Insert for mounting into an inflatable tire

An insert, tire technology, applied in tire parts, wheels, transportation and packaging, etc., can solve the problems of fragmentation, filling, difficult tires, etc., to achieve easy installation, reduce wear, improve operational reliability and life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

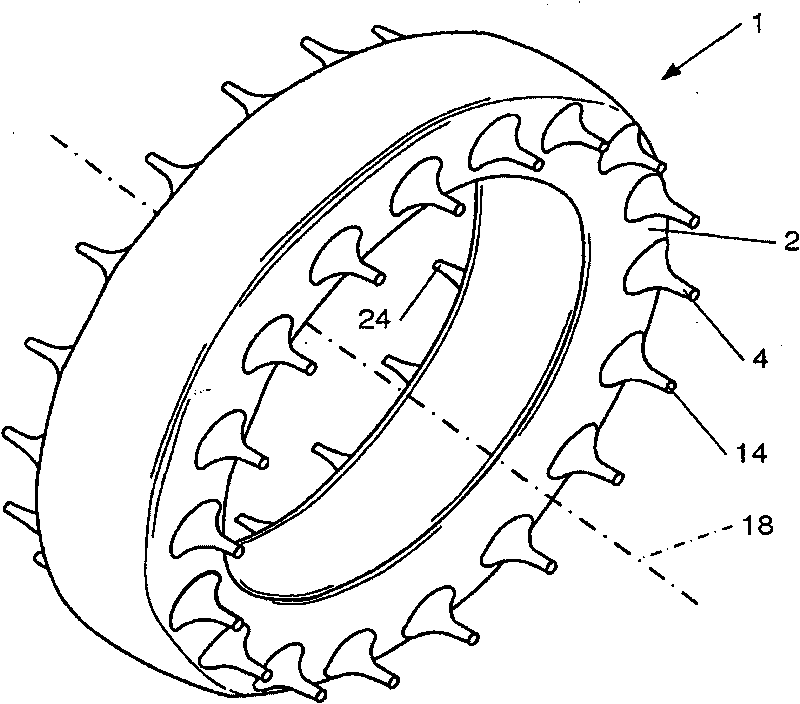

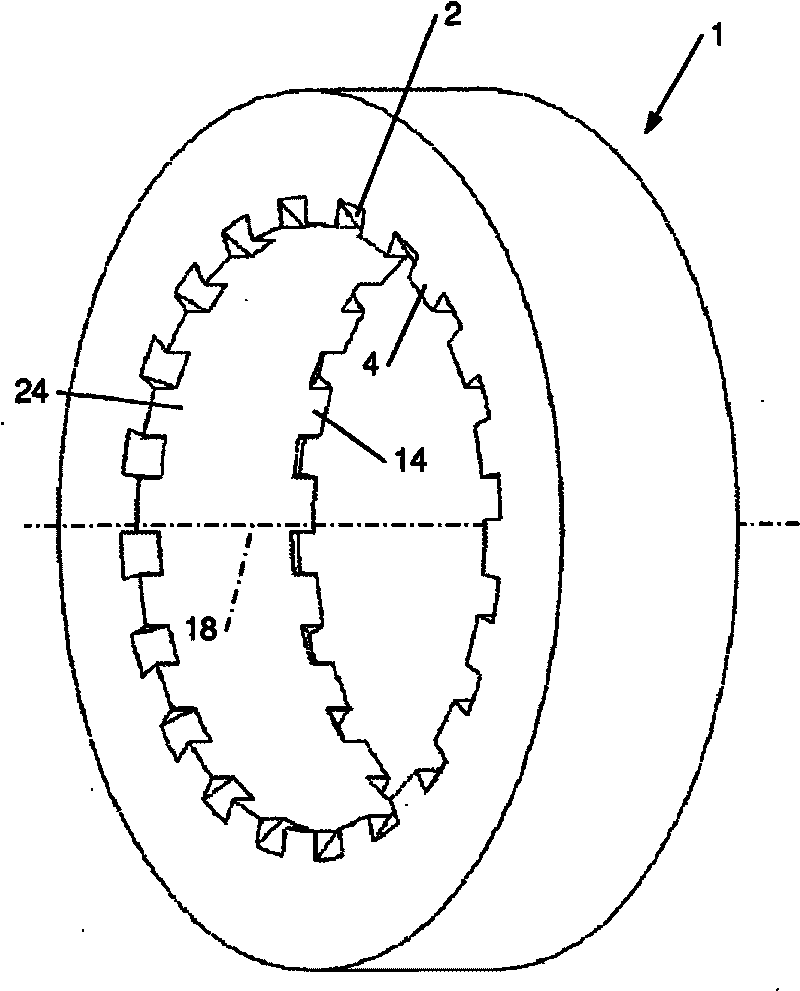

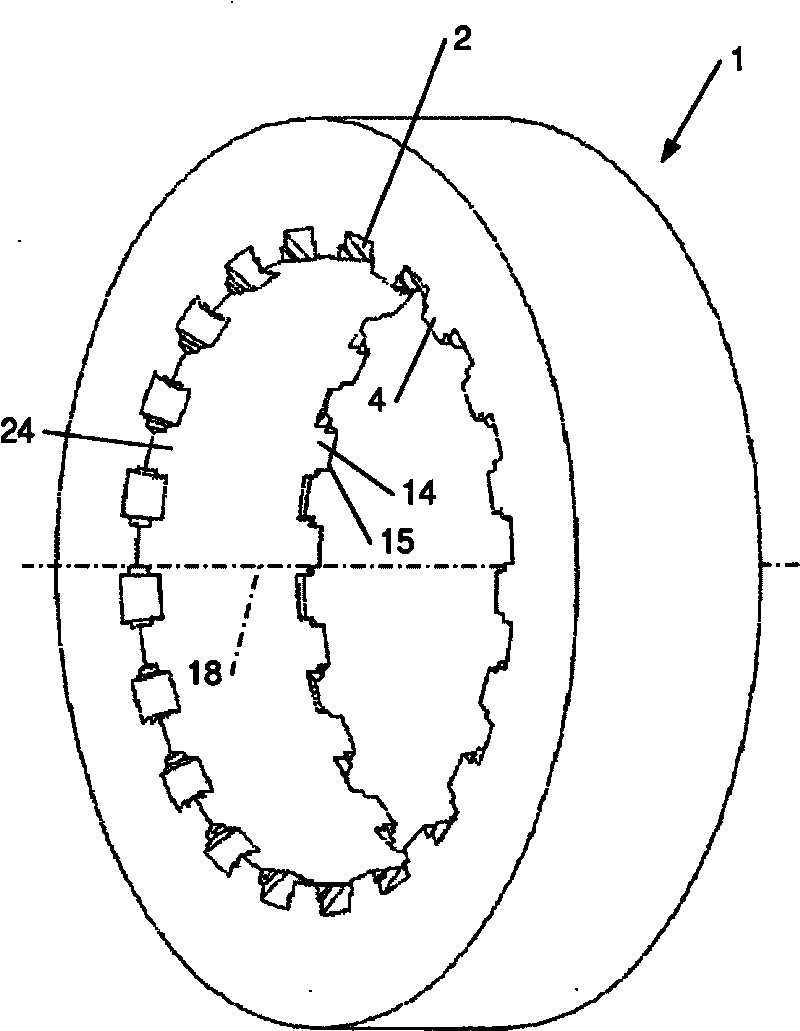

[0036] exist Figure 4 The preferred embodiment of the inflatable tire 5 represented in includes an annular shaped tire body along the circumference of the tire 5, which includes a tread portion 10 formed for the tire 5 along the circumference of the tire 5. rolling surface19. The annular shaped tire body of the tire 5 preferably comprises a carcass 9 supporting a tread portion 10 . The tread portion 10 and the carcass 9 are in no way critical and any other annular shape tire body known to a person skilled in the art is feasible.

[0037]The annular shaped tire body extends along the circumference of the tire 5 about the central rotational axis 18 of the tire 5 . The carcass 9 preferably comprises a first circumferential sidewall 12 extending from the first side 11 of the tread portion 10 towards the axis of rotation 18 of the tire 5; and a second circumferential sidewall 22 extending from the first side 11 of the tread portion 10 The two sides 21 extend towards the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com