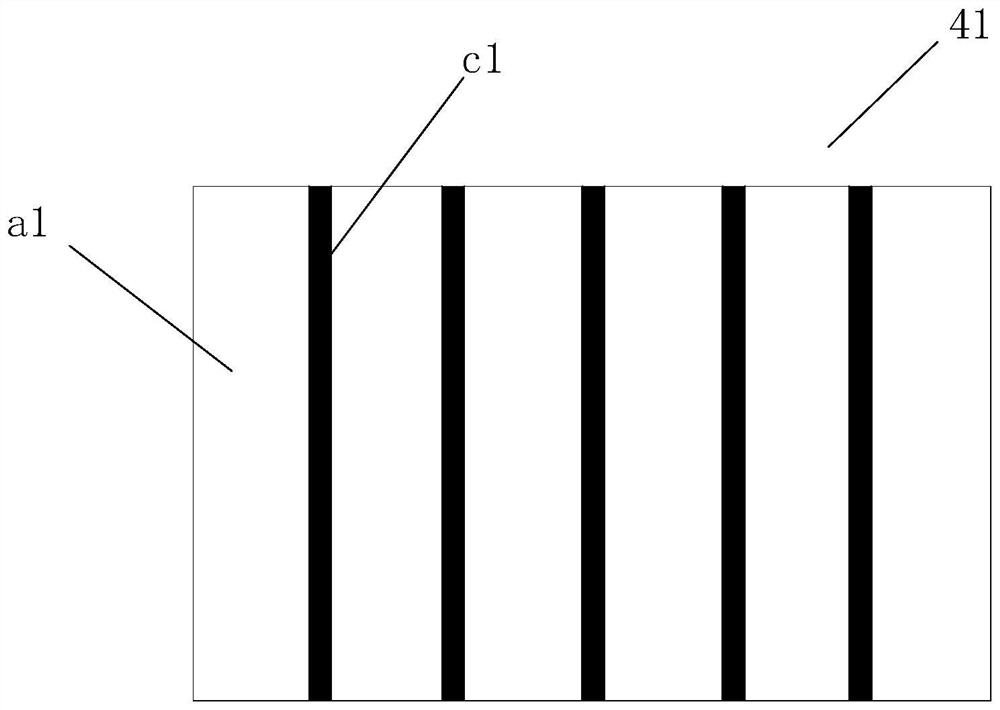

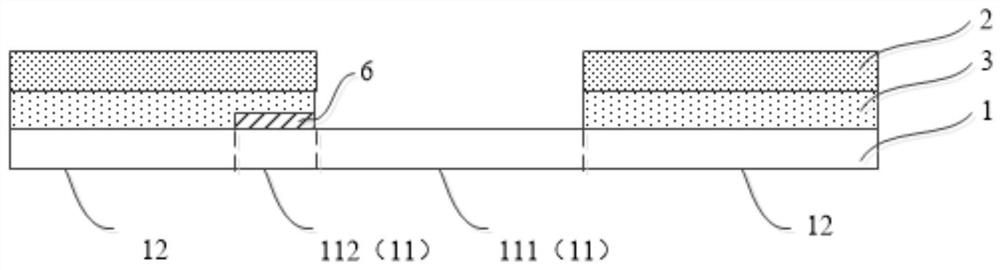

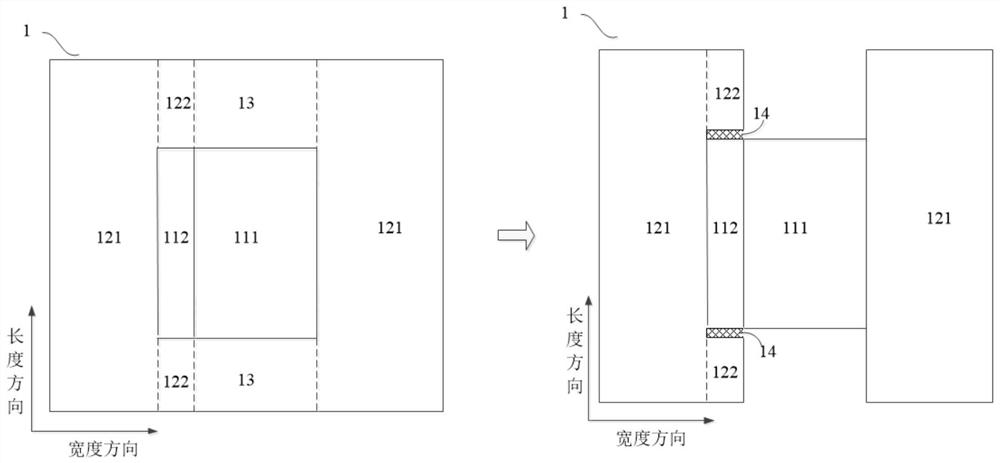

Backlight module and display device

PendingCN110161753AHigh structural reliabilityExtended service lifeOptical light guidesNon-linear opticsRelative displacementLight guide

The invention discloses a backlight module and a display device. The backlight module comprises a bottom plate, a side frame and a light guide plate, wherein the bottom plate and the side frame form an accommodating space, the light guide plate is arranged in the accommodating space and comprises a corner part positioned in a corner area of the light guide plate, and at least one buffer structureis arranged between the corner part and the side frame. The buffer structure can reduce the relative displacement generated between the light guide plate and a metal frame when the light guide plate is impacted, thereby reducing the impact force of the light guide plate on a light bar and the force of the light guide plate driving the light bar circuit board bonded on the light guide plate to move, reducing the shearing force to which the lamp strip circuit board is subjected, and reducing the risk of tearing of the light bar. Therefore, the backlight module and the display device can improvethe reliability of the backlight module and the display effect of the display device.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

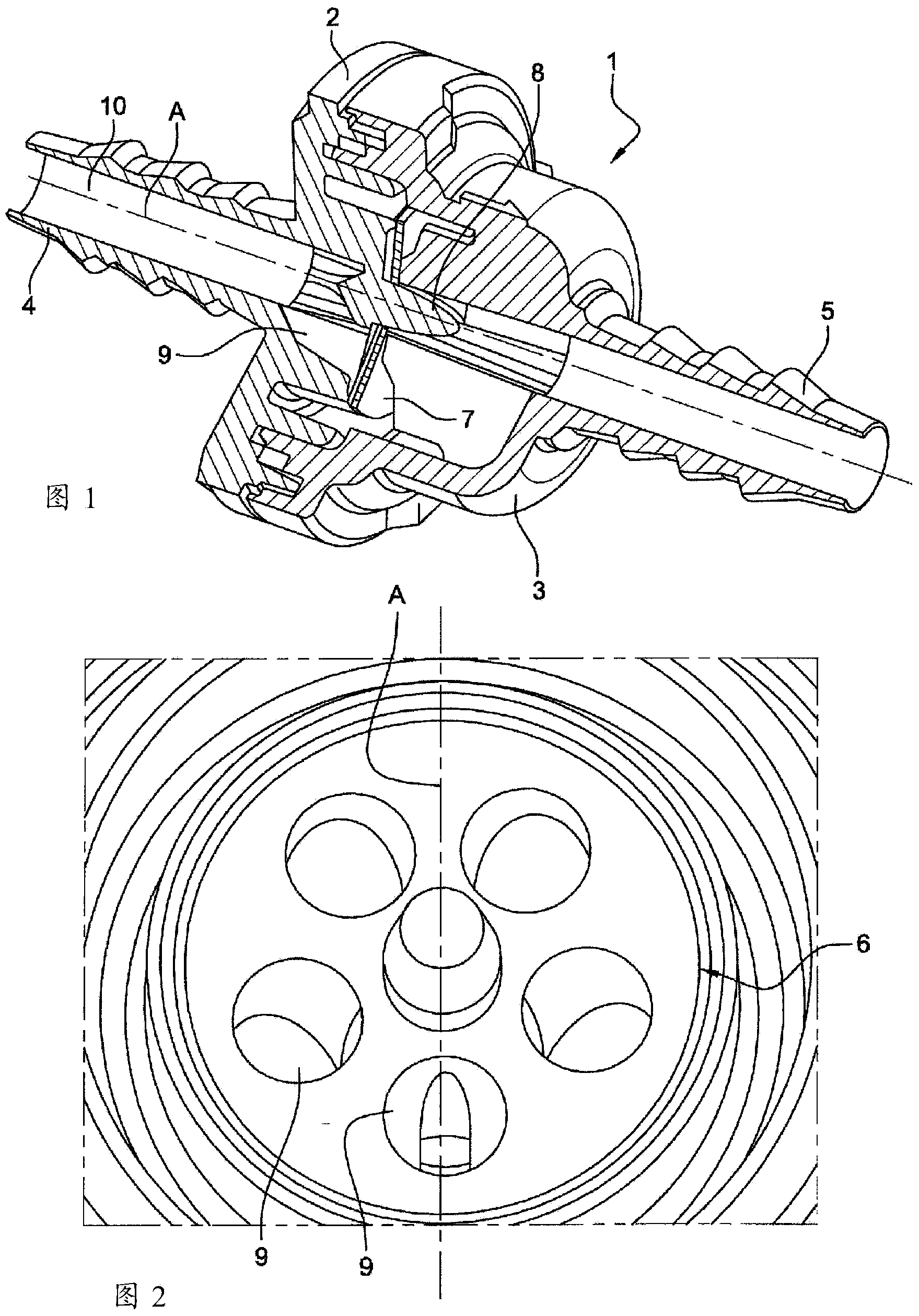

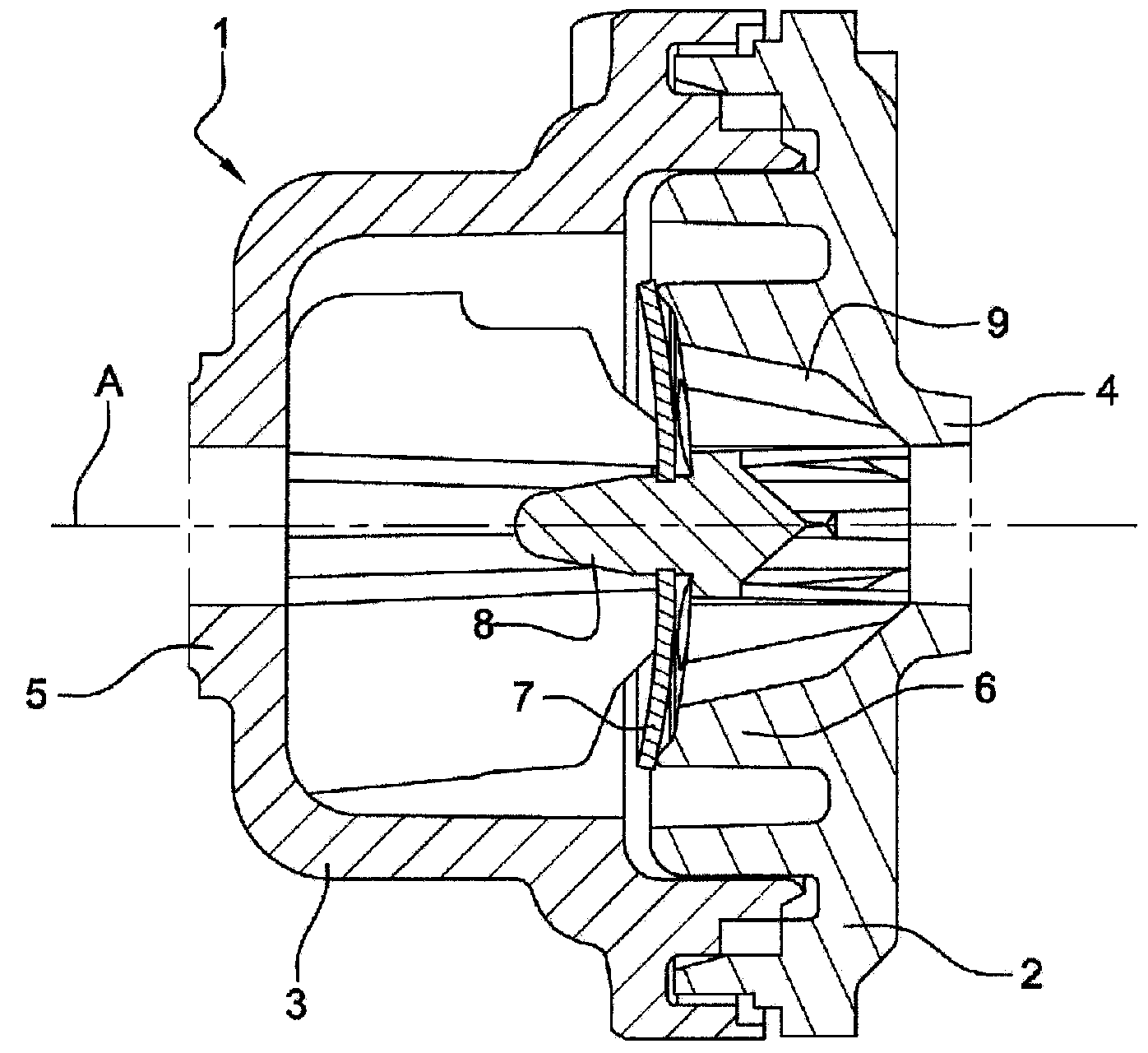

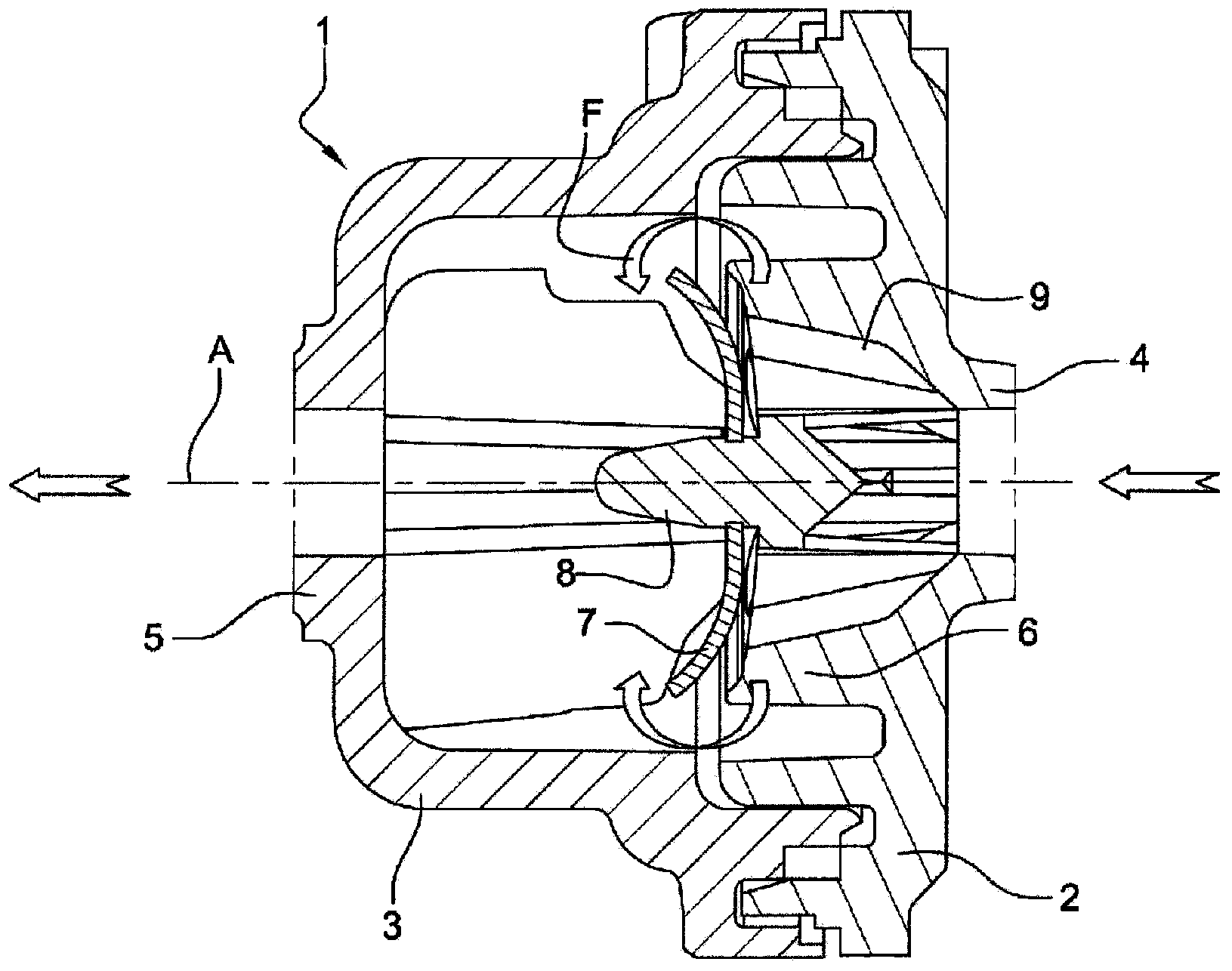

Diaphragm check valve

ActiveCN104114922AIncrease channel cross sectionReduce the useful bearing surfaceCheck valvesThin material handlingDiaphragm valveDiaphragm check

The invention relates to a valve including a body, a seat (6), and a flexible diaphragm capable of being urged against the seat (6) while sealing the passage openings (9) of said seat. Each of the passage openings (9) has an oblong shape and is arranged with the largest dimensions thereof oriented in radial directions of the seat (6). The invention can be used as a check valve or flow control valve for gaseous fluids, in particular in the automotive field.

