Method for increasing front screen-to-body ratio, screen installing structure and mobile terminal

An installation structure and a front screen technology, applied in a method of increasing the front screen ratio, the screen installation structure and the field of mobile terminals, can solve the problems of affecting the screen ratio, increasing the front screen ratio, etc., so as to improve the screen ratio , the effect of improving structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Such as Figure 5 As shown, the embodiment of the present invention provides a method for increasing the proportion of the front screen, and the method includes the following steps:

[0056] S101. Set the display screen and the backlight board of the screen in the corresponding accommodation grooves of the inner shell or the middle frame in sequence, and fill the gaps around the display screen and the backlight board with an elastic material;

[0057] S102. After the elastic material is cured to form an elastic filling layer, cover the display screen with a glass cover plate, and attach the surrounding surface of the glass cover plate to the upper surface of the elastic filling layer.

[0058] Wherein, a support step is provided corresponding to the inner shell or the middle frame of the glass cover plate, and the upper surface of the elastic filling layer and the support step are attached around the glass cover plate.

[0059] Wherein, the width of the supporting step i...

Embodiment 2

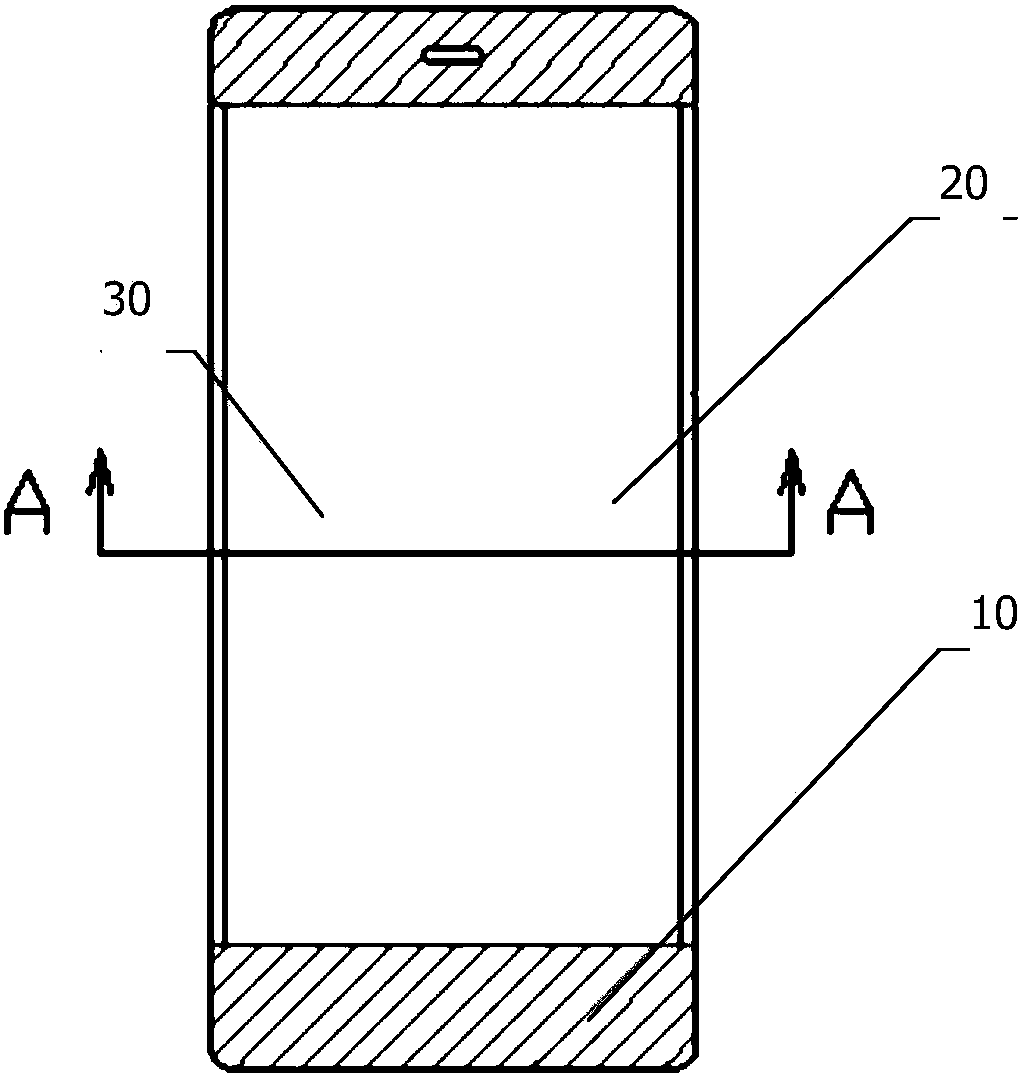

[0062] Based on the same inventive concept, another aspect of the present invention, such as Figure 6 As shown, a screen installation structure is also provided, including an inner shell or a middle frame 10, an elastic filling layer 50, and the display screen 22 and the backlight plate 21 of the screen 20 are sequentially provided with corresponding contents of the inner shell or the middle frame 10. The elastic filling layer 50 is arranged in the gap between the display screen 22 and the backlight 23 and the inner shell or the edge of the middle frame 10; the glass cover plate 23 of the screen 20 Attached to the upper surface of the elastic filling layer 50 .

