Patents

Literature

70results about How to "Promotes buoyant removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

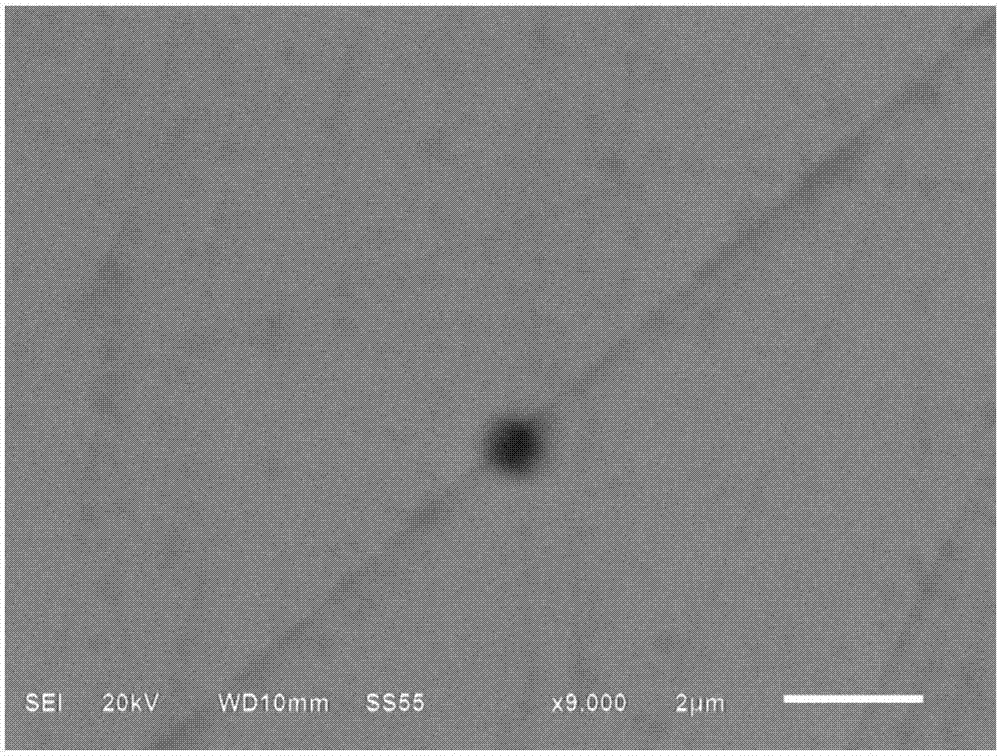

Smelting method capable of reducing inclusions of spring steel

The invention discloses a smelting method capable of reducing inclusions of spring steel. The smelting method includes the following steps of (1) smelting through a high carbon withdrawing process; (2) argon blowing; (3) refining in an LF furnace; (4) vacuum treatment; (5) LF soft blowing; and (6) spring steel rolling. Especially, aluminum-free deoxidation is adopted during smelting through the high carbon withdrawing process, and a low-alkalinity slag process is adopted during refining in the LF furnace. According to the smelting method capable of reducing inclusions of spring steel, on the basis of researching thermodynamics and kinetics for separation out of inclusions, the content of oxides is lowered by controlling the deoxidation depth during smelting, the low-alkalinity slag process facilitates plasticization of inclusions, the plasticized inclusions can easily aggregate and grow up, flotation removal is facilitated during soft blowing in secondary refining, and therefore the purpose of controlling the level of nonmetal inclusions of spring steel is achieved; and the problem of judgment amending caused by exceeding of inclusions is completely solved, and the production cost is greatly lowered.

Owner:武汉钢铁有限公司

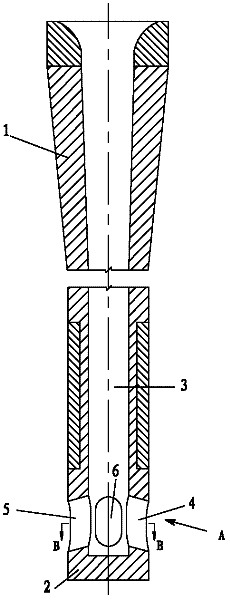

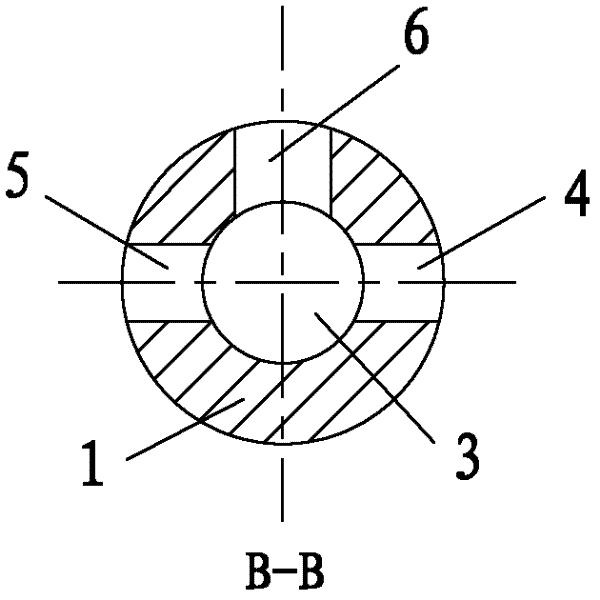

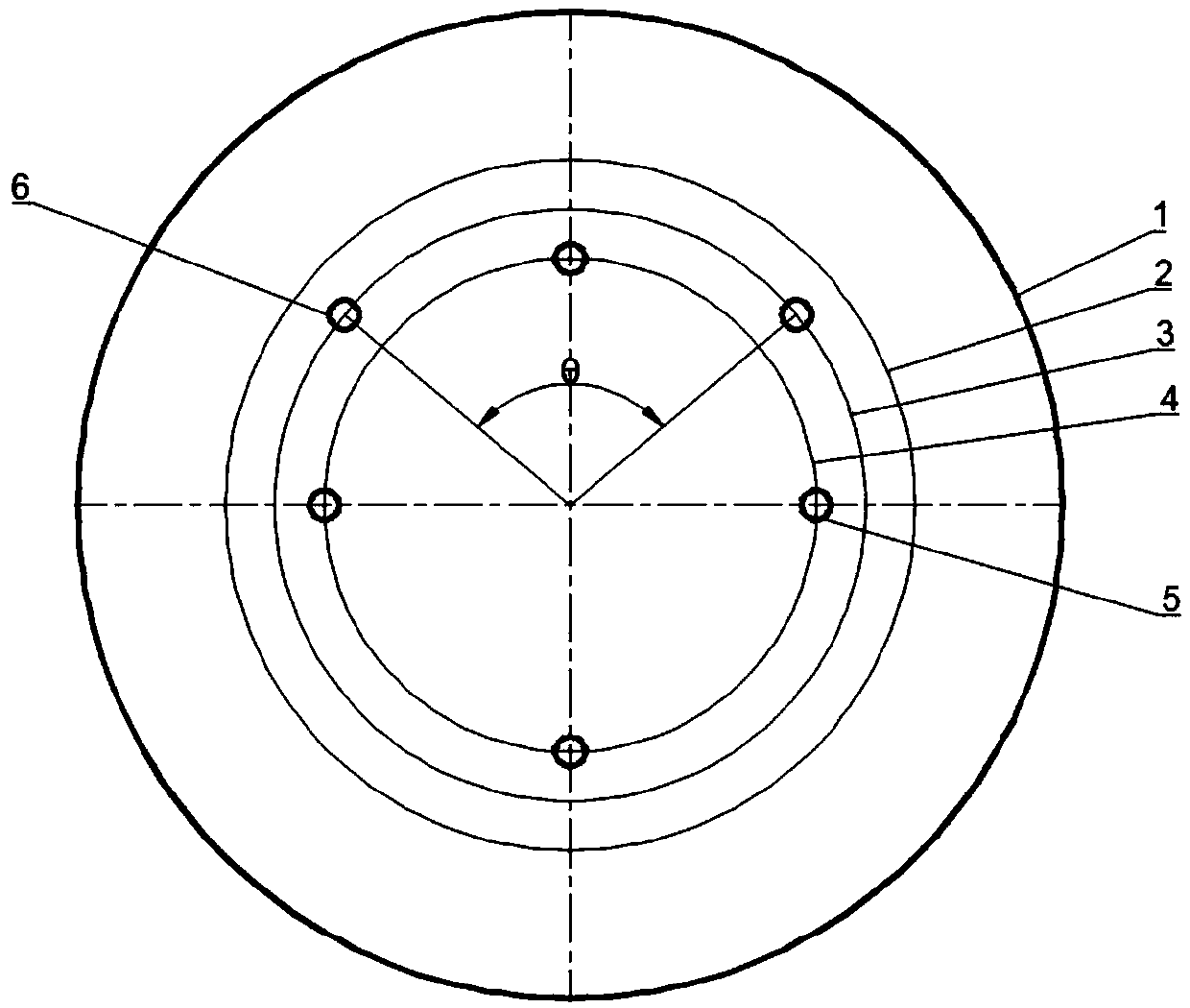

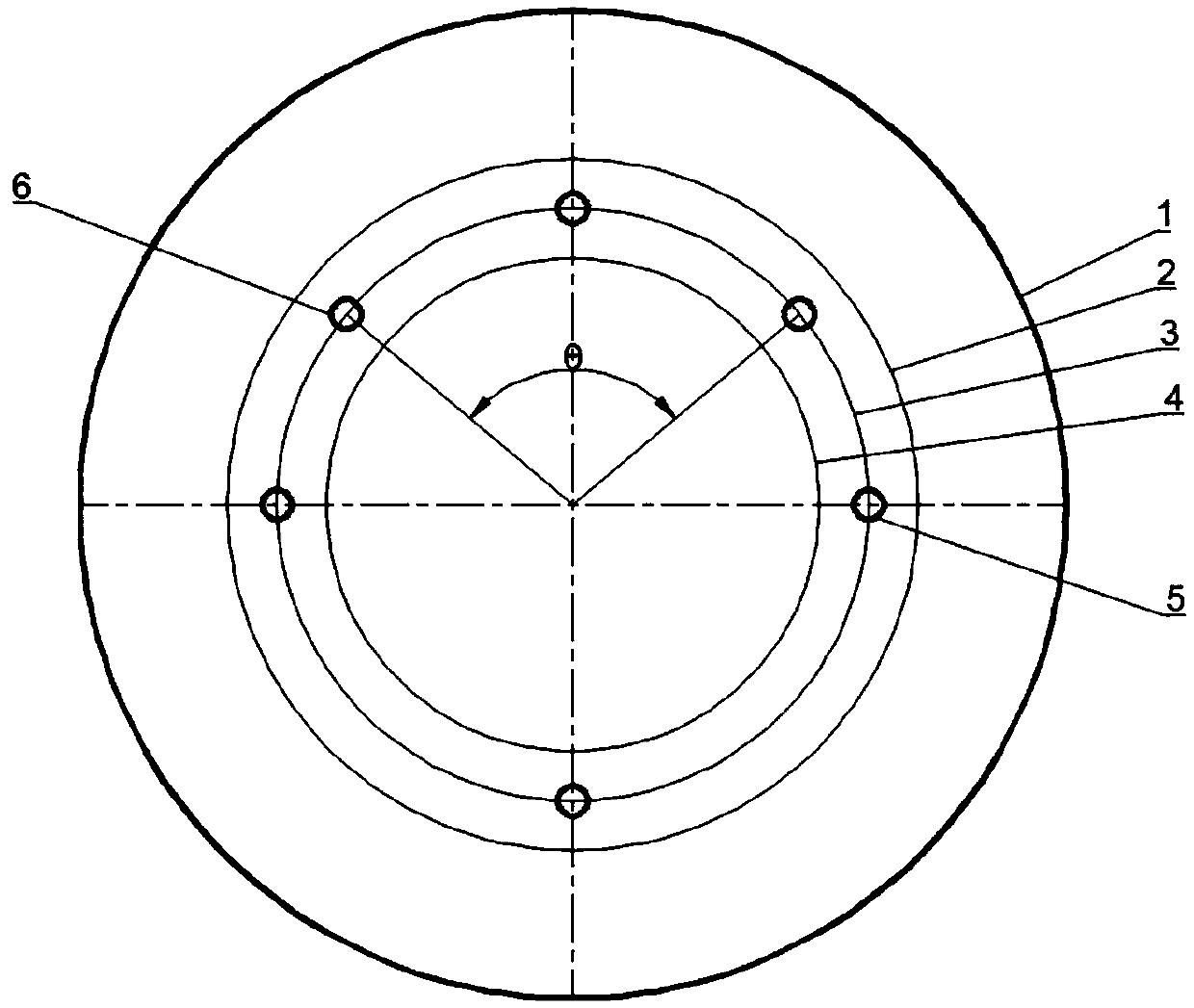

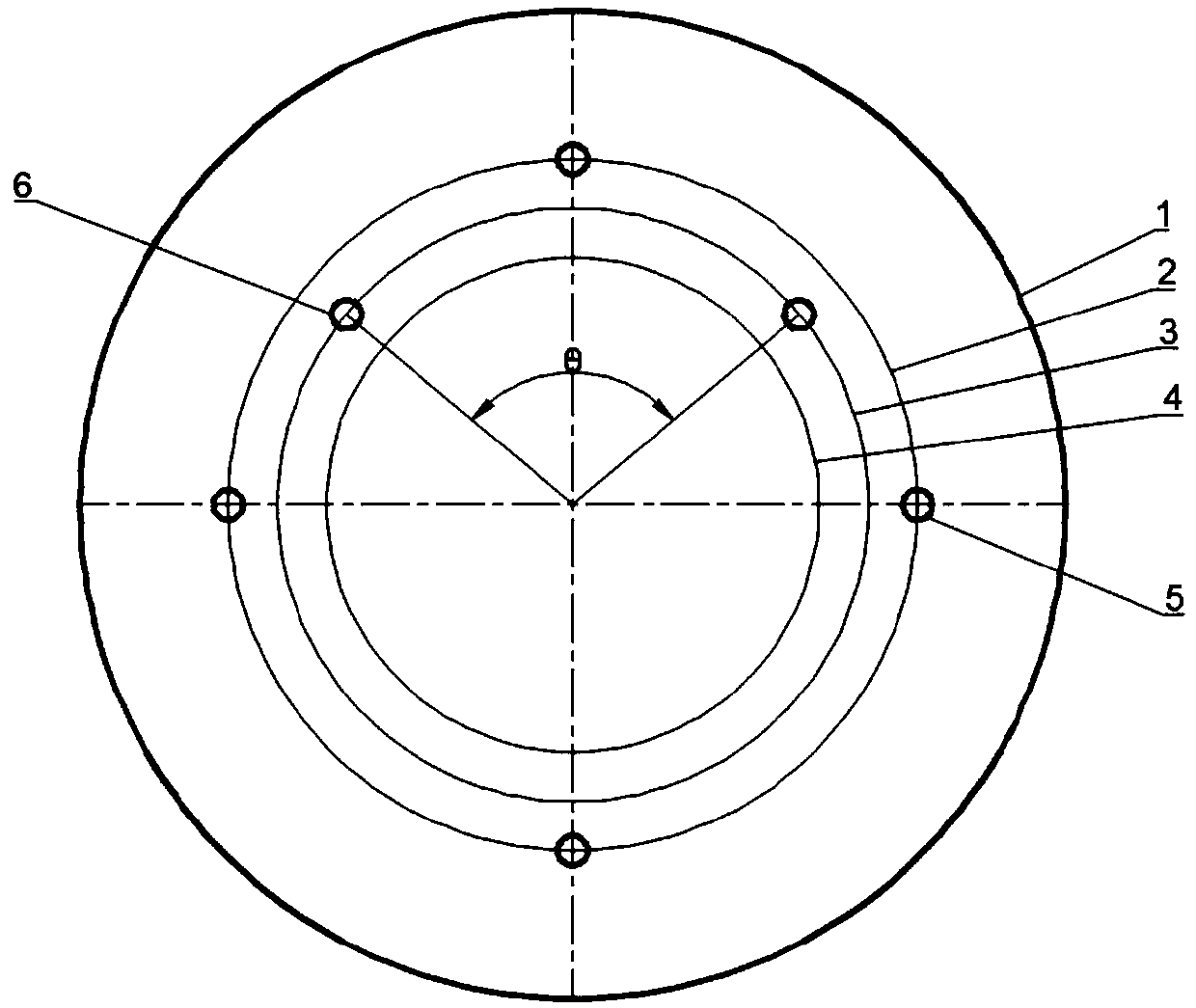

Arrangement Structure of Submerged Nozzle for Shaped Billet Crystallizer

InactiveCN102294454ADisperse impact forceRaise heat centerMelt-holding vesselsLiquid steelAxis of symmetry

The invention relates to an arrangement structure of submerged nozzles for a special-shaped billet crystallizer. In the special-shaped billet crystallizer, two submerged nozzles are respectively arranged in two triangular areas where the flange of the special-shaped billet and the web intersect and casting is performed simultaneously; the two nozzles The position is axially symmetrical along the vertical line of the web center of the profiled billet; the third holes of each nozzle are opposite and aligned with the center of the web, and the center line between the left and right sides of the third hole coincides with the center line of the web. The holes are distributed axially symmetrically along the centerline of the web. During pouring, the two nozzles are symmetrically arranged in the triangular area of the profiled billet, the holes on the symmetrical sides of the nozzle are aligned with the two ends of the flange, and the third hole is aligned with the center of the web. The submerged nozzle and its arrangement can obviously disperse the impact force of molten steel, improve the thermal center of molten steel, promote the uniformity of temperature and composition in the cross-section of the crystallizer, facilitate the removal of inclusions and reduce cracks and segregation. Quality defects.