Owner:AKWEL SA

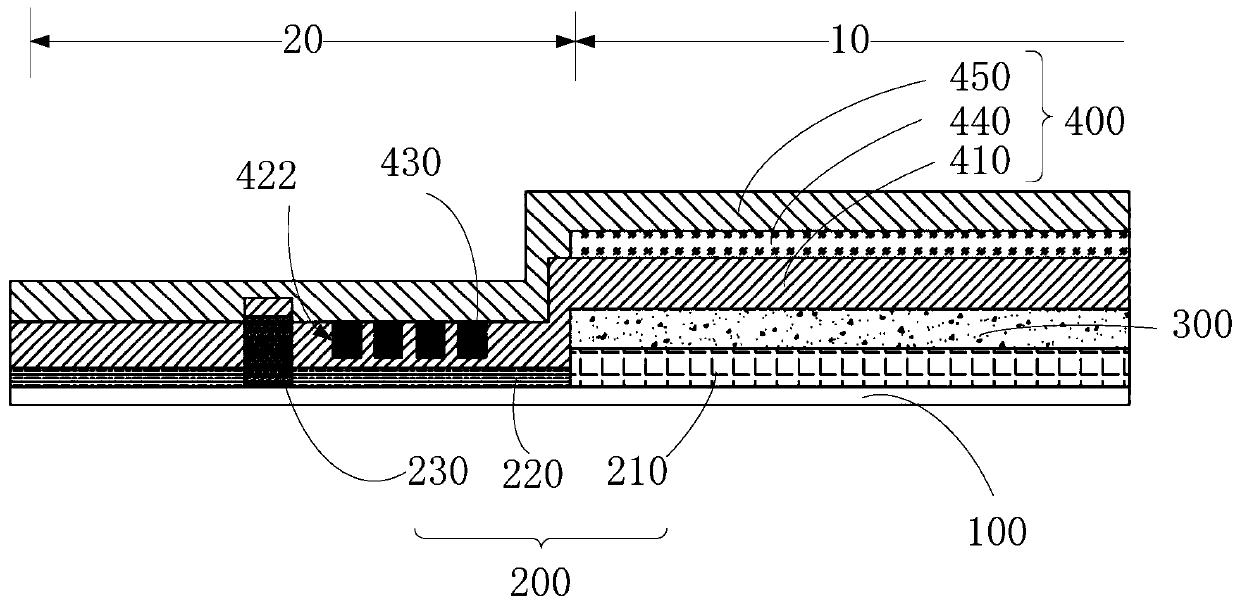

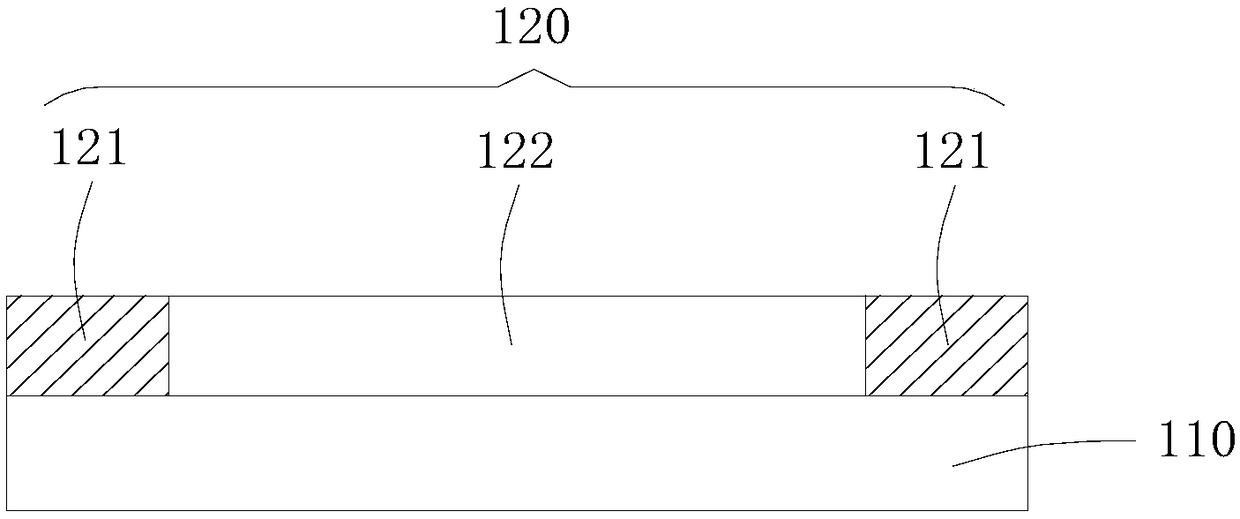

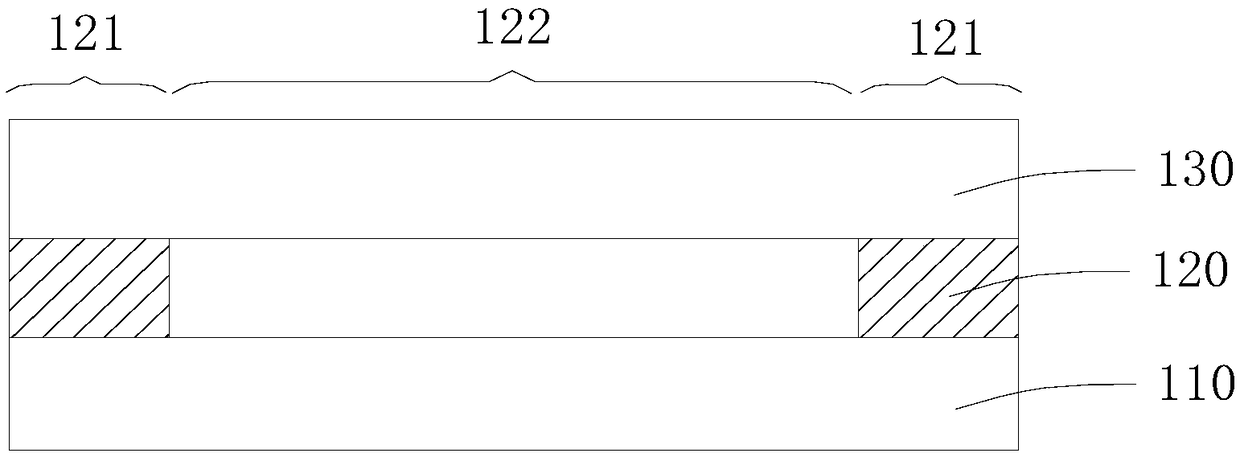

Display panel and manufacturing method thereof

InactiveCN111129347AImprove packaging effectReduced risk of tearingSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneMechanical engineering

The invention discloses a display panel and a manufacturing method thereof. According to the display panel, a hollow part is arranged on a first inorganic packaging layer, a structure for filling andpackaging the anti-cracking piece in the hollow part is combined, and the stress of the packaging film of the display panel in the cutting process or the bending process is well dispersed, therefore,the tearing risk of the inorganic layer part in the packaging film is reduced, the packaging performance of the packaging film is improved, the narrow bezel of the OLED display panel is better facilitated. In addition, the manufacturing method of the display panel adopts a mature process for manufacturing the hollow part and the packaging anti-cracking piece, and the manufacturing method is suitable for batch manufacturing.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

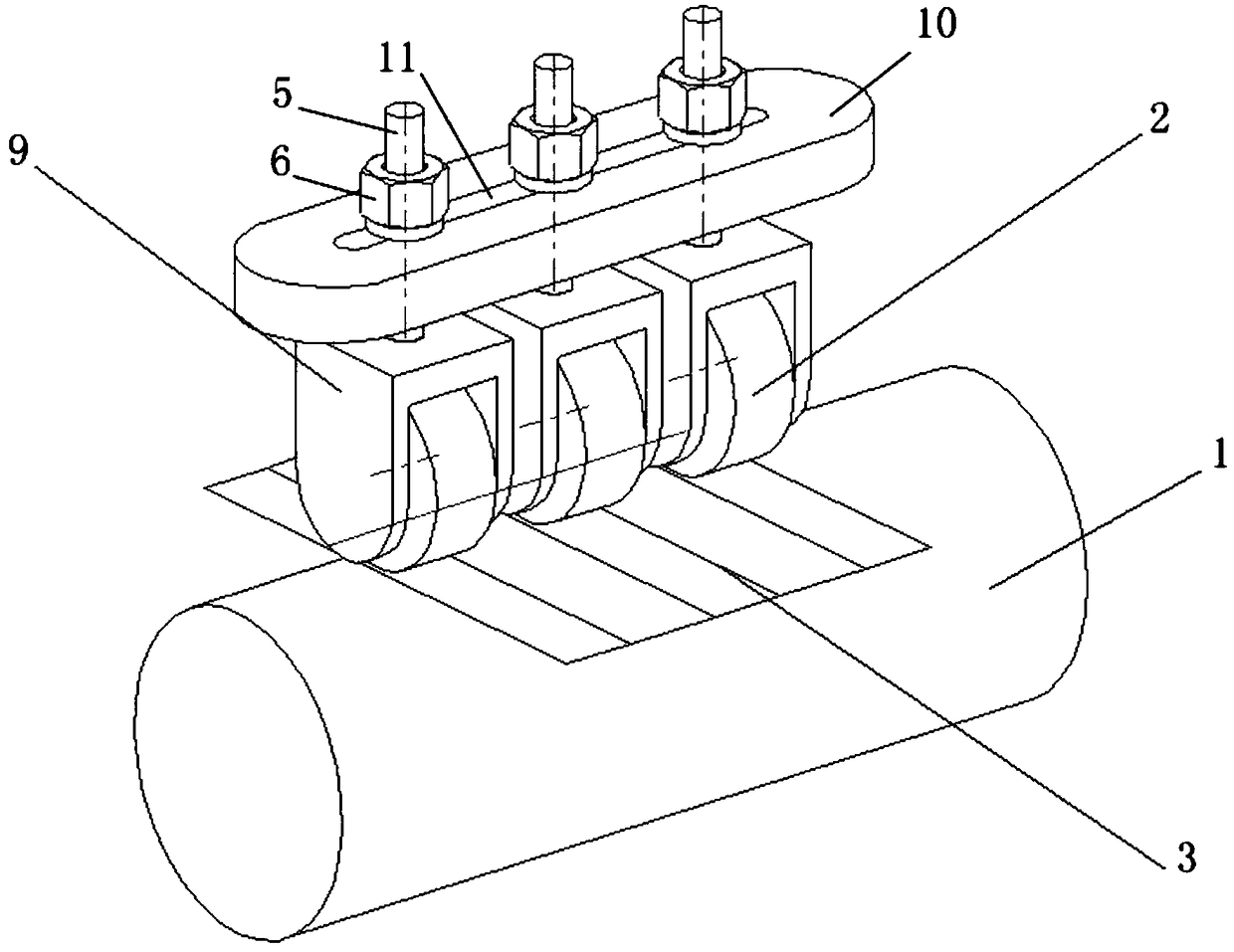

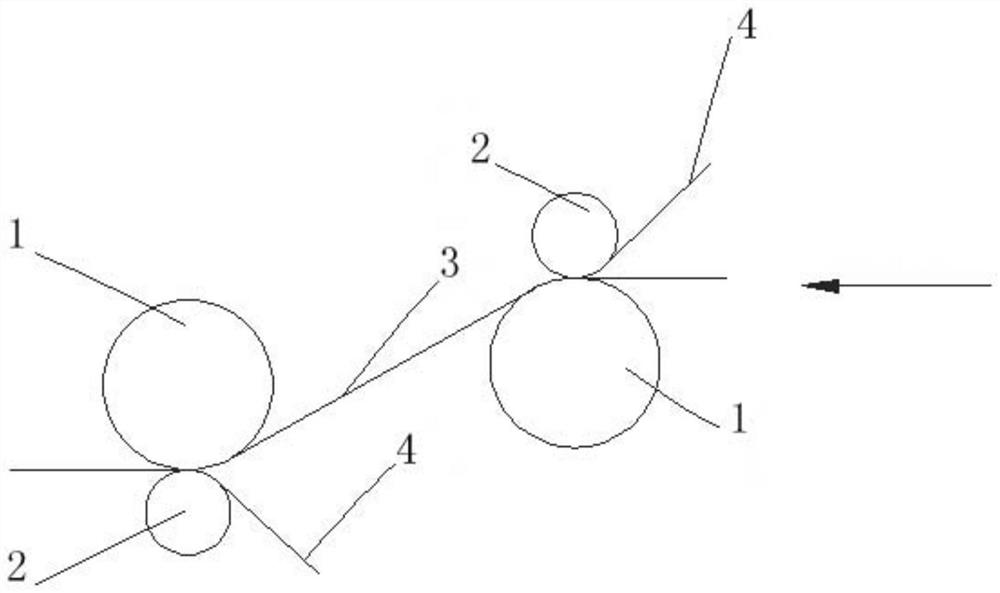

A lithium battery electrode sheet roll wrinkle prevention device and method

ActiveCN109037589AEasy rolling operationImprove tear resistanceElectrode rolling/calenderingWrinkle skinEngineering

The invention provides a lithium battery electrode sheet anti-wrinkle roller device and an anti-wrinkle method, which can simultaneously coat a pole piece AB surface, reduce the risk of pole ear tearing, simultaneously coat a pole piece AB surface, can transmit the extrusion force to the pole ear head, and increases the anti-tearing ability of the pole ear head. According to different thickness offoil, different thickness of roller and different width of foil, the depressing force of roller can be adjusted, and the bias rectifying bracket and PET film roll can be adjusted or replaced according to the need, which is convenient for different types of lithium batteries to roll.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

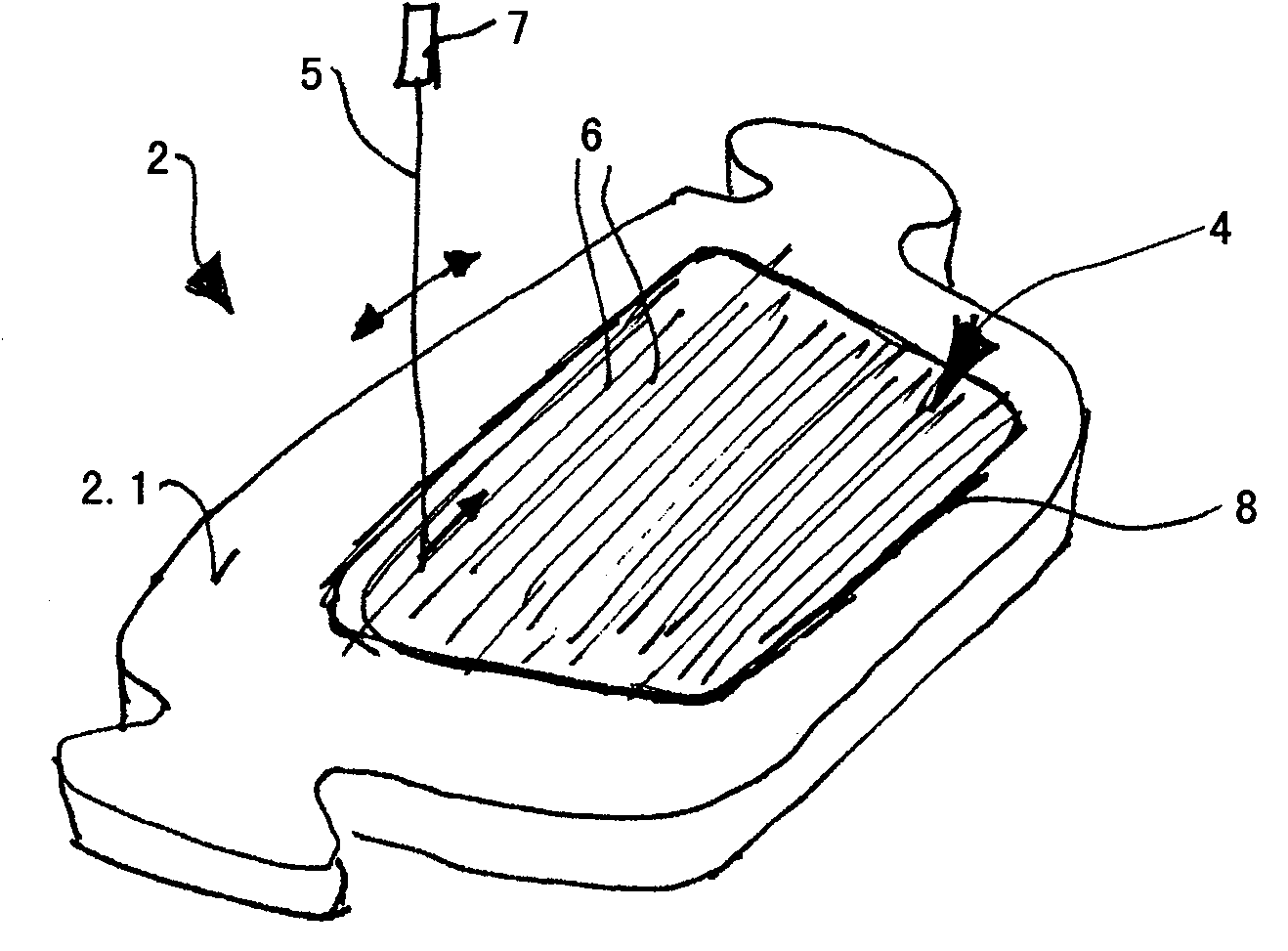

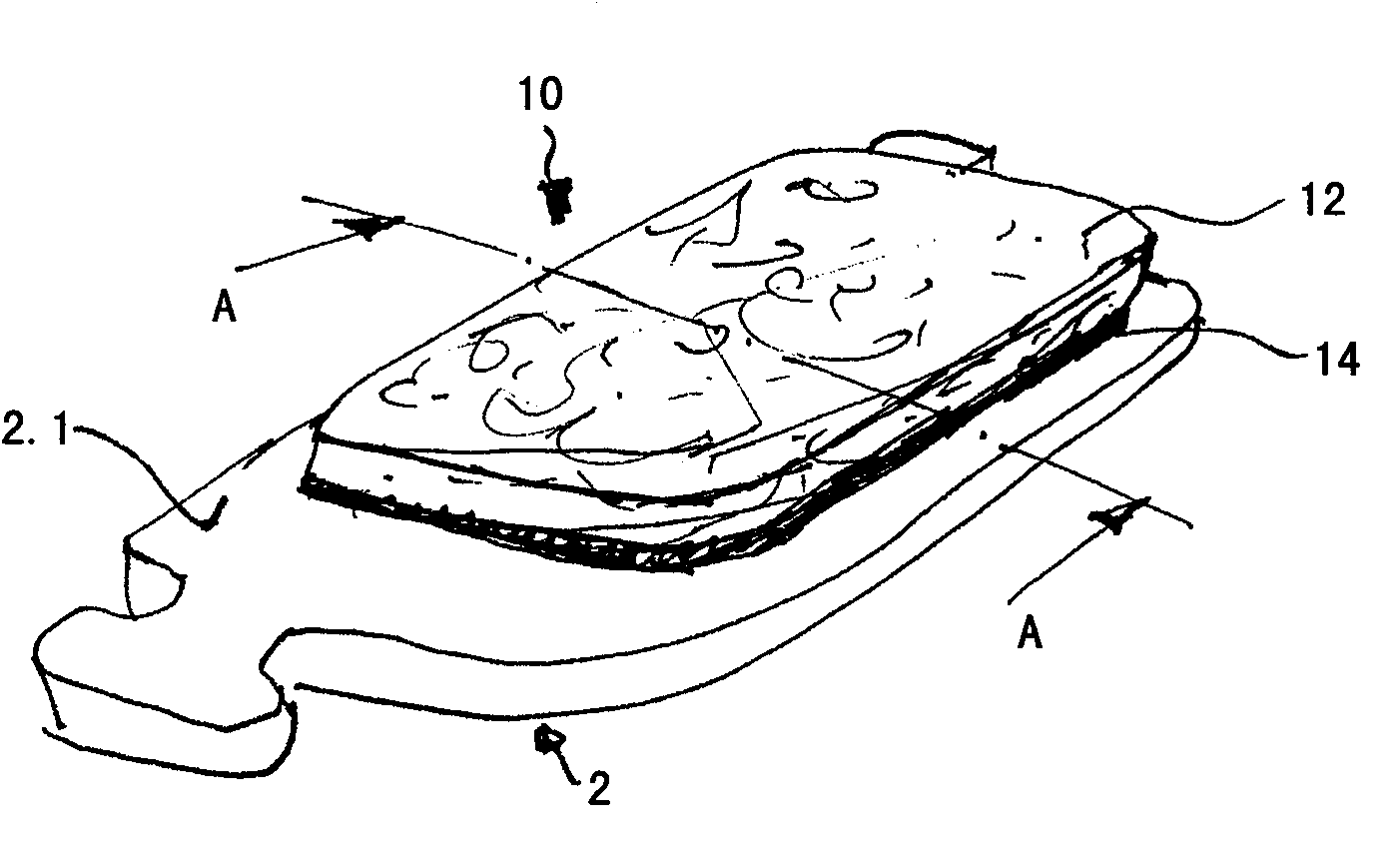

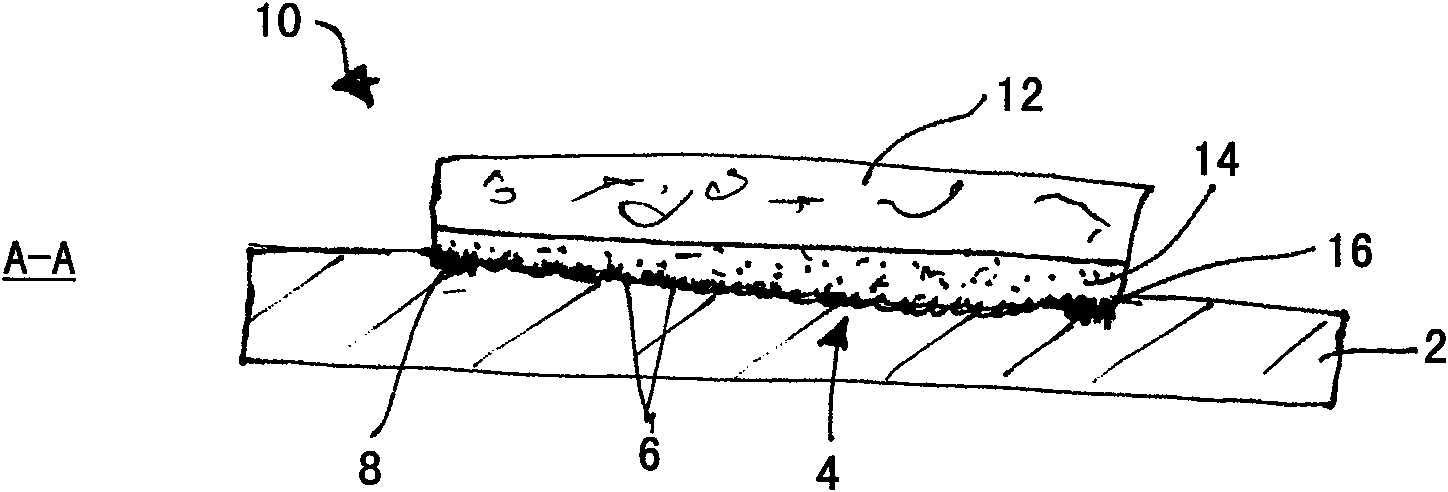

Method for processing a lining holder

ActiveCN101806329AFirmly connectedGood adhesionBraking elementsFriction liningHigh energyEngineering

The invention relates to a method for processing a lining holder (2) disposed to be used for making a brake block (10), the brake block has a friction liner (12) to be arranged on the lining holder (2), the method involves performing surface treatment of a processing area (4) of a lining support surface (2.1) by introducing a structure into the processing area by high-energy radiation. For the friction liner (12) is fixed on the lining holder (2) better, the structure differing from the rest of the processing area is processed in an edge (8) of the processing area (4).

