Backlight module and display device

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problems of light guide plate shaking, light source damage, poor reliability of backlight module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to reduce the probability of tearing of the light bar of the backlight module, improve the reliability of the backlight module, and improve the display effect of the display device, an embodiment of the present invention provides a backlight module and a display device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

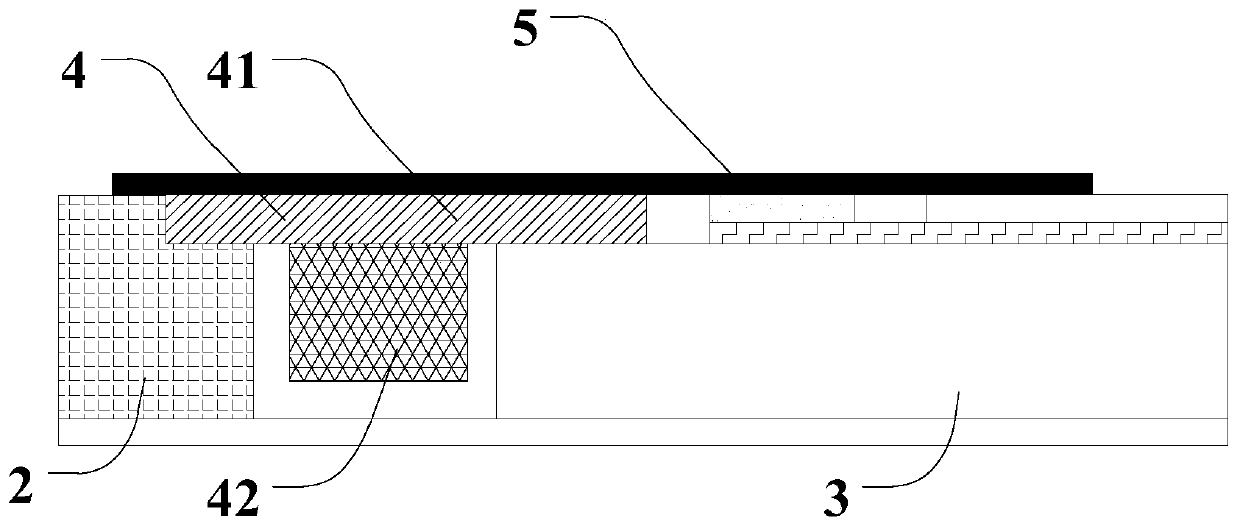

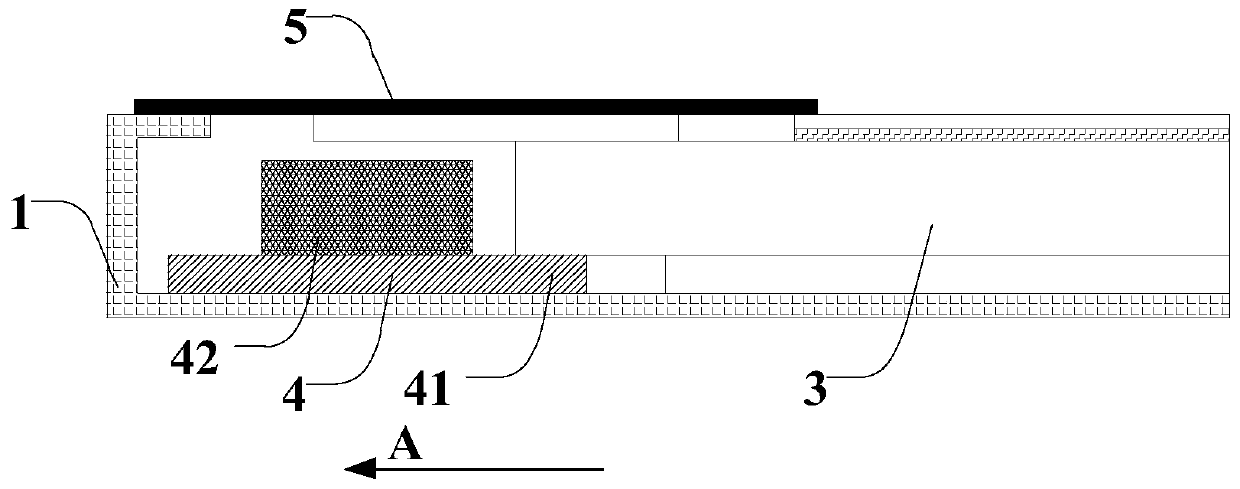