Owner:WISDRI ENG & RES INC LTD

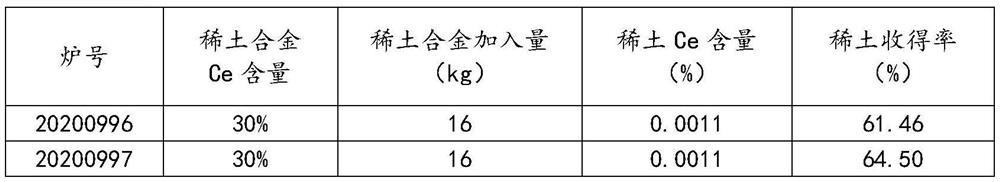

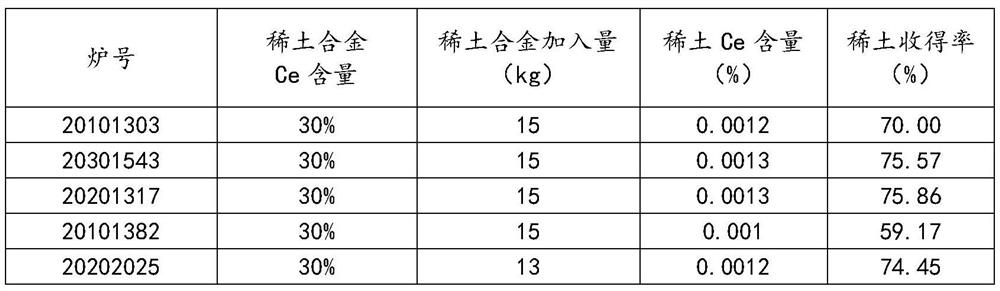

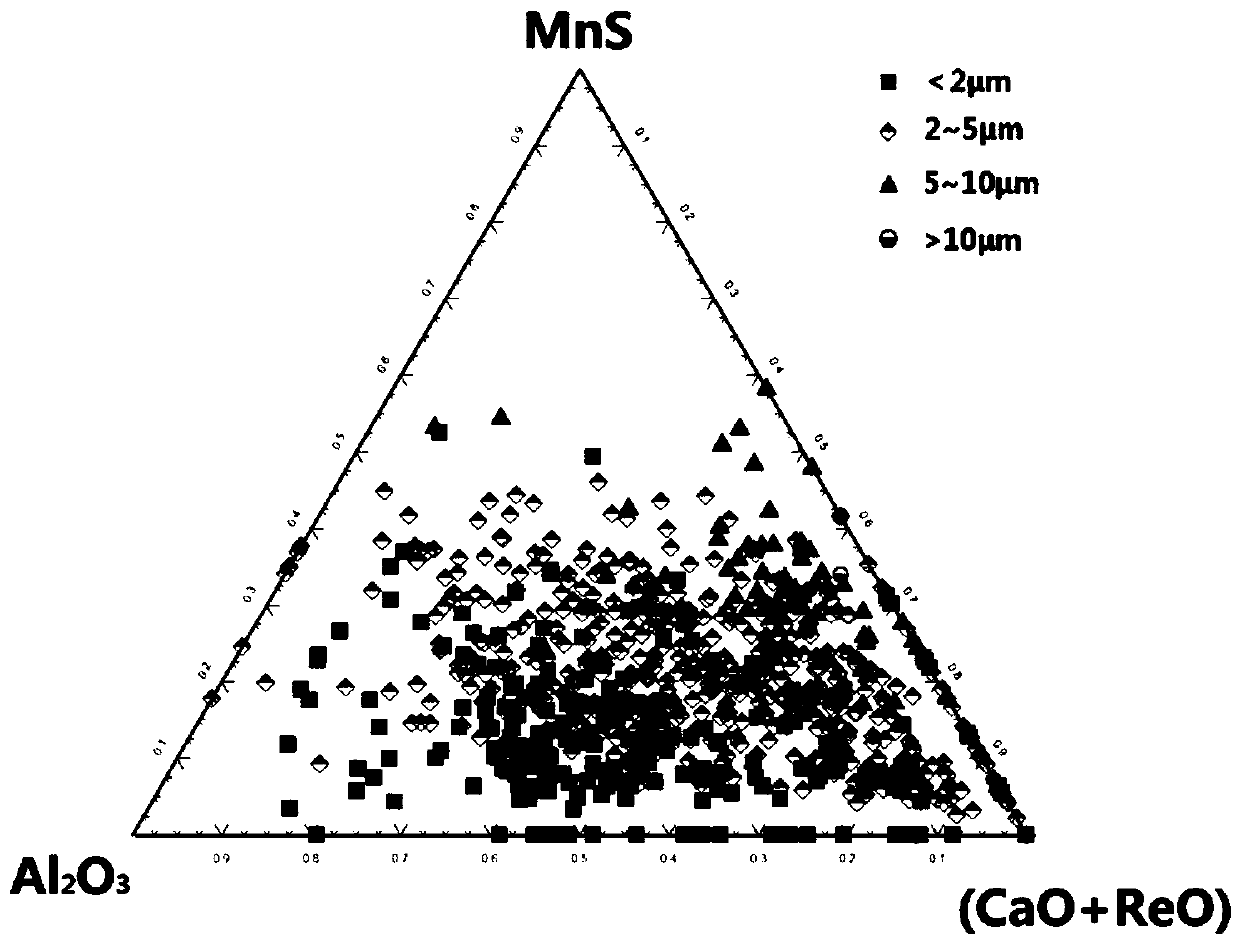

Rare earth adding control method for high-strength rare earth girder steel

InactiveCN112226578AImprove cleanlinessEvenly distributedManufacturing convertersSteelmakingMetallurgy

The invention discloses a rare earth adding control method for high-strength rare earth girder steel. The cleanliness of molten steel of rare earth high-strength girder steel and the yield of rare earth in the steel is improved by optimizing the steel-making process. In early-stage rare earth steel research, due to the fact that the key control processes such as a rare earth adding mode, adding time and the like are not completely mastered, the yield of rare earth is low and is about 35%; and meanwhile, the number of rare earth composite inclusions in steel is large, and the continuous castingpourability of a casting machine is poor. In order to increase the yield of the rare earth, the cleanliness of molten steel is guaranteed before the rare earth is added, and the component uniformityof the rare earth in the molten steel is guaranteed after the rare earth is added. Meanwhile, protective pouring is conducted in the casting process of a casting machine, secondary oxidation of the molten steel is prevented, and the yield of the rare earth in the steel can be remarkably increased.

Owner:BAOTOU IRON & STEEL GRP

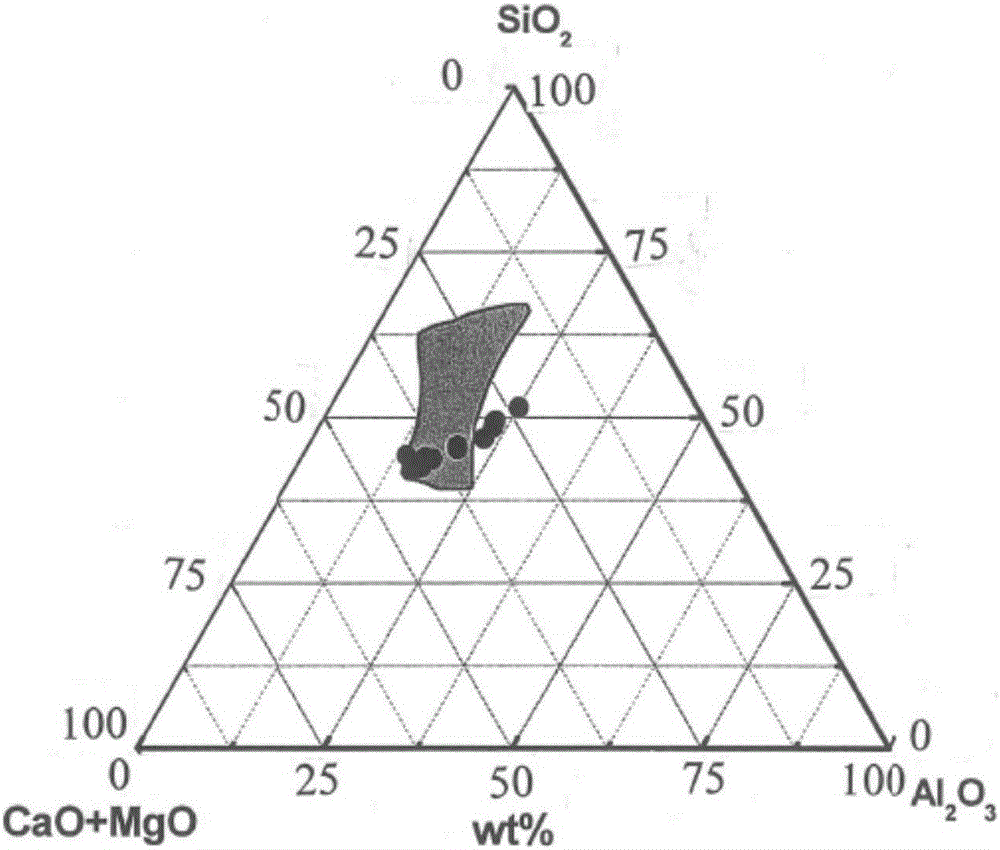

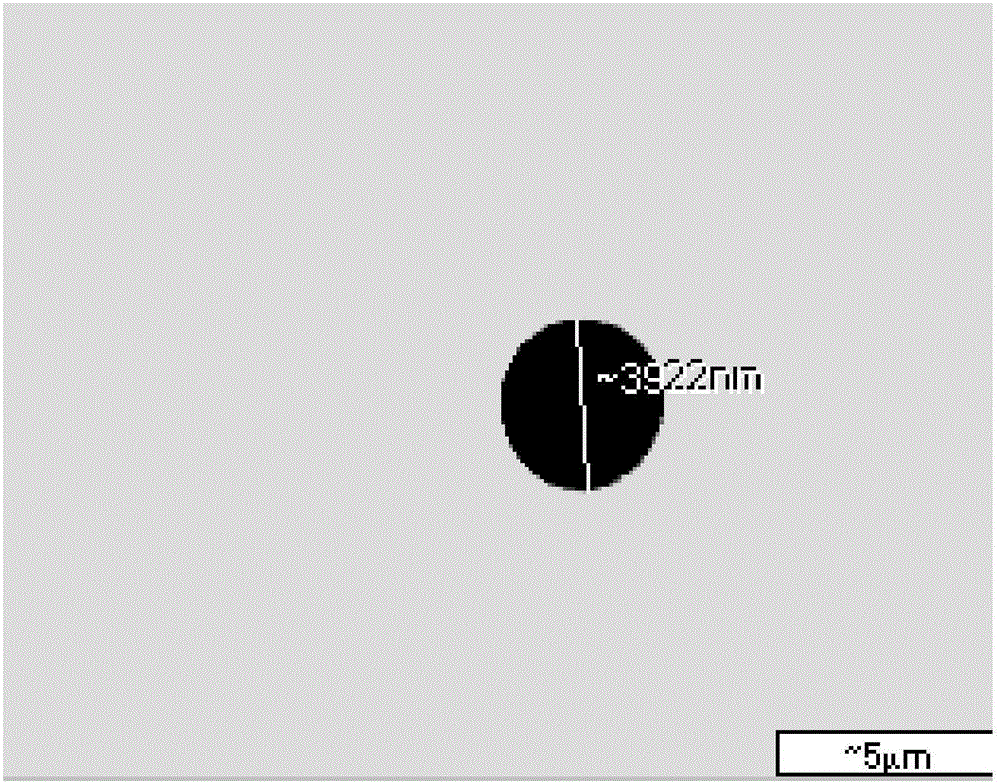

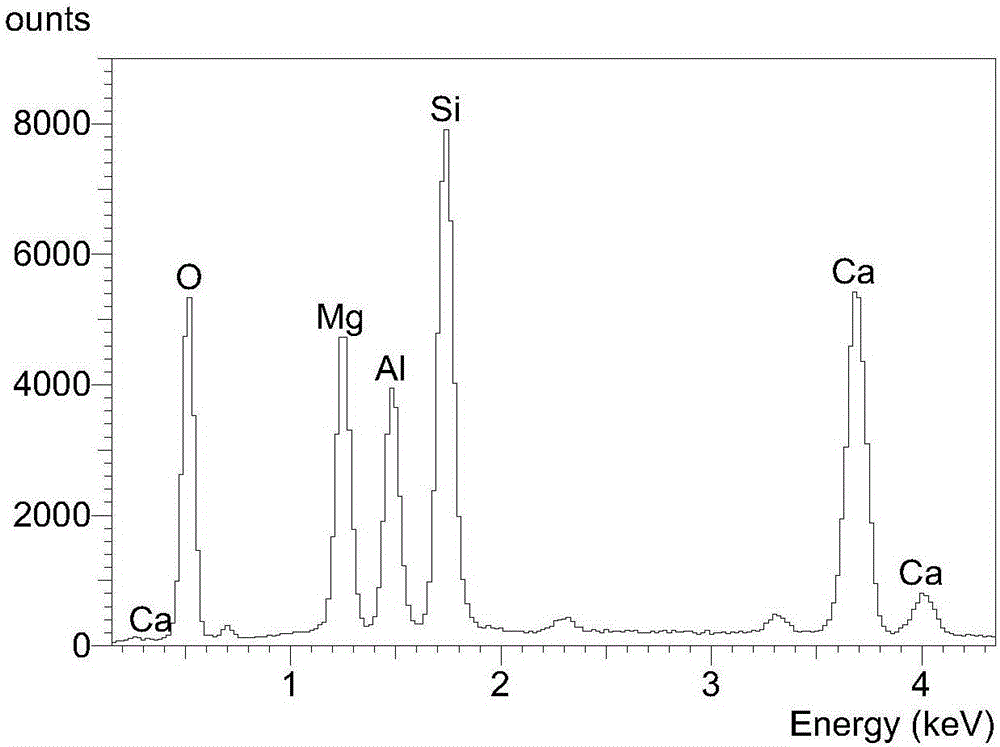

Low content aluminium silicon cacium barium alloy and its manufacture method

InactiveCN1769502APromotes buoyant removalPlay the role of purifying molten steelHeating furnaceSilicon

This invention blongs to the silicon calcium barium alloy used in steel liquid deoxidizing and its making method, wherein the aluminimum content in the alloy is low. This alloy uses silica, lime, barites, burnt carbon containing C higher than 80%, fluorite and steel bits as raw materials, then adds these materials to the mine heat furnace to smelt with matching mix method, wherein the content of the silicon calcium barium alloy with low aluminium as follows:Siú¢50-65úÑ, Caú¢8-16úÑ, Baú¢10-16úÑ, Alú¢0.5-1úÑ, Síœ0.05úÑ, Píœ0.05úÑ, Fe surplus. The content of the aluminium in this invention is under 1%, and when using deoxidier to oxidize the steel liquid of the heavy steel, the aluminium contemn in the acid solution can be controlled under 0.004úÑú¼and the composite lard substances with low melting point can go up on the steel solution to be easy to wipe off, which plays a role of purifying steel liquid.

Owner:安康市光大铁合金有限公司 +1

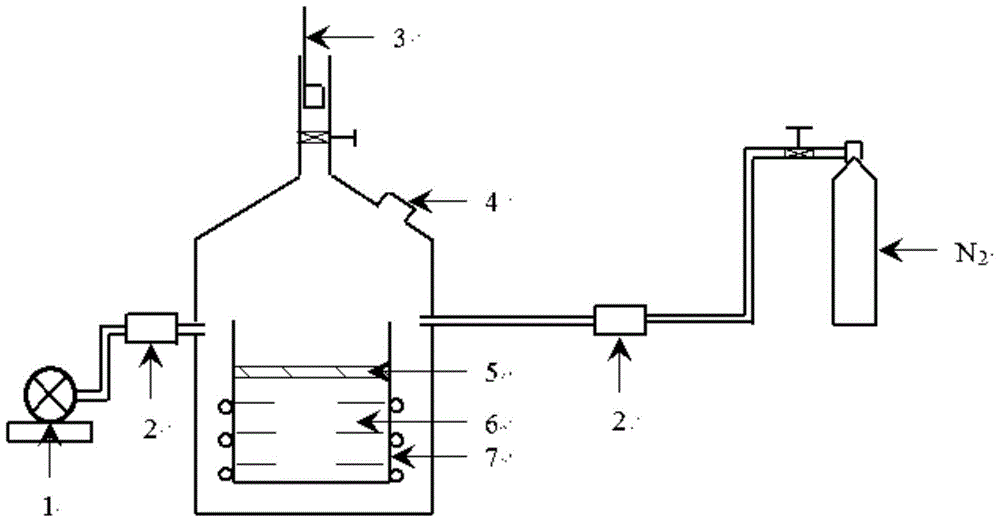

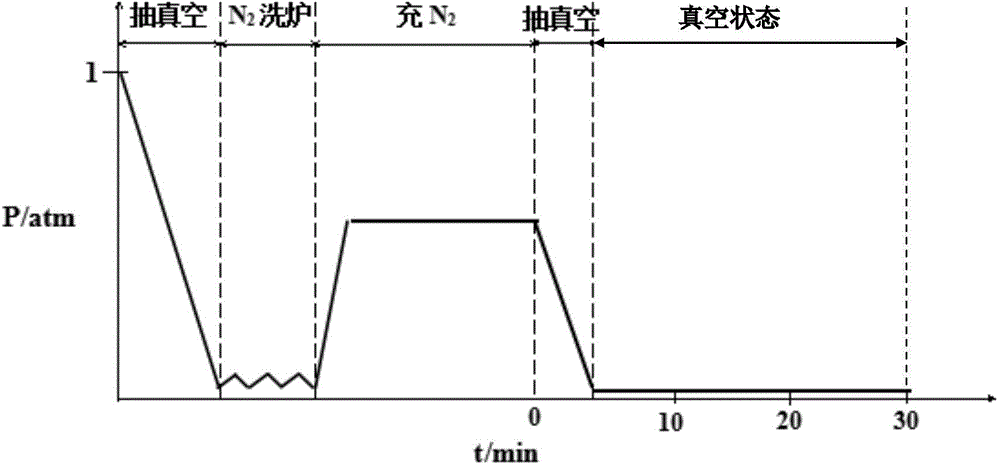

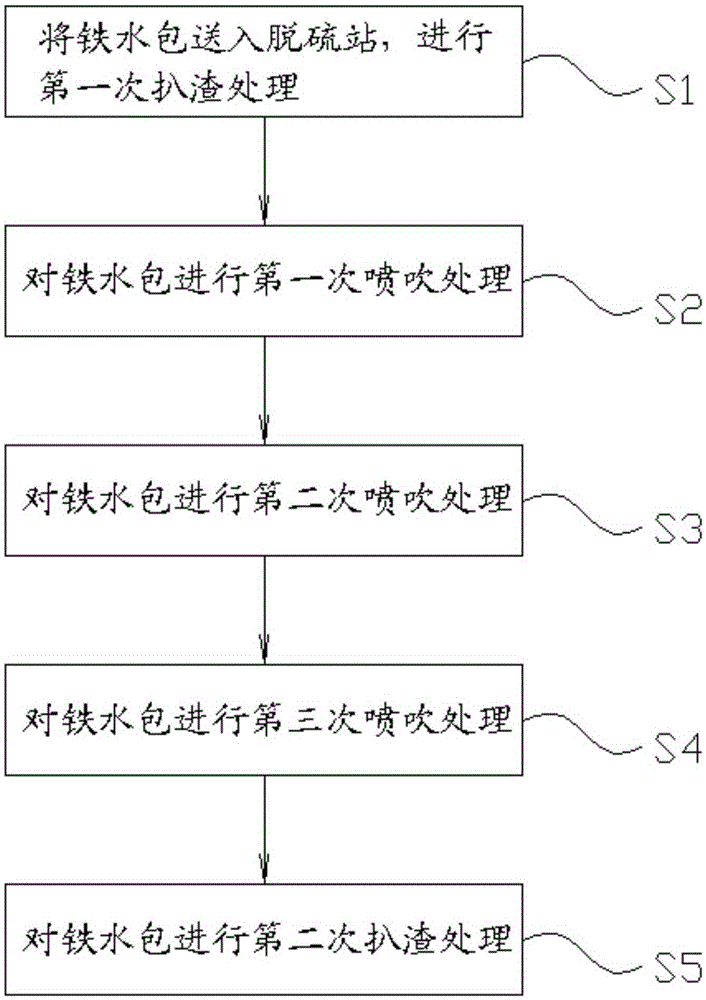

Process method for smelting high purity steel through VD vacuum treatment device

ActiveCN111378811AReduce slaggingGood removal effectManufacturing convertersSlagNon-metallic inclusions

The invention provides a process method for smelting high purity steel through a VD vacuum treatment device. The method comprises the following steps of KR molten iron desulfuration, wherein it is ensured that before putting into a furnace, S in molten iron is smaller than or equal to 30 ppm; top and bottom combined blowing converter blowing, wherein the mass percent omega [C] of converter tappingC is larger than or equal to 0.08%; external refining and argon refining, wherein in the full process, weak stirring is carried out, and calcium aluminum silicon series slag with the basicity being 2.0 to 4.5 is adopted; and VD treatment, wherein 20 to 35 min VD treatment is adopted, high-vacuum holding of strength is achieved, in the treatment process, according to the strong-weak-strong mode, the bottom stirring argon strength is controlled in a time interval manner, after VD vacuum breaking, a manner that soft blowing is adopted, large-particle inclusions are removed, molten steel is subjected to standing, and small particle inclusions are removed is adopted for further improving the molten steel purity. It is known that through the particular VD treatment process stirring control modeis adopted for assisting with a proper refining slag system and a soft blowing operation method, molten steel slag entrapment can be effectively reduced, the removing effect of non metal inclusions can be improved, and the method is suitable for production of various low, middle and high carbon steel with the carbon content being 0.15 to 1.05%.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

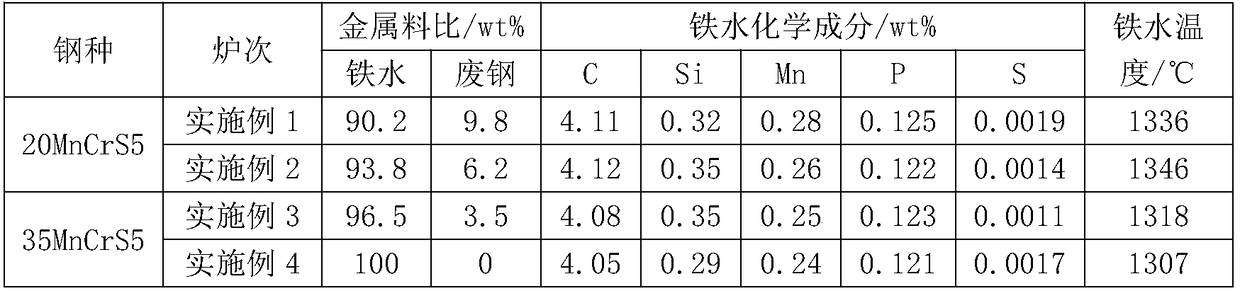

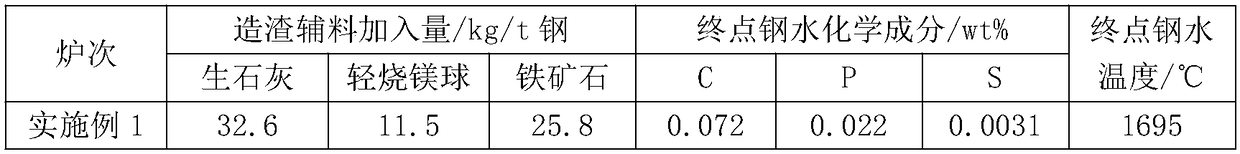

Production method for aluminum killed molten steel containing sulfur

InactiveCN108977613AQuality Percentage GuaranteeAvoid it happening againManufacturing convertersProcess efficiency improvementSteelmakingSlab caster

