Submerged nozzle for special-shaped blank casting and arrangement mode thereof

An immersion-type, special-shaped billet technology, applied in the field of metallurgy, can solve problems such as difficult to meet the requirements of low-cost and stable production of special-shaped billets, reduce the service life of nozzles, burn safety production accidents, etc., and achieve the improvement of billet structure and surface quality, The effect of ensuring safe production and improving the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

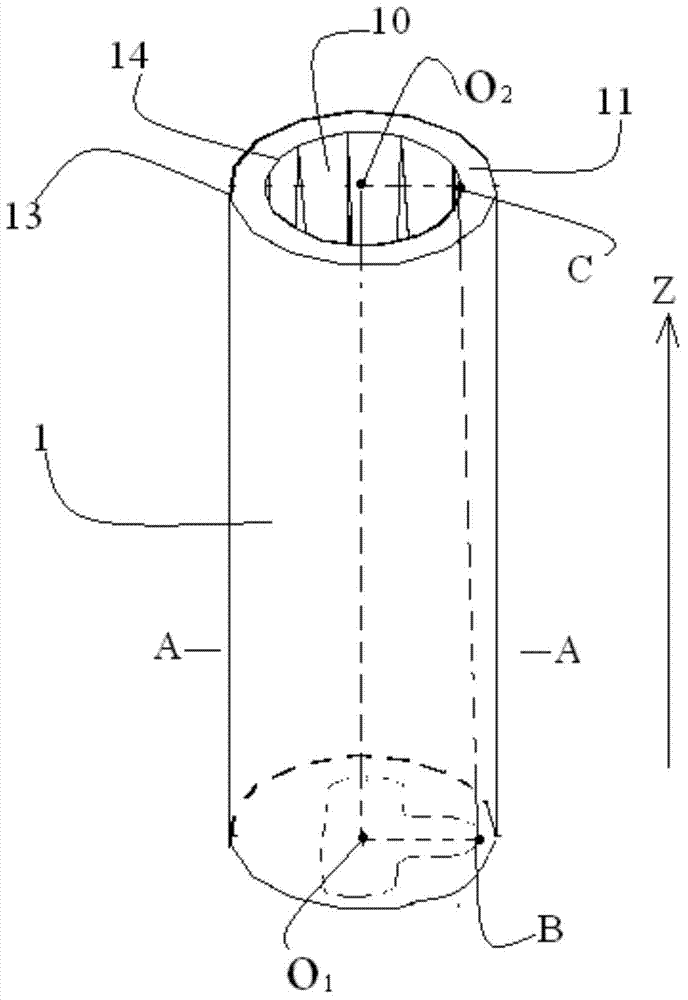

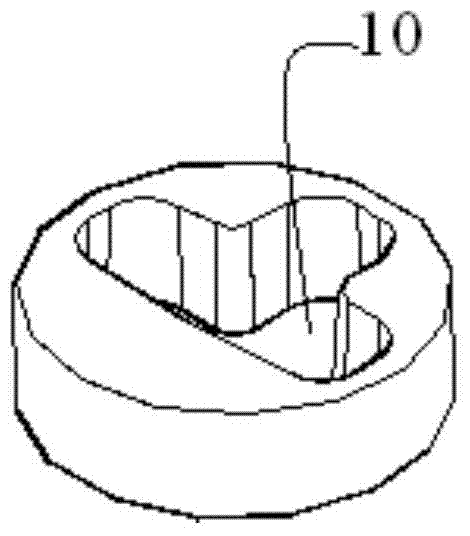

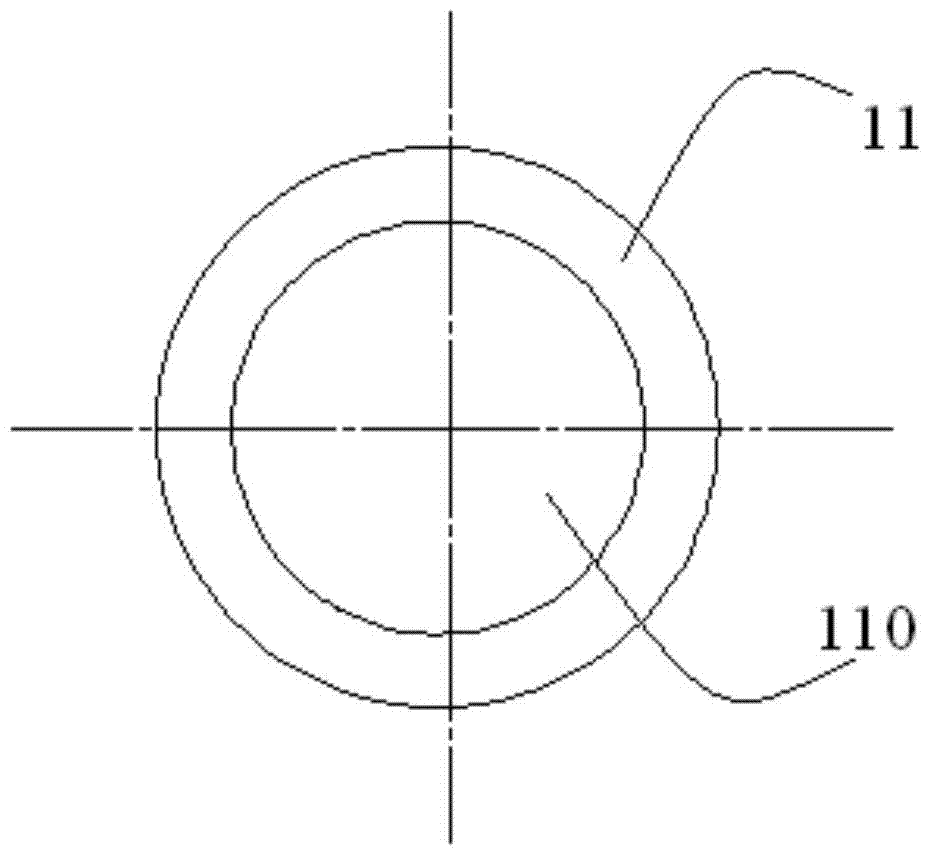

[0029] see Figure 1-4, the embodiment of the present invention provides a submerged nozzle for special-shaped billet casting, which includes: a side wall 1, the side wall 1 is in the shape of a ring, and a vertically transparent hole is formed in the middle of the side wall 1 along the axis direction Z. The through hole, that is, the upper and lower ends of the side wall 1 are open. The side wall 1 includes an upper end surface 11, a lower end surface 12, an outer surface 13 and an inner surface 14. The upper end surface 11 is formed with a first opening 110. In other words, the first opening is formed by the intersection of the through hole and the plane where the upper end surface 11 is located. The first opening It is circular; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com