Owner:TMD FRICTION SERVICES

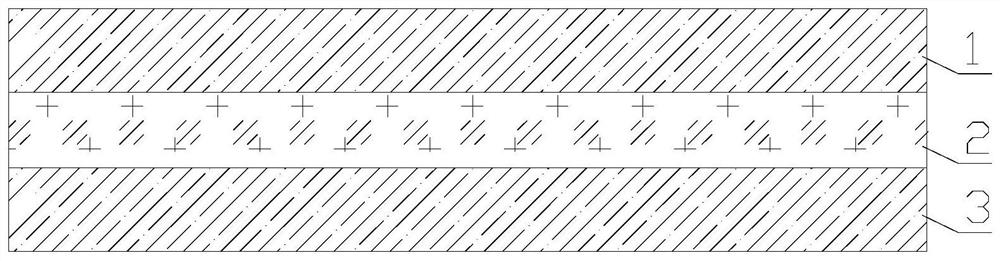

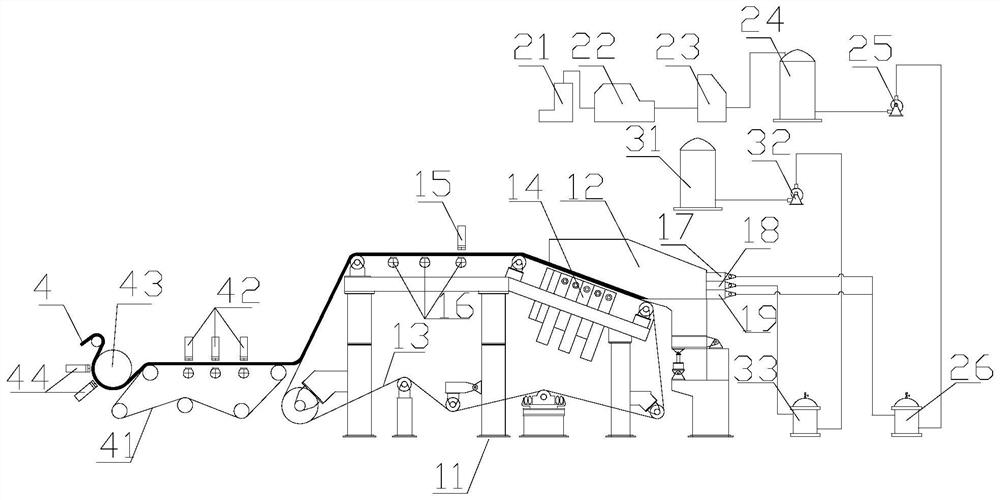

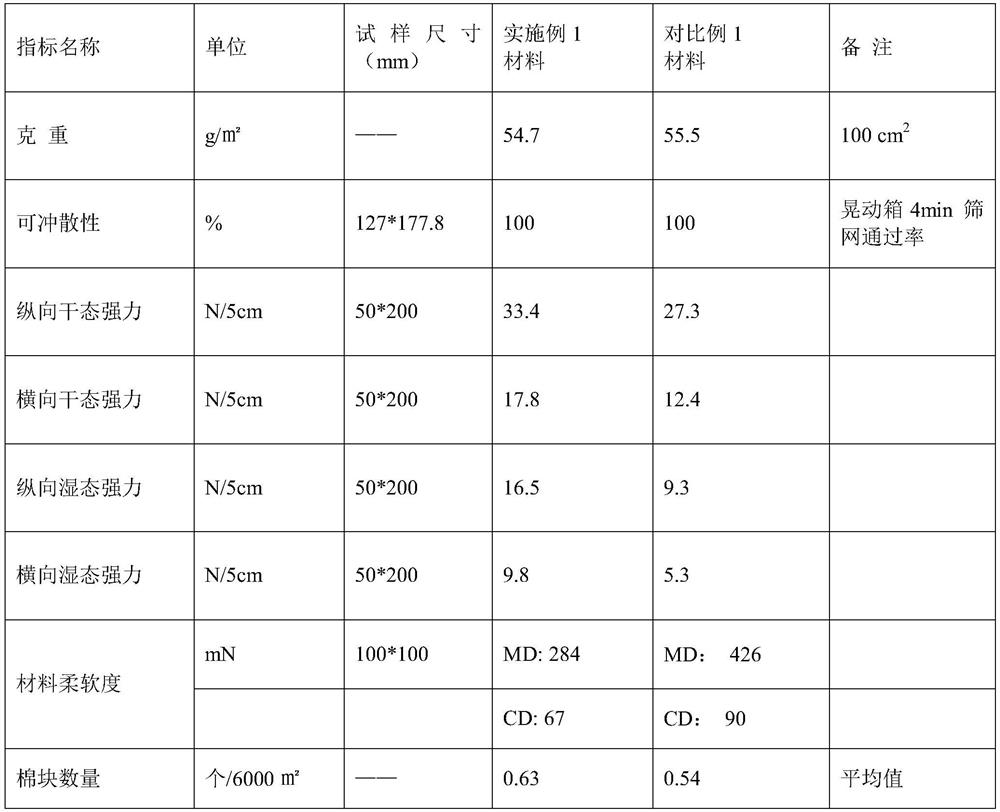

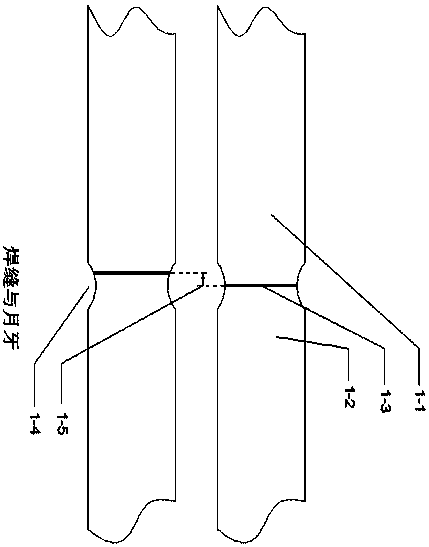

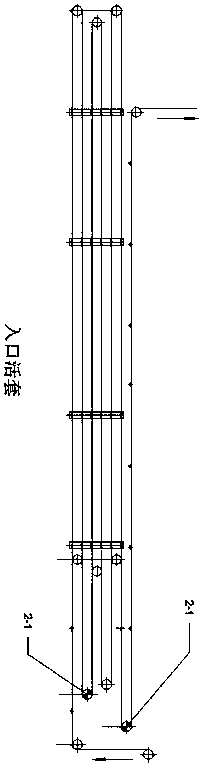

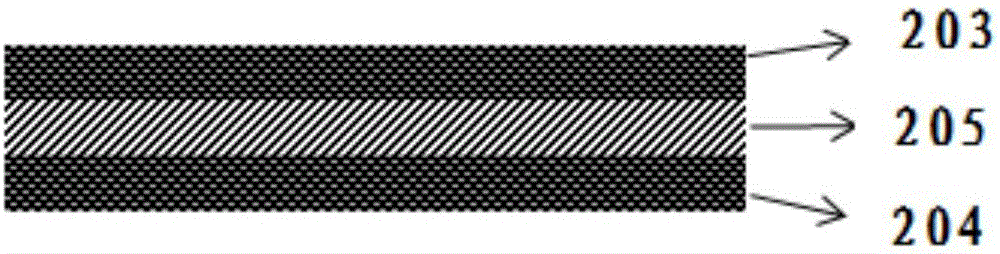

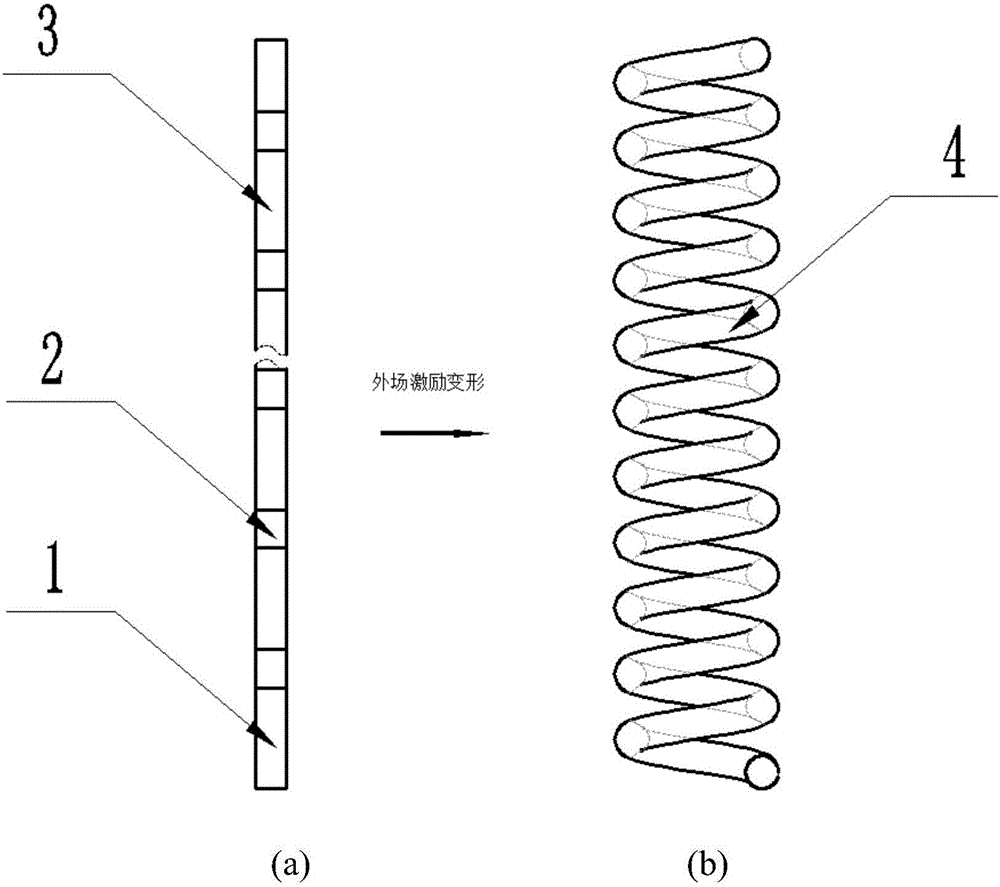

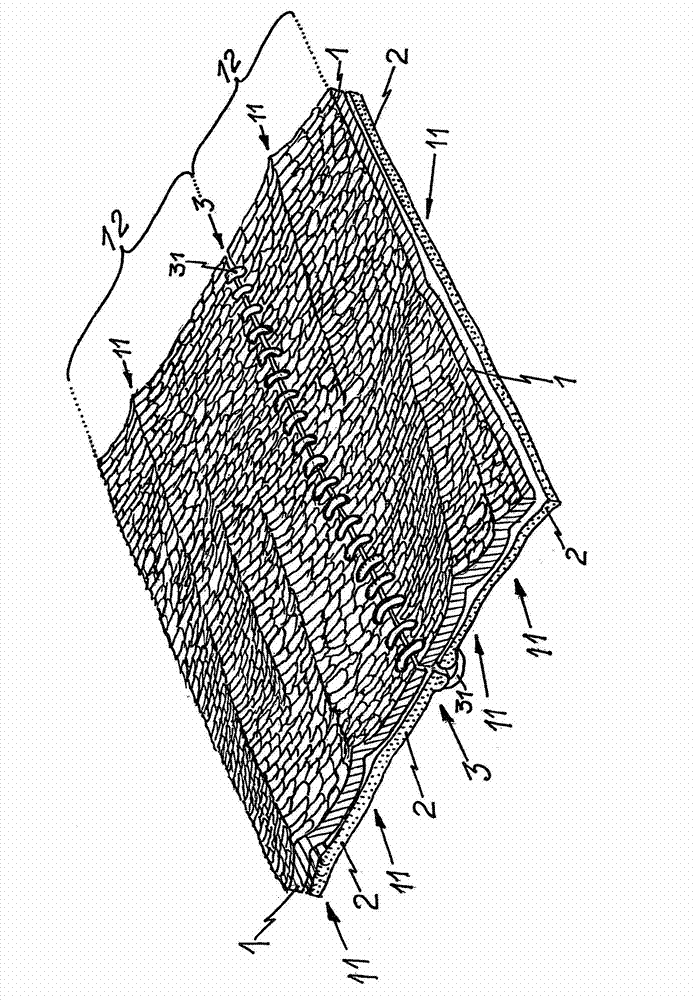

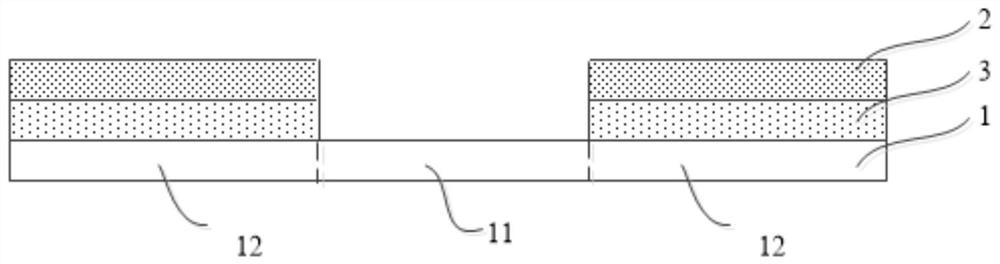

Plant fiber dispersible material and preparation method thereof

ActiveCN112411246AGood flexibilityReduced risk of tearingDomestic applicationsNon-woven fabricsPolymer sciencePlant fibre

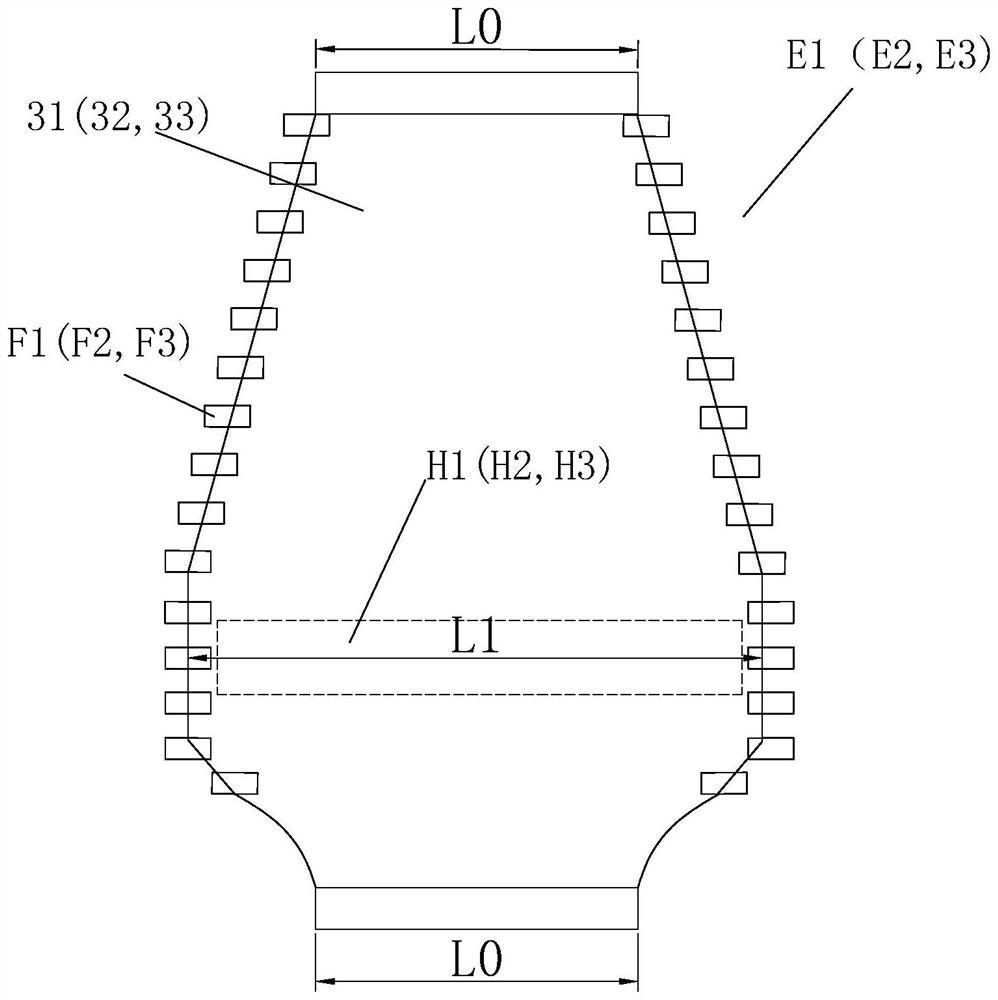

The invention relates to the field of non-woven materials, and discloses a plant fiber dispersible material and a preparation method thereof. The plant fiber dispersible material comprises an upper fiber layer (1), a middle fiber layer (2) and a lower fiber layer (3) which are mutually entangled and overlapped, wherein the average length of fibers in the upper fiber layer and the lower fiber layeris greater than the average length of fibers in the middle fiber layer; raw materials of the upper fiber layer and the lower fiber layer comprise chopped plant fibers and / or plant fiber linters; andraw materials of the middle fiber layer comprise plant fiber pulp. According to the invention, natural plant fibers are used as main raw materials, and the plant fiber dispersible material which is high in wet strength, soft in hand feeling and low in scrap falling amount can be prepared through a special wet spunlace non-woven process.