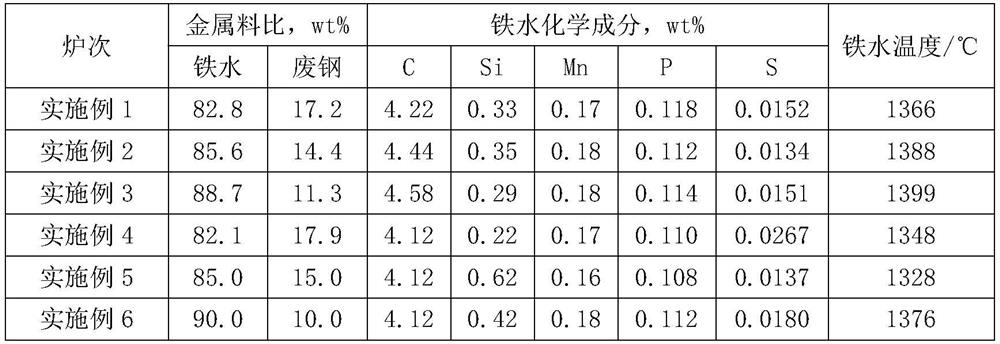

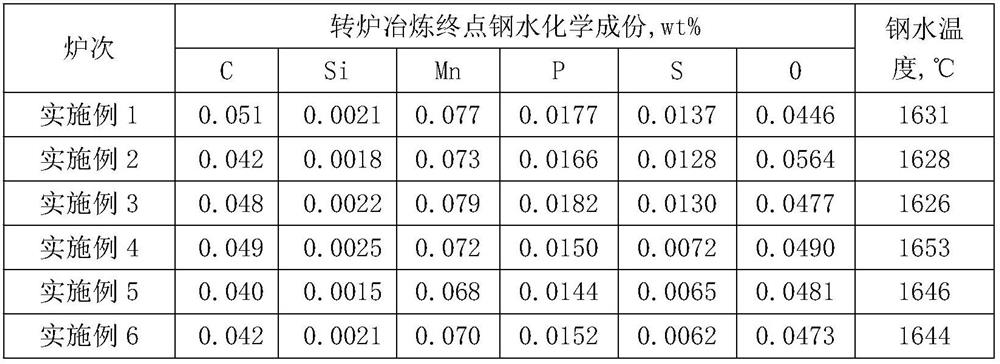

The invention discloses a production method for aluminum killed molten steel containing sulfur, and the production method mainly solves the technical problems that control over impurities in the aluminum killed molten steel containing the sulfur produced by converter smelting in the prior art is difficult, and normal casting of a slab continuous casting machine cannot be met. According to the technical scheme adopted by the invention, the production method for the aluminum killed molten steel containing the sulfur comprises the following steps of: adopting a top-bottom combined blowing converter to smelt molten steel, and adding the following raw materials of metal main ingredients including, by weight, 92%-100% of molten iron and the balance light waste steel; controlling slagging auxiliary materials in a converter smelting process, and adding the converter slagging auxiliary materials to conduct slagging while introducing oxygen to ignite by a converter oxygen lance; controlling a converter smelting end point, and detecting w[C] in molten steel at the converter smelting end point; immediately tapping after converter blowing is ended; transporting molten steel to a refining furnace for controlling the temperature of the molten steel and regulating alloy components; and transporting the molten steel to an RH furnace to refine. The aluminum killed molten steel containing the sulfur is produced by the method and is good in quality and good in pourability.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

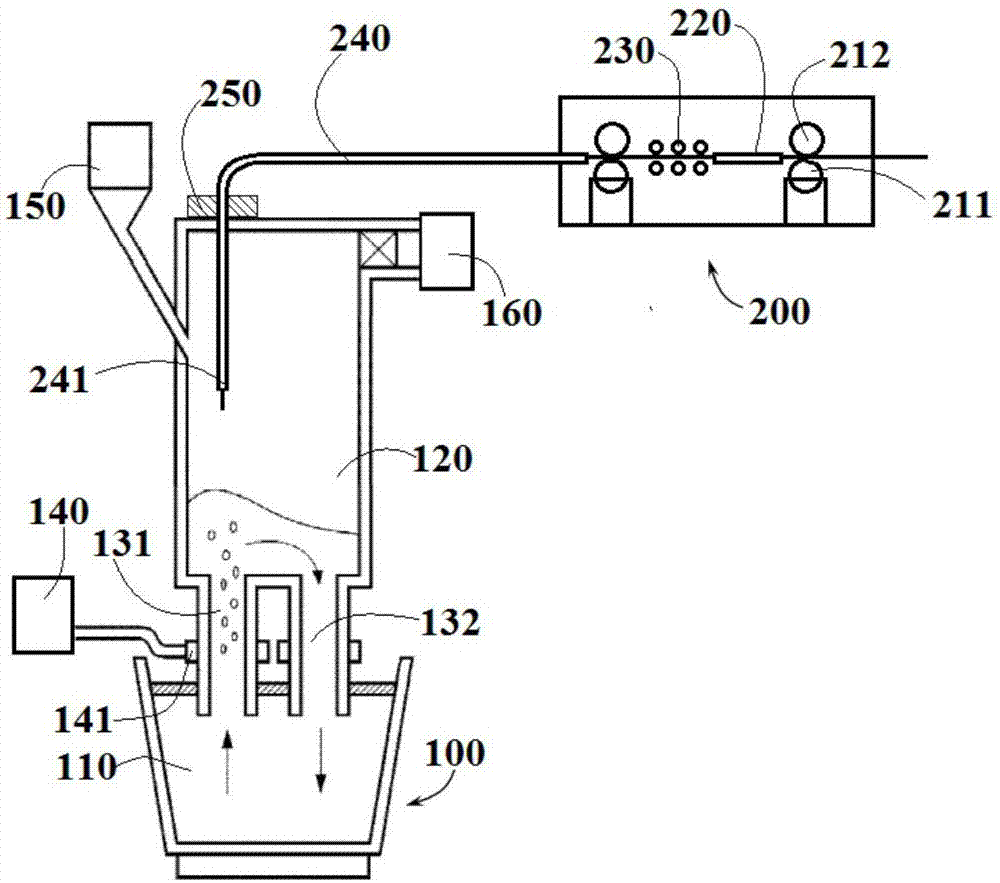

RH refining system using purifying agent core-spun yarn and refining method thereof

The invention discloses an RH refining system and a refining method using a purifying agent cored wire, and belongs to the technical field of RH refining. The RH refining furnace of the present invention includes a ladle, a vacuum chamber and a vacuum pumping mechanism, the vacuum chamber is arranged on the upper part of the ladle, and the ascending pipe and the descending pipe at the lower part of the vacuum chamber are inserted into the ladle; The wire conduit, the driving wheel and the driven wheel of the driving mechanism are arranged correspondingly, the driving mechanism is used to drive the purifying agent cored wire, the stabilizing wheel set is arranged between the driving mechanism and the wire feeding conduit; the conduit outlet of the wire feeding conduit is set at the riser pipe The upper part: Purifying agent cored wire is fed into the RH refining furnace to purify molten steel through the wire feeding unit. The cleaning agent cored wire of the present invention is in contact with molten steel on the upper part of the riser, thereby promoting the mixing effect of the cleaning agent cored wire and molten steel, and the cleaning agent cored wire can promote the growth, floating and removal of inclusions, Thereby improving the cleanliness of molten steel.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

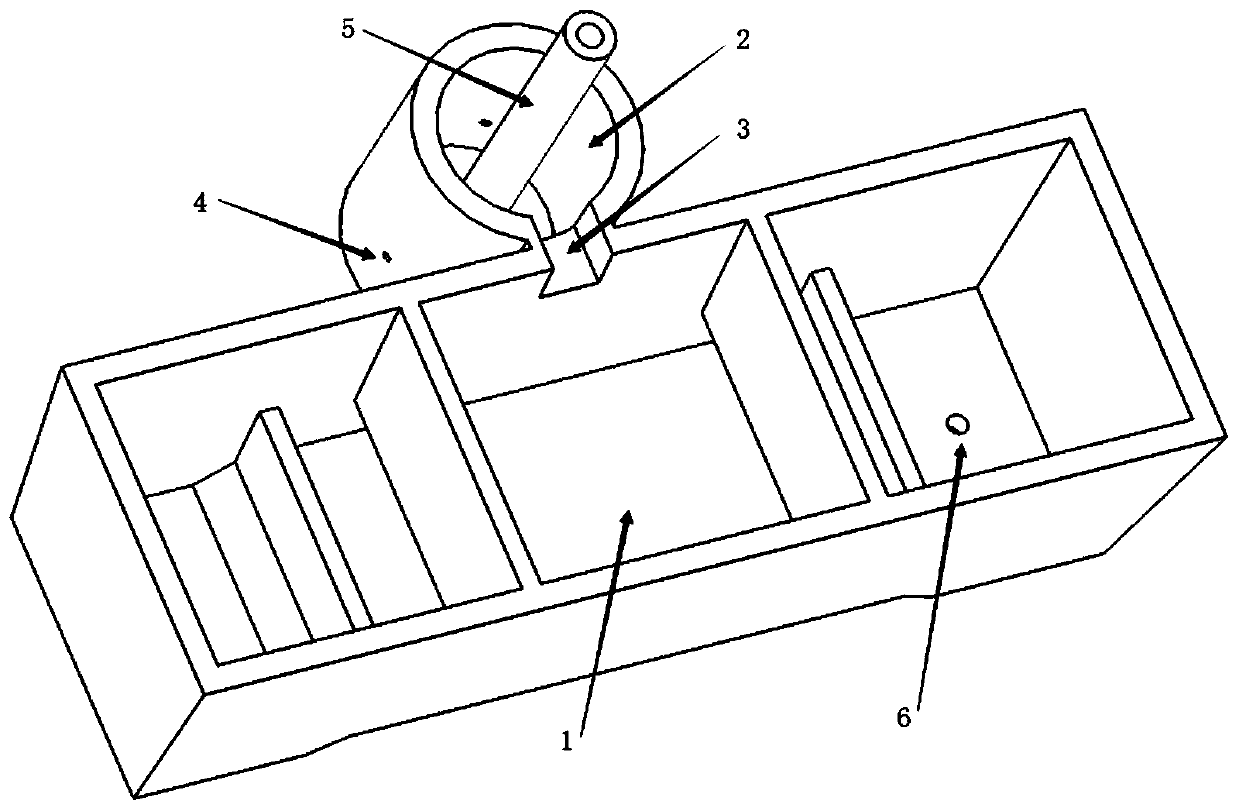

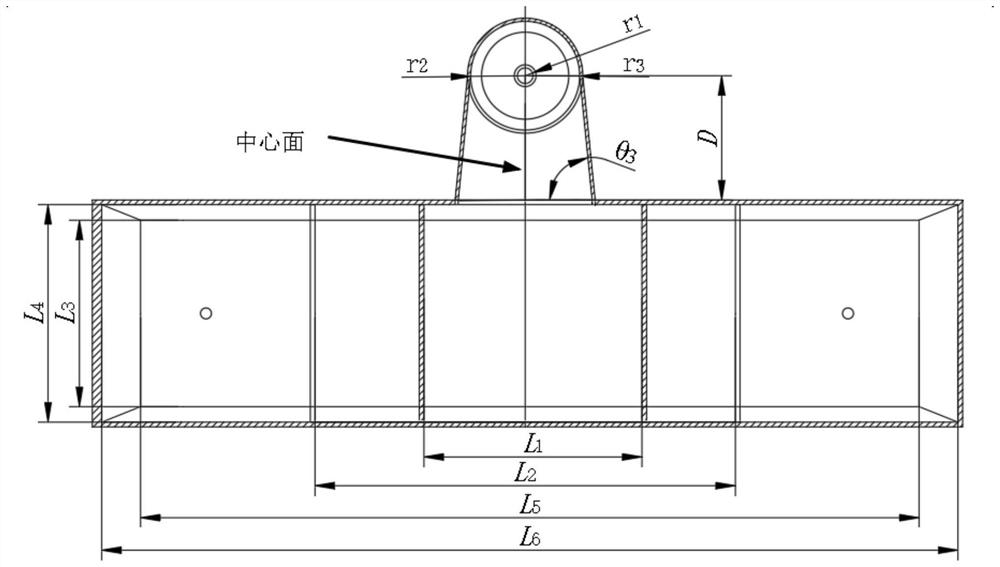

Pneumatic swirling tundish for continuous casting

InactiveCN110238375APromote collision growthFacilitate floating removalMelt-holding vesselsTundishEngineering

The invention provides a pneumatic swirling tundish for continuous casting, the pneumatic swirling tundish is composed of a tundish main body and an external tundish swirling chamber; the tundish main body communicates with the external tundish swirling chamber by a trench or a groove; a plurality of inclined blowing air holes are uniformly formed in the side wall away a certain height from the bottom of the external tundish swirling chamber along the circumference, the trench or the groove is positioned in the middle position of the tundish, the center surface of the trench or the groove is coincided with the center surface of the tundish main body and the external tundish swirling chamber; and the whole pneumatic swirling tundish is symmetric in left and right sides. The pneumatic swirling tundish for the continuous casting provided by the invention has the advantages of simple structure and low cost, and can realize the rotating flow of the molten steel under the driving action of the gas, and combines the bubble impurity removing to improve the removal efficiency of inclusions in the tundish.

