Slab continuous casting submersed nozzle

A slab continuous casting and immersion technology, which is applied in the field of continuous casting of steel, can solve the problems of unfavorable crystallizer lateral temperature and text uniformity, unfavorable mold temperature and composition uniformity, unfavorable inclusions and bubble floating removal, etc. problems, to achieve the effect of uniform solidification, continuous casting process improvement, avoiding remelting and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

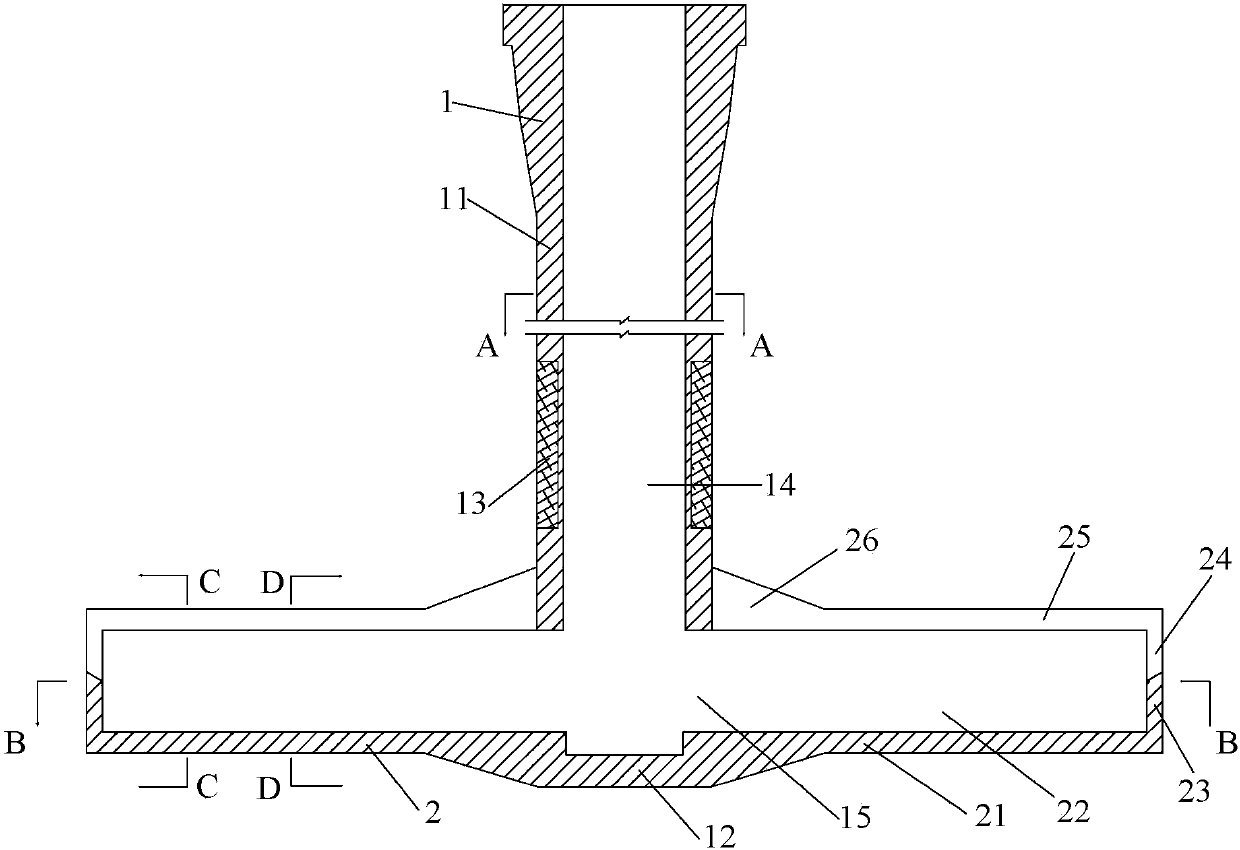

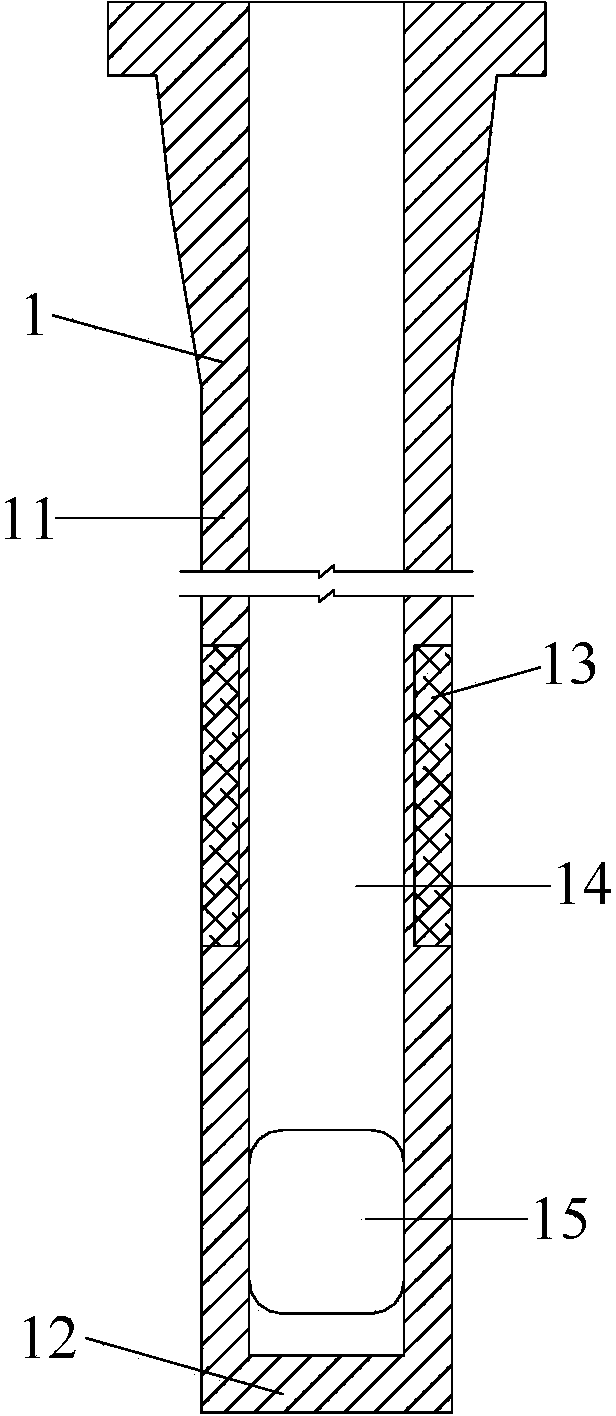

[0031] Below in conjunction with specific embodiment of the present invention and description attached Figure 1-8 The technical scheme of the present invention will be further described.

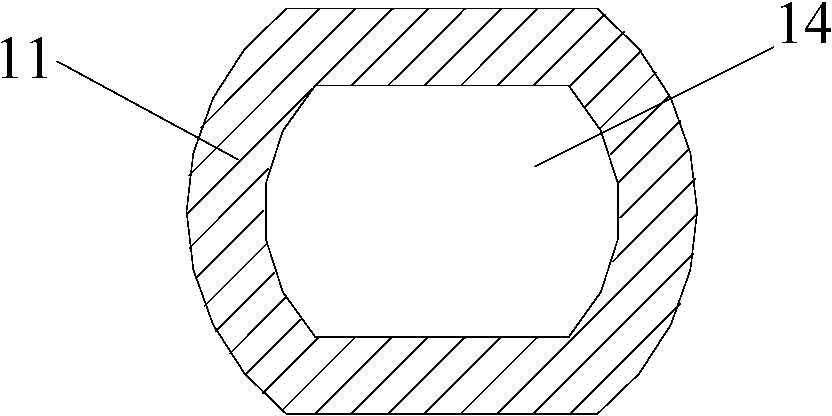

[0032] Such as Figure 1 to Figure 6 As shown, the slab continuous casting submerged nozzle involved in the present invention is composed of a vertical section 1 and a horizontal section 2. The vertical section 1 includes a side wall 11 and a closed bottom 12. On the outer side of the side wall 11 A ring-shaped slag line 13 is provided, the depth of the slag line 13 is 10-25 mm, the height is 100-160 mm, and the distance between the lower end of the slag line 13 and the lower surface of the nozzle bottom 12 is 60-120 mm; the side wall 11 and The bottoms 12 are connected to each other and form a hollow cavity 14 with an open top in the vertical direction. The cross-sectional shape of the side wall 11 and the hollow cavity 4 can be circular, square with chamfered corners or flat front and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com