Method for preventing weld seam strip breakage of thin material strip steel

A strip welding and strip breaking technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high strip tension, enlargement, strip breaking, etc. The effect of avoiding weld breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

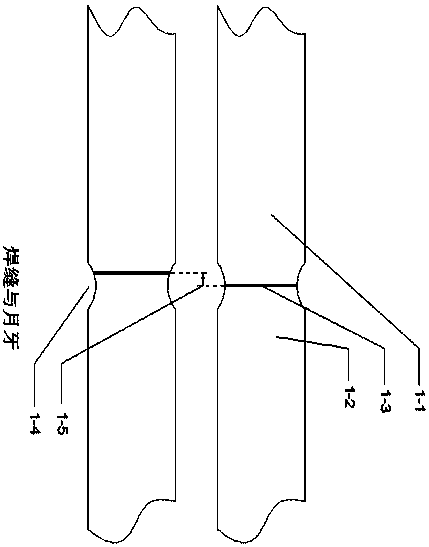

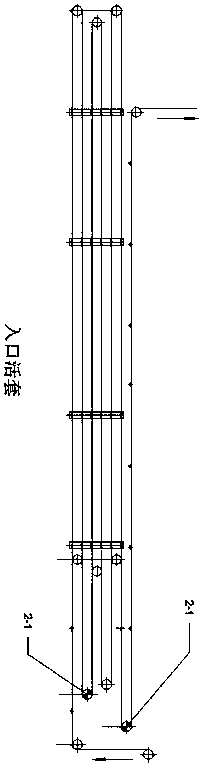

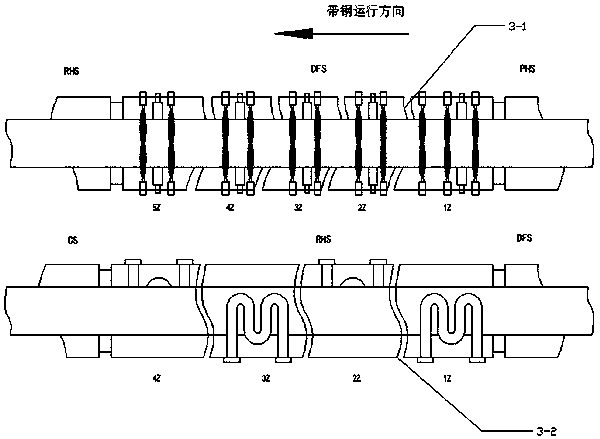

[0025] Embodiment 1: see Figure 1-Figure 5 , a method for preventing weld seam breakage of thin strip steel, said method comprising the following steps: 1) welding control; 2) entry looper control; 3) continuous annealing control, 4) air knife control, 5) flattening correction control.

[0026], said step 1) Welding control; including using a wooden hammer to verify the weld 1-3 and a wooden hemispherical hammer to perform a hammer test on the weld 1-3; after the welding is completed, use a wooden hammer to test the weld 1-3 Hammering at 15 cm on the side and the middle position, if there is no cracking, the weld 1-3 is qualified; if cracking occurs, a second re-welding is required; the edge weld is set to asymmetrical edge filling operation, when the weld is in When the crescent scissors are ready to fill the edge, jog the position of the weld seam forward or backward by 5-10CM to ensure that there is more than 2CM shear at the weld seam after cutting. In this way, it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com