Owner:NORTHEASTERN UNIV

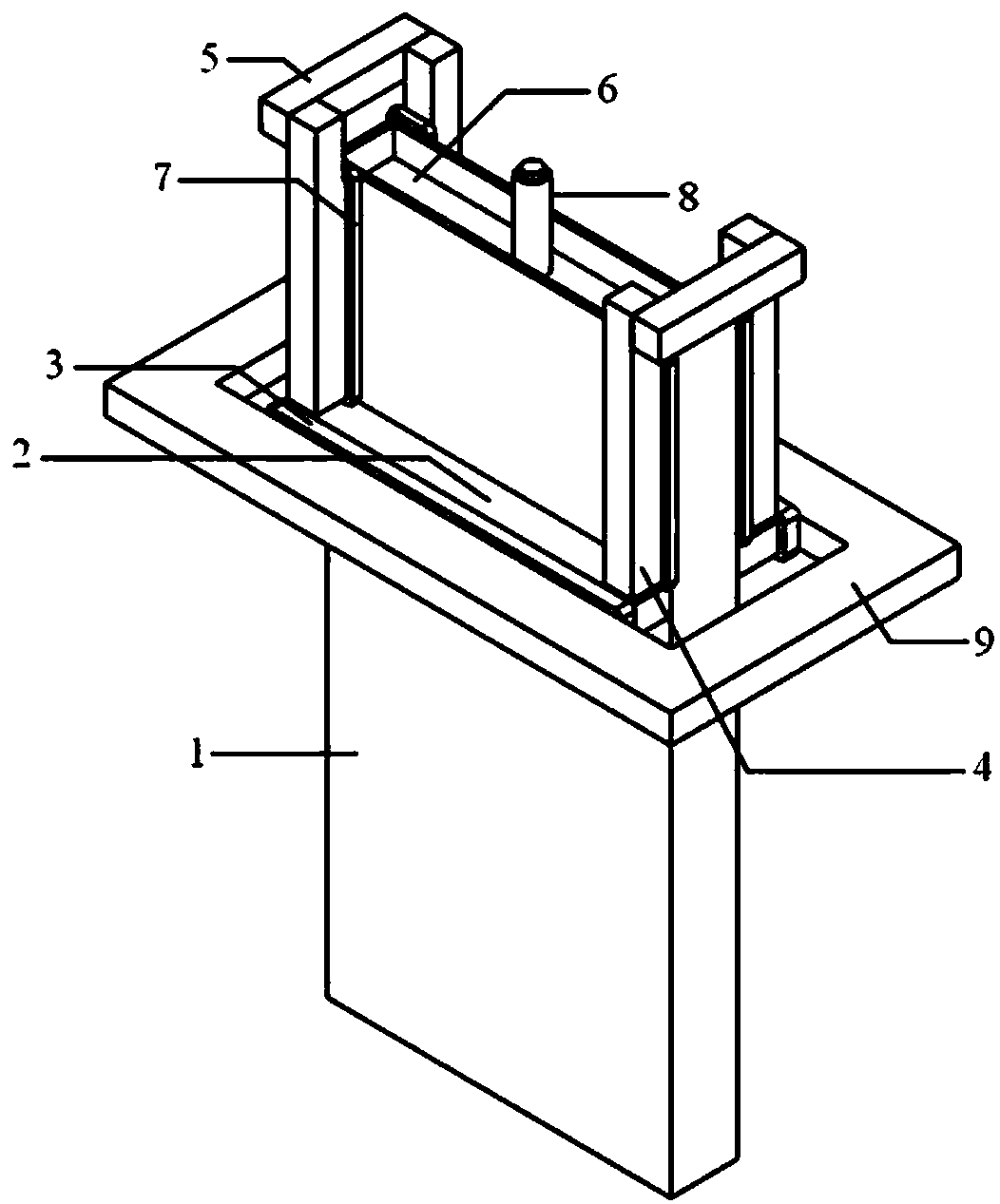

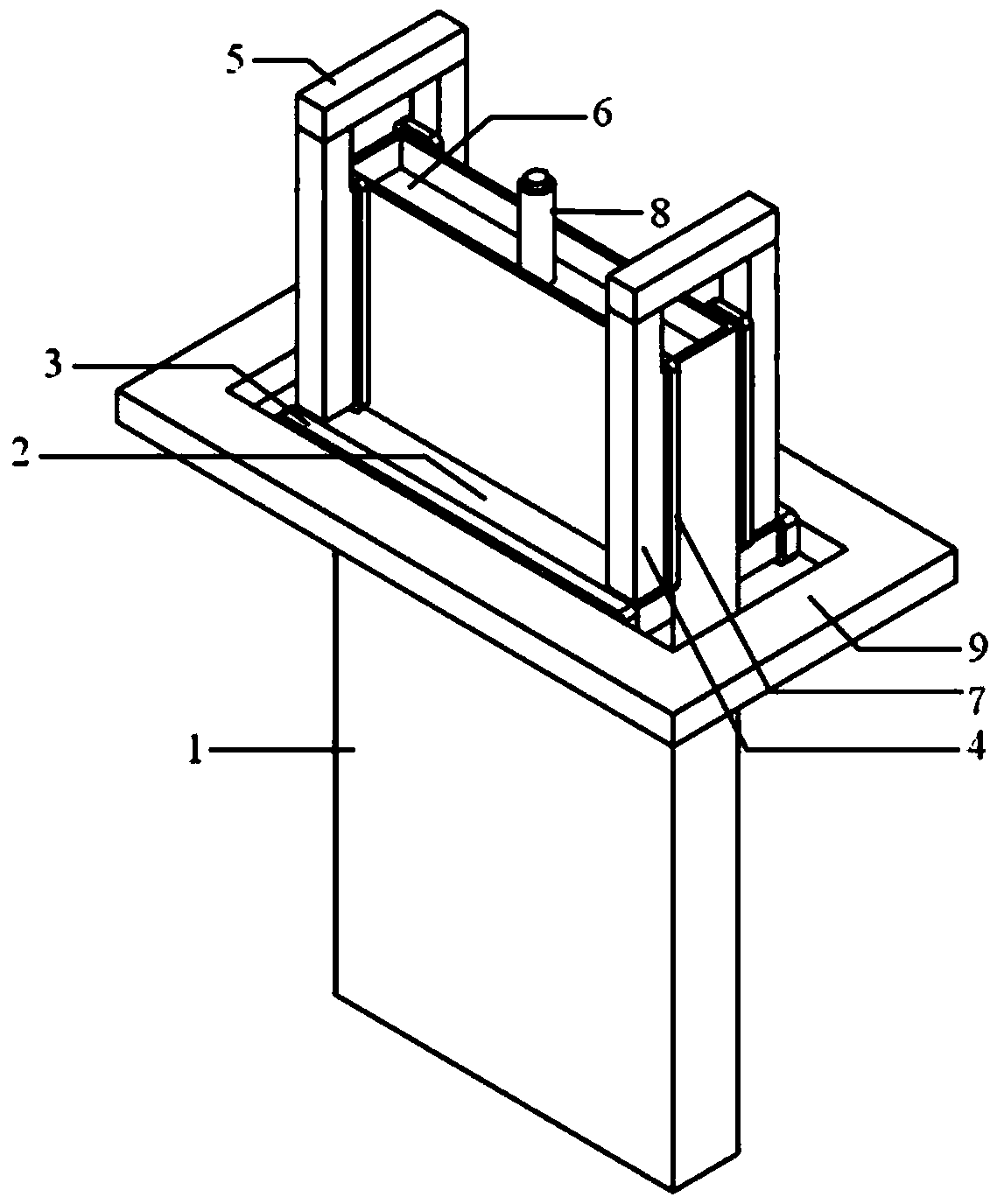

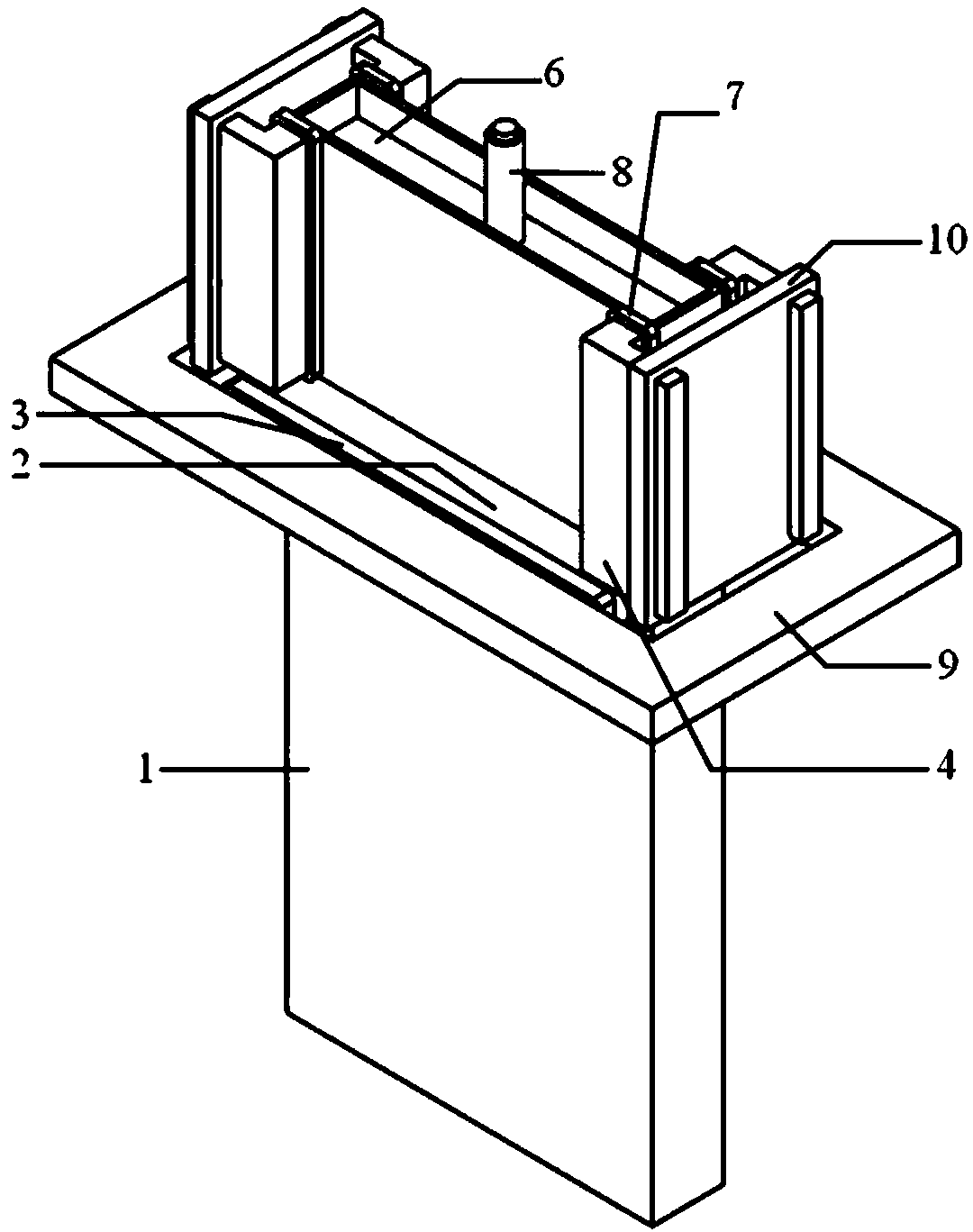

Independent adjustable combined electromagnetic braking device and method for controlling flowing of molten steel

The invention discloses an independent adjustable combined electromagnetic braking device and method for controlling flowing of molten steel. The device comprises a crystallizer, wherein horizontal magnetic poles are arranged on the wide surface of the crystallizer, horizontal excitation coils are arranged on the outer sides of the two horizontal magnetic poles correspondingly, a magnetic yoke isarranged on the crystallizer in a sleeve mode, the magnetic yoke corresponds to the horizontal excitation coils, the inner surface of the magnetic yoke is in clearance fit with the outer surfaces of the horizontal excitation coils and the outer surface of the crystallizer, vertical magnetic poles are arranged on the positions, above the horizontal magnetic poles, of the wide surface of the crystallizer, vertical excitation coils are arranged between the crystallizer and the vertical magnetic poles, the horizontal magnetic poles are not connected with the vertical magnetic poles, horizontal iron cores or vertical iron cores are arranged on the two groups of vertical magnetic poles, one end of an immersion type water opening is connected with a middle bag, and the other end of the immersiontype water opening extends into the crystallizer. The device is formed by combining one pair of horizontal magnetic poles and two pairs of vertical magnetic poles, and the current intensity applied bythe excitation coils on the three pairs of magnetic poles can be independently regulated and controlled according to the actual flowing state of the molten steel in the crystallizer.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

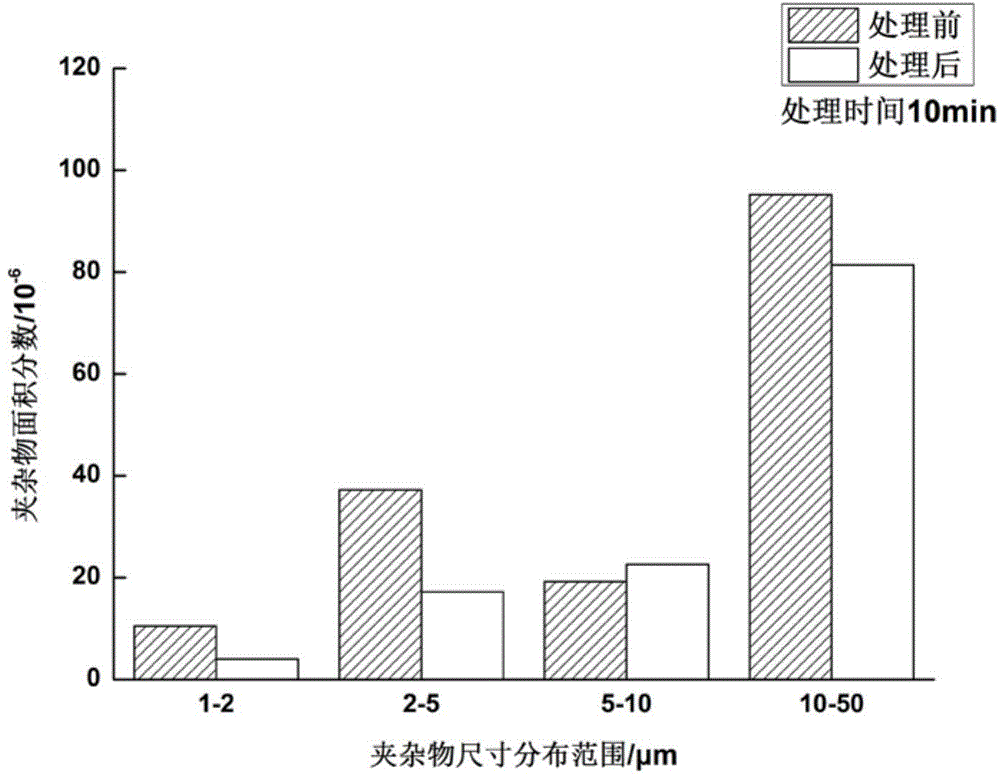

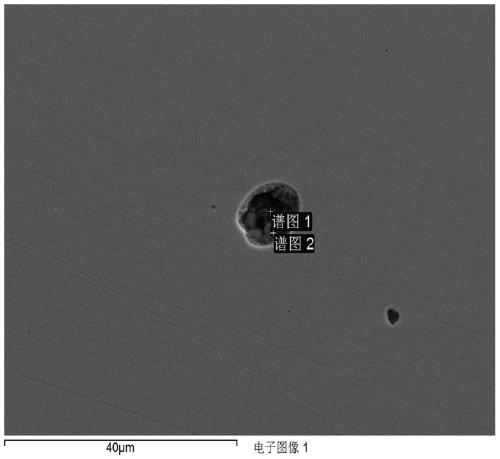

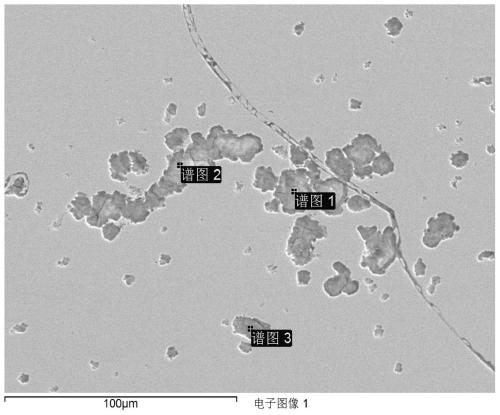

Method for removing microscopic nonmetallic inclusion in molten steel by using nitrogen-increasing nitrogen-precipitating process

Owner:UNIV OF SCI & TECH BEIJING

Process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation

The invention discloses a process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation. Lime stones are grinded to powder with a particle size below 1 mm, are uniformly mixed with graphite carbons with a carbon content of 90%, and are pressed to calcium carbonate carbon balls with a diameter of 30 mm by a dry powder ball press, wherein the adding proportion of the lime stones is 93 mass% of the carbon balls; the adding proportion of the graphite carbons is 7 mass% of the carbon balls; the carbon content in the calcium carbonate carbon balls is controlled at 6 mass%; and in the steel tapping process of an electric furnace or a converter after smelting, 1.5 kg carbon balls are added in each tonnage of steel.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

Production technology for controlling B-type inclusions in pipeline steel

The invention belongs to the technical field of iron and steel metallurgy, and particularly relates to a production technology for controlling B-type inclusions in pipeline steel. The production technology sequentially comprises the processes of hot metal pretreatment, converter smelting, converter tapping, LF furnace refining and continuous casting, wherein the LF furnace refining process sequentially comprises the steps of energized heating treatment, B-type inclusion modification treatment and softblow treatment; the B-type inclusion modification treatment step comprises addition of a rareearth slag modification agent; calculated according to that the total mass percent of the rare earth slag modification agent is 100%, the rare earth slag modification agent comprises 50% to 60% of lime, 5% to 10% of rare earth, 20% to 25% of total aluminum and 5% to 15% of a fluxing agent. According to the production technology, the B-type inclusions in pipeline steel are controlled through the rare earth slag modification agent, the B-type inclusions in pipeline steel are converted into compound rare earth inclusions, removal of the B-type inclusions in a follow-up technology is facilitated,a traditional B-type inclusion calcium treatment production technology is simplified, and quality of pipeline steel is improved.