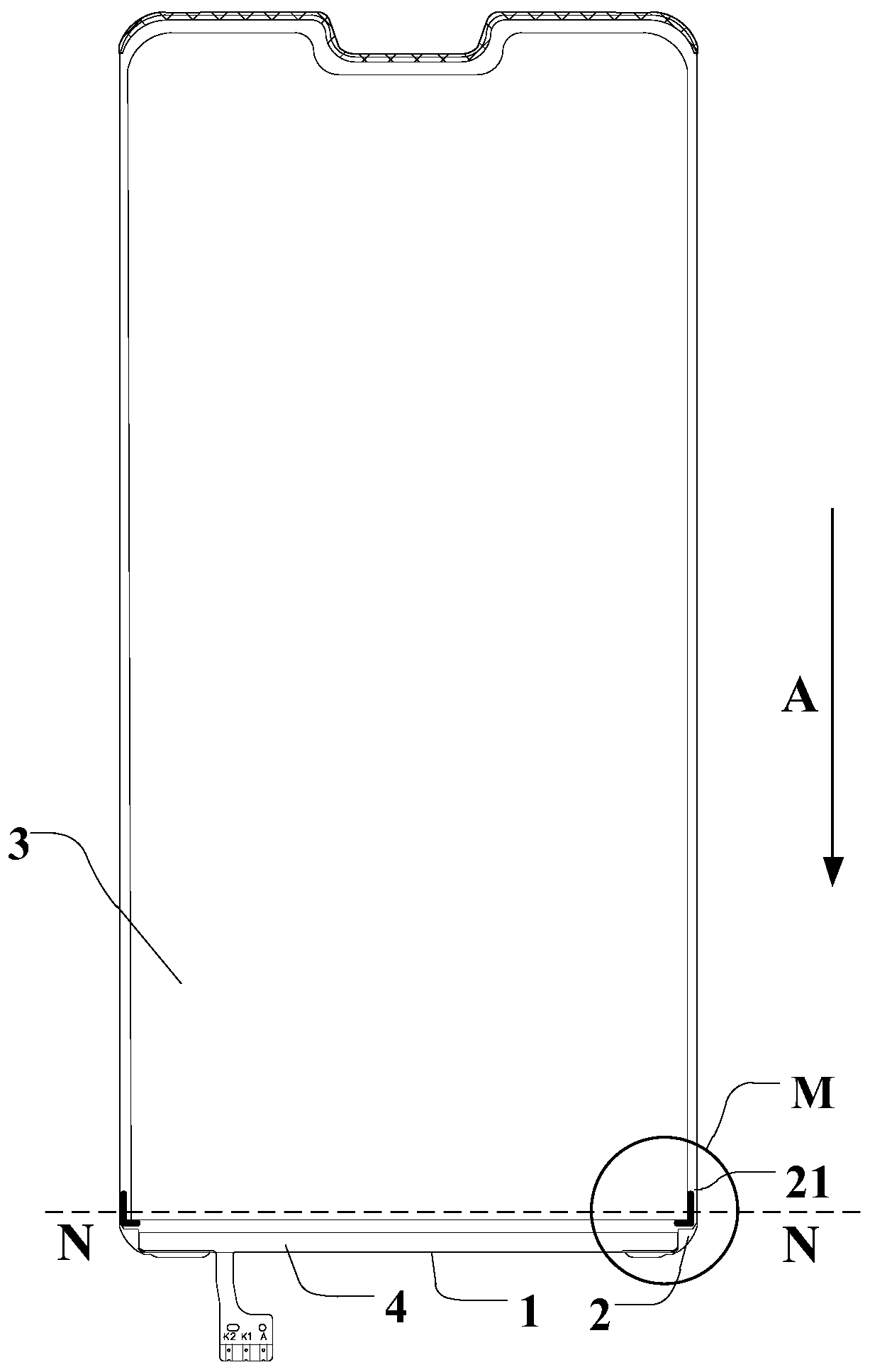

[0052] Such as Figure 1 to Figure 2 As shown, among them, figure 1 It is a schematic diagram of a partial cross-sectional structure of a backlight module according to an embodiment of the prior art; figure 2 It is a schematic diagram of a partial cross-sectional structure of a backlight module according to another embodiment of the prior art. The backlight module can be divided into positive group type and reverse group type according to the installation structure of the light bar 4 . The backlight module ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com