Owner:HANGZHOU NBOND NONWOVENS

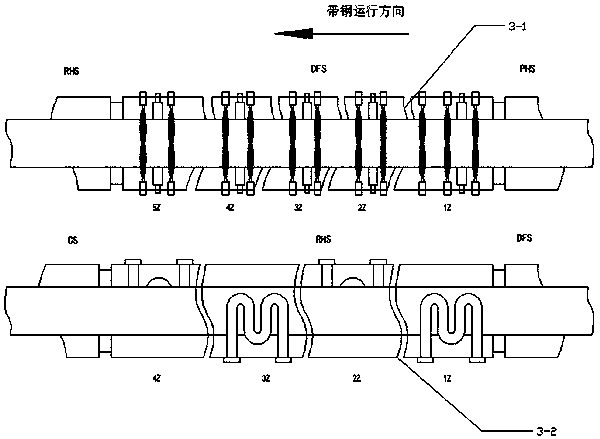

Method for preventing weld seam strip breakage of thin material strip steel

ActiveCN109014646AEffective controlReduce tensionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamStrip steel

The invention relates to a method for preventing weld seam strip breakage of thin material strip steel. The method is characterized by comprising the following steps of (1) welding control; (2) entryloop control; (3) continuous annealing control; (4) air knife control; and (5) leveling and withdrawing-straightening control. The method effectively avoids the technical problem of the weld seam strip breakage of the strip steel through the coordinated control of multiple steps.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

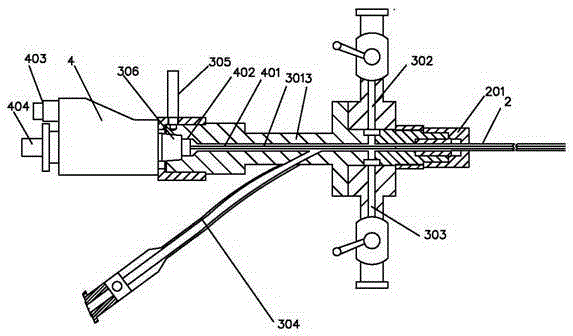

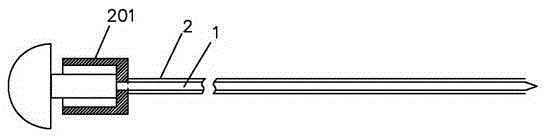

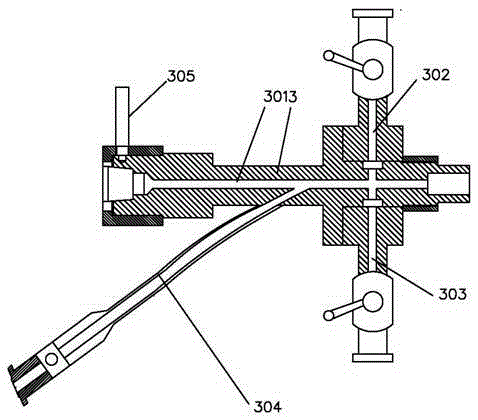

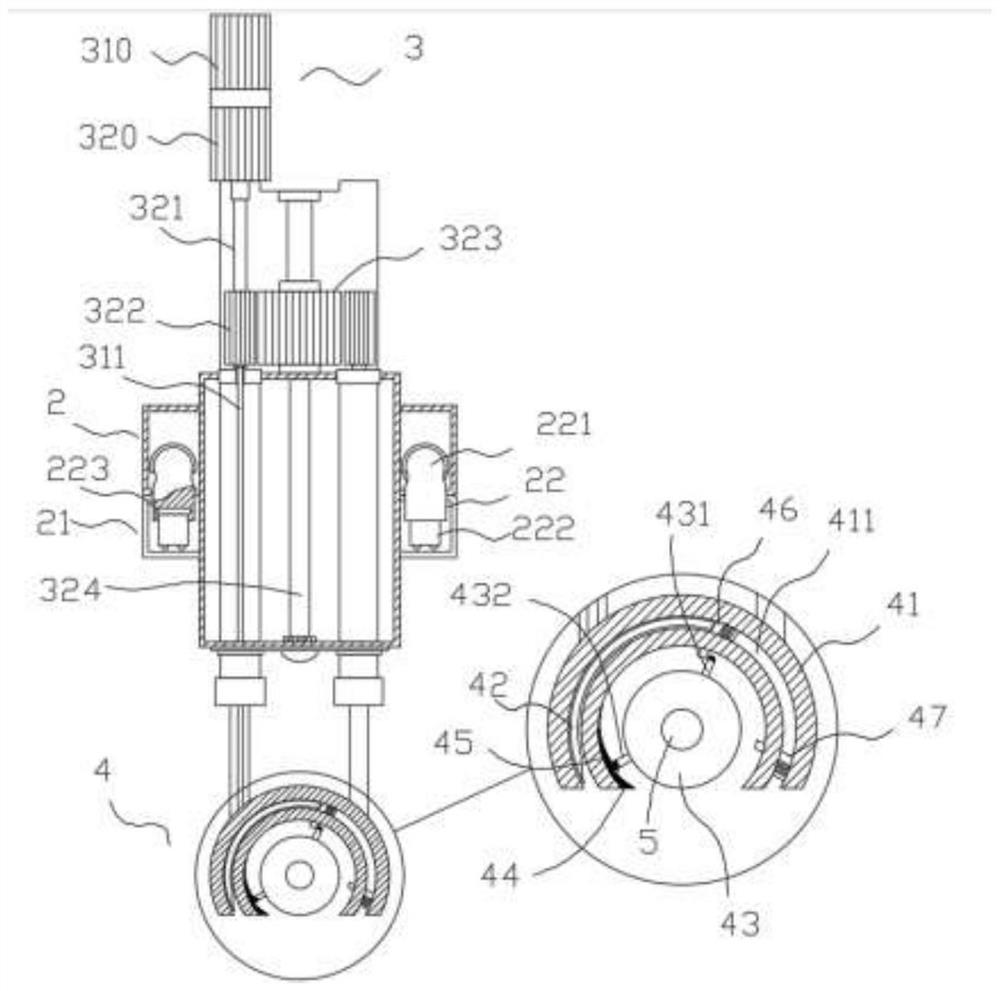

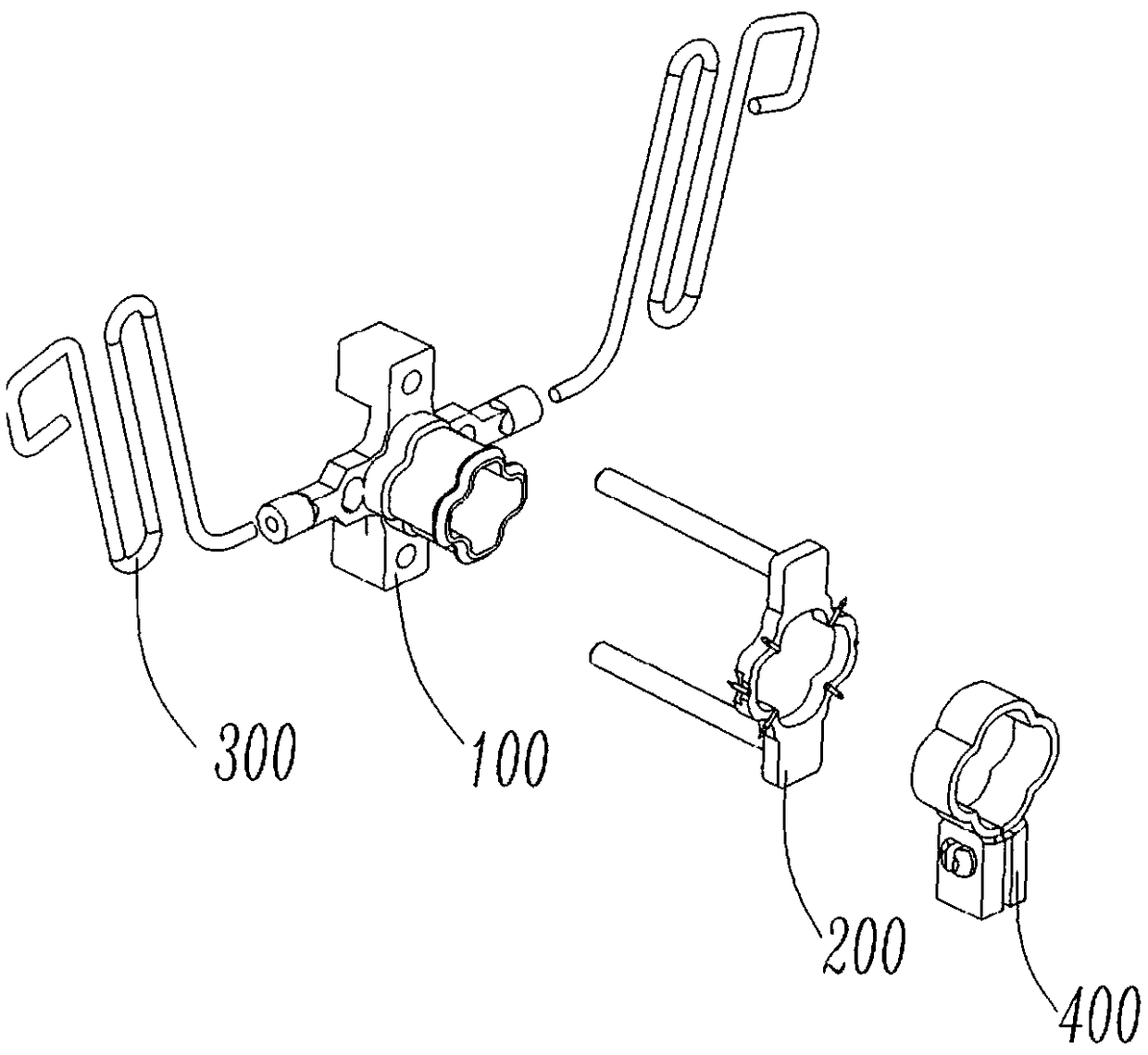

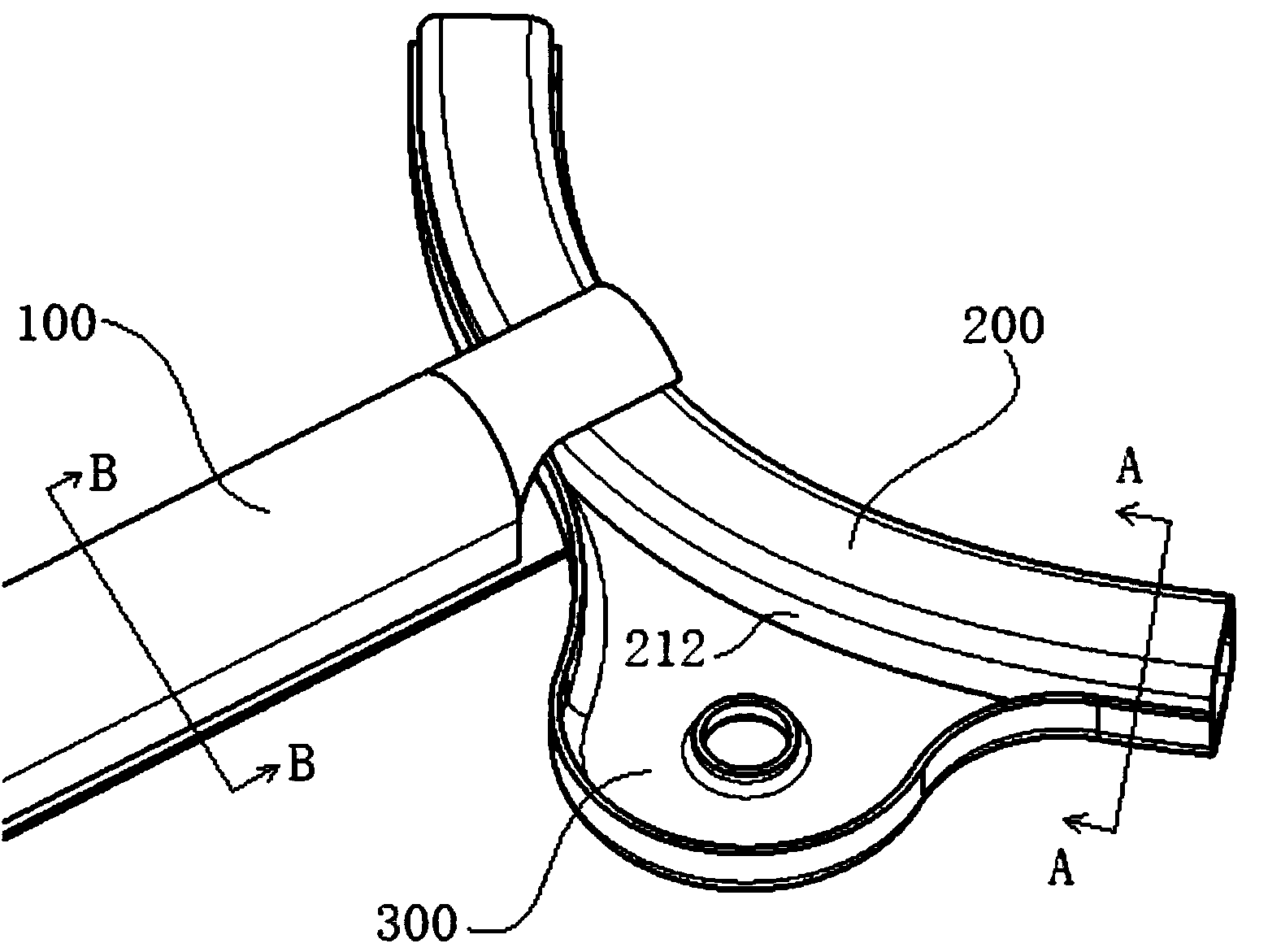

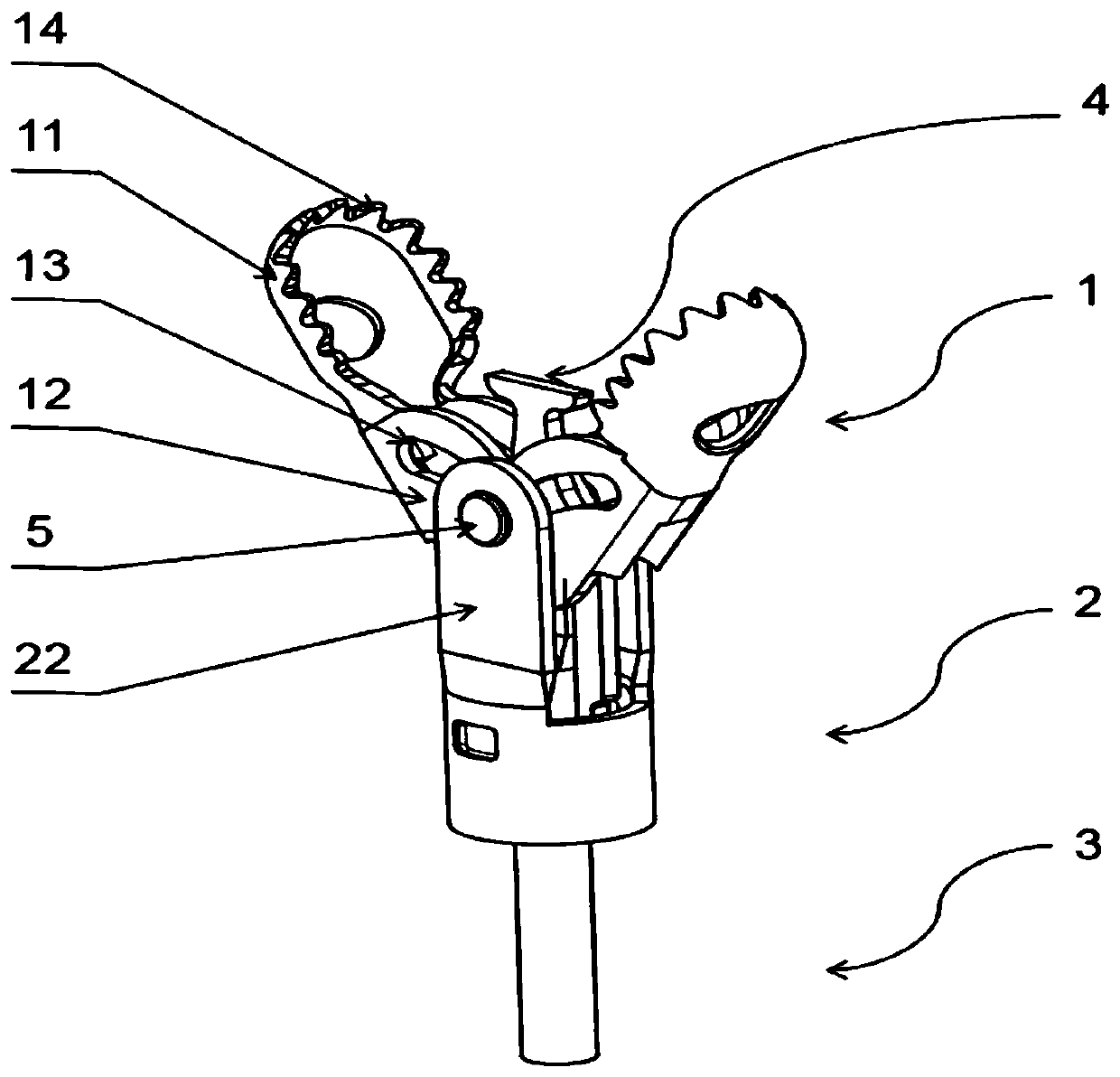

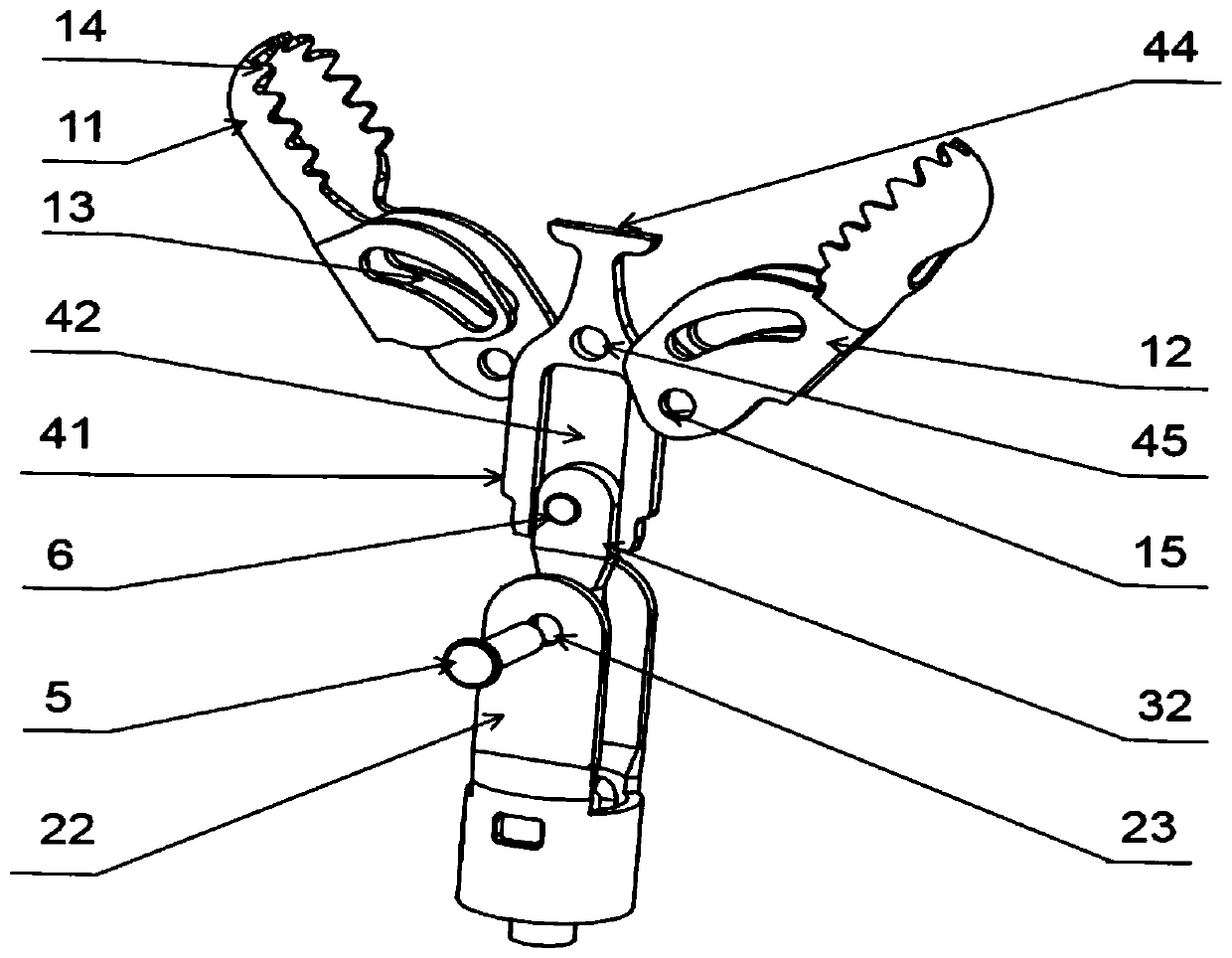

a percutaneous nephroscope

ActiveCN103070720BLower tolerance requirementsReduce work intensitySurgical needlesTrocarRenal CalixUltimate tensile strength

A percutaneous nephroscope comprises a bridge assembly, a puncture needle, a sheath assembly and a lens assembly, wherein the bridge assembly is provided with a bridge passage and a bridge base, and the sheath assembly is provided with a sheath passage and a sheath base arranged on the end of the sheath passage. In the step of puncture, the front end of the puncture needle is inserted into and extends out of the sheath passage, and the end of the puncture needle abuts against the sheath base; when the sheath base is tightly connected with the bridge base, the sheath passage communicates with the bridge passage, and the lens assembly sequentially passes through the bridge passage and the sheath passage. The percutaneous nephroscope has the following advantages: (1) the operating procedure is simplified, the time of an operation can be shortened, the requirement on the endurance of patients is decreased, and the working intensity of doctors can be decreased; (2) particularly, unnecessary expansion which can cause the pain and tissue injuries of patients is reduced; (3) because the diameter of the sheath is small, the percutaneous nephroscope can be flexibly operated in the narrow spaces of the renal pelvis and the renal calyx, the risk of tearing kidney tissues is reduced, and moreover, the surgical cut is small and can easily heal up after the operation.

