Flexible printed circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of flexible printed circuit boards, printed circuit manufacturing, multilayer circuit manufacturing, etc., can solve the problems of single-sided contact and conduction of pads, and achieve the goal of reducing pad tearing risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for manufacturing a flexible circuit board provided by an embodiment of the present invention is introduced in detail.

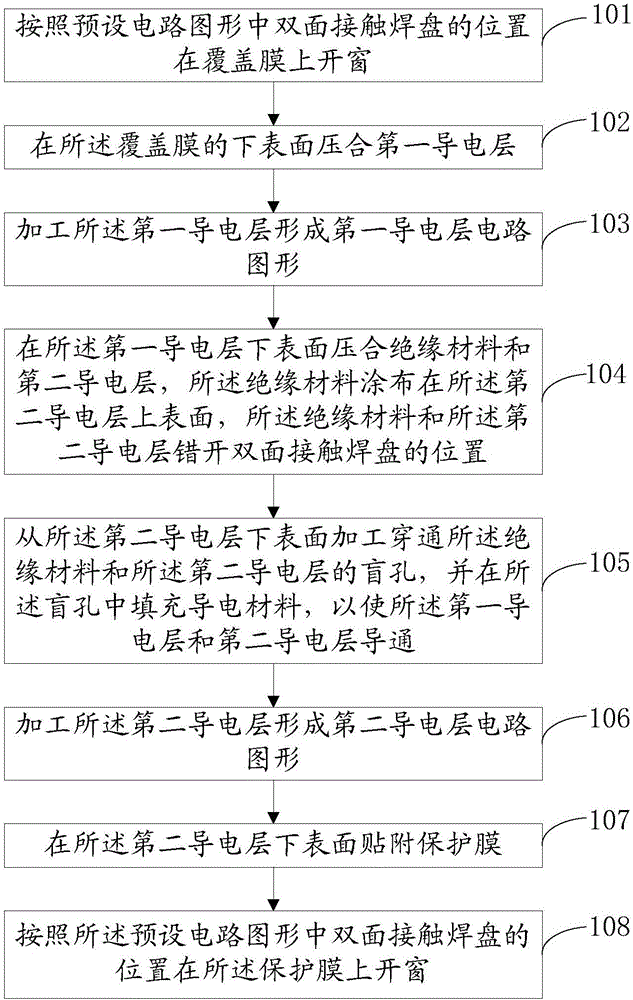

[0035] refer to figure 2 , shows a flow chart of a method for manufacturing a flexible circuit board in an embodiment of the present invention.

[0036] Step 101, opening windows on the cover film according to the positions of the double-sided contact pads in the preset circuit pattern.

[0037] In this embodiment, the cover film may include a polyimide film and a thermosetting adhesive coated on the polyimide film, and the cover film protects and insulates the wire circuit of the circuit board. According to the positions of the double-sided contact pads in the preset circuit pattern, windows are opened on the cover film. The window opening method can be at least one of laser processing window opening or mechanical mold punching window opening.

[0038] Step 102, pressing the first conductive layer on the lower surface of the covering film...

Embodiment 2

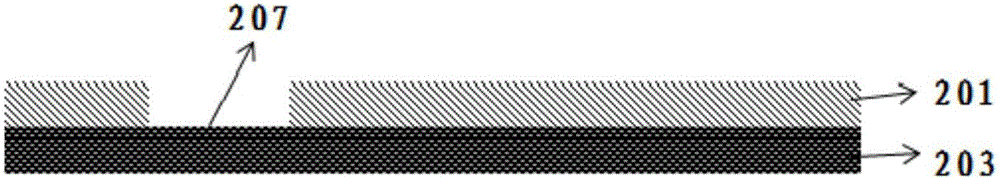

[0066] see Figure 3 to Figure 6 , a detailed introduction to a flexible circuit board provided by an embodiment of the present invention, the flexible circuit board includes:

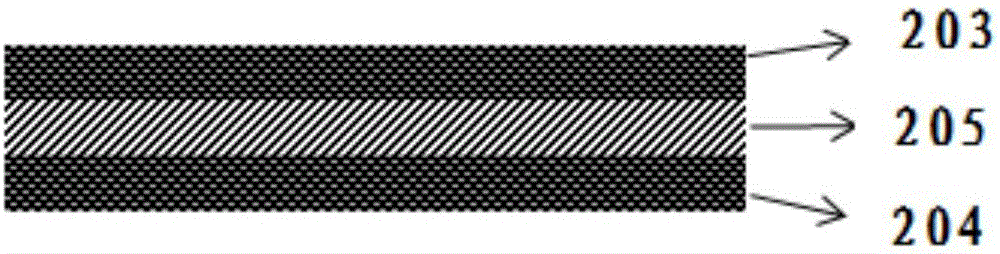

[0067] Covering film 201, protective film 202, first conductive layer 203, second conductive layer 204, insulating material 205, blind hole 206;

[0068] The cover film 201, the first conductive layer 203, the insulating material 205, the second conductive layer 204, and the protective film 202 are pressed from top to bottom to form the flexible circuit board;

[0069] The cover film 201 and the protective film 202 are opened at the position 207 of the double-sided contact pad in the preset circuit pattern;

[0070] The insulating material 205 and the second conductive layer 204 are pressed together with the first conductive layer by staggering the position 207 of the double-sided contact pad;

[0071] The insulating material 205 is coated on the upper surface of the second conductive layer 204;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com