Owner:湖南华菱涟源钢铁有限公司 +1

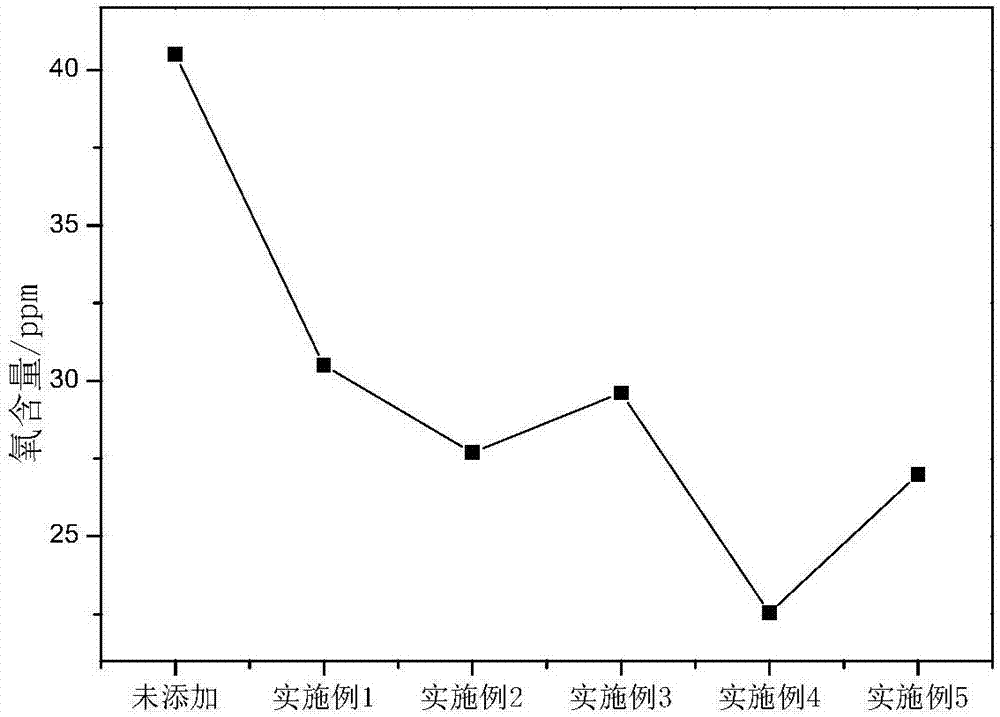

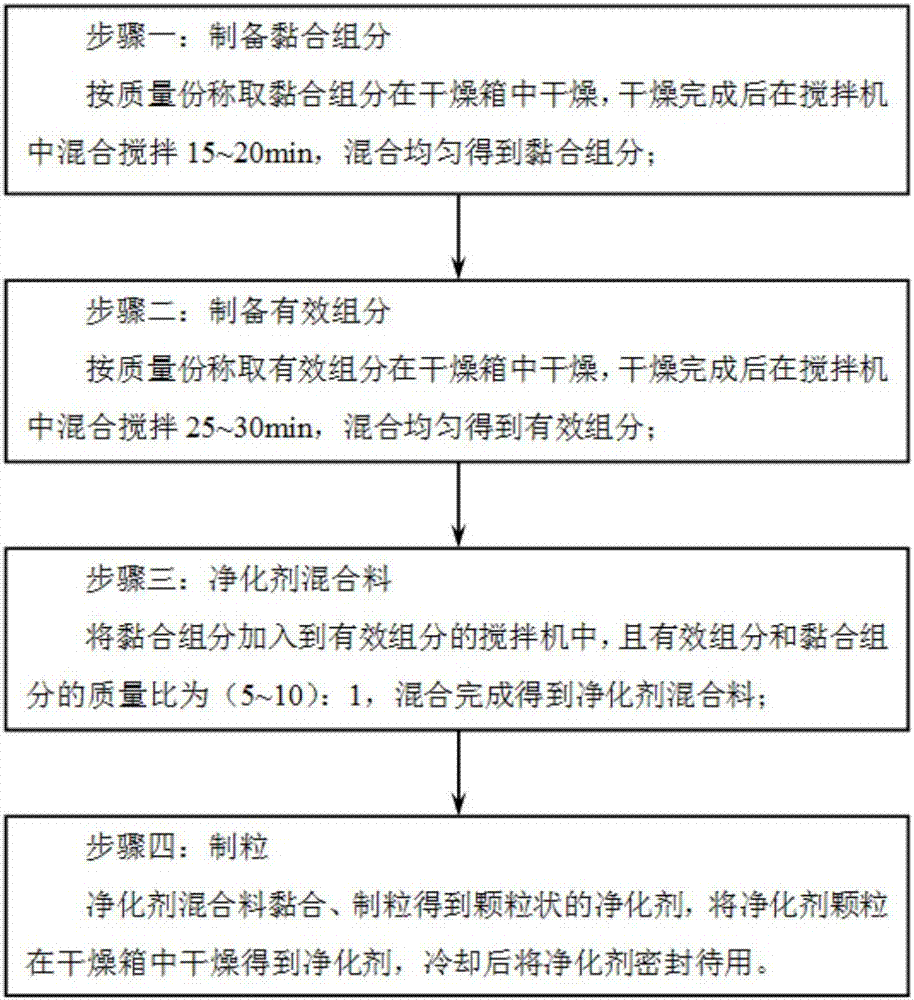

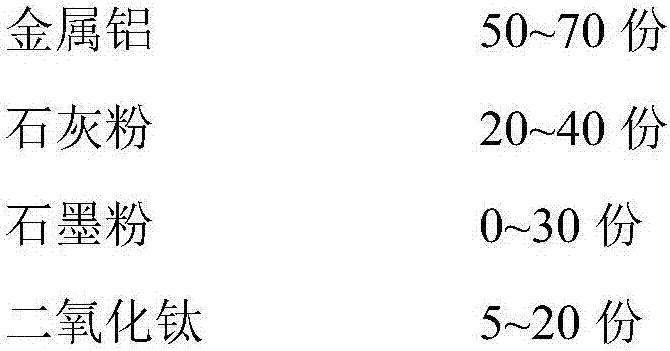

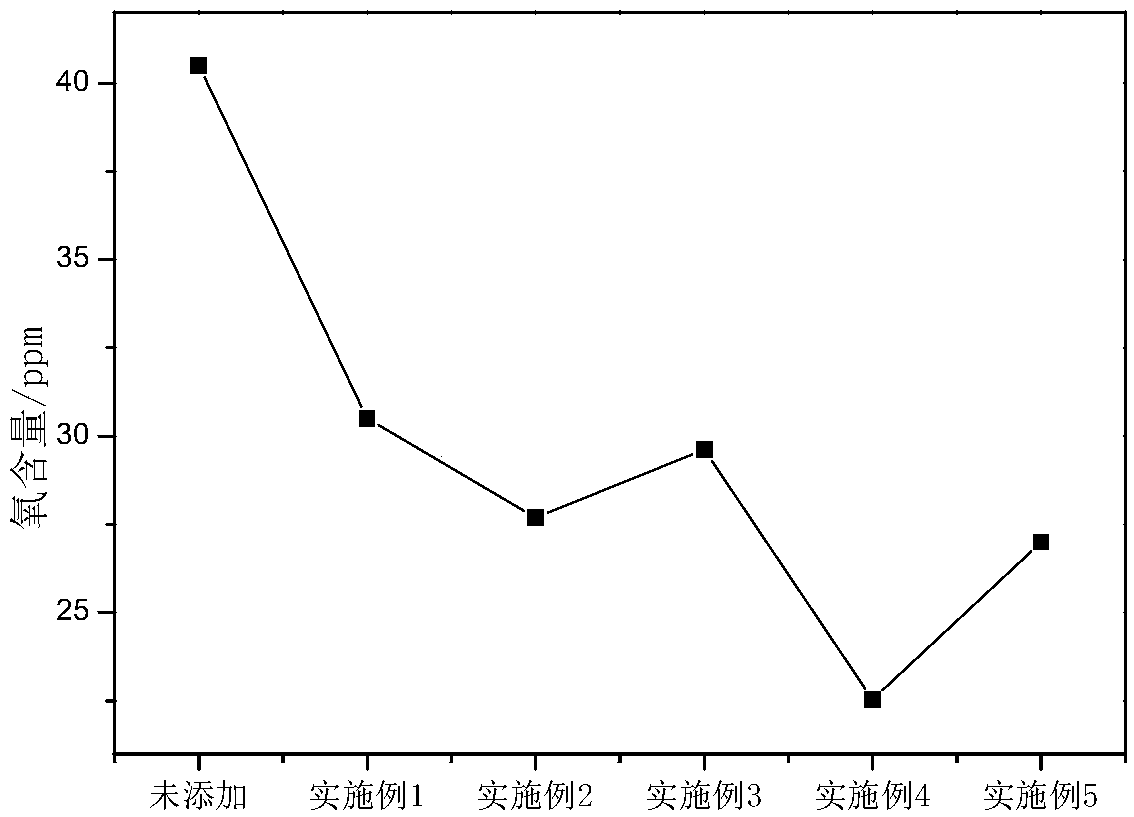

Preparation method for molten steel purifying agent

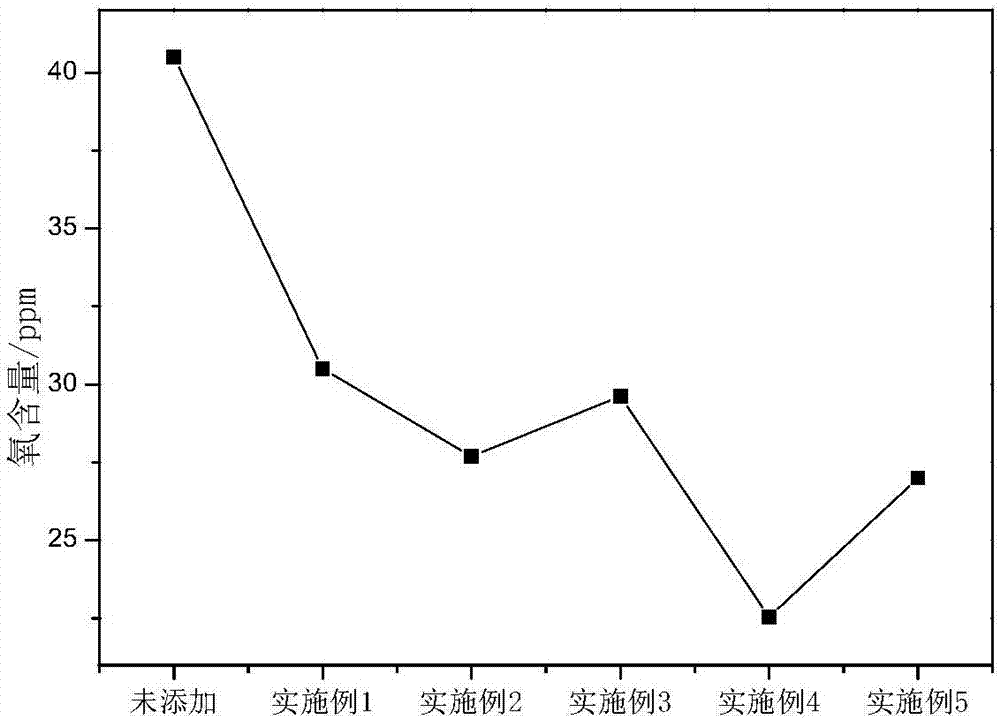

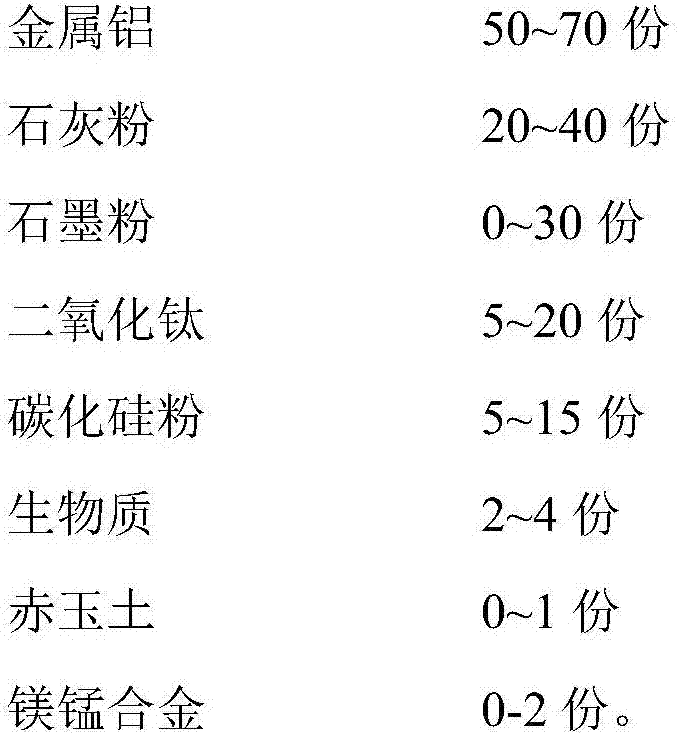

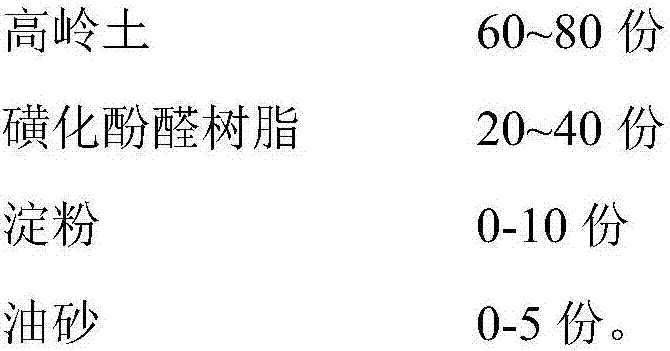

ActiveCN107245546ANo secondary pollution to molten steelProduce secondary pollutionTransportation and packagingMetal-working apparatusMolten steelBULK ACTIVE INGREDIENT

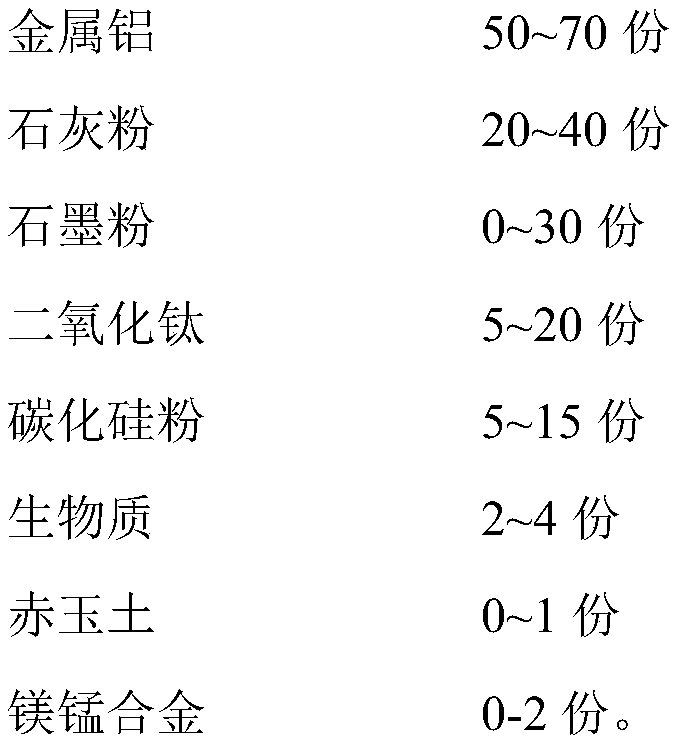

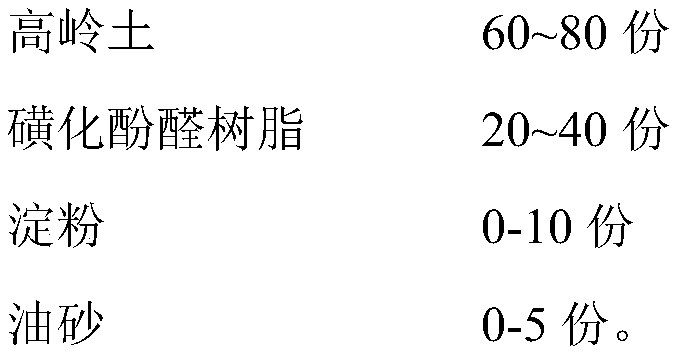

The invention discloses a preparation method for a molten steel purifying agent, and belongs to the technical field of steel purifying and smelting. The preparation method comprises the following steps of: mixing active ingredients with adhesion components to obtain a purifying agent mixture, wherein a mass ratio of the active ingredients to the adhesion components is (5-10) to 1, the active ingredients comprise metal aluminum, lime powder, silicon carbide powder, titanium dioxide and biomass, and the adhesion components comprise kaolin and sulfonated phenolic resin; and under action of a briquetting machine or a pelletizer, adhering and pelletizing the purifying agent mixture to obtain a granular purifying agent, and drying and cooling the granular purifying agent for later use. The purifying agent prepared by the preparation method reduces content of oxygen in molten liquid, and CO gas generated by reaction promotes floating removal of inclusion, so that removal of inclusion in steel is promoted; molten liquid treated by the purifying agent is relatively small in residual inclusion dimension and is uniform in distribution; and the active ingredients are matched with the adhesion components, so that the purifying effect of molten steel can be improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

Molten steel purifying agent for removing inclusions in molten steel

The invention discloses a molten steel purifying agent for removing inclusions in molten steel, and belongs to the technical field of net steel smelting. The purifying agent is granular, and comprises an effective component and an adhesive component; the mass ratio of the effective component to the adhesive component is (5-10): 1; the effective component comprises metal aluminum, lime powder, silicon carbide powder, titanium dioxide and biomass; the adhesive component comprises kaolin and sulfonated phenolic resins; the purifying agent is spherically granular; and the granular diameter is 5-10 mm. The oxygen content in the molten steel is reduced by the purifying agent; CO gas generated by the reaction accelerates the upward floating removal of the inclusions and the removal of the inclusions in the steel; the inclusions remained in the molten steel treated by the purifying agent are smaller in size and uniformly distributed; the content of the inclusions in the steel treated by the molten steel purifying agent is prominently reduced; the inclusions in the steel are denatured; and the purifying effect of the molten steel is obvious.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

Desulfurizing method for molten iron containing sulfur

Owner:SHOUGANG CORPORATION +1

Control method for inclusions in high-titanium steel, high-titanium steel and preparation method of high-titanium steel

ActiveCN114381574AReduce burning loss and oxidationHigh yieldProcess efficiency improvementSlagTitanium

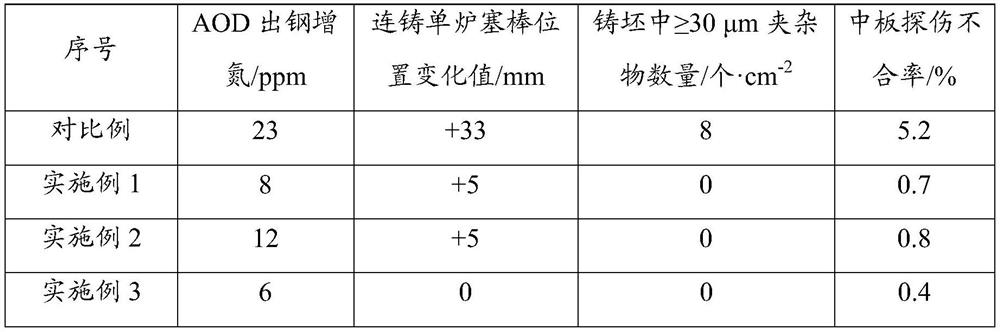

The invention belongs to the technical field of iron and steel smelting, and relates to a control method of high-titanium steel inclusions, high-titanium steel and a preparation method of the high-titanium steel. The control method for the high-titanium steel inclusions comprises the steps that (1) after AOD blowing is finished, silicon-aluminum composite deoxidation is adopted; (2) aluminum shots, lime and fluorite are added into the molten steel after slagging-off, and argon is blown from the bottom for stirring; (3) titanium alloy blocks are added for titanium alloying, the adding amount of the titanium alloy blocks is calculated according to the yield of 65-80%, and argon bottom blowing continues after titanium alloying; (4) tapping and keeping argon oxygen decarburization (AOD) bottom blowing argon; and (5) after the component temperature of the molten steel and the components of the slag are adjusted through the LF, pure calcium wires or silicon-calcium blocks are fed. According to the control method for the high-titanium steel inclusions, the defects of nozzle nodulation, 'fish formation 'of a continuous casting crystallizer and inclusion on the surface of a product or failure in flaw detection caused by precipitation of a large amount of TiN are overcome.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