Owner:中山市环能缪特斯医疗器械科技有限公司

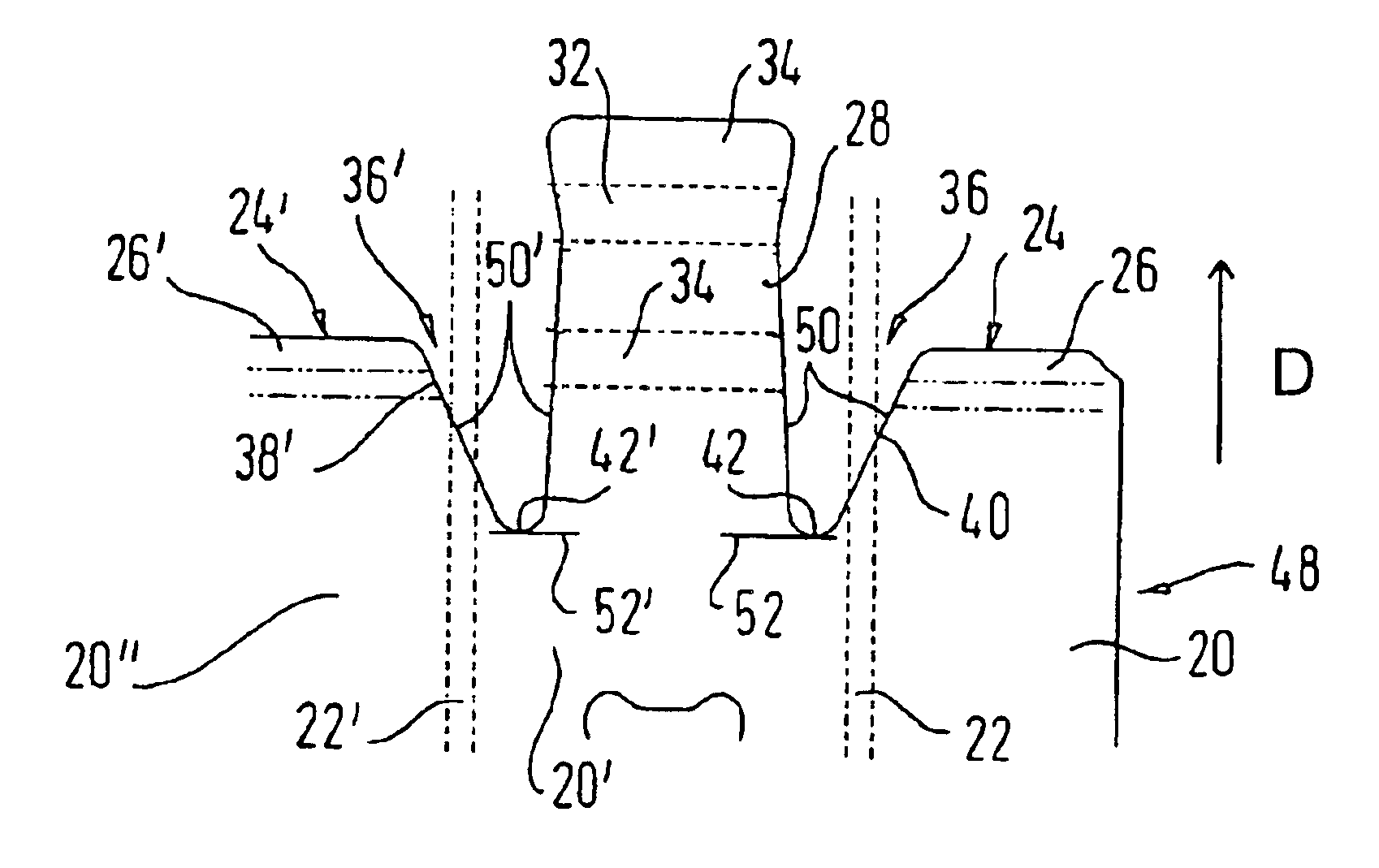

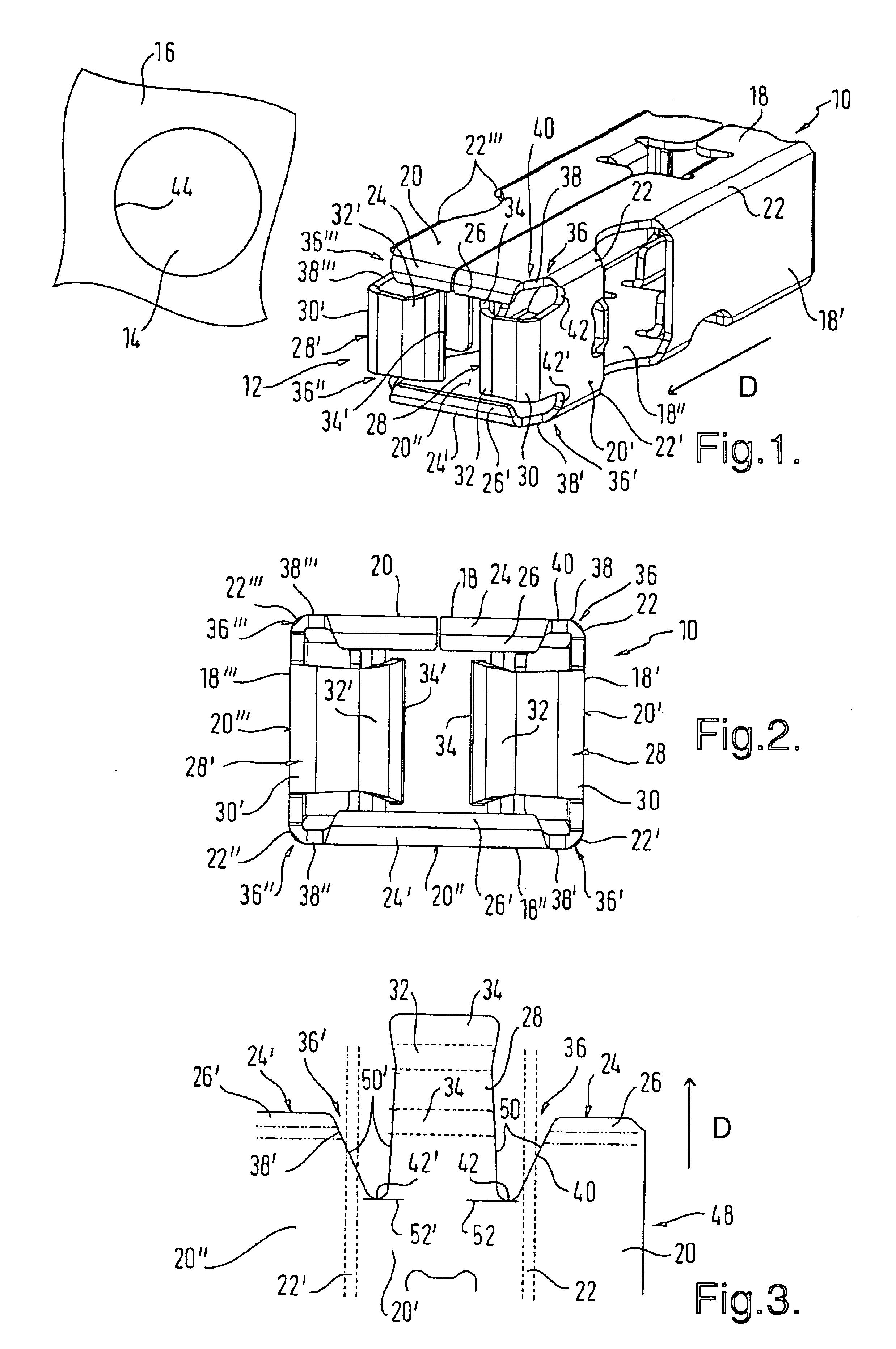

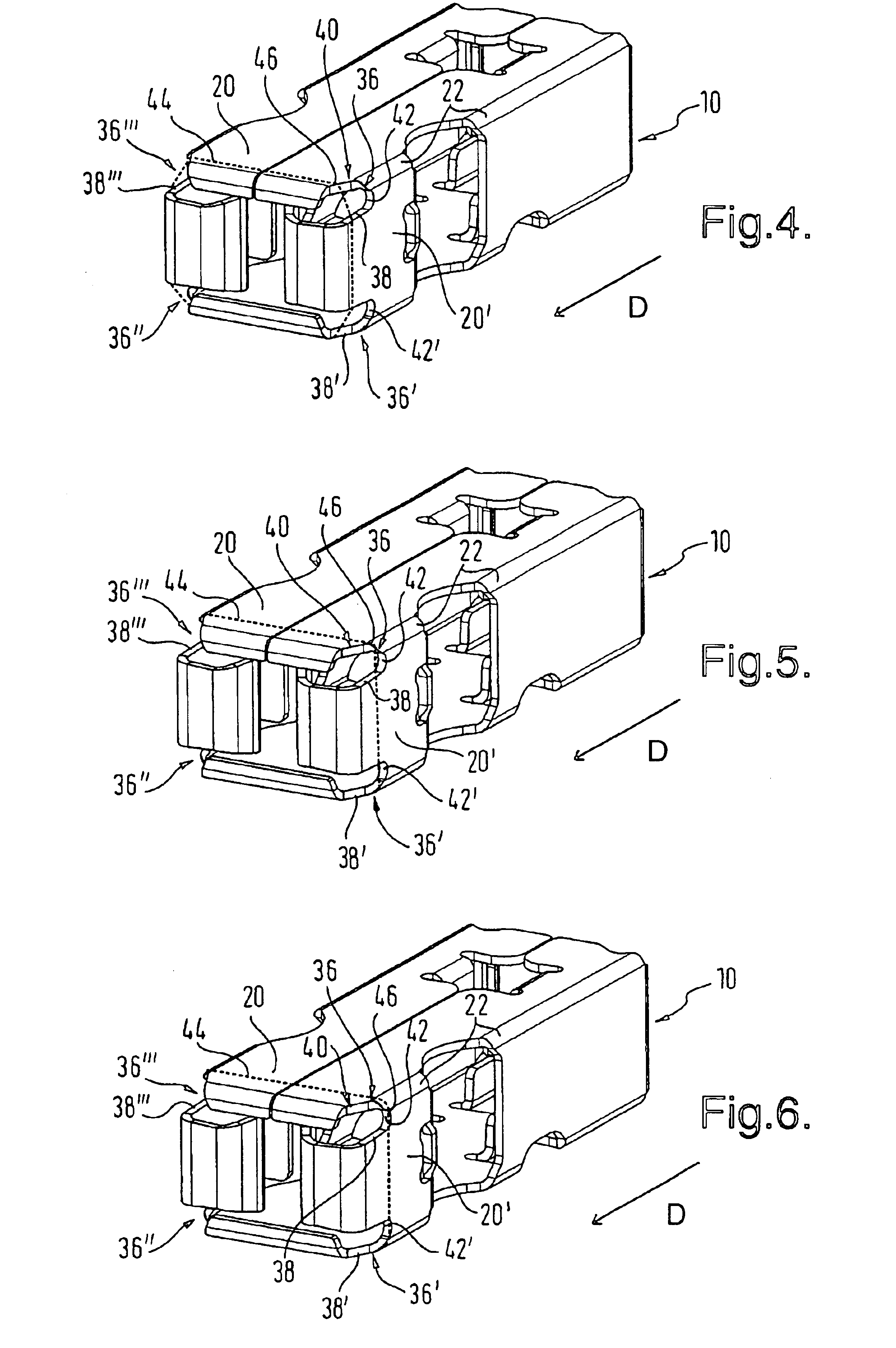

Plug contact element and a method for manufacturing a housing part for same

InactiveUS6942528B2Reduced risk of tearingReduce areaContact member manufacturingCoupling contact membersEngineeringContact element

The plug contact element for the at least partial pushing through an opening, in particular a round opening, in an elastic material along a push through direction of the plug contact element comprises a housing part having at least two wall regions which are substantially planar and inclined with respect to one another at least at a front side of the housing part and which are connected to one another via an arched or bent connection region, with the housing part having at least one indentation which opens to a front side of the housing part which lies in the push through direction and of which the indentation edge at least partly forms a front-side edge of the arched or bent connection region, with the indentation edge having an apex or a tangent which is orthogonal to the push through direction, the apex or tangent being provided only at the boundary between the connection region and one of the bordering wall regions or at one of the bordering wall regions.

Owner:DELPHI TECH INC

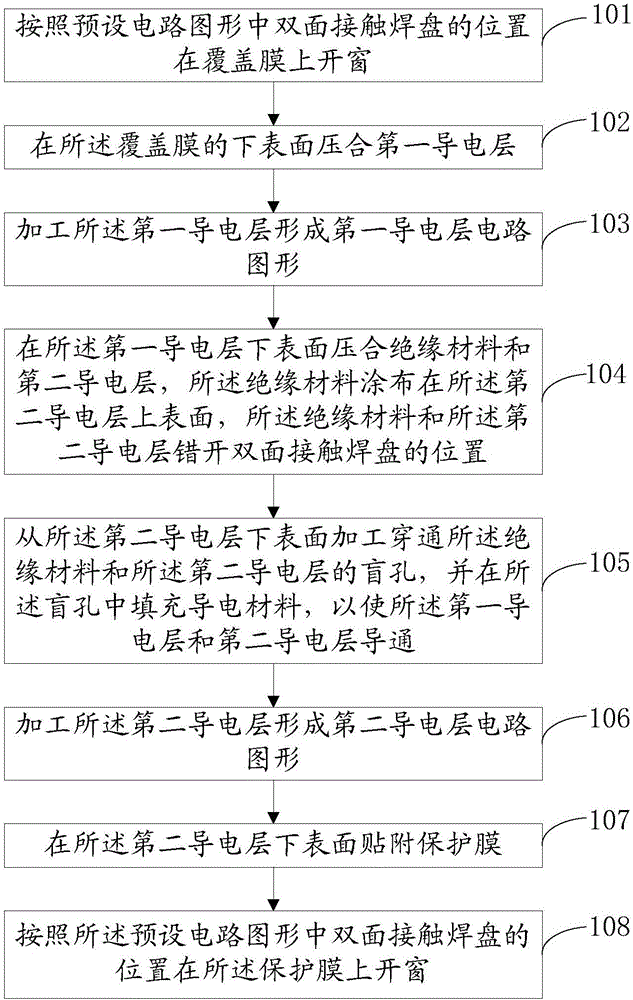

Flexible printed circuit board and manufacturing method thereof

ActiveCN106793584AReduced risk of tearingMeet weldingFlexible printed circuitsElectrical connection printed elementsTectorial membranePunching

The present invention provides a flexible printed circuit board and a manufacturing method thereof. The method comprises: performing windowing on a cover film according to the position of a two-sided contact bonding pad in a preset circuit pattern; performing press fit of a first conducting layer at the lower surface of the cover film; processing the first conducting layer to form a first conducting layer circuit pattern; performing press fit of insulation materials and a second conducting layer at the lower surface of the first conducting layer, wherein the upper surface of the second conducting layer is coated with the insulation materials, the insulation materials and the second conducting layer staggered with the position of the two-sided contact bonding pad; processing a blind hole punching through the insulation materials and the second conducting layer at the lower surface of the second conducting layer, and allowing the blind hole to be filled with conducting materials; processing the second conducting layer to form the second conducting layer circuit pattern; attaching a protective film to the lower surface of the second conducting layer; and performing windowing on the protective film according to the position of the two-sided contact bonding pad in the preset circuit pattern. The flexible printed circuit board is provided with a bonding pad which realizes two-sided contact and conduction through the first conducting layer so as to satisfy welding and conduction requirements and reduce the risk of the tearing of the bonding pad.

Owner:VIVO MOBILE COMM CO LTD

A 4D printing method for artificial vascular stents

ActiveCN104116578BFast preparationSimplify molding manufacturing equipmentStentsBlood vesselsMetallic materialsAlloy

The invention discloses a method for forming an artificial vascular stent through 4D printing. The method comprises the following steps that (1) shape memory polymers or shape memory alloy serves as a transformable material unit, polymer materials or metal materials serve as a base body material unit, and an initial vascular stent configuration is designed; (2) the transformable material unit and the base body material unit are printed into a needed original 3D configuration with a direct fusion forming method, or a laser area selective fusion forming mode or a micro jet molten drip electromagnetic constraint forming mode is selected as a shape memory alloy printing forming mode to manufacture the vascular stent; (3) heat preservation and slow cooling are conducted on the original 3D configuration or the vascular stent obtained in the step (2); (4) performance tests are conducted on the formed vascular stent so that the vascular stent can meet using requirements, and thus the 4D printing forming of the artificial vascular stent is completed, wherein the performance tests include the mechanics performance test, the incentive transformation test and the medical performance test.

