Pneumatic rotational flow upper nozzle base brick for continuous casting tundish

A technology of continuous casting tundish and nozzle seat bricks, which is applied in the field of metallurgy, can solve the problems of weakened swirling effect, blockage of air holes, complicated manufacturing process, etc., and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

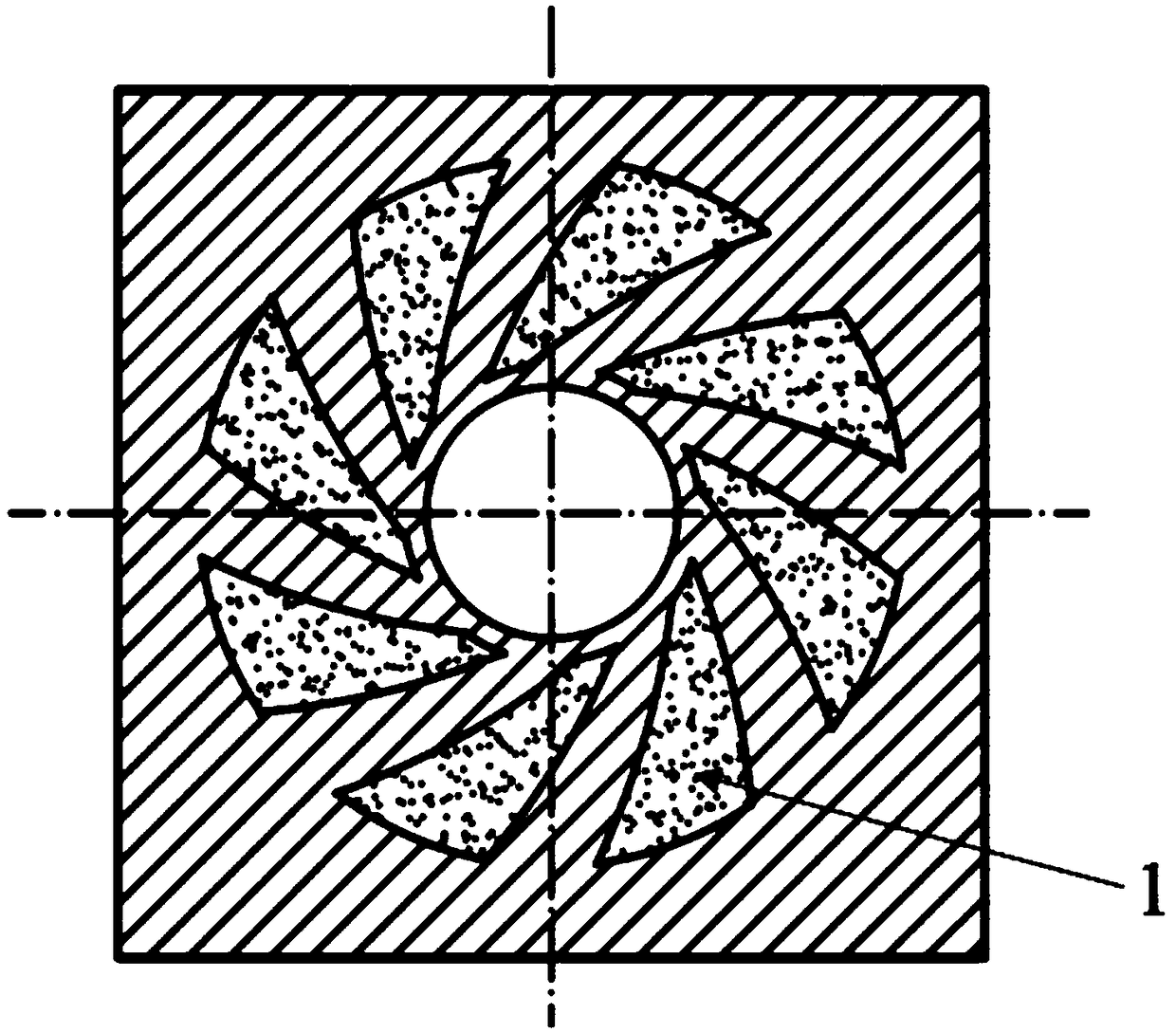