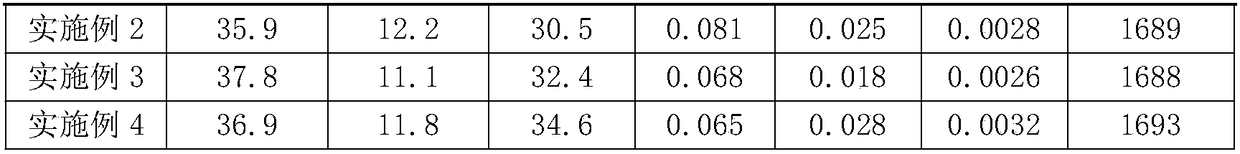

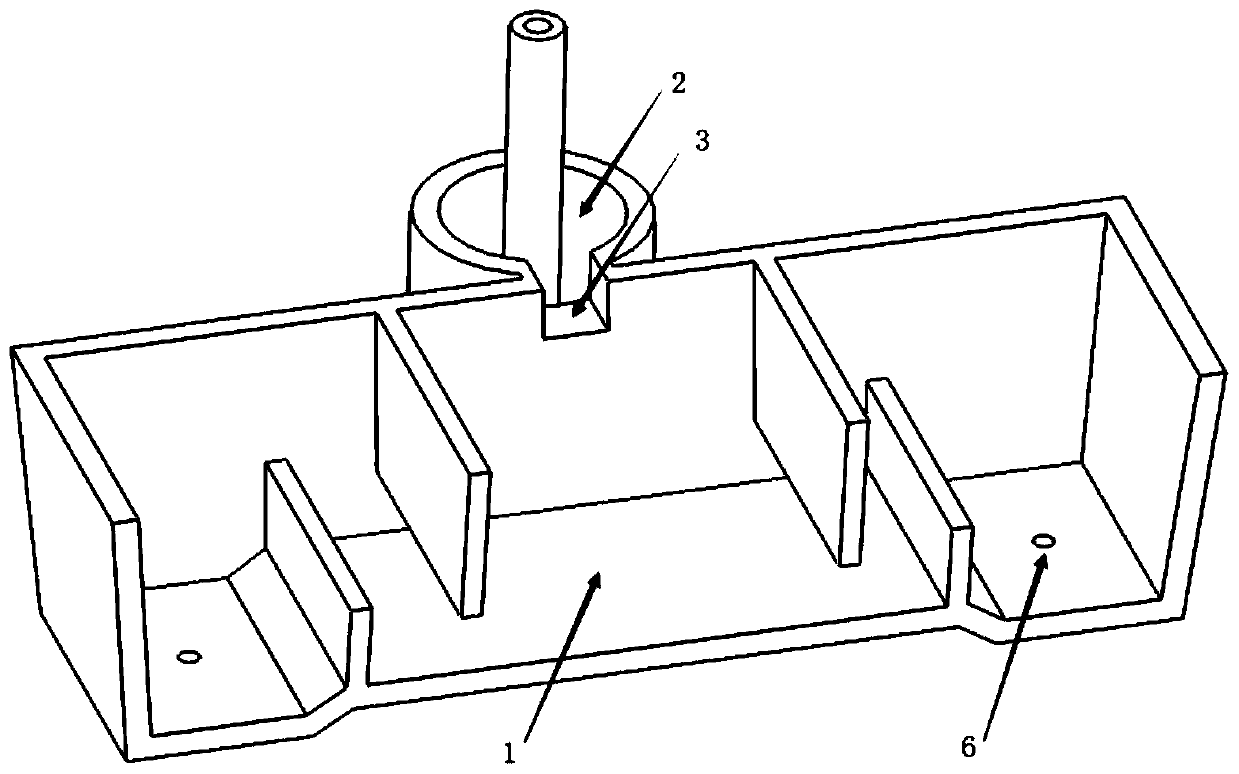

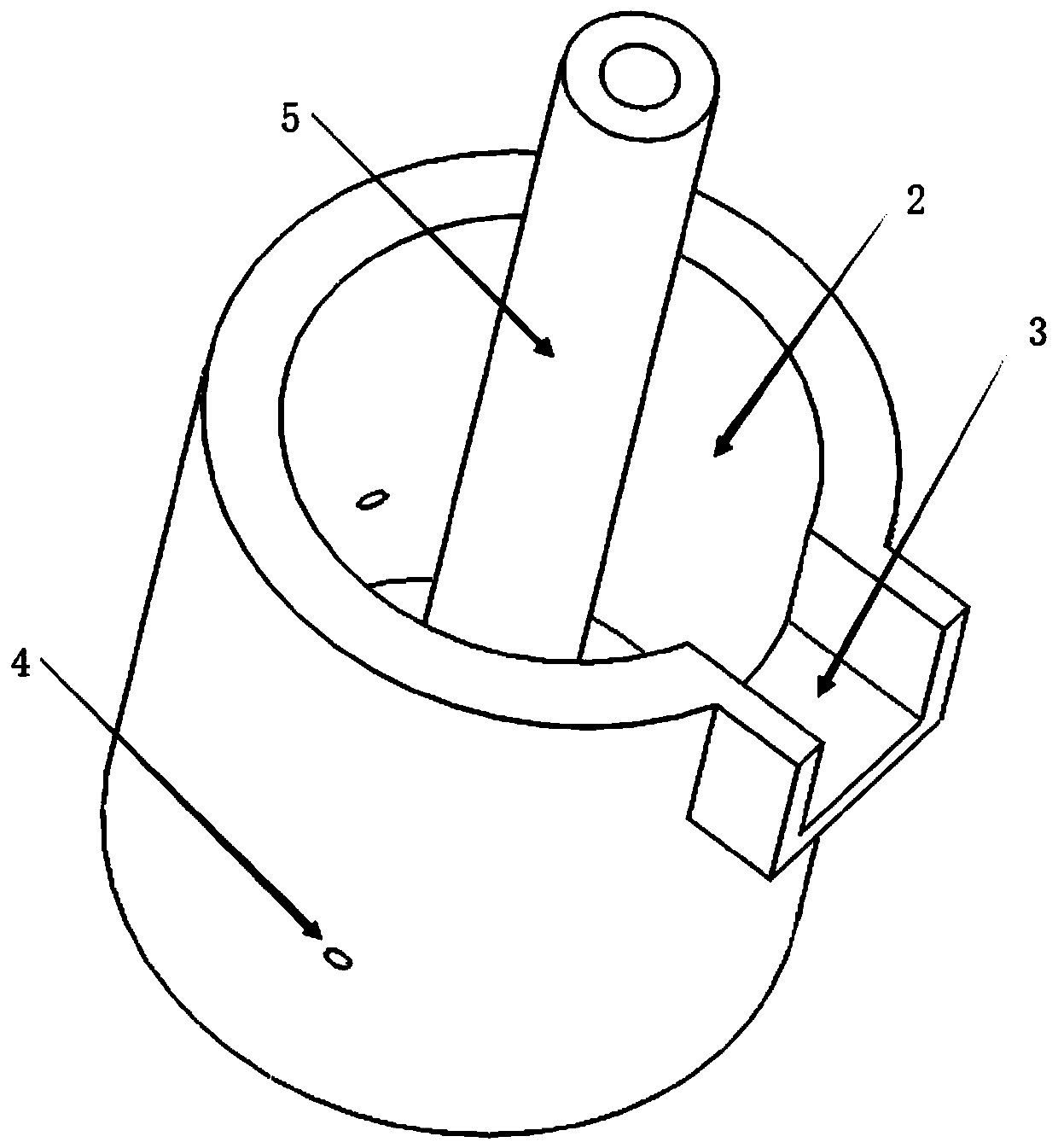

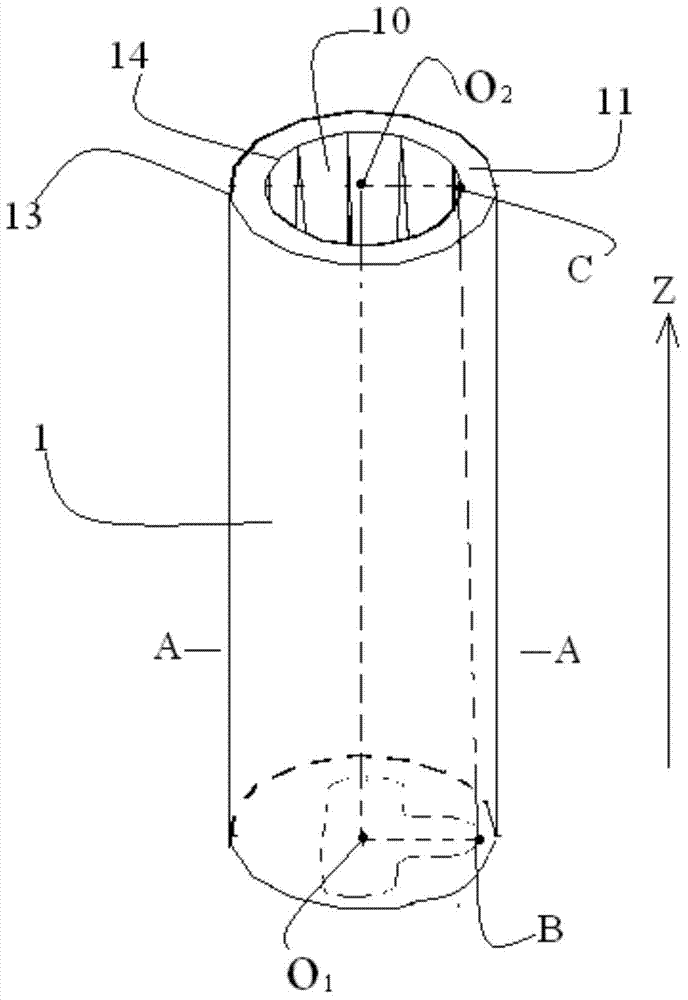

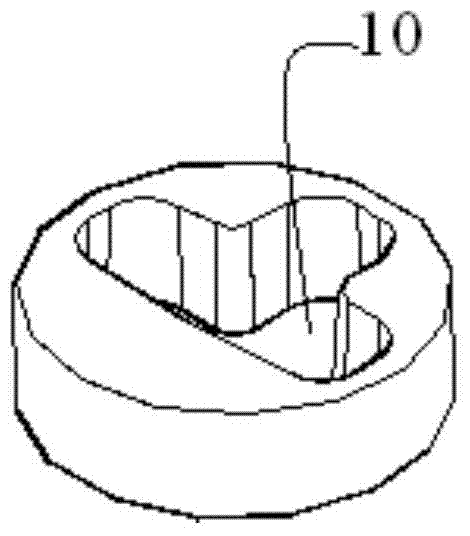

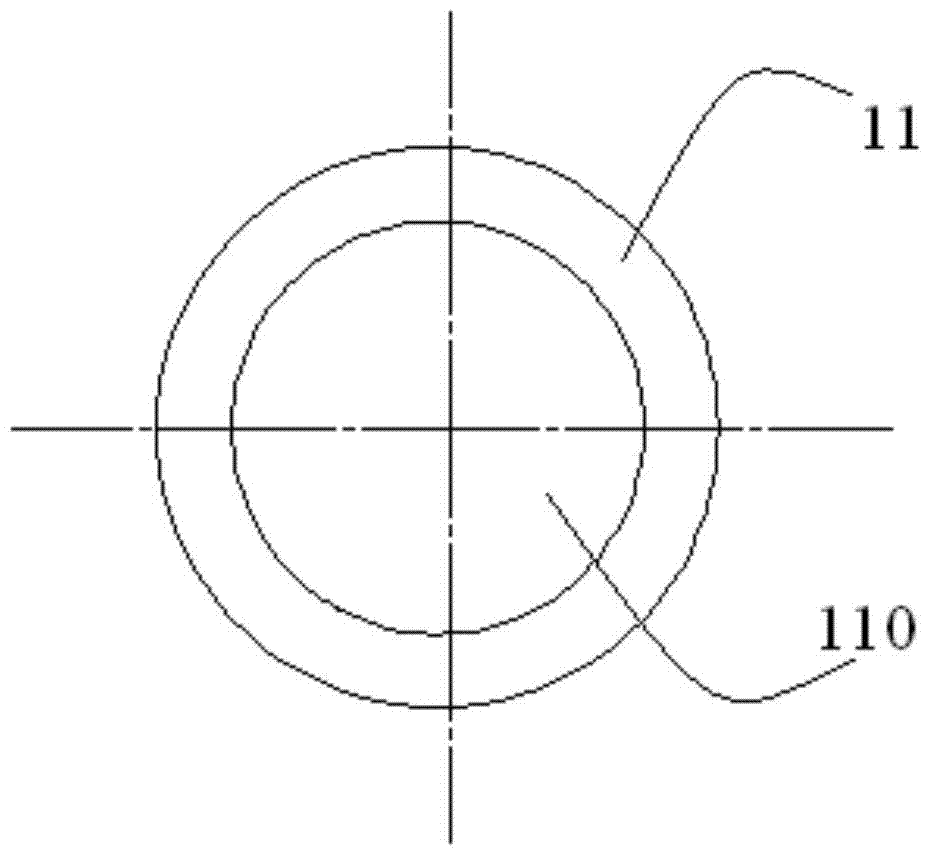

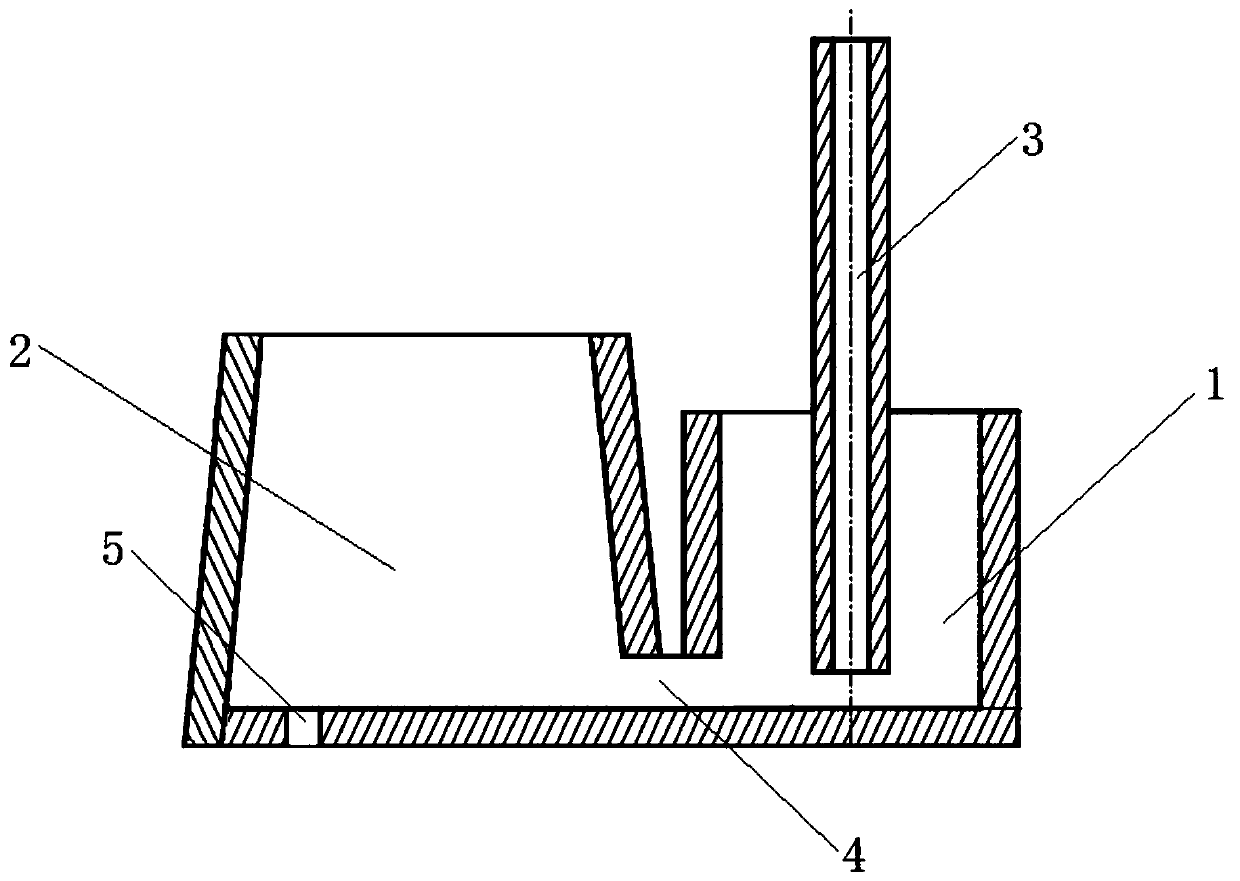

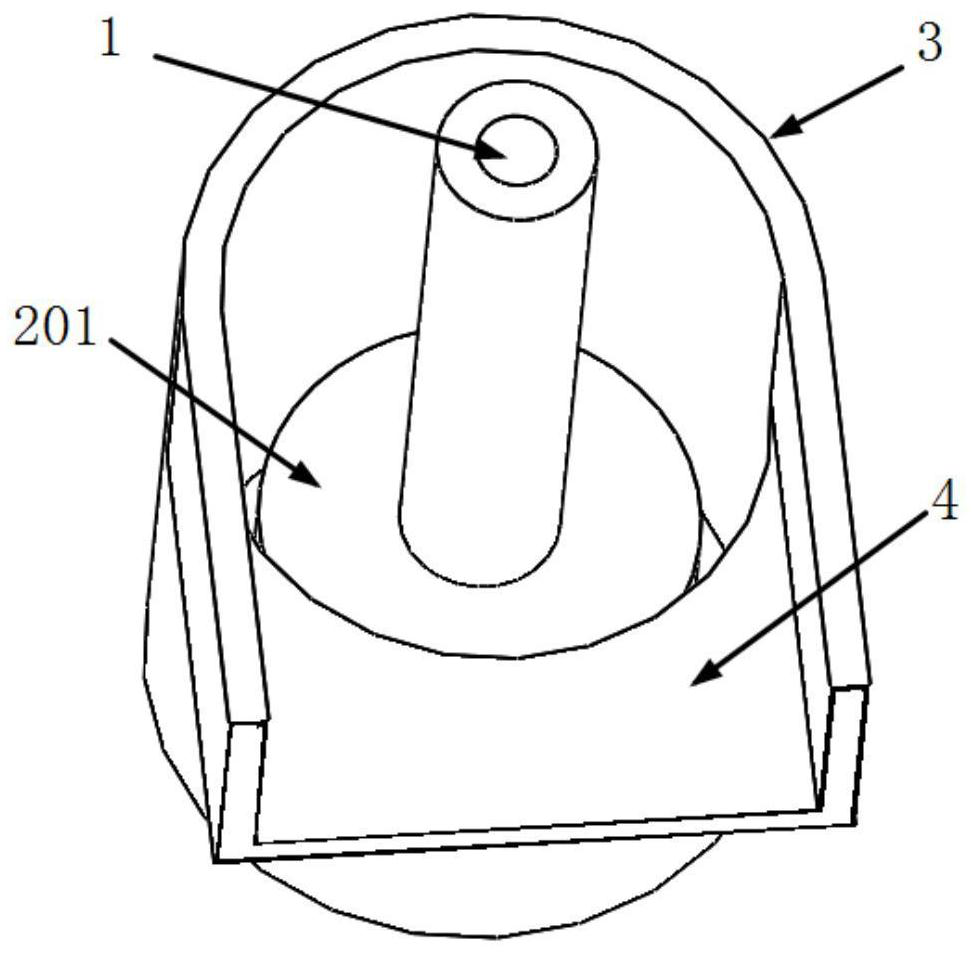

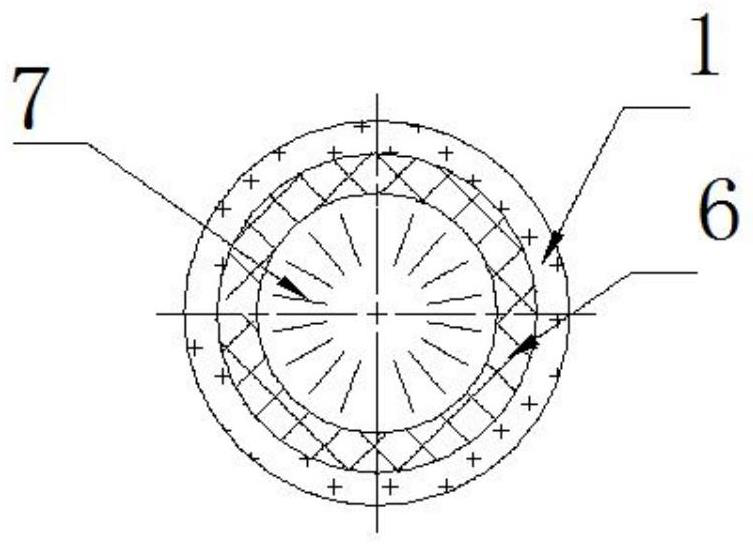

Submerged nozzle for special-shaped blank casting and arrangement mode thereof

ActiveCN104117665AImprove liquidityRaise heat centerMelt-holding vesselsNon-metallic inclusionsMolten steel

The invention discloses a submerged nozzle for special-shaped blank casting and an arrangement mode thereof. The submerged nozzle is annular, and a side wall with a hollow inner cavity is formed. A circular first opening is formed in the upper end face of the side wall, and a T-shaped second opening is formed in the lower end face of the side wall. A vertical part and a horizontal part which is connected with the middle of the vertical part are arranged on the edge of the second opening, the center of the circle of the first opening and the center of the second opening are both placed on the axis of the side wall, and the area of the first opening is equal to the area of the second opening. The hollow inner cavity is formed by correspondingly extending to the edge of the second opening from the edge of the first opening in the quasi-generatrix direction in a cut-through mode. According to the scheme, a stable and even flow field can be formed in a crystallizer, particularly the temperature and component uniformity in the transverse direction of the heat center of molten steel and the cross section of the crystallizer are improved, floating removal of nonmetallic inclusion in the molten steel and primary blank shell growth can be facilitated, and casting blank texture and surface quality are improved.

Owner:LAIWU IRON & STEEL GRP

Method for controlling subcutaneous pinholes and bubbles of medium-carbon boron-added steel continuous casting billet

The invention relates to a method for controlling subcutaneous pinholes and bubbles of medium-carbon boron-added steel continuous casting billet. The method comprises the following steps that boron content in medium-carbon boron-added steel is reduced; a solid argon-blowing-free stopper rod and an argon-blowing-free upper nozzle are designed and adopted to control the argon source; special protective slag with high basicity and low flame is designed; the argon flow between slide plates is reduced to 2-4 L / min to ensure the back pressure of 0.1-0.2 bar, and micro-positive pressure control is realized; the maximum pulling speed of a medium-carbon boron-added steel casting machine is limited to 1.4 m / min; and different automatic slag changing processes of a submerged nozzle is designed to reduce submerged depth. The influence of boron on solidification of medium-carbon boron-added steel slabs is controlled and reduced by composition design, and the contact time of the protective slag is reduced; the sources of argon and protective slag gas in steel by process design; and the floating removal of the gas in the steel is promoted by process optimization and adjustment, the defects of pinholes and bubbles at the edge of the casting billet is well controlled, the process is simple, and the adaptability and popularization are strong.

