Diaphragm check valve

A flexible film and check valve technology, applied to the structure of the check valve, the "seat" part of the check valve, and the field of gaseous fluids, can solve problems such as tearing and film rupture, and achieve mechanical pressure enhancement, tearing The effect of reducing the risk of cracking and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

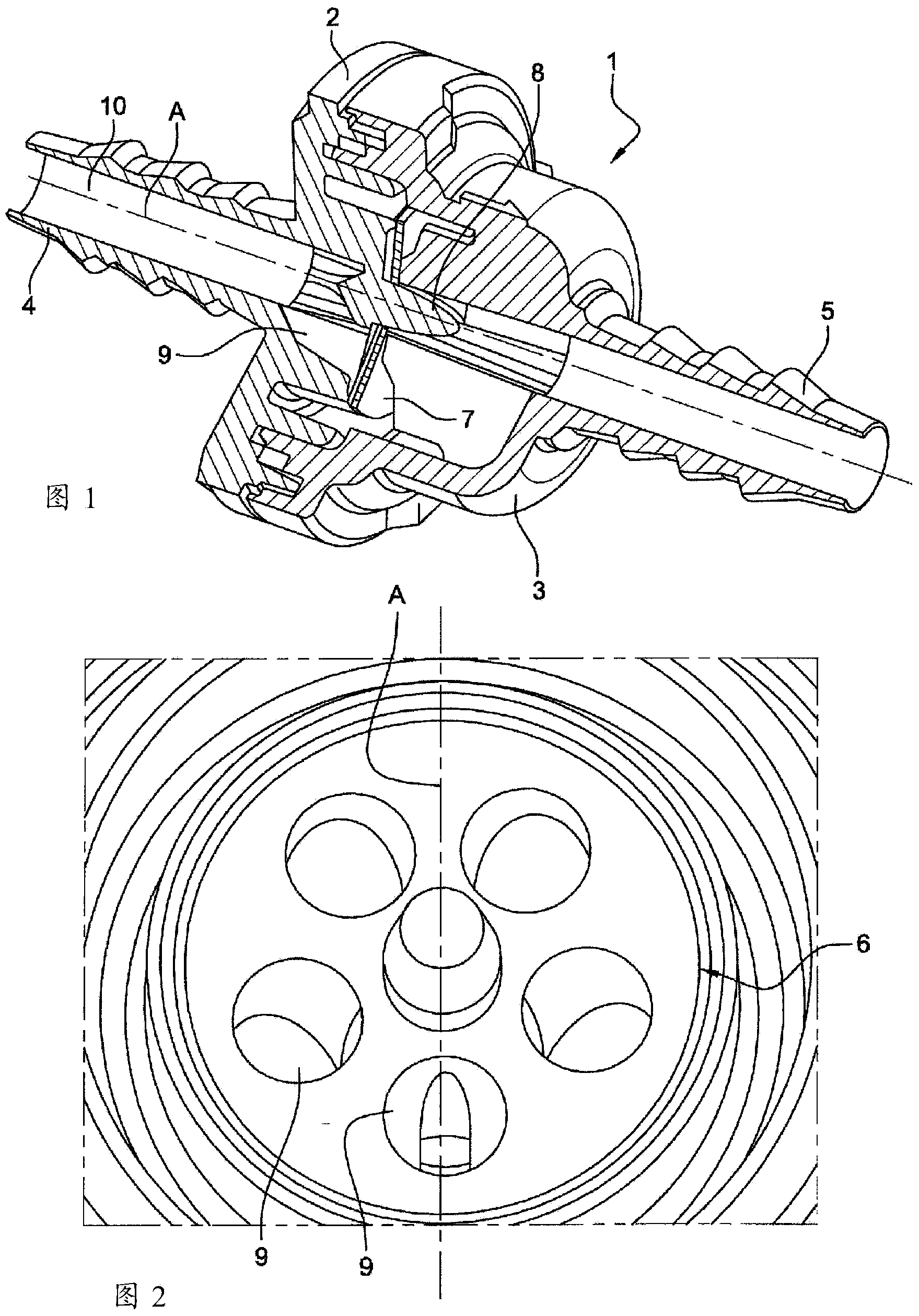

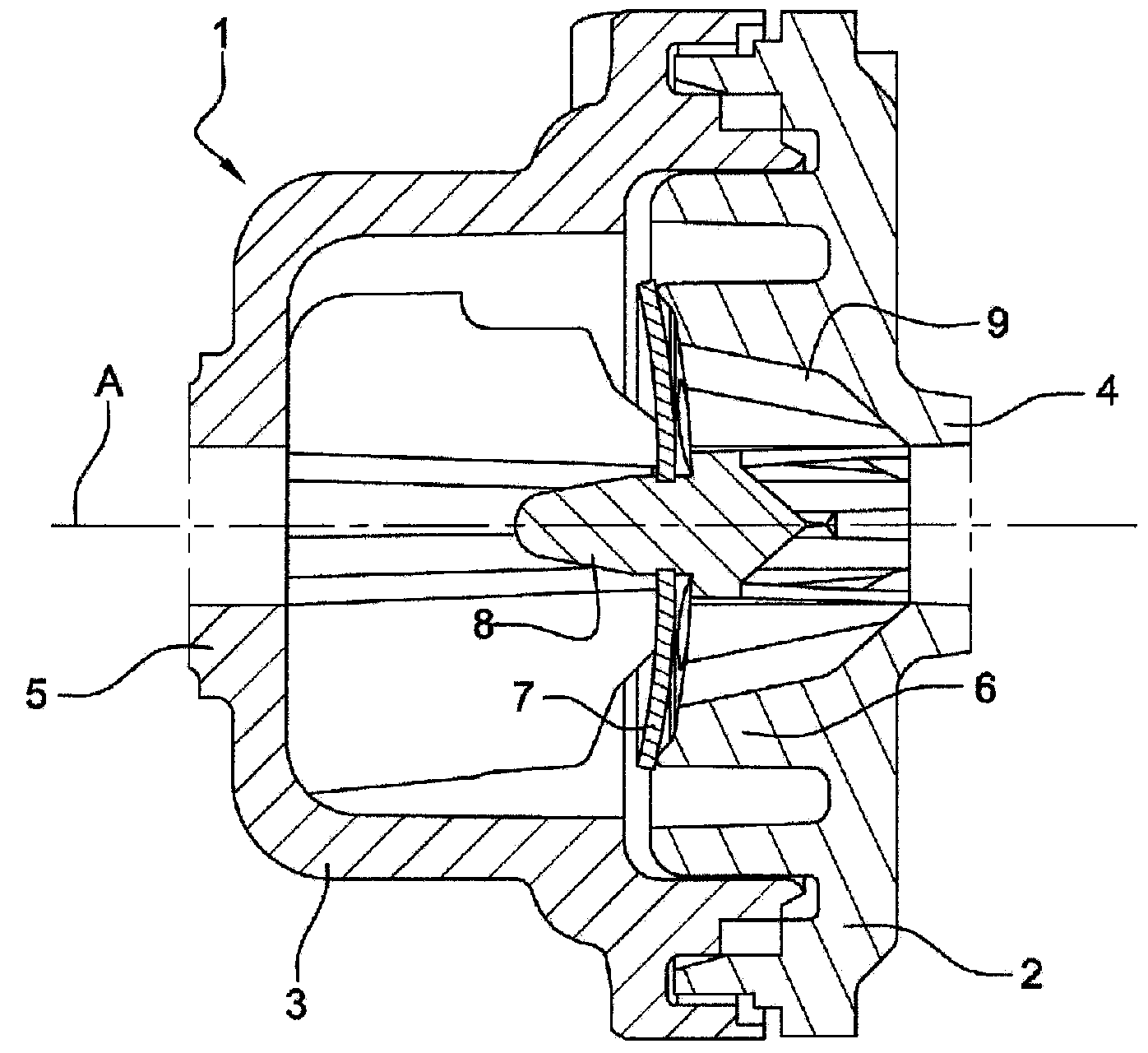

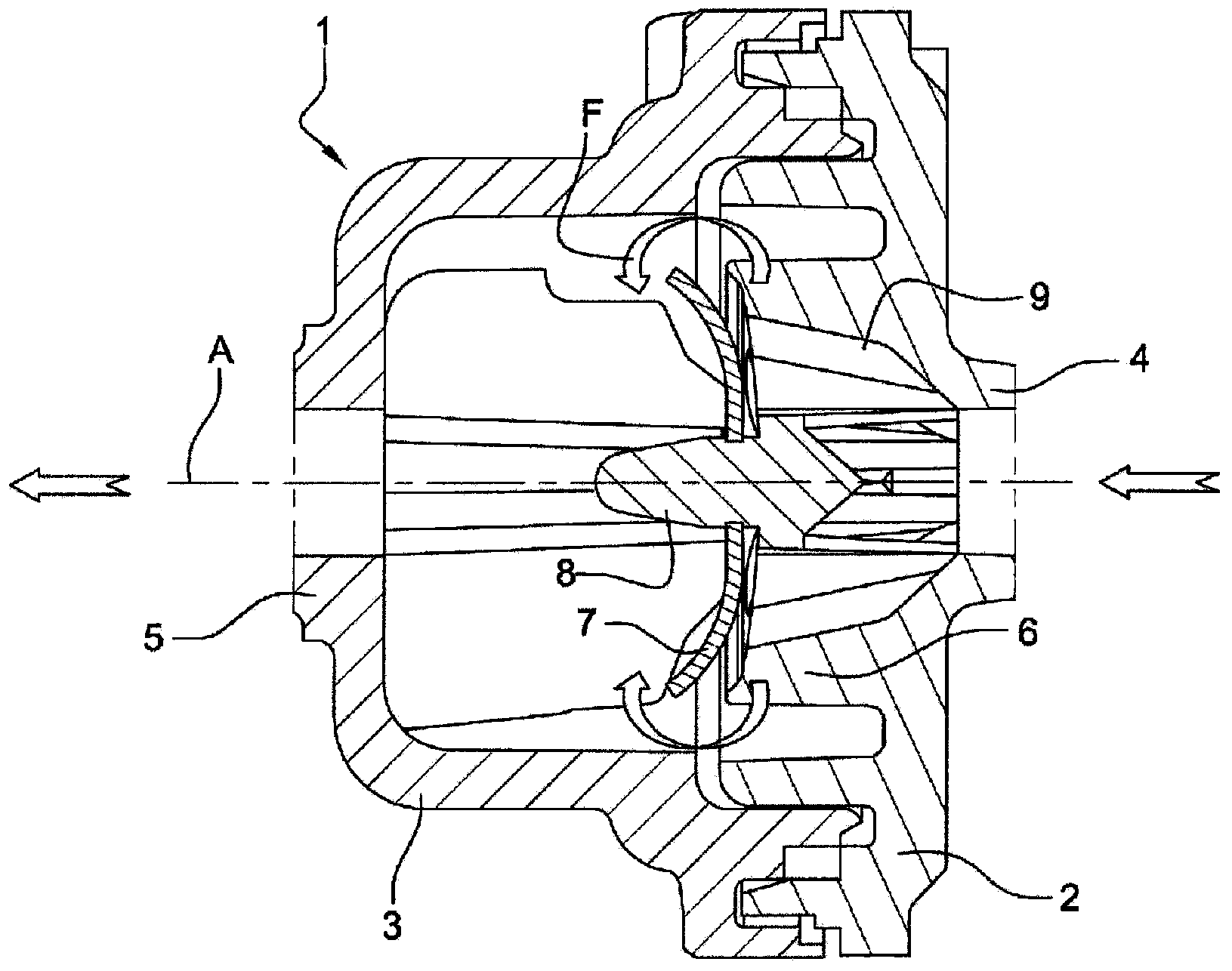

[0063] refer to figure 1 , 3 , 4, 6 and 7, non-return valves, designated as a whole with reference 1 and hereinafter simply referred to as "valve", comprise a hollow body consisting of two connecting parts 2 and 3 arranged along the same longitudinal axis A. The first part 2 of the body extends through an inlet end part 4 for fluid, while the second part 3 of the body extends through an outlet end part 5 for fluid.

[0064] The valve seat 6 , here incorporated into the first part 2 of said body, extends transversely to the longitudinal axis A. As shown in FIG. A flexible membrane 7 of circular shape, mounted inside said body, opposite one surface of the valve seat 6, the membrane 7 is here fixed by its centre. In particular, as figure 1 , 3 Diaphragm 7 is held on a central pin 8 integral with valve seat 6, as shown in FIGS.

[0065] The valve seat 6 is pierced by a plurality of passage ports 9 , all arranged around the axis A, in particular around the central pin 8 . Por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com