Desulfurizing method for molten iron containing sulfur

A hot metal desulfurization and molten iron technology, applied in the field of steelmaking, can solve the problems of low utilization rate of desulfurization agent, large consumption of desulfurization agent, reduction of desulfurization cost, etc., to achieve optimal desulfurization kinetics, high utilization rate of desulfurization agent, and reduction of desulfurization cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

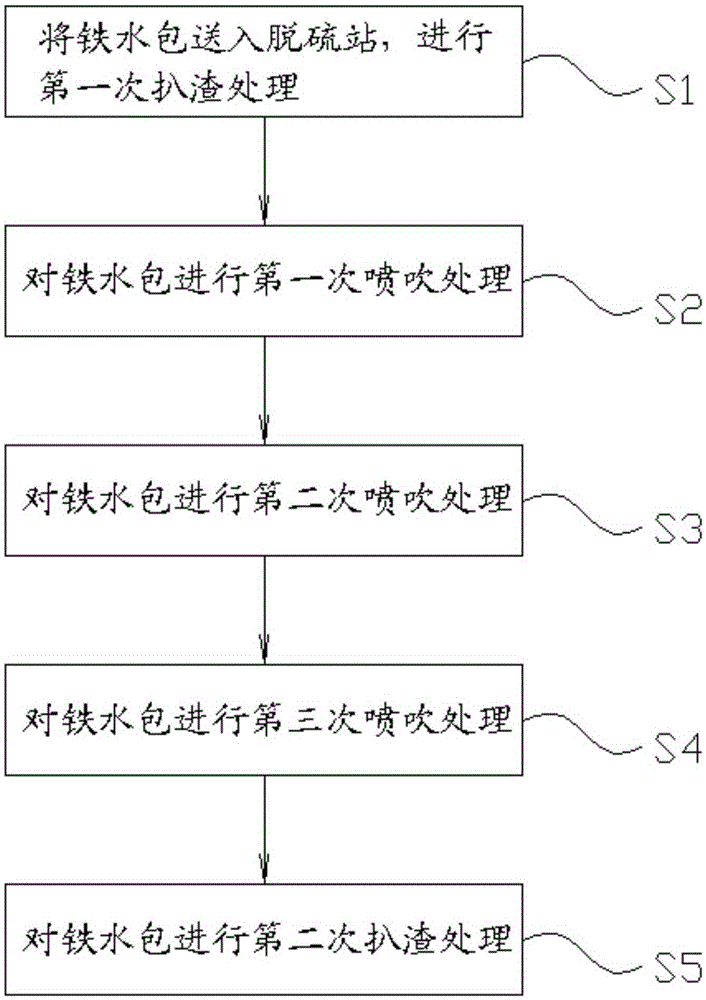

[0047] Desulfurization is carried out by using a low-cost desulfurization method for medium-high sulfur molten iron. The composition of the molten iron before desulfurization is: by mass percentage, C: 4.33%, Si: 0.41%, Mn: 0.10%, P: 0.073%, S: 0.041, Ti: 0.07 , the temperature of molten iron is 1358°C, and the specific steps of the desulfurization method are:

[0048] S1: After the molten iron enters the desulfurization station, the slag removal operation is performed first, and the amount of slag removal is 50% of the total slag amount in the ladle in terms of mass percentage.

[0049] S2: After the slag removal, the injection is divided into three stages. In the first injection process, the injection volume of the powder is 1.0kg per ton of iron, and the powder injection rate is 720kg / h. The chemical composition of the powder 40% CaO, 30% CaC 2 , 30% Mg, nitrogen injection flow rate of 120Nm 3 / h, the injection pressure of the spray gun is 0.44MPa, the ratio of the powder...

Embodiment 2

[0055] Desulfurization is carried out by low-cost desulfurization method for medium and high-sulfur hot metal. The composition of hot metal before desulfurization is: by mass percentage, C: 4.23%, Si: 0.31%, Mn: 0.11%, P: 0.077%, S: 0.060, Ti: 0.05 , the temperature of molten iron is 1341°C, the specific steps of the desulfurization method are:

[0056] S1: After the molten iron enters the desulfurization station, the slag removal operation is performed first, and the amount of slag removal is 50% of the total slag amount in the ladle in terms of mass percentage.

[0057] S2: After the slag removal, the injection is divided into three stages. In the first injection treatment, the injection volume of the powder is 1.1kg per ton of iron, and the powder injection rate is 720kg / h. The chemical composition of the powder 40% CaO, 30% CaC 2 , 30% Mg, nitrogen injection flow rate is 110Nm 3 / h, the injection pressure of the spray gun is 0.43MPa, the ratio of the powder injection rat...

Embodiment 3

[0063] Desulfurization is carried out by using a low-cost desulfurization method for medium-high sulfur molten iron. The composition of the molten iron before desulfurization is: by mass percentage, C: 4.41%, Si: 0.33%, Mn: 0.12%, P: 0.084%, S: 0.052, Ti: 0.09 , the temperature of molten iron is 1359°C, and the specific steps of the desulfurization method are:

[0064] S1: After the molten iron enters the desulfurization station, the slag removal operation is performed first, and the amount of slag removal is 50% of the total slag amount in the ladle in terms of mass percentage.

[0065] S2: After the slag removal, the injection is divided into three stages. In the first injection process, the injection volume of the powder is 1.0kg per ton of iron, and the powder injection rate is 720kg / h. The chemical composition of the powder 40% CaO, 30% CaC 2 , 30% Mg, nitrogen injection flow rate of 120Nm 3 / h, the injection pressure of the spray gun is 0.45MPa, the ratio of the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com