Owner:SD STEEL RIZHAO CO LTD

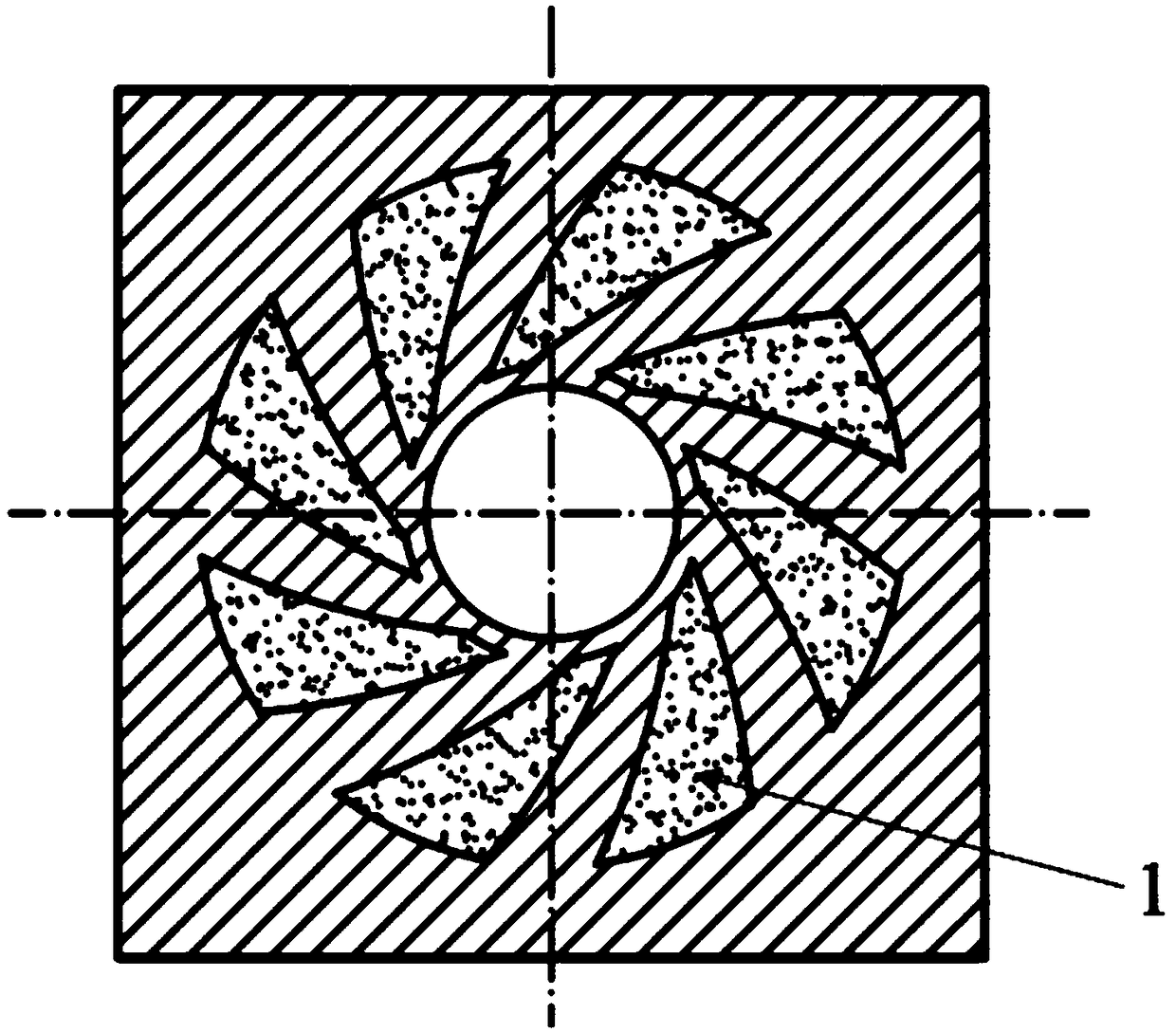

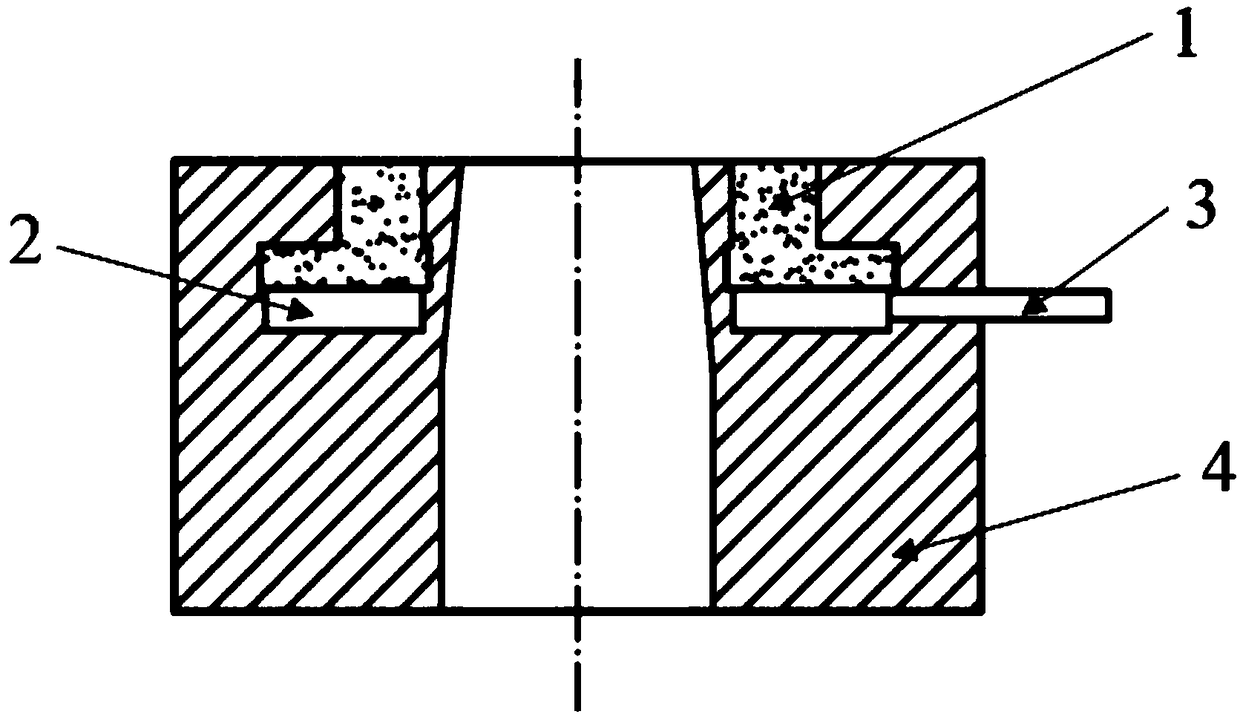

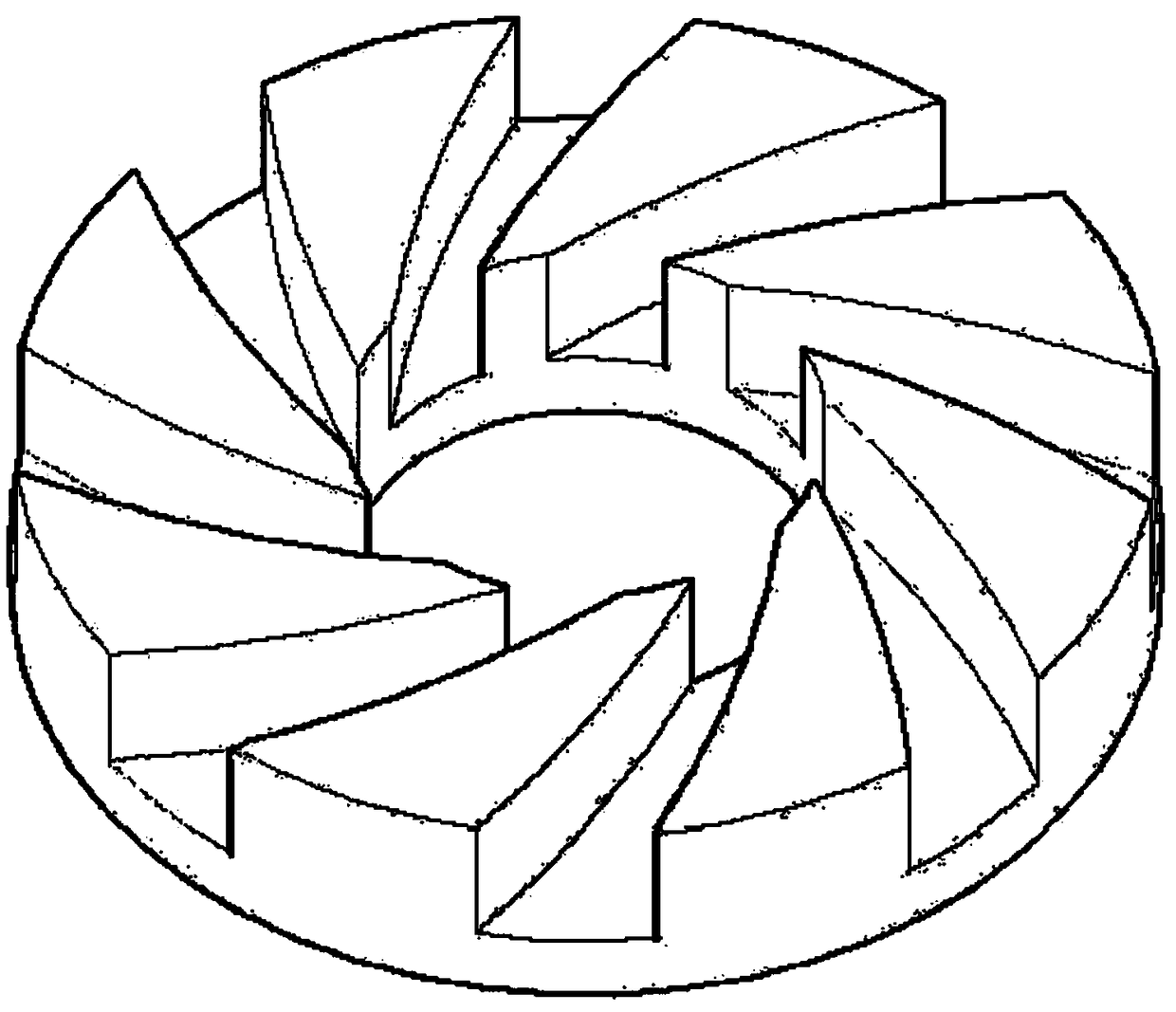

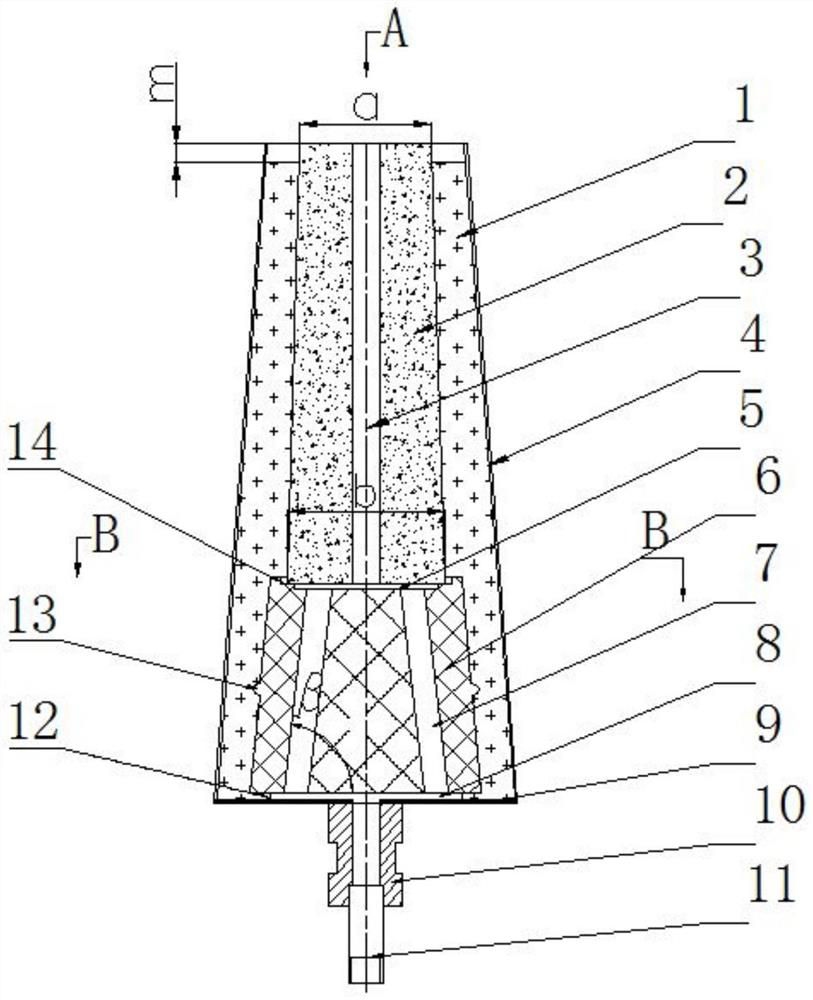

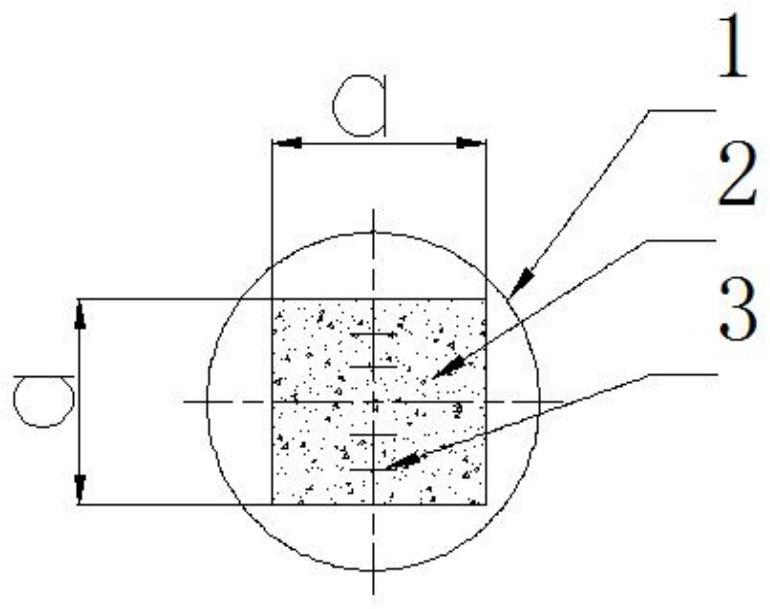

Pneumatic rotational flow upper nozzle base brick for continuous casting tundish

The invention discloses a pneumatic rotational flow upper nozzle base brick for continuous casting tundish. The pneumatic rotational flow upper nozzle base brick comprises breathable bricks, an air chamber, an air inlet pipe and a upper nozzle base brick body; the breathable bricks are located on the upper portion of the upper nozzle base brick and arranged in the upper nozzle base brick body; each breathable brick comprises an upper fan-shaped breathable portion and a lower circular-ring-shaped breathable portion; the air chamber is located between the lower circular-ring-shaped breathable portions of the breathable bricks and the upper nozzle base brick body and communicates with the breathable bricks; and one end of the air inlet pipe is connected with the side of the air chamber, and the other end of the air inlet pipe penetrates out of the side face of the upper nozzle base brick body and is connected with an external connecting pipe. According to the pneumatic rotational flow upper nozzle base brick for the continuous casting tundish, argon is blown into the fan-shaped breathable bricks to form an annular air curtain, and inclusion floating and removing are promoted; and meanwhile, molten steel rotational flow channels are formed in spiral gaps of the fan-shaped breathable bricks, rotational flowing of molten steel in a tundish nozzle is achieved, adhesion between inclusion and the inner wall of the tundish nozzle is reduced, collision between small bubbles and the inclusion which enter the tundish nozzle is promoted, and the effects of purifying the molten steel, preventing tundish nozzle blocking and reducing casting blank rim holes are achieved.

Owner:WUHAN UNIV OF SCI & TECH

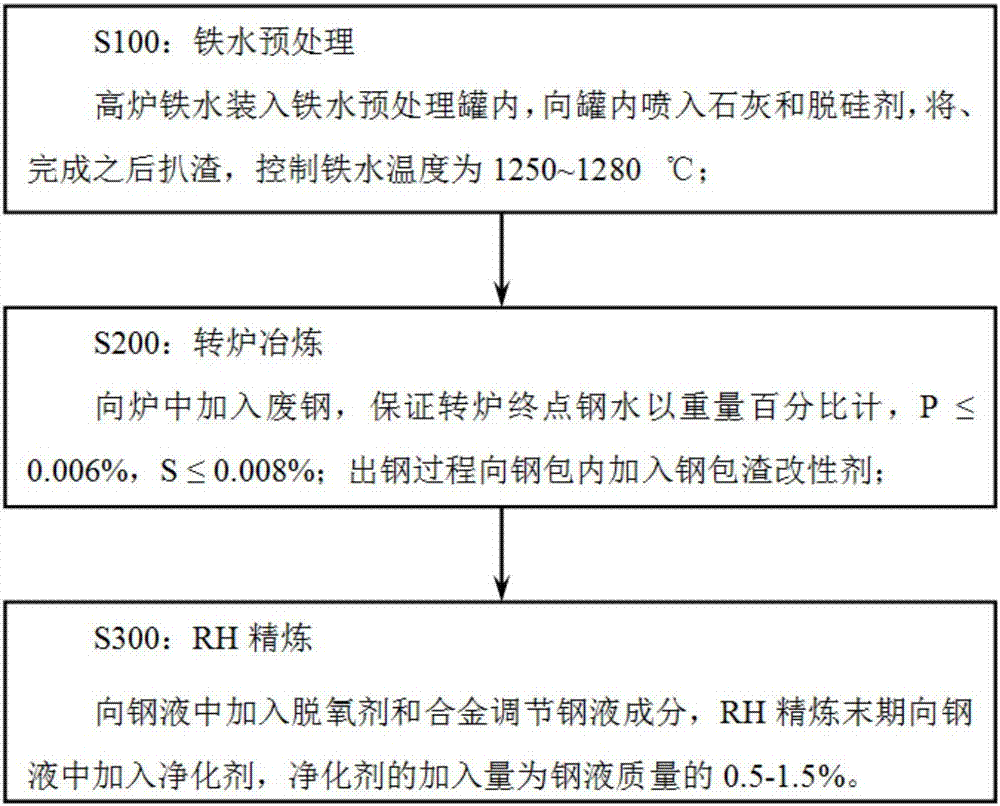

Smelting method and production process of clean steel

ActiveCN107236844AImprove smelting qualityImprove purification effectManufacturing convertersProcess efficiency improvementSteelmakingPre treatment

The invention discloses a smelting method and a production process of clean steel and belongs to the technical field of steelmaking. Molten iron is subjected to desilicication and desulphurization treatment through molten iron pretreatment and then is smelted in a converter; in the tapping process, a steel ladle slag modifier is added into a steel ladle; the steel ladle slag modifier comprises light-burning dolomite; the content of P and S in the treated molten iron is controlled to meet the relation of P<=0.006% and S<=0.008%; and at the terminal stage of RH refining, a purifying agent with the adding quantity accounting for, by mass, 0.05-1.5% of the molten steel is added into the molten steel. The molten iron is subjected to desilicication and desulphurization treatment through molten iron pretreatment and then is smelted in the converter, in the tapping process, the steel ladle slag modifier is added into the steel ladle, and at the terminal stage of RH refining, the purifying agent is added into the molten steel, so that the purifying effect of the molten steel is improved, and the smelting quality of the clean steel is further improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

Smelting method and production technology of electrical steel

InactiveCN107217124AImprove purification effectImprove cleanlinessProcess efficiency improvementElectrical steelMass ratio

The invention discloses a smelting method and a production technology of electrical steel and belongs to the technical field of pure steel smelting. After molten steel is smelted in a converter, the molten steel is conveyed to be subjected to the RH refining technology, and the flow of circulation gas ranges from 100 Nm<3> / h to 300 Nm<3> / h; and a purifying agent is added in the molten steel in the RH refining tail stage, and the target components of the electrical steel are controlled, wherein C is controlled to be smaller than or equal to 0.003%, Si is controlled to range from 0.7% to 1.0%, Mn is controlled to range from 0.2% to 0.3%, P is controlled to be smaller than or equal to 0.03% and S is controlled to be smaller than or equal to 0.005%. The purifying agent includes effective components and adhesive components, wherein the mass ratio of the effective components to the adhesive components is (5-10):1. By means of the smelting method and the production technology of the electrical steel, due to molten iron pretreatment, converter smelting and the RH refining technology and due to the fact that the purifying agent is added into the molten steel, the size of residual inclusions in the molten steel is small, the residual inclusions are evenly distributed, the residual inclusions are basically subjected to denaturating treatment, the purifying effect of the molten steel is improved, and the electrical steel cleanliness is improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

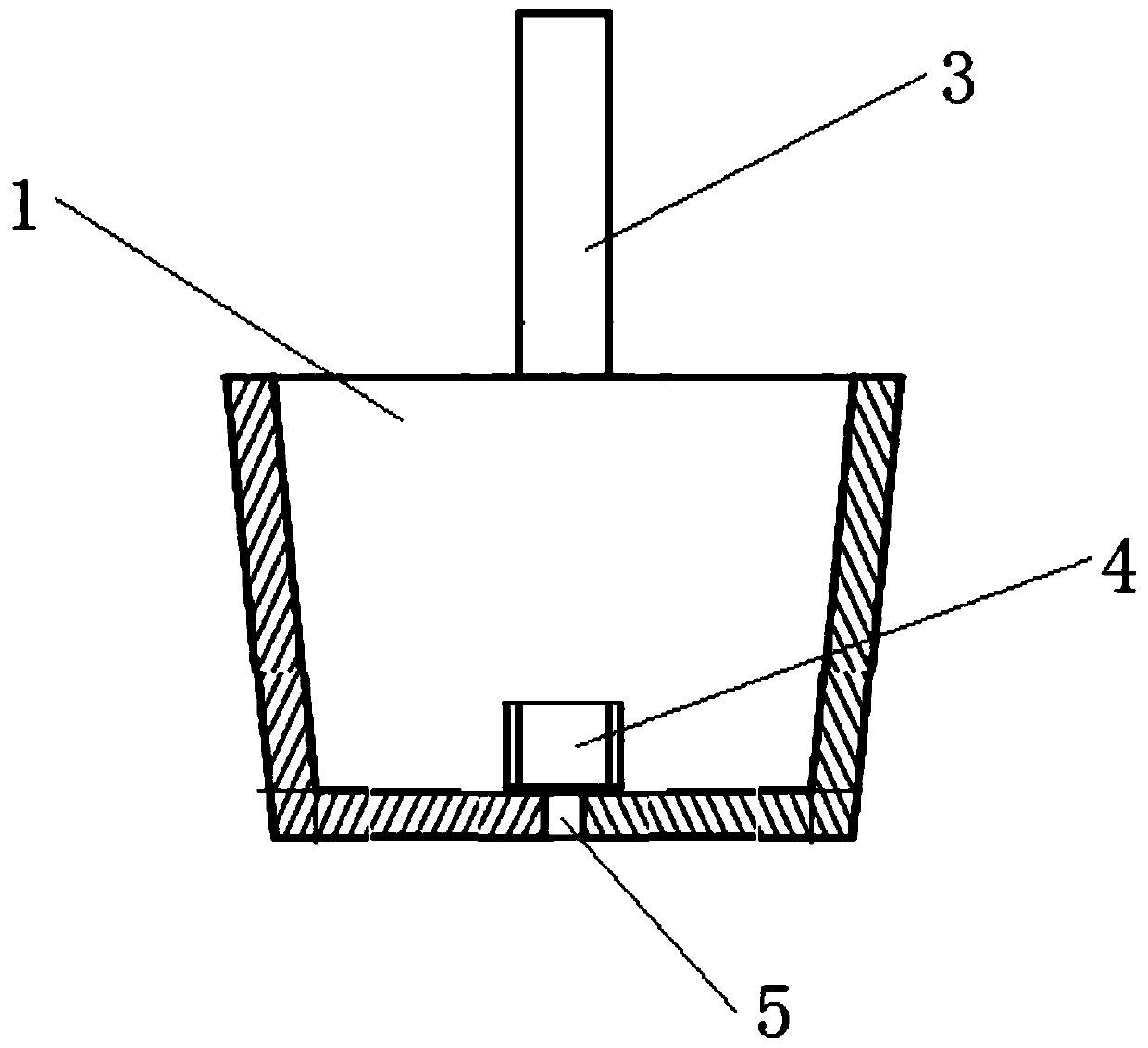

Gas protection method applied to pouring process of middle column pipe and device thereof

InactiveCN111154947APromote collision growthPromotes buoyant removalMelt-holding vesselsPipeRotational flow

The invention provides a gas protection method applied to a pouring process of a middle column pipe and a device thereof. The method comprises the following steps of step 1, when molten steel does notflow into a steel ladle, introducing inert gas into the steel ladle through a vent at the bottom of the steel ladle until the molten steel completely flows into the steel ladle, wherein the gas blowing direction of the inert gas is similar to the horizontal tangential direction of the rotational flow of the molten steel; step 2, stopping introducing the inert gas into the vent, and feeding the purified molten steel in the steel ladle into a molten steel tundish through the vent; and step 3, opening a water port at the bottom of the molten steel tundish so as to inject the molten steel in themolten steel tundish into a crystallizer for solidification forming. Compared with a conventional pouring process of the middle column pipe, the gas protection method has the advantages that the steelladle is arranged at the outer side; the molten steel realizes rotating flowing through gas driving, so that the collision enlarging of inclusions is promoted; the upward floating removal of the inclusions is facilitated; and the removal efficiency of the inclusions is greatly improved.

