Sleeve-removing shifting fork mechanism and method

A technology for unloading sleeves and sleeves, which is applied in the field of cold-rolled strip steel equipment, can solve the problems of messy discharge and large impact, and achieve the effect of convenient handling and lightening strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] In order to illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, and features of the present invention will be described with reference to the accompanying drawings.

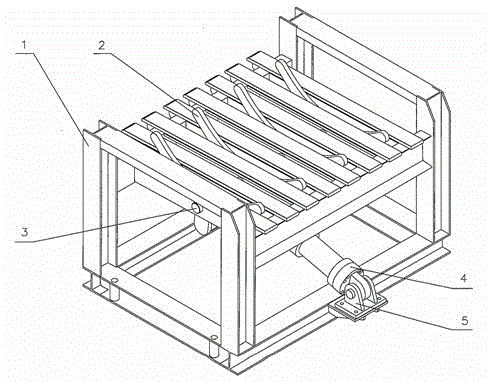

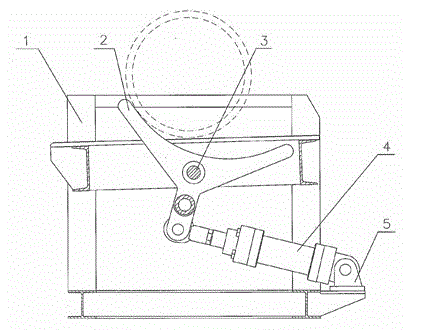

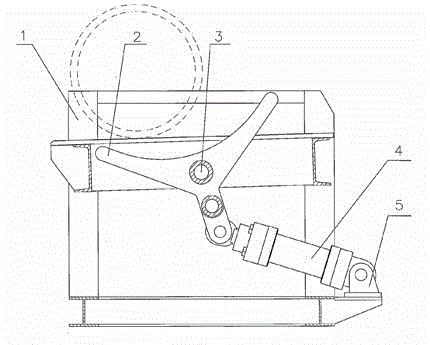

[0015] Such as figure 1 As shown, a sleeve unloading shift fork mechanism includes a frame body 1, a shift fork unit 2, a long pin shaft 3, a telescopic hydraulic cylinder 4, and a hydraulic cylinder support 5. The frame body 1 is a rectangular body and passes through a foot The bolts are fixed to the foundation. The fork unit 2 is fixed by the long pin shaft 3 in the middle of the rectangular body; the top of the rectangular body is evenly divided by the long partitions, which make the top surface form an inclined platform, and the platform is used for the sleeve to roll. The empty slots between the long partitions allow the shift fork of the shift fork unit 2 to be easily extended; the shift fork of the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com