Plant fiber dispersible material and preparation method thereof

A plant fiber and chopped plant fiber technology, applied in the field of non-woven materials, can solve the problems of low wet strength, different fiber lengths, and more fiber agglomeration, and achieve the goal of reducing ultra-short fiber sticking to the net and reducing pulp Loss, reduce the effect of fiber shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] A preparation method of plant fiber flushable material, comprising the following steps:

[0079] 1) Preparation of chopped plant fibers: One or more plant fibers are opened and removed by an opening and cleaning machine with sawtooth rollers, and then the opened plant fibers are longitudinally sorted so that the curled plant fibers are combed into a straight state and made into plant fiber strips; the plant fiber strips are cut to make chopped plant fibers.

[0080] 2) Preparation of upper and lower fiber layer slurries: add chopped plant fibers and / or plant fiber linters to water and stir to disperse the fibers, use a slit filter to remove flocculated fiber clusters and neps, and make a concentration of 0.1-2wt% fiber mixed slurry, and the filtered flocculated fiber clusters and neps are mixed with the raw materials in step 3) for disintegration.

[0081] 3) Preparation of medium fiber layer slurry: add water to the plant fiber pulp and stir to disintegrate, after dis...

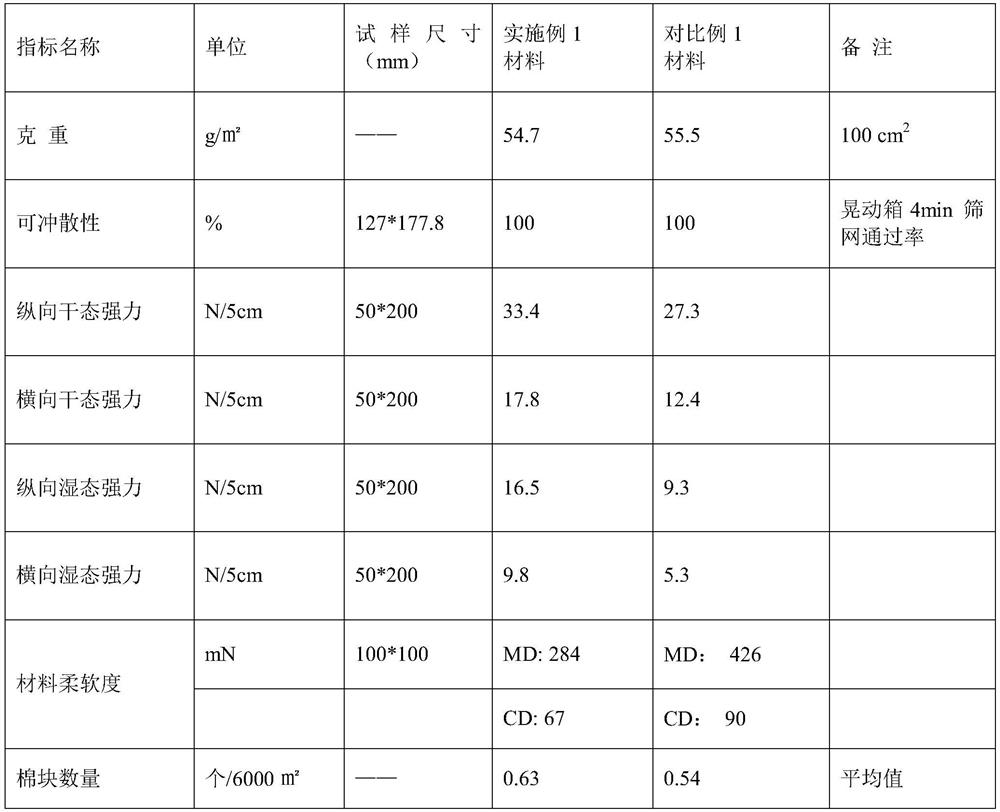

Embodiment 1

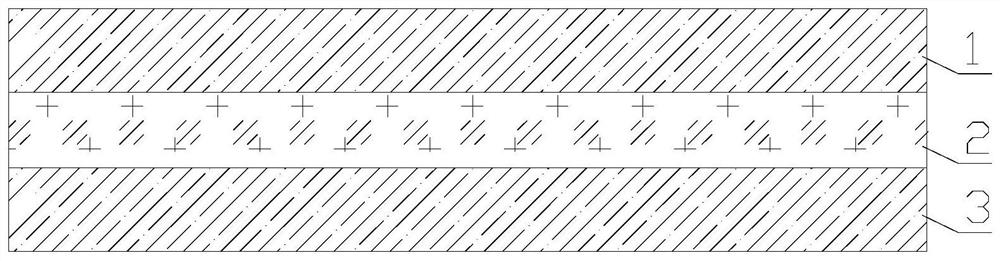

[0094] A plant fiber flushable material with a mass per unit area of 54.7g / m 2 , including the upper, middle and lower fiber layers that are superimposed and connected to each other; wherein the upper fiber layer and the lower fiber layer are composed of chopped absorbent cotton