Owner:马鞍山市星新机械材料有限公司

A kind of molten steel cleaning agent for removing inclusions in molten steel

The invention discloses a molten steel purifying agent for removing inclusions in molten steel, and belongs to the technical field of net steel smelting. The purifying agent is granular, and comprises an effective component and an adhesive component; the mass ratio of the effective component to the adhesive component is (5-10): 1; the effective component comprises metal aluminum, lime powder, silicon carbide powder, titanium dioxide and biomass; the adhesive component comprises kaolin and sulfonated phenolic resins; the purifying agent is spherically granular; and the granular diameter is 5-10 mm. The oxygen content in the molten steel is reduced by the purifying agent; CO gas generated by the reaction accelerates the upward floating removal of the inclusions and the removal of the inclusions in the steel; the inclusions remained in the molten steel treated by the purifying agent are smaller in size and uniformly distributed; the content of the inclusions in the steel treated by the molten steel purifying agent is prominently reduced; the inclusions in the steel are denatured; and the purifying effect of the molten steel is obvious.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

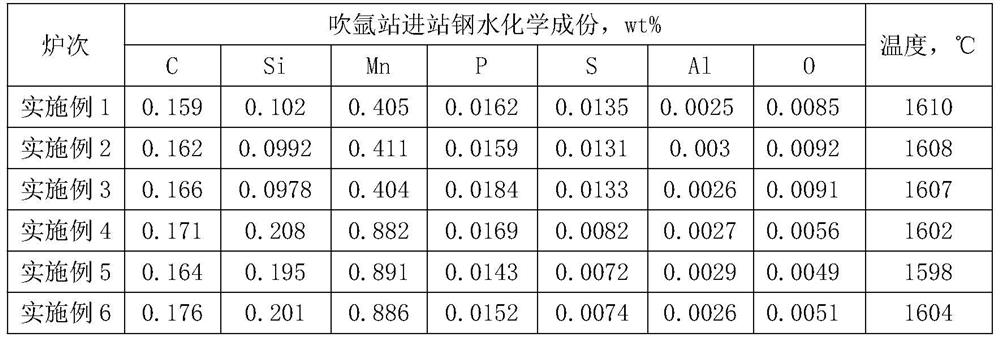

Production method of low-aluminum carbon structural molten steel

The invention discloses a production method of low-aluminum carbon structural molten steel. The production method mainly solves the technical problems that existing carbon structural steel produced by a slab continuous casting machine is poor in cleanliness and high in deoxidation cost. According to the technical scheme, the production method of the low-aluminum carbon structural molten steel comprises the following steps that a top-bottom combined blowing converter is adopted for smelting, and 80%-100% of molten iron is added by mass percent; controlling a converter smelting end point, and detecting w [C] and molten steel temperature in molten steel at the converter smelting end point; tapping immediately after converter blowing is finished, and blowing argon at the bottom of a steel ladle in the converter tapping process; molten steel in the steel ladle is conveyed to an argon blowing station for molten steel temperature regulation and final deoxidation; and carrying out weak stirring on the molten steel fed with the aluminum wire. The low-aluminum carbon structural steel produced by the method disclosed by the invention is low in deoxidation cost, and the deoxidation cost per ton of steel is reduced by 12-22 yuan; and the cleanliness of the steel is high, and the total oxygen weight content in tundish molten steel is 0.0015-0.0025%.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

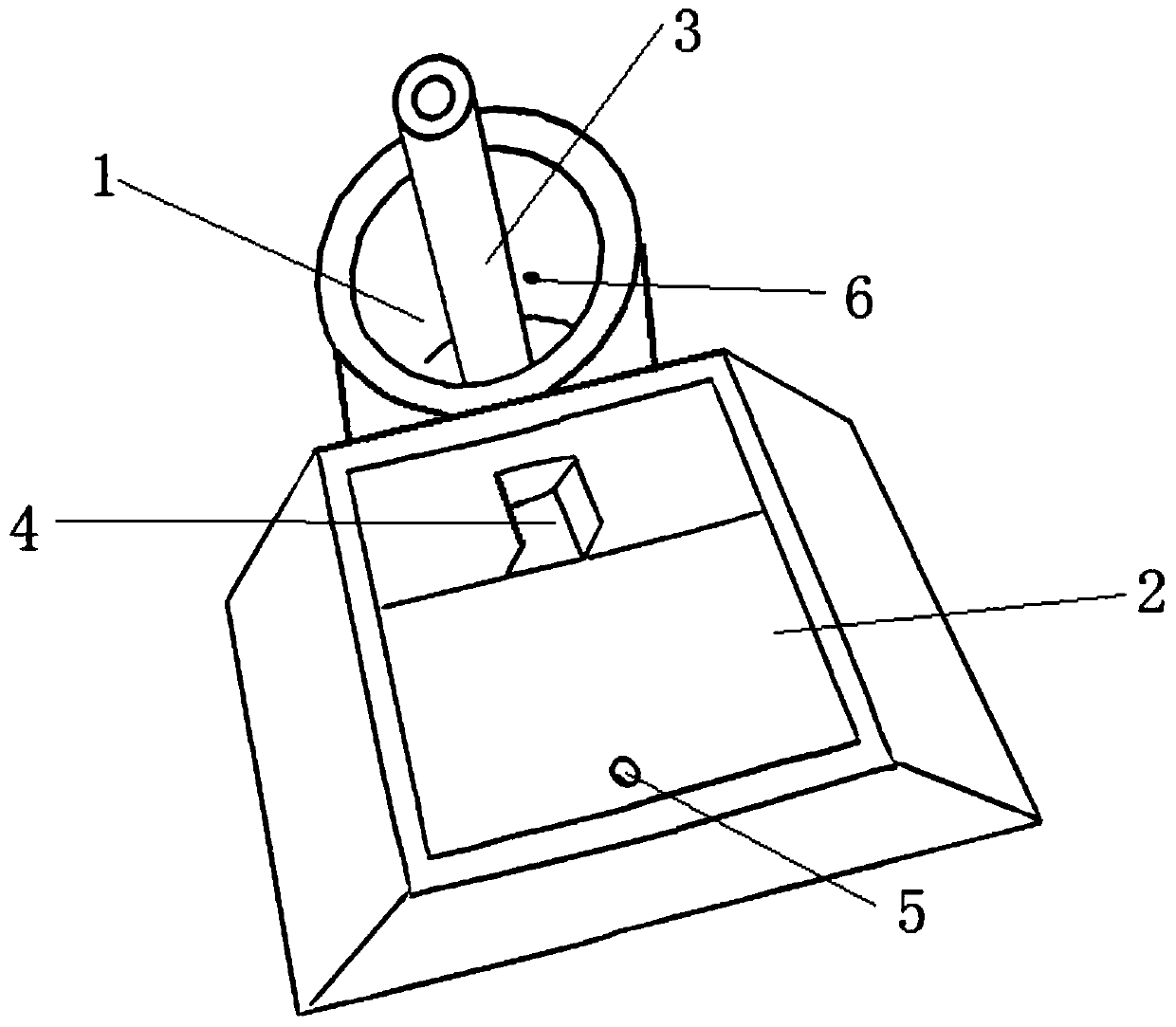

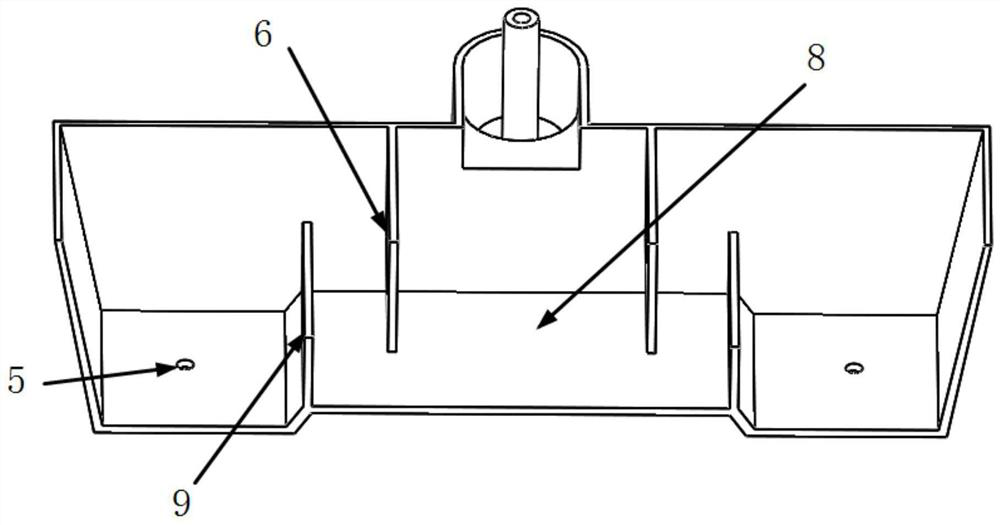

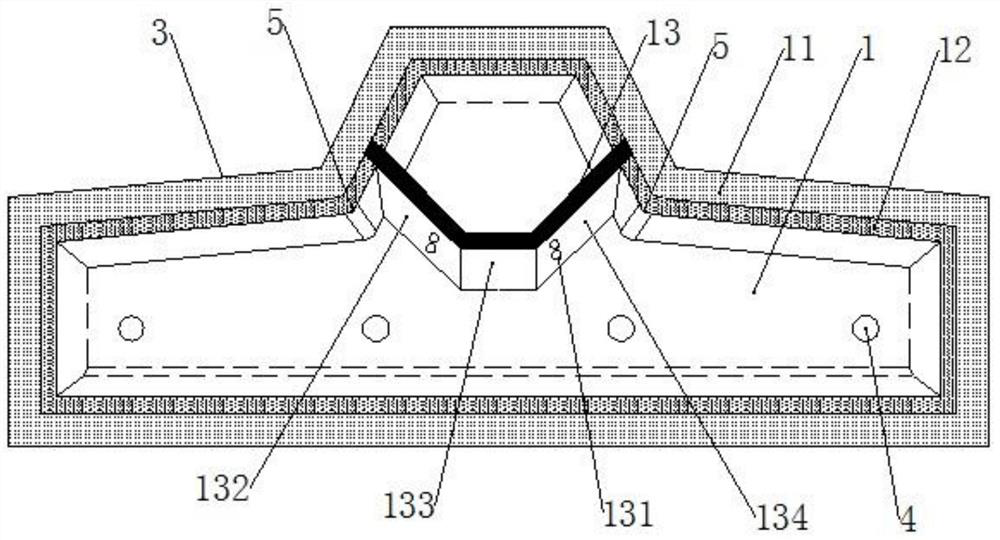

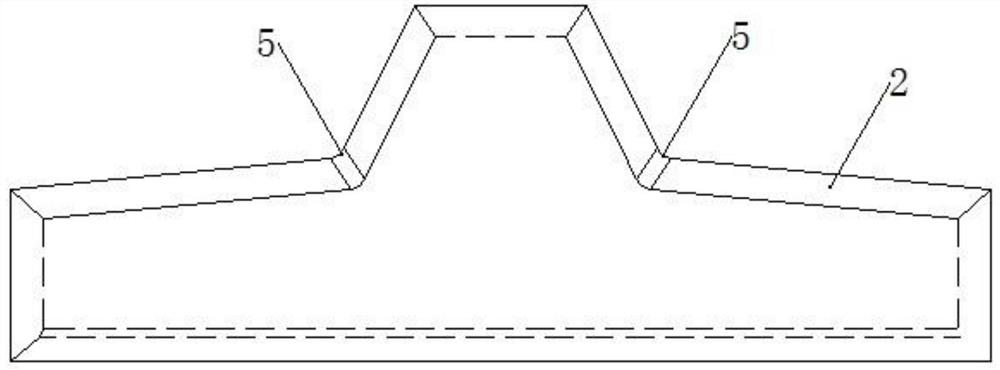

Split type tundish turbulence inhibitor

The invention discloses a split type tundish turbulence inhibitor which comprises a turdish body and an external turbulence inhibiting region, wherein the external turbulence inhibiting region comprises a controller upper part, a controller lower part and a chamber. The turbulence inhibitor is additionally arranged in the external turbulence inhibiting region, so that molten steel enters the turbulence inhibitor from a long nozzle to generate fierce upward backflow by impacting the lower part of the bottom controller; then the controller upper part blocks the molten steel flow which is upwardsimpacted, so that the molten steel flow downwards flows to the bottom of the external turbulence inhibiting region, then upwards flows out of the external turbulence inhibiting region from a positionbetween the turbulence inhibitor and the wall surface of the external turbulence inhibiting region, and finally flows to the turdish body. On one hand, the turbulence inhibitor weakens turbulence intensity of the molten steel to reduce turbulent kinetic energy, so that impact, on a slag-metal interface, of the molten steel is reduced; on the other hand, speed of making the molten steel enter thetundish body is increased, piston flow volume is increased, the size of a dead region is reduced, stay time of molten steel is prolonged, good flow fields are created for removing impurities, and theimpurities can be floated and removed better.

Owner:NORTHEASTERN UNIV

Tundish permanent lining preparation method and construction molding bed thereof

The invention provides a tundish with a permanent lining and a construction molding bed thereof. The tundish comprises the permanent lining; the permanent lining comprises a tundish wall and a tundishbottom; the tundish wall is of a T-shaped groove structure, and the tundish wall comprises an impact area tundish wall and a pouring area tundish wall of a convex part; an arc-shaped transition partis arranged at the inflection point joint between the inner side of the impact area tundish and the inner side of the pouring area tundish wall; a water gap hole is arranged on the tundish bottom andcommunicates with the interior and exterior of an accommodating cavity; a working lining layer attached to the inner wall surface of the permanent lining layer; and a slag blocking wall, which is tightly connected with the permanent lining layer and arranged at the position of the impact area tundish wall of the permanent lining layer, wherein the slag blocking wall and the convex part of the T-shaped groove define an impact area, and a flow guide hole is arranged on the slag blocking wall and penetrates through the interior and the exterior of the wall body of the slag blocking wall. The tundish permanent lining prepared by using the construction molding bed of the invention is low in manufacturing cost, good in using effect and long in service life.

Owner:DAYE SPECIAL STEEL CO LTD

Ultralow-phosphorus continuous casting steel billet, and production method and application thereof

ActiveCN114032355AReduce contentImprove cleanlinessManufacturing convertersProcess efficiency improvementRefining (metallurgy)Smelting process

The invention belongs to the technical field of ferrous metallurgy, and particularly relates to an ultralow-phosphorus continuous casting steel billet, and a production method and an application thereof. The production method comprises the steps of molten iron pretreatment, a converter duplex dephosphorization and decarburization procedure, LF refining, RH vacuum refining and continuous casting, the converter duplex dephosphorization and decarburization procedure comprises dephosphorization converter smelting and decarburization converter smelting, and the lance position, the oxygen supply amount, the bottom blowing flow, the slag, the alkalinity and other parameters in the dephosphorization converter smelting process and the decarburization converter smelting process are limited. The content of impurities such as phosphorus, sulfur, nitrogen and hydrogen in the continuous casting steel billet prepared by the method is extremely low, the cleanliness of molten steel is improved, the prepared steel billet is stable in quality and high in purity, the center of the steel billet does not have the defects of looseness and the like, and the rephosphorization problem caused by single slag or double slag of a traditional converter in the prior art is solved.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

Composite air brick and argon blowing refining method in continuous casting ladle pouring process

PendingCN114433829AIncrease the lengthReduce the slit widthMelt-holding vesselsManufacturing engineeringIndustrial engineering

The invention relates to a composite air brick and an argon blowing refining method in a continuous casting ladle pouring process. The air brick comprises a pouring body, a dispersion block and a safety warning device, wherein the dispersion block and the safety warning device are arranged in the pouring body from top to bottom; a plurality of slit air channels A penetrating through the dispersion block are vertically formed in the dispersion block; a lower air chamber is arranged at the bottom of the safety warning device, an upper air chamber is arranged at the top of the safety warning device, a plurality of slit air passages B which are through up and down are arranged in the safety warning device, the plurality of slit air passages B are uniformly distributed in the safety warning device along the circumference, and the lower ends of the slit air passages B are gradually inclined outwards; and the slit air passage A, the upper air chamber, the slit air passage B and the lower air chamber are communicated. The air brick has the excellent performance of large air permeability, stable air permeability, long service life and the like, after refining treatment in an LF refining furnace is completed, the air brick is hoisted to a continuous casting rotary table, argon blowing is carried out in the continuous casting steel ladle pouring process to remove inclusions, the soft blowing time in the later stage of LF refining is shortened, the removal rate of the inclusions is increased, and molten steel standing layering is restrained.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Four-hole circulating bottom argon blowing method for rapidly mixing molten steel

The invention relates to a four-hole circulating bottom argon blowing method for rapidly mixing molten steel. Four argon blowing holes are uniformly distributed in the inner diameter 0.5-0.7R positionof the bottom of a steel ladle, when steel ladle bottom blowing begins, the four argon blowing holes blow argon in sequence and in a circulating mode, the blowing flow of the argon blowing holes is changed based on the sine rule, the blowing flow range of a sine wave peak is from 8 pi to 20 pi m<3> / h, the total blowing flow of the four argon blowing holes is 16-40 m<3> / h, and the cycle time of circulating argon blowing is 1-4 t, wherein the t is the time needed by the argon from the argon blowing holes to reach the molten steel level. According to the method, an argon flow channel can be effectively prevented from being formed in the molten steel, and the kinetic energy of the argon is fully utilized to stir the molten steel; and a higher blowing rate can be generated, stirring strength is increased, the volume of dead zone in the steel ladle is further reduced, and components and temperature of the molten steel are rapidly and uniformly distributed. The method can fully use the stirring effect of the argon on the molten steel, shorten molten steel mixing time, reduce smelting cost and improve refining efficiency.

Owner:WUHAN UNIV OF SCI & TECH

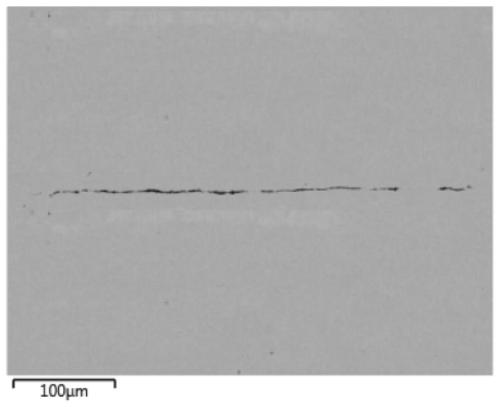

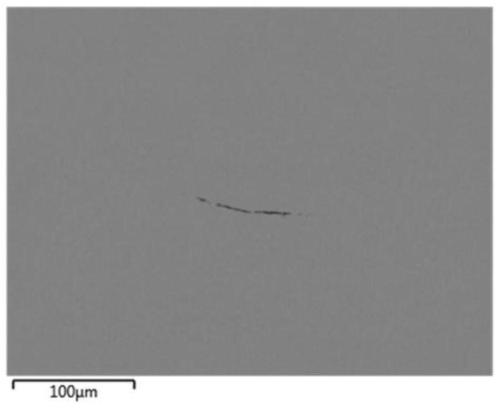

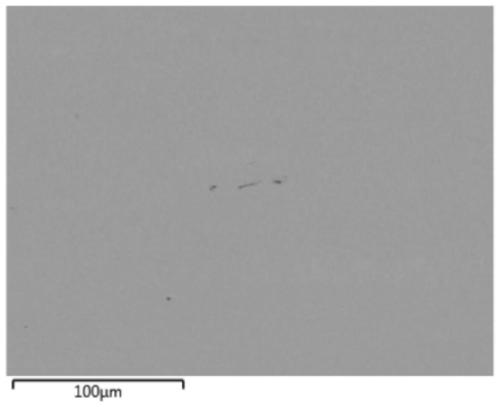

Low-silicon microalloyed high-temperature carburized gear steel and manufacturing method thereof

InactiveCN112593036AImprove fatigue lifeReduced enrichmentSolid state diffusion coatingManufacturing convertersAustenite grainSlag

The invention discloses low-silicon microalloyed high-temperature carburized gear steel and a manufacturing method thereof. The manufacturing method includes the steps that about 20% of scrap steel isadded into a converter, then molten iron is added for smelting, final steel tapping control targets are that C is larger than or equal to 0.08% and P is smaller than or equal to 0.015%, sliding plateslag stopping operation is conducted in the steel tapping process, and discharged slag is reduced; and alloying is started about 90 seconds after tapping is started, and ferro-aluminum, carbon powder, an alloy and lime are added in sequence. According to the low-silicon microalloyed high-temperature carburized gear steel and the manufacturing method thereof, enrichment of inclusions at the innerside of a gate is greatly reduced, steady-state control over a stopper curve in the casting process is achieved, involving of large-size inclusions due to the fact that the stopper curve suddenly fluctuates is avoided, continuous casting production of at least six furnaces can be achieved, and meanwhile the service fatigue life of a gear is remarkably prolonged; and abnormal growth of austenite grains is hindered, and the austenite grain coarsening temperature of the gear steel is increased, so that the effects of preventing mixed grains and coarse grains of the austenite grains of the gear steel after high carburizing temperature are achieved.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com