Unloading buffer hydraulic system

A technology of hydraulic system and hydraulic oil tank, which is applied in fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as serious water hammer, improve safety, reduce strong impact, and prevent loosening and oil leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

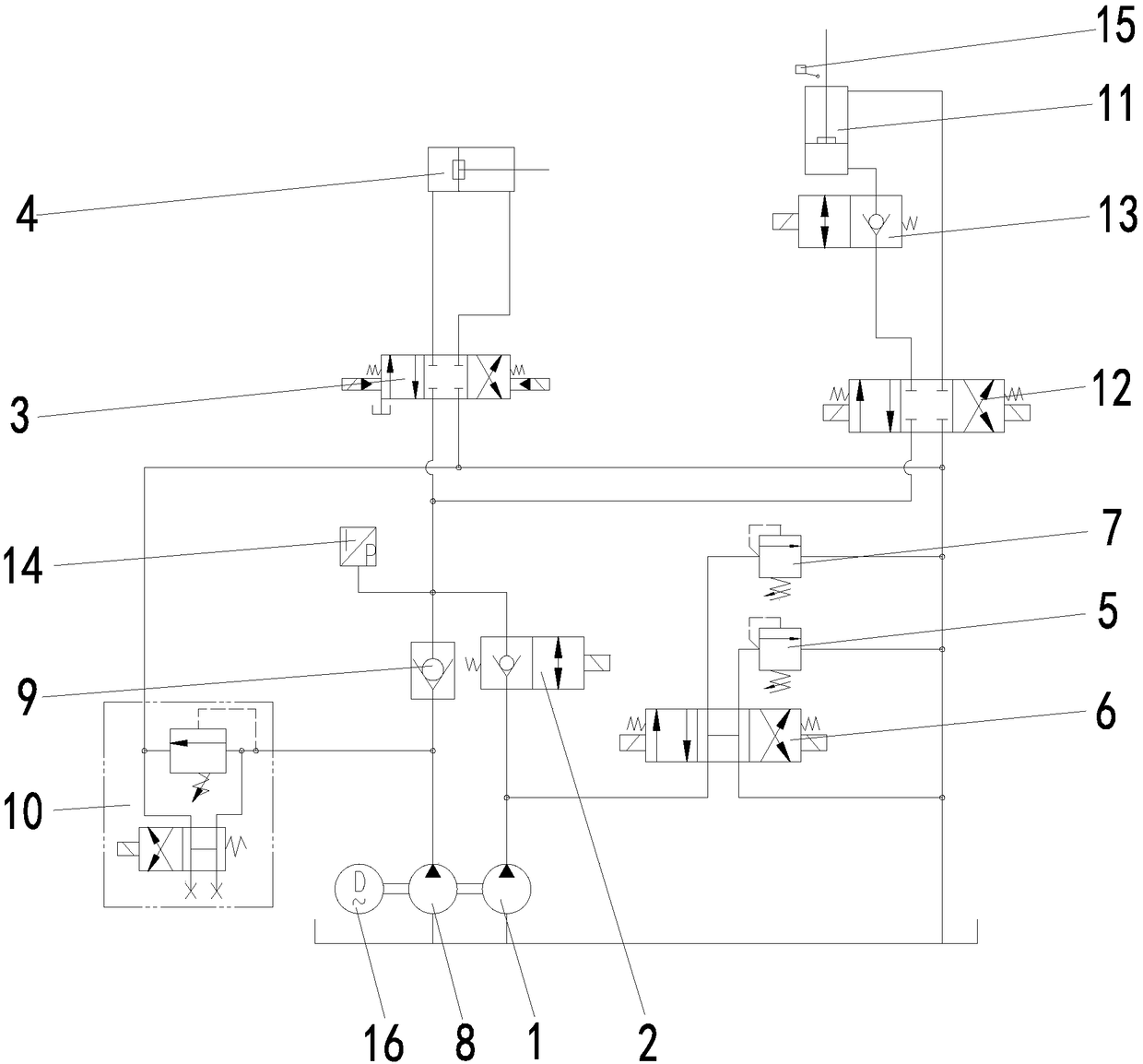

[0038] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0039] see figure 1 , the present invention provides an unloading buffer hydraulic system, the system includes a first pump body 1, a first reversing valve 2, a second reversing valve 3, a push plate cylinder 4 and a low pressure relief valve of the first pump body , the first pump body 1 communicates with the hydraulic oil tank and the second reversing valve 3 through the main pressure oil circuit, and the two oil outlets of the second reversing valve 3 respectively push the rod chamber and the rodless chamber of the plate cylinder 4 The oil return port of the second reversing valve 3 communicates with the hydraulic oil tank through the oil return line. The first reversing valve 2 is arranged between the first pump body 1 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com