RH refining system using purifying agent core-spun yarn and refining method thereof

A technology of purifying agent and cored wire, applied in RH refining system and its refining field, can solve the problem of limited purification effect of molten steel, and achieve the effect of promoting mixing effect, small size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

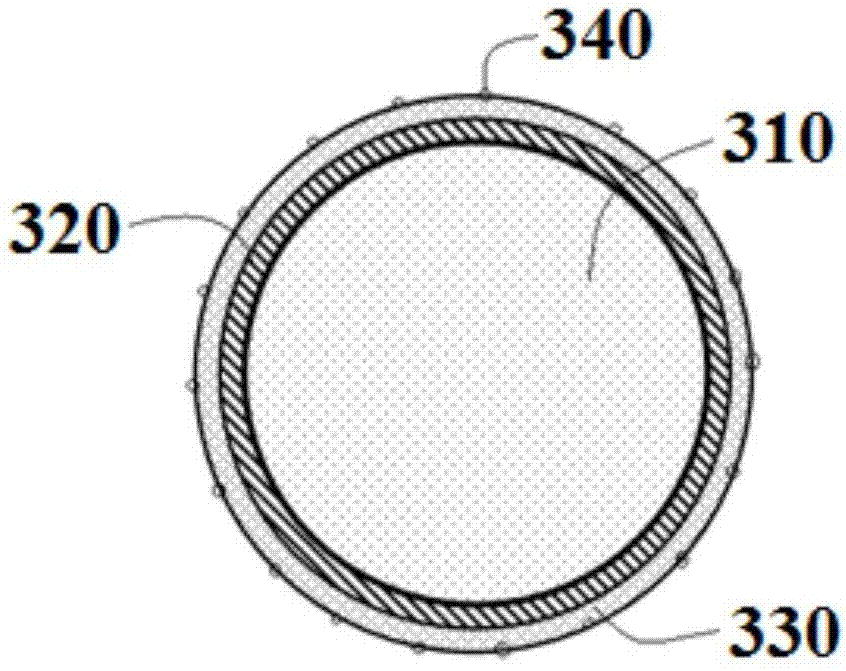

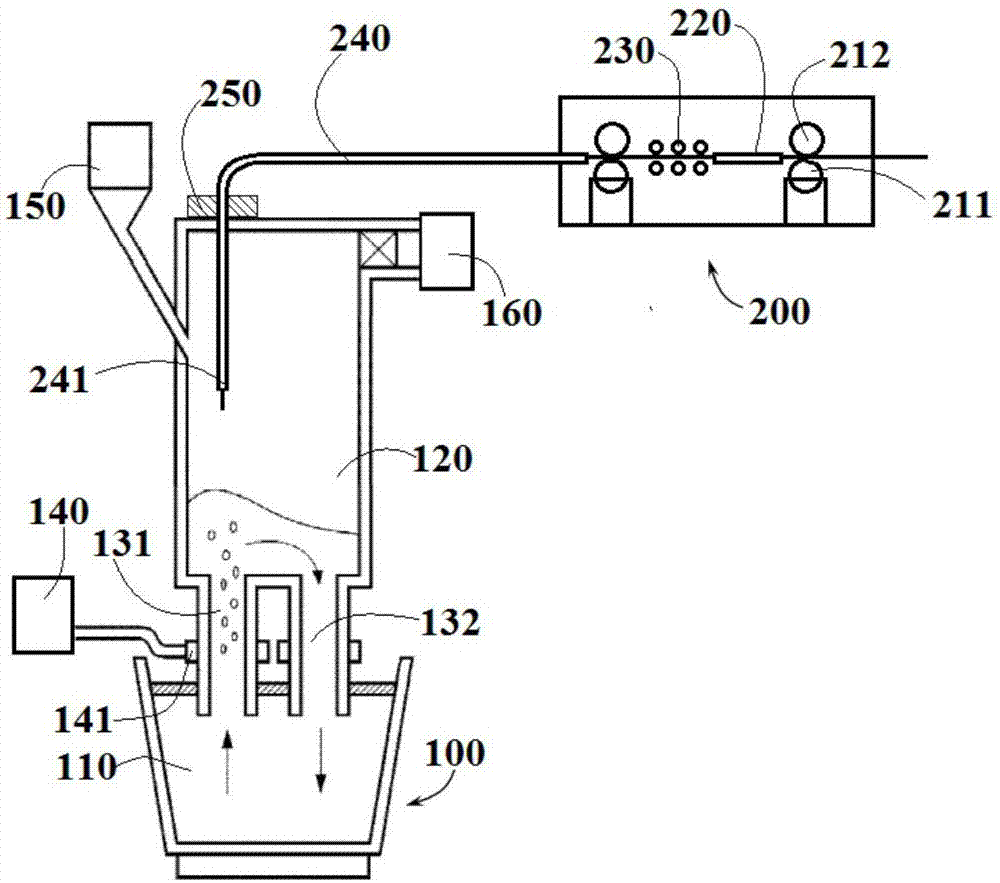

[0046] like figure 1 and image 3 As shown, a RH refining system using purifying agent cored wire in this embodiment includes a RH refining furnace 100 and a wire feeding unit 200, and the RH refining furnace 100 includes a ladle 110, a vacuum chamber 120 and a vacuum mechanism 160 , the vacuum chamber 120 is arranged on the top of the ladle 110, the riser 131 and the downcomer 132 at the bottom of the vacuum chamber 120 are inserted into the ladle 110, the vacuum mechanism 160 is arranged on the top of the vacuum chamber 120, and the vacuum mechanism 160 is used for vacuuming The chamber 120 provides a vacuum environment; the RH refining furnace 100 also includes an air blowing mechanism 140, and the nozzle 141 of the air blowing mechanism 140 is arranged at the lower part of the riser pipe 131, and the air blower mechanism 140 blows argon into the riser pipe 131 through the nozzle 141, Promote the rise of molten steel in the riser pipe 131 . The vacuum chamber 120 is provi...

Embodiment 2

[0086] The basic content of this embodiment is the same as that of Example 1, except that the cleaning agent is in the form of granules, the cleaning agent is in the form of spherical particles, and the diameter of the particles is 5-10mm; the cleaning agent includes effective components and bonding components, and the effective components The mass ratio to the adhesive component is (5-10):1, preferably 5:1 in this embodiment.

[0087] The effective components in the purification agent of this embodiment also include graphite powder, red jade soil and magnesium-manganese alloy; the effective components are composed according to the following mass parts, 50-70 parts of metal aluminum, 20-40 parts of lime powder, and 0-30 parts of graphite powder part, 5-20 parts of titanium dioxide, 5-15 parts of silicon carbide powder, 2-4 parts of biomass, 0-1 part of red jade soil, 0-2 part of magnesium-manganese alloy; the present embodiment is 50 kg of metal aluminum, 20 kg of lime powder, ...

Embodiment 3

[0090] The basic content of this embodiment is the same as that of Example 1, except that the adhesive component of the purifying agent also includes starch and kaolin, and the adhesive component is composed of the following parts by mass: 60-80 parts of kaolin, 20-40 parts of sulfonated phenolic resin parts, starch 0-10 parts, oil sands 0-5 parts. This embodiment is composed according to the following mass: 80 kg of kaolin, 40 kg of sulfonated phenolic resin, 5 kg of starch, and 2 kg of oil sand. The mass ratio of the effective component to the binding component is 6:1, and the mixture is obtained after the mixing is completed. Experimental result is basically the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com