Owner:XI AN JIAOTONG UNIV

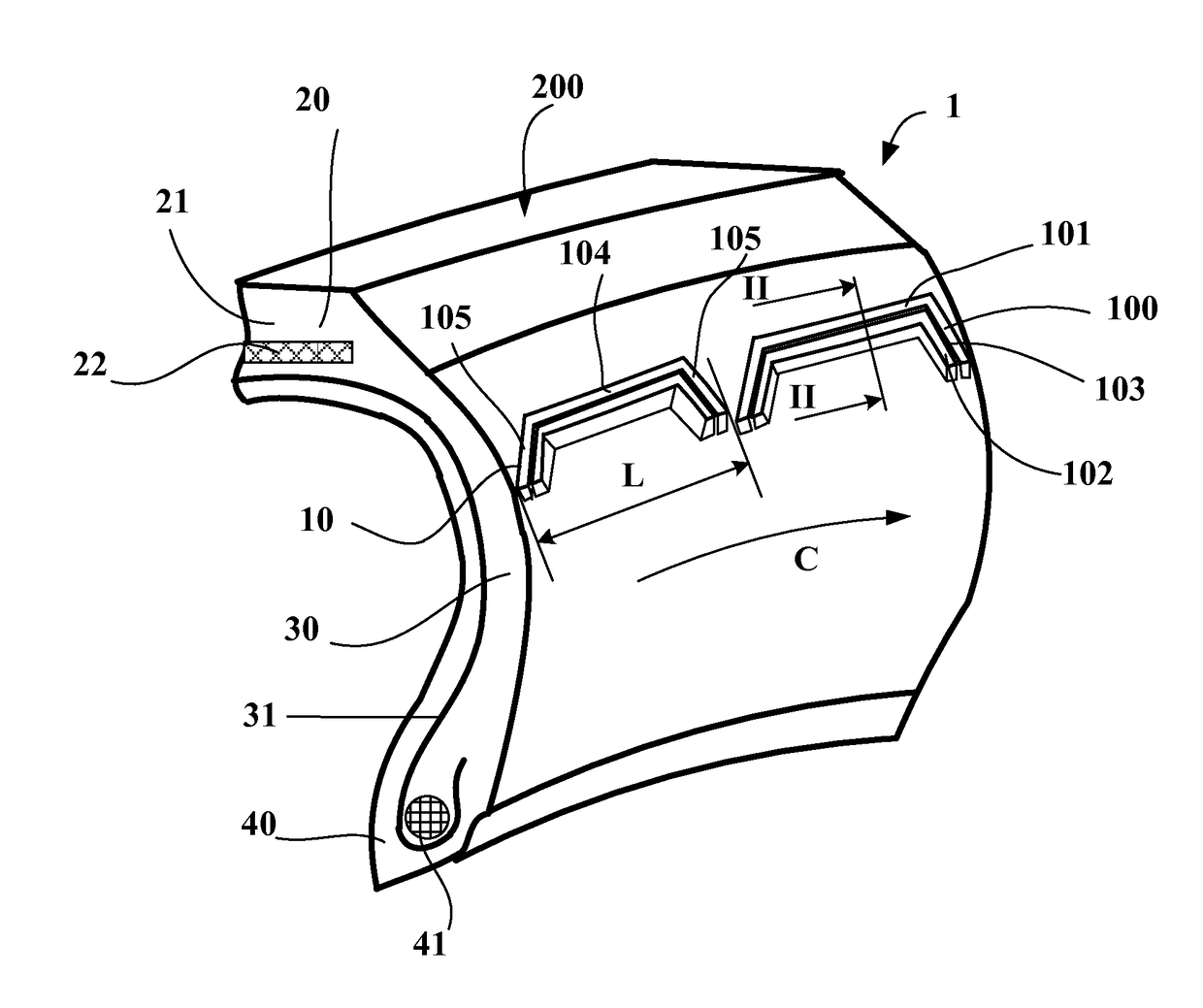

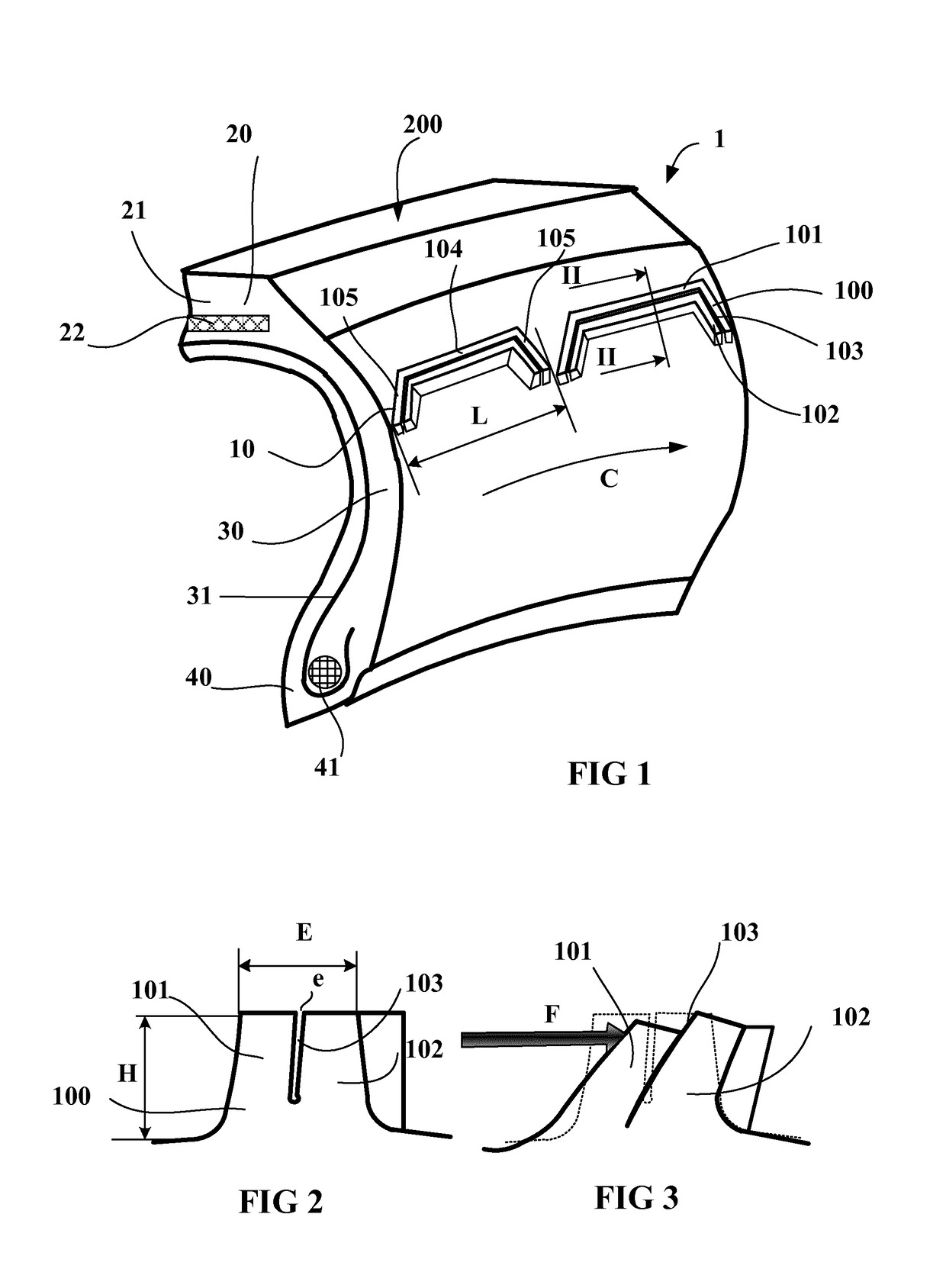

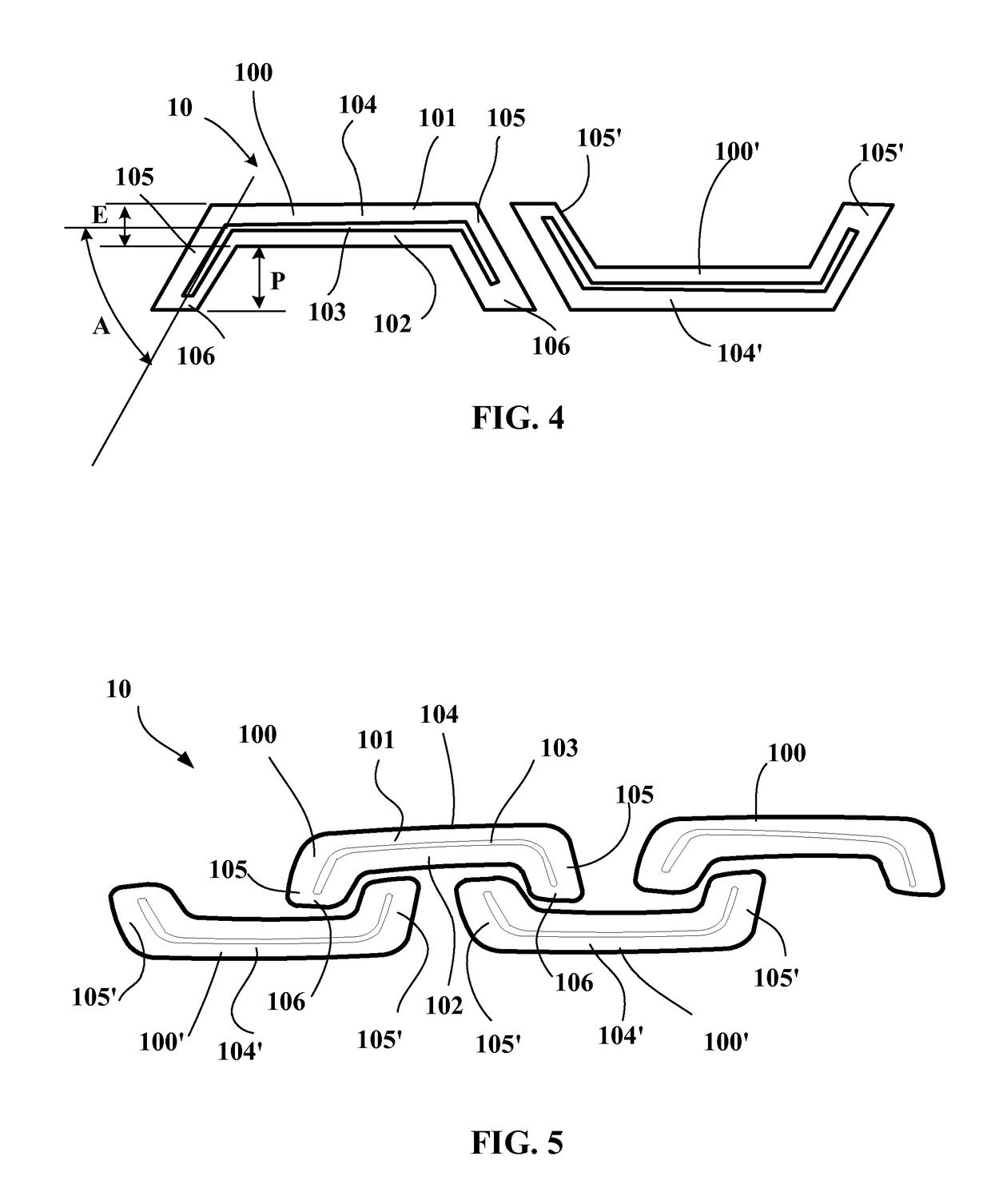

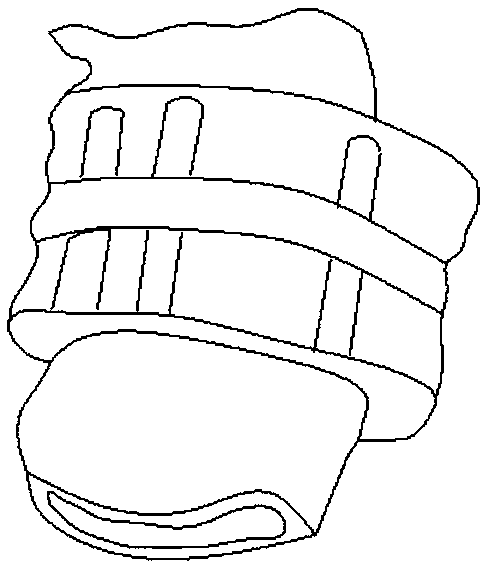

Device for protecting a tire wall

ActiveUS20180229557A1Reduced risk of tearingIncrease forceHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

The tire comprises a carcass reinforcement which extends into sidewalls. The tire is also provided with a protection device that protects against external attack. The protection device comprises a plurality of raised elements of height H that are arranged in the circumferential direction. The tire is also constructed such that each raised element is formed of at least two parts which are at least partially disjointed from one another along a separation zone. The separation zone is oriented substantially in the circumferential direction. Each part is able to come into contact with another part of the same raised element when one of the parts comes into contact with an external obstacle.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

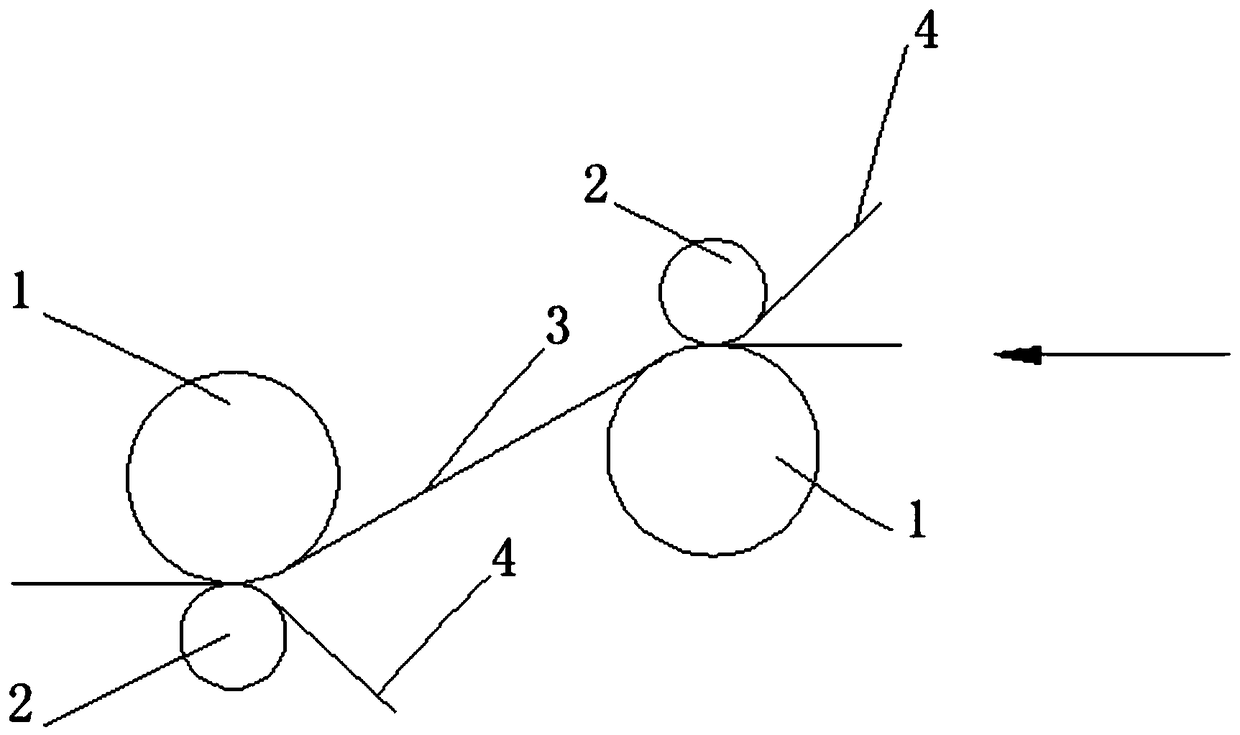

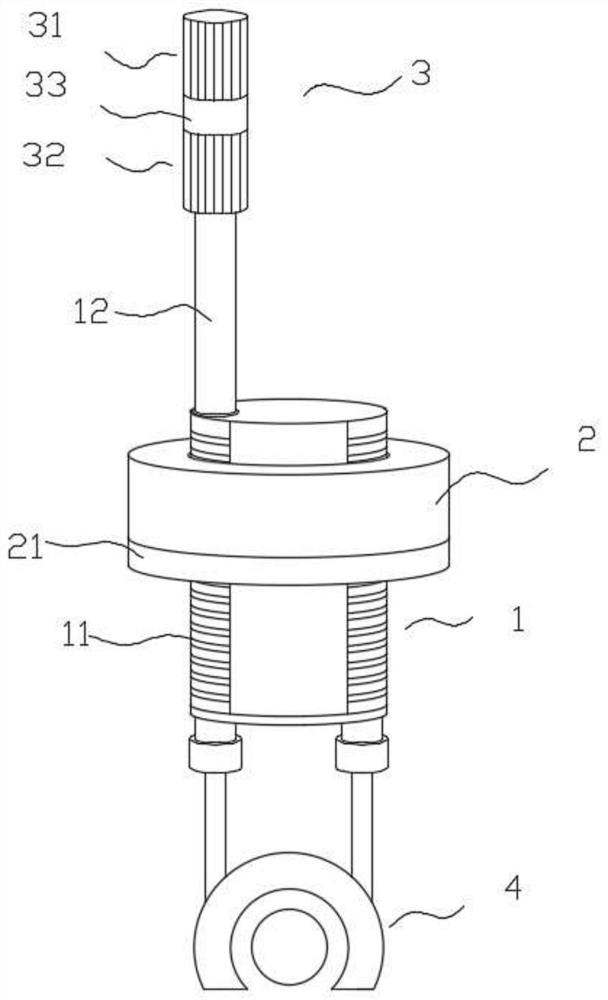

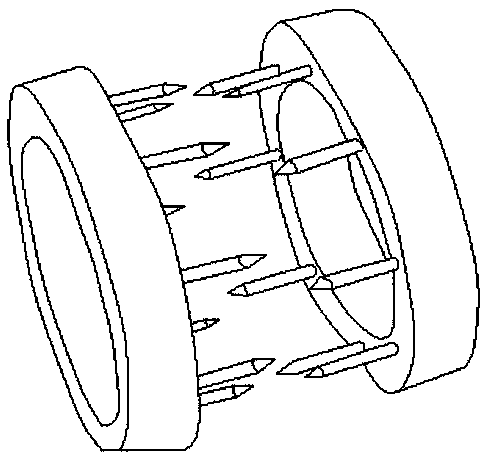

Insert for mounting into an inflatable tire

InactiveCN101743138ALow directional stabilityHigh speedTyre partsWheelsRotational axisFilling materials

An inflatable tire (5) comprising an annularly shaped tire body extending along a circumference (20) of the tire (5) around a central rotational axis (18) of the tire (5), at least partially delimiting an annular space (6) surrounding the rotational axis (18) and enclosing an inflatable volume (7) for receiving a condensed state filling material (8), the annular space (6) containing an insert (1) in view of decreasing the inflatable volume (7) so that less inflating material (8) is needed to inflate the tire (5), characterised in that the assembly of the insert (1) and the annularly shaped tire body comprises positioning means (4) which permit positioning and at least temporarily fixing the position of the insert (1) into the annular space (6) of the tire (5).