[0063] Wherein, corresponding to the glass cover plate 23 , a supporting step is provided on the periphery of the inner shell or the middle frame 10 , and the supporting step is flush with the upper surface of the elastic filling layer 50 .

[0064] Wherein, the glass cover plate 23 is arranged on the upper surface ...

Embodiment 3

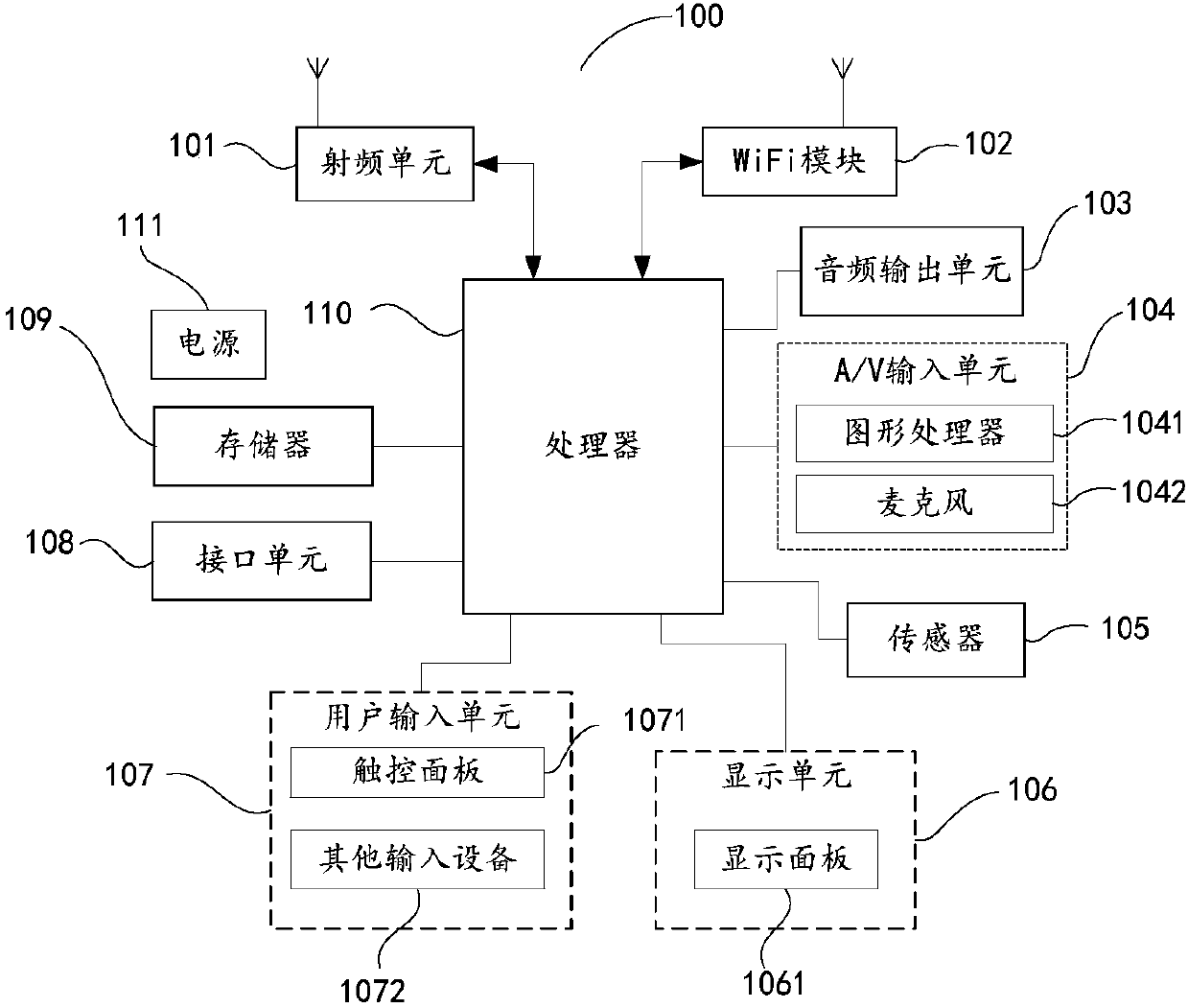

[0069] Based on the same inventive concept, another aspect of the present invention also provides a mobile terminal, which has the above-mentioned screen installation structure, specifically, includes an inner shell or middle frame 10, an elastic filling layer 50, a display screen 22 of the screen 20, The backlight plate 21 is sequentially arranged in the containing groove corresponding to the inner shell or the middle frame 10, and the elastic filling layer 50 is arranged between the display screen 22 and the backlight plate 23 and the inner shell or the middle frame. The gap between the edges of the frame 10 ; the glass cover 23 of the screen 20 is attached to the upper surface of the elastic filling layer 50 .

[0070] Wherein, corresponding to the glass cover plate 23 , a supporting step is provided on the periphery of the inner shell or the middle frame 10 , and the supporting step is flush with the upper surface of the elastic filling layer 50 .

[0071] Wherein, the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com