fibers and absorbent cotton linters with an average length of 5mm; the middle fiber layer is composed of an average length of 2.3mm Composed of cotton pulp; the fibers in the upper, middle and lower layers are entangled with each other. Wherein the upper fiber layer and the lower fiber layer each account for 15% of the material mass, and the middle fiber layer accounts for 70% of the material mass.

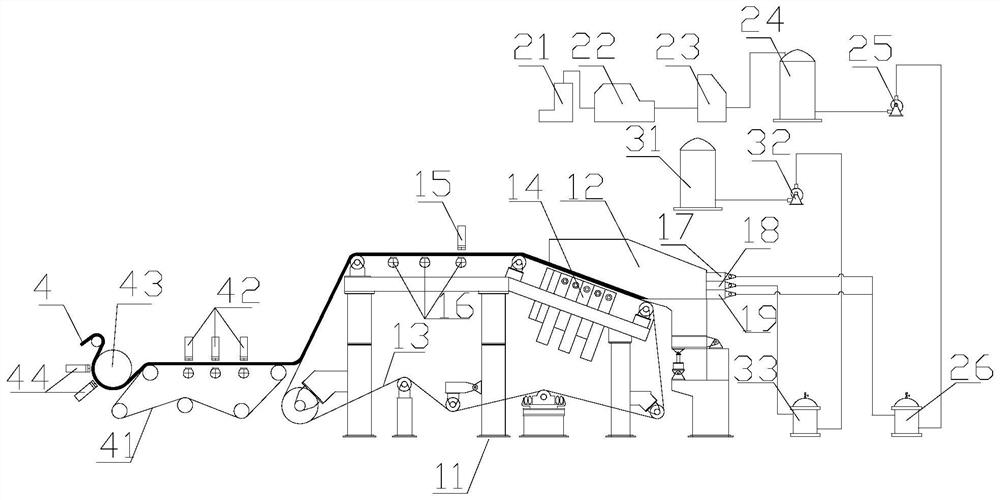

[0095] A kind of preparation method of cotton fiber flushable material, adopts such as figure 2 The device shown comprises the following steps:

[0096] 1. Preparation of chopped cotton fibers

[0097] The cotton fiber is sent to the cotton opening and cleaning machine to open and remove impurities; ...

Embodiment 2

[0110] A plant fiber flushable material with a mass per unit area of 30g / m 2 , including the upper, middle and lower fiber layers that are superimposed and connected to each other; the upper fiber layer and the lower fiber layer are composed of chopped hemp fibers with an average length of 8 mm; the middle fiber layer is composed of hemp fiber pulp with an average length of 2 mm, and the average Composed of cotton pulp with a length of 2.3 mm; the fibers in the upper, middle and lower layers are entangled with each other. Wherein the upper fiber layer and the lower fiber layer each account for 20% of the material mass, and the middle fiber layer accounts for 60% of the material mass.

[0111] A preparation method for a hemp plant fiber flushable material, comprising the following steps:

[0112] 1. Preparation of chopped hemp fiber

[0113]Send the hemp fiber into the cotton opening and cleaning machine to loosen and remove impurities; then send the opened fiber to the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com