Owner:速力达控股股份有限公司

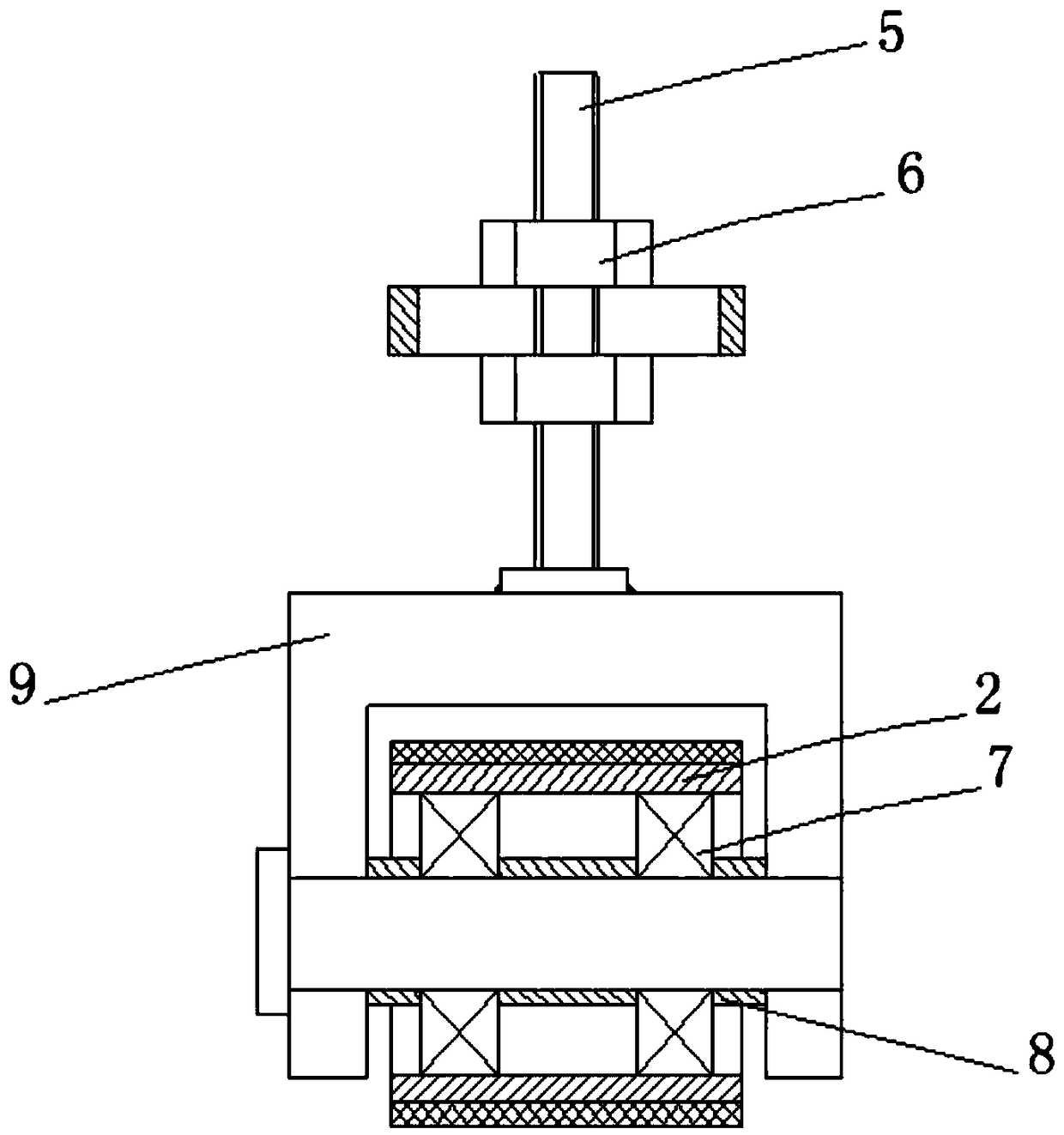

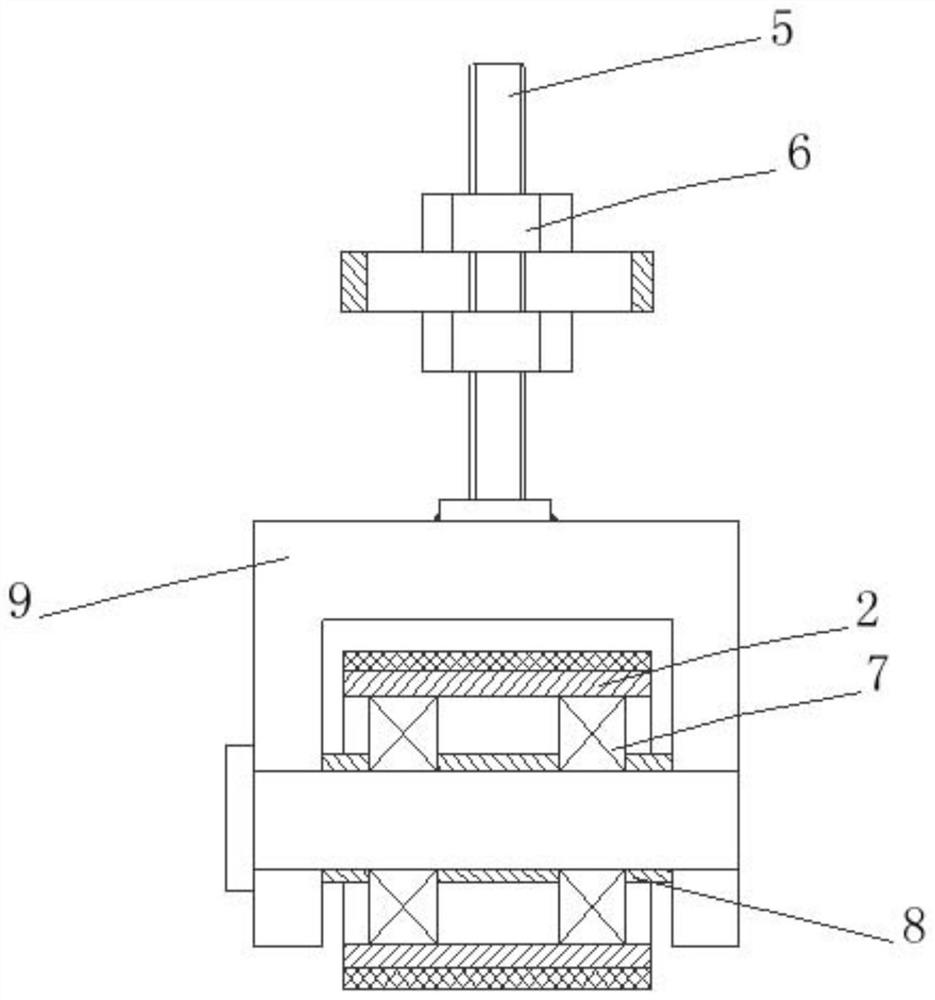

Intraperitoneal wound suturing device based on anvil block position feedback

The invention discloses an intraperitoneal wound suturing device based on anvil block position feedback. The intraperitoneal wound suturing device mainly comprises an extending pipe, a supporting block, an operating mechanism and a suturing mechanism. The suturing mechanism comprises an arc-shaped fixing strip connected to the interior of the bottom end of a connecting rod shell and provided withan arc-shaped sliding groove, an arc-shaped suture needle arranged in the sliding groove in a sliding manner; a push block and a pull block accounting for half of the width of the sliding groove, arranged in the sliding groove in the sliding mode and assisting the suture needle in completing the suture period; a sewing wheel arranged at the circle center of the fixing strip, a first jacking columnarranged on the sewing wheel and used for pushing the push block, a second jacking column arranged on the sewing wheel and used for pushing the pull block, a reset spring arranged on the side face ofthe push block and the side face of the pull block, and a first ramp and a second ramp are used for separating the first jacking column from the push block as well as separating the second jacking column from the pull block. During suturing, secondary injury to wounds of patients can be reduced, and the suture needle is convenient to operate and suitable for wide popularization.

Owner:高媛

Rolling anti-wrinkle device and anti-wrinkle method for lithium battery pole piece

ActiveCN109037589BEasy rolling operationImprove tear resistanceElectrode rolling/calenderingStructural engineeringPole piece

The invention provides a lithium battery electrode sheet anti-wrinkle roller device and an anti-wrinkle method, which can simultaneously coat a pole piece AB surface, reduce the risk of pole ear tearing, simultaneously coat a pole piece AB surface, can transmit the extrusion force to the pole ear head, and increases the anti-tearing ability of the pole ear head. According to different thickness offoil, different thickness of roller and different width of foil, the depressing force of roller can be adjusted, and the bias rectifying bracket and PET film roll can be adjusted or replaced according to the need, which is convenient for different types of lithium batteries to roll.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

Elastic leather clothing

The invention relates to leather clothing, comprising an outer layer made of leather, which is connected to an inner layer made of elastic material, wherein the leather is provided with folds over the majority of the surface area of the leather, wherein said folds are distributed approximately regularly over the surface area and connect the leather to the elastic material by means of a plurality of seams that are spaced from each other, and the elastic material is a textile woven fabric.

Owner:克里斯廷·贝克-韦伯

Percutaneously implantable replacement heart valve device and method of making same

InactiveUS20150351902A1Guaranteed recovery periodReturning to hostBalloon catheterHeart valvesTissue materialVALVE PORT

A method of making a replacement heart valve device whereby a fragment of biocompatible tissue material is treated and soaked in one or more alcohol solutions and a solution of glutaraldehyde. The dried biocompatible tissue material is folded and rehydrated in such a way that forms a two- or three-leaflet / cusp valve without affixing of separate cusps or leaflets or cutting slits into the biocompatible tissue material to form the cusps or leaflets. After the biocompatible tissue material is folded, it is affixed at one or more points on the outer surface to the inner cavity or a stent.

Owner:COLIBRI HEART VALVE

Substrate structure and fabrication method thereof

ActiveCN108336093ASmall sizeReduce stressSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBond Force

The invention relates to a substrate structure and a fabrication method thereof. The fabrication method of the substrate structure comprises the following steps of providing a support substrate; forming an exposed light-sensitive material layer on the support substrate, wherein the exposed light-sensitive material layer is provided with a first bonding force region and a second bonding force region, and the bonding force of the first bonding force region and the support substrate is smaller than the bonding force of the second bonding force region and the support substrate; and forming a flexible substrate on the exposed light-sensitive material layer, removing the light-sensitive material on the first bonding force region and the flexible substrate to obtain a patterned light-sensitive material layer and a patterned flexible substrate layer so as to obtain the substrate. In the fabrication method of the substrate structure, the first bonding force region and the second bonding force region in arbitrary patterns can be obtained by exposure; and since the bonding force of the first bonding force region and the support substrate is relatively small, the light-sensitive material on the first bonding force region and the flexible substrate are removed from the support substrate, so that versatile patterns of the substrate structure is achieved.

Owner:YUNGU GUAN TECH CO LTD

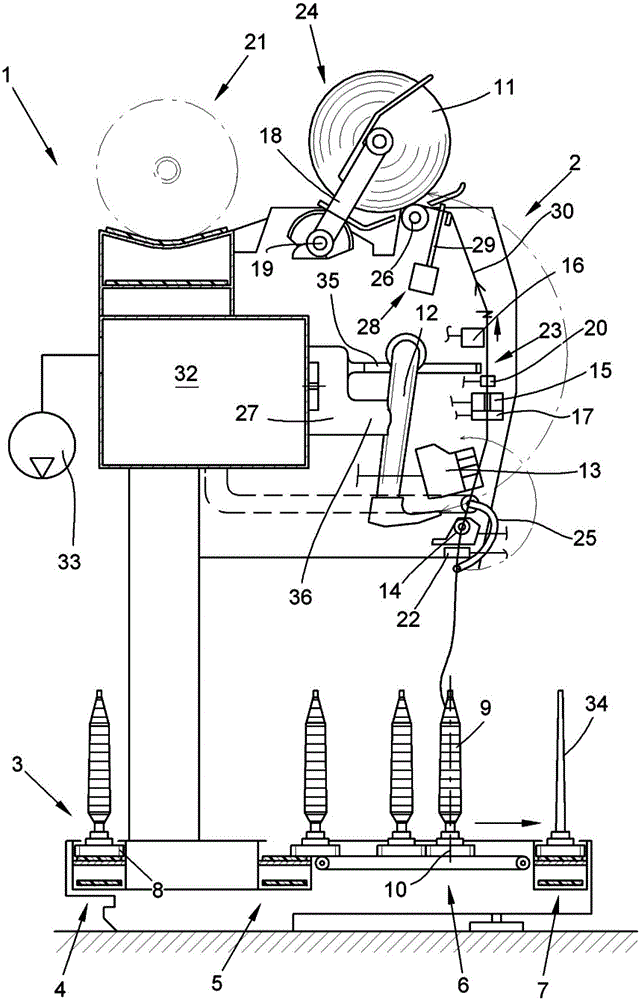

Method and device for controlling the negative pressure on a thread catching or cleaning nozzle of a workstation of a textile machine

InactiveCN105314462ARealize the yarn catching and clearing functionReduce negative pressureFilament handlingYarnWinding machine

The present invention relates to a method and device for controlling the negative pressure on a thread catching or cleaning nozzle (23) of a workstation (2) of a textile machine (1) in particular to a winding machine for producing winding bobbins (11), wherein the workstation (2) is provided with a thread connecting device (13) for connecting upper threads from the winding bobbins (11) to lower threads to be wound on the winding bobbins (11). The method guarantees that at least during the first phase of a winding process started after thread connection between the upper threads and the lower threads is formed to form threads (30), no negative pressure or so low negative pressure is applied to the thread catching or cleaning nozzle (23), and the thread catching or cleaning nozzle (23) does not suck in the threads during the starting phase.

Owner:SAURER GERMANY GMBH & CO KG

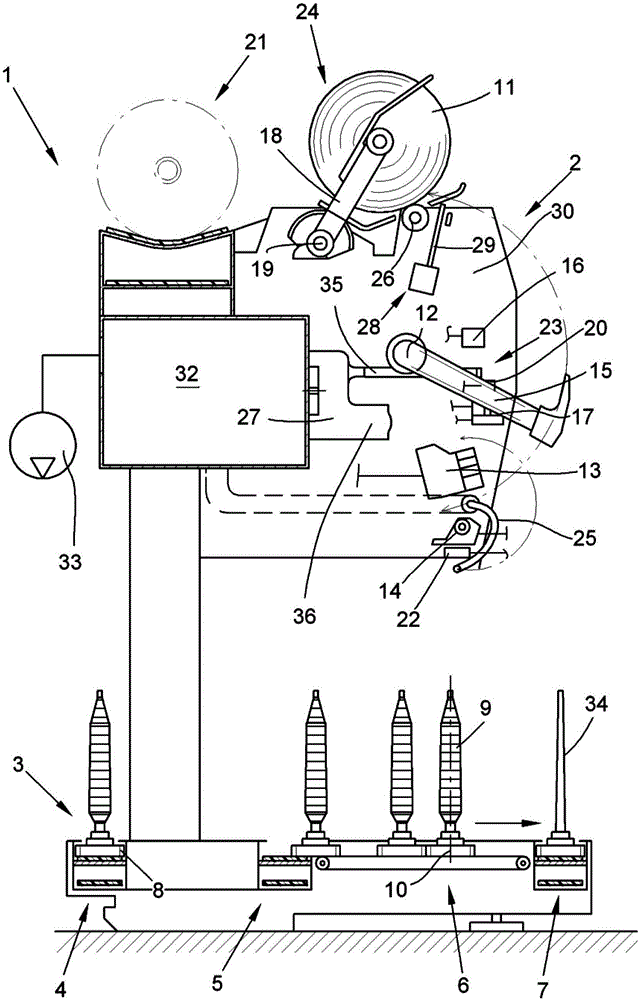

Breathable elastic composite non-woven fabric and manufacturing method thereof

PendingCN113558866AImprove breathabilityUnfetteredAbsorbent padsBaby linensPolymer scienceNonwoven fabric

The invention discloses breathable elastic composite non-woven fabric which is composed of a surface layer non-woven fabric body, a middle layer elastic film and a bottom layer non-woven fabric body, the surface layer non-woven fabric body and the bottom layer non-woven fabric body are each provided with a plurality of strip-type protruding areas and a plurality of strip-type concave areas which are transversely arranged, funnel-shaped open holes are formed in the middle-layer elastic film, and strip-type breathable channels are formed between the protruding areas of the surface layer non-woven fabric body and the bottom layer non-woven fabric body, so that internal wet and hot air can permeate into the breathable channel space formed by the bottom layer non-woven fabric body and the elastic film through the bottom layer non-woven fabric body during wearing, the wet and hot air rapidly diffuses in the length direction and the height direction of the breathable channel space in the breathable channels, enters the breathable channel space formed by the elastic film and the surface layer non-woven fabric body through the holes of the elastic film, and then is discharged out of the elastic composite non-woven fabric, so that the effect of rapid heat conduction and moisture removal is achieved.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

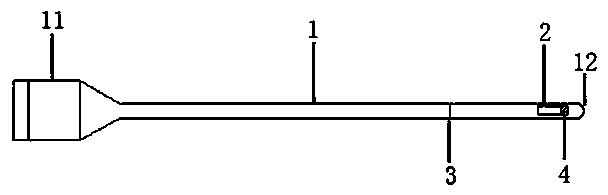

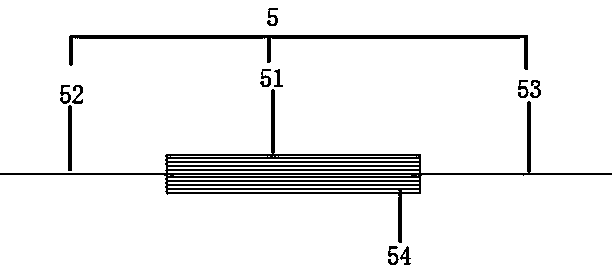

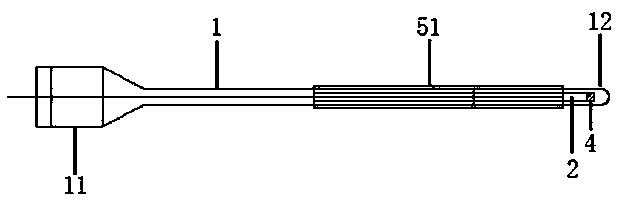

Lacrimal ductule stone removing device and lacrimal ductule stone removing method

The invention relates to a lacrimal ductule stone removing device and a lacrimal ductule stone removing method. The lacrimal ductule stone removing device comprises a probe and a guide wire, wherein aprobe cap end connected with an injector is arranged at one end of the probe, the other end of the probe is a closed end, a side hole penetrating through the side wall is formed in the side wall of the probe and close to the closed end, and a mark line is arranged in the position, 12 mm away from the closed end, of the side wall of the probe; and the guide wire comprises an elastic tow as well asa single-strand wire A and a single-strand wire B connected to two ends of the elastic tow respectively, one single-strand wire penetrates through the probe from the probe cap end, is pulled out of the side hole and tensioned and fixed with the other single-strand wire on the side of the probe cap end, so that the elastic tow is tightly closed to the side wall of the probe. The lacrimal ductule stone removing device and the lacrimal ductule stone removing method remove stone in lacrimal ductules by using low-cost medical materials and a simple operation method, consider protection of dacryonand lacrimal ductule structures and functions, and are a device and a technology easy to promote.

Owner:逄作祥 +1

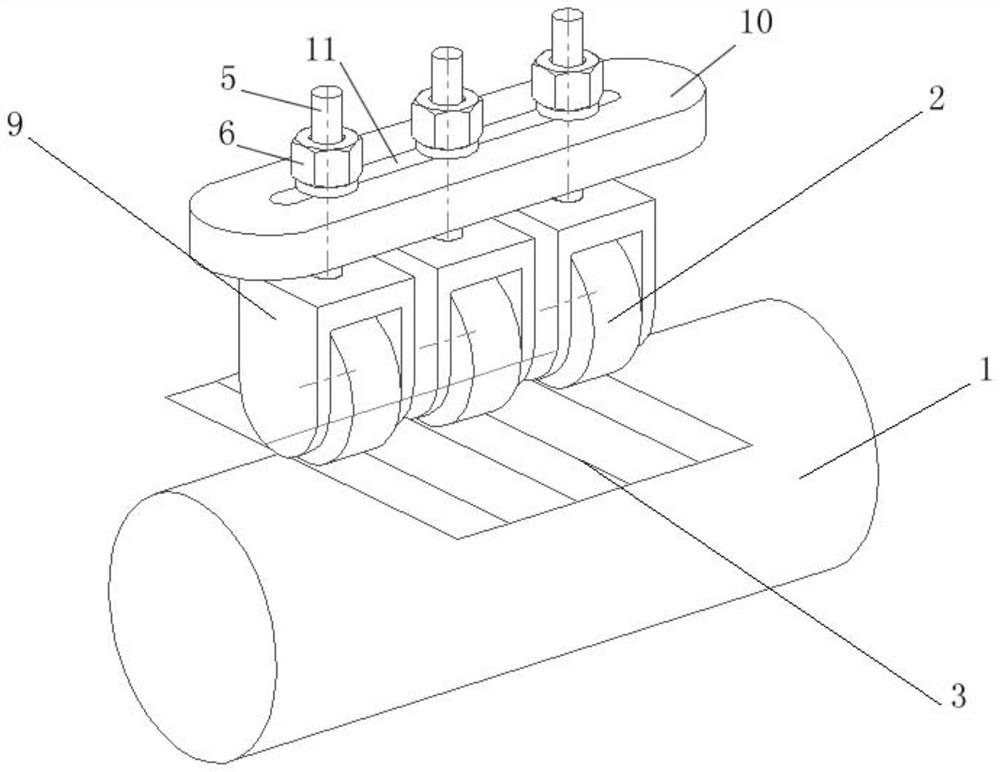

A small lumen anastomat and a method for using the same

ActiveCN109199499ANot easy to flip operationNot easy to operate while flipping overSurgical staplesMedicineBlood arterial

The invention discloses a small lumen anastomat and a method for using the same, in order to solve the technical problem of arterial blood vessel and human body small lumen anastomosis. The structurecomprises a fixed sleeve, a movable sleeve and a locking buckle. One end of the fixed sleeve is provided with a cylinder shoulder. The other end of the fixed sleeve is provided with an anastomosis connection end. The movable sleeve sleeves the cylinder wall of the fixed sleeve and provided with a hanging needle, and the movable sleeve has the freedom of movement sliding along the length directionof the fixed sleeve. When the length of the movable sleeve meets the requirement that one end close to the cylinder shoulder is in contact with the cylinder shoulder, the anastomotic connection end isexposed relative to the end face of the other end of the movable sleeve. The locking buckle is made of elastic material and has an annular shape and is provided with a locking part. The inner hole shape of the locking buckle is matched with the shape of the anastomotic connection end. The anastomat is characterized in that the cylinder wall of the fixed sleeve is provided with at least one recessin the direction of the inner cavity, and the outer shape of the cylinder cavity of the movable sleeve is adapted to the outer shape of the fixed sleeve. The anastomat can improve the success rate ofthe operation and make the operation more safe.

Owner:盐木医疗科技(北京)有限公司

Rigid-flex board and manufacturing method thereof

ActiveCN113573475AIncrease widthIncrease one-way bend radiusPrinted circuit assemblingPrinted circuits structural associationsIsolation layerStructural engineering

The invention relates to the technical field of PCBs, and discloses a rigid-flex board and a manufacturing method thereof. The rigid-flex board comprises a flexible board, a first bonding sheet and a first rigid board which are laminated in sequence, wherein the flexible board comprises a flexible area and a rigid-flex combination area; the flexible area comprises an original flexible area and an extended flexible area; the rigid-flex combination area comprises first combination areas and second combination areas, the first combination areas are connected to the two sides of the flexible area in the width direction, and the second combination areas are located on the two sides of the extended flexible area in the length direction, separated from the extended flexible area and connected with the first combination areas on the same side; the extended flexible area is separated from the first bonding sheet through an isolating layer, and the isolating layer can be separated from the extended flexible area during bending; and the first rigid board and the first bonding sheet are respectively provided with a windowing area which is consistent with the original flexible area in position and size. On the basis of a conventional original flexible area, the extended flexible area is added, the overall width of the flexible area is enlarged, and the one-way bending radius of the flexible area is increased.

Owner:DONGGUAN SHENGYI ELECTRONICS

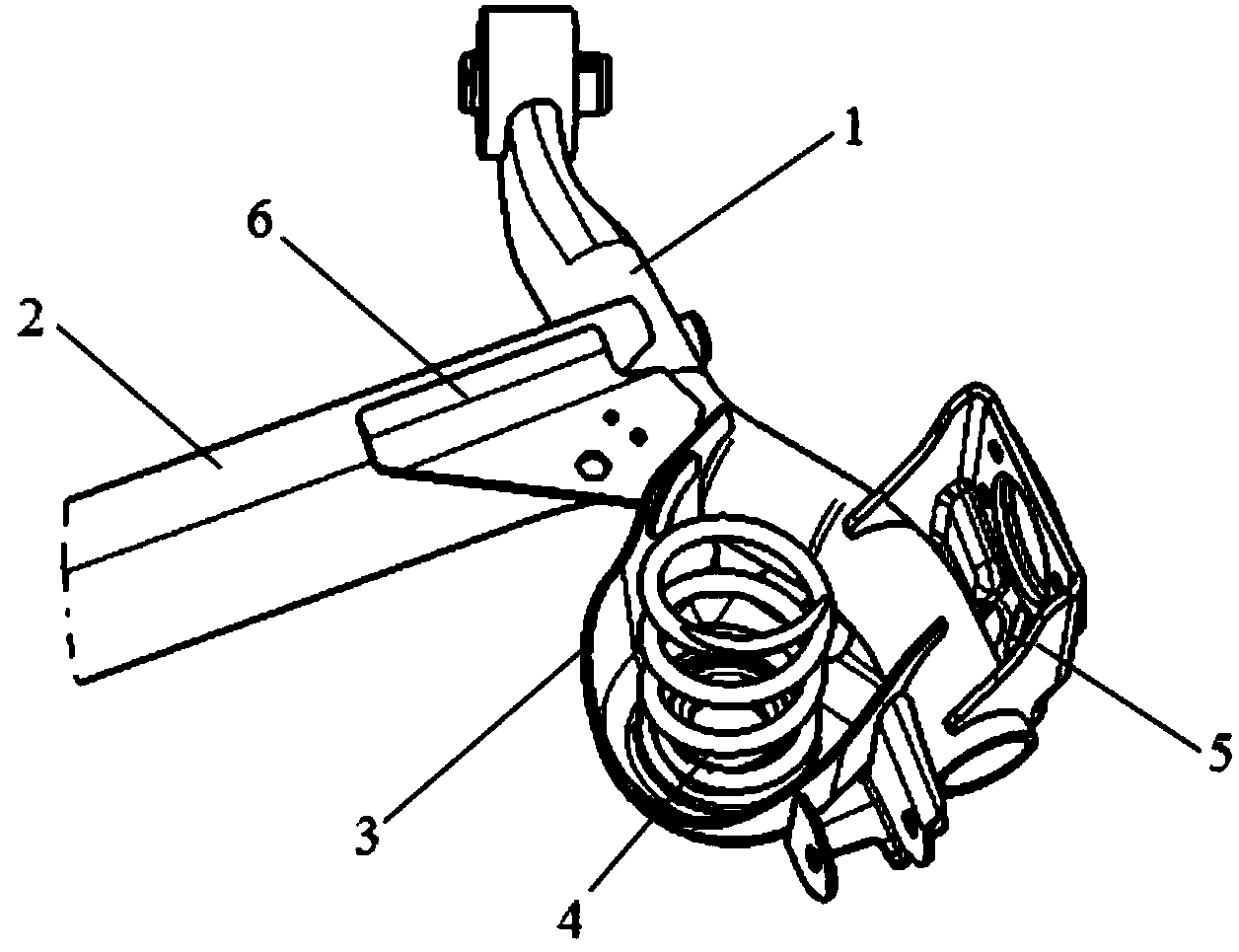

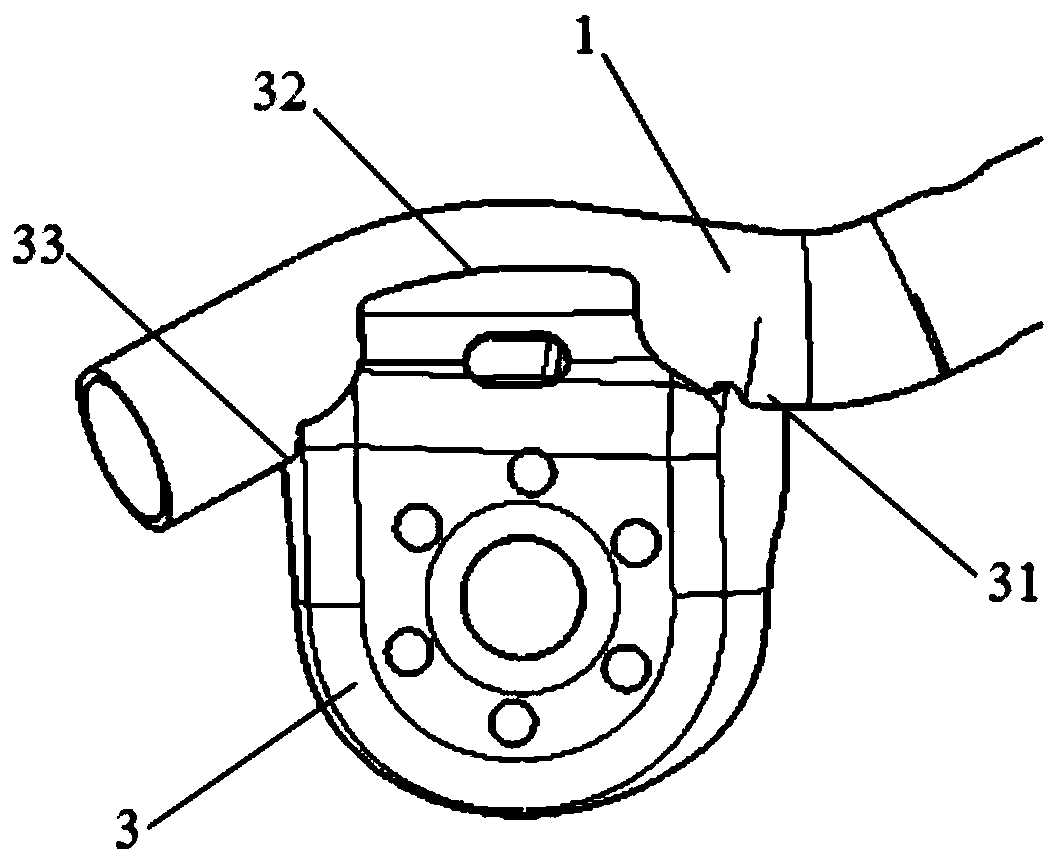

Longitudinal arm of torsion beam suspension frame and torsion beam suspension frame

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

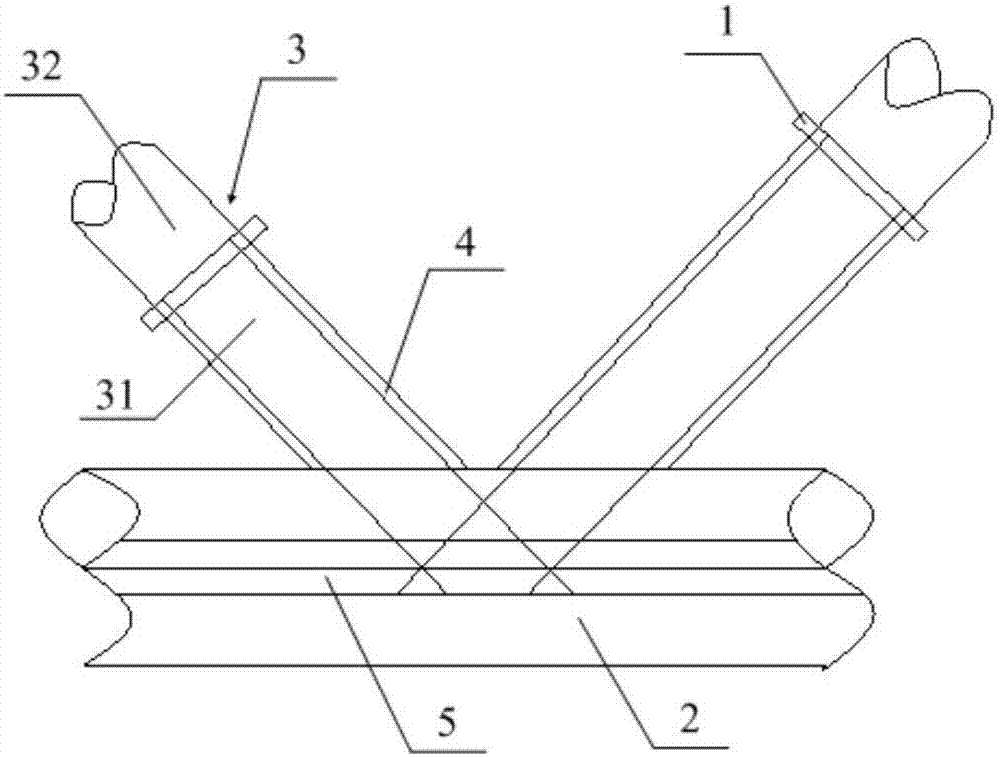

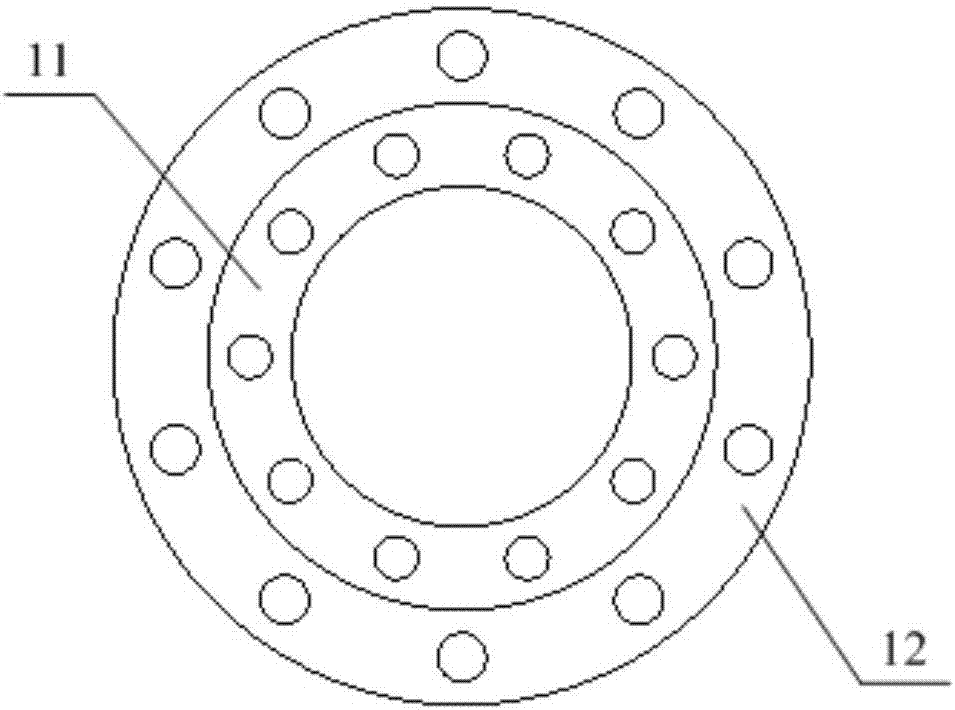

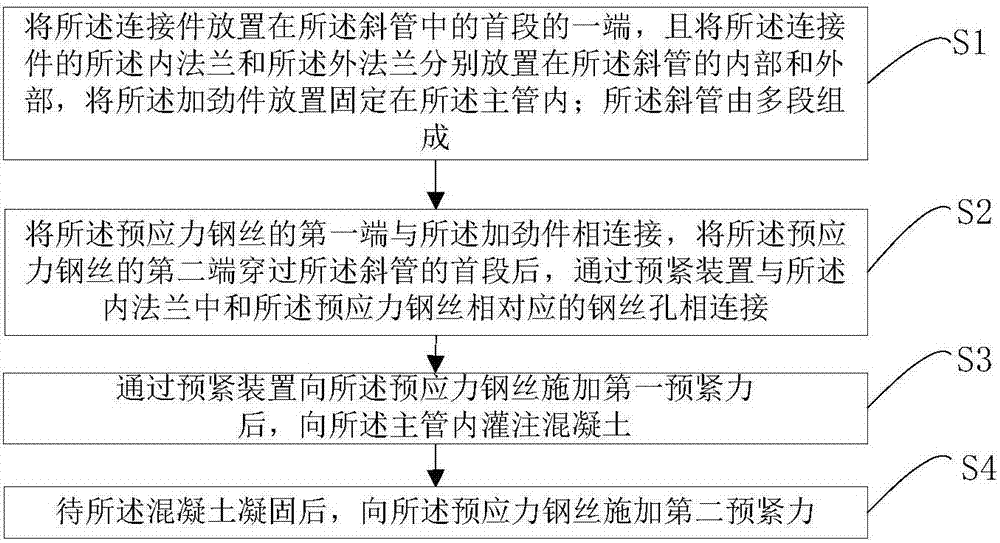

Concrete-filled steel tube power transmission tower intersecting joint with prestressed steel wires and manufacturing method for concrete-filled steel tube power transmission tower intersecting joint

The invention provides a concrete-filled steel tube power transmission tower intersecting joint with prestressed steel wires and a manufacturing method for the concrete-filled steel tube power transmission tower intersecting joint. The intersecting joint comprises a flange, a main pipe and two inclined pipes; the inclined pipes are composed of a plurality of sections; one of the inclined pipes is arranged at an acute angle with the main pipe, and the other inclined pipe is arranged at an obtuse angle with the main pipe; and both the first sections of the two inclined pipes are connected with the main pipe; the first section is connected with a secondary section through a connecting piece, wherein the second section is connected with the first section; the prestressed steel wires are arranged in the inclined pipes; a stiffening piece is arranged in the main pipe; first ends of the prestressed steel wires are connected with the stiffening piece, and second ends of the prestressed steel wires are connected with the connecting piece. According to the concrete-filled steel tube power transmission tower intersecting joint with the prestressed steel wires, the prestressed steel wires are fixed through the arranged stiffening piece and bears tensile force and bending moment of the inclined pipes, the risk of tearing of joint intersecting line welding seams is reduced, therefore, the tensile force and the bending moment applied to the welding seams when the inclined pipes are in tension are reduced by the intersecting joint, and the risk that the welding seams are cracked is reduced.

Owner:CHINA ELECTRIC POWER RES INST +2

Disposable biopsy forceps

PendingCN110876631AStable positionSimple structureSurgeryVaccination/ovulation diagnosticsEngineeringBiopsy forceps

The invention relates to a disposable biopsy forceps, which at least comprise the following structures: a forceps head assembly which comprises at least two forceps heads of which the far ends can beoppositely opened or closed; a forceps seat, wherein the near end of the forceps head is connected with the far end of the forceps seat through a connecting piece; a control line, wherein the far endof the control line is connected with the near end of the forceps head assembly so as to drive the forceps head assembly to be opened or closed; a gasket, wherein the far end side of the gasket is connected with the forceps seat through the connecting piece, the near end side of the gasket is provided with two extension parts which are oppositely arranged and extend towards the near end, an extension channel is formed between the two extension parts, and the far end of the control line moves in the extension channel. The biopsy forceps have the technical effects of being simple in structure, stable and reliable.

Owner:MICRO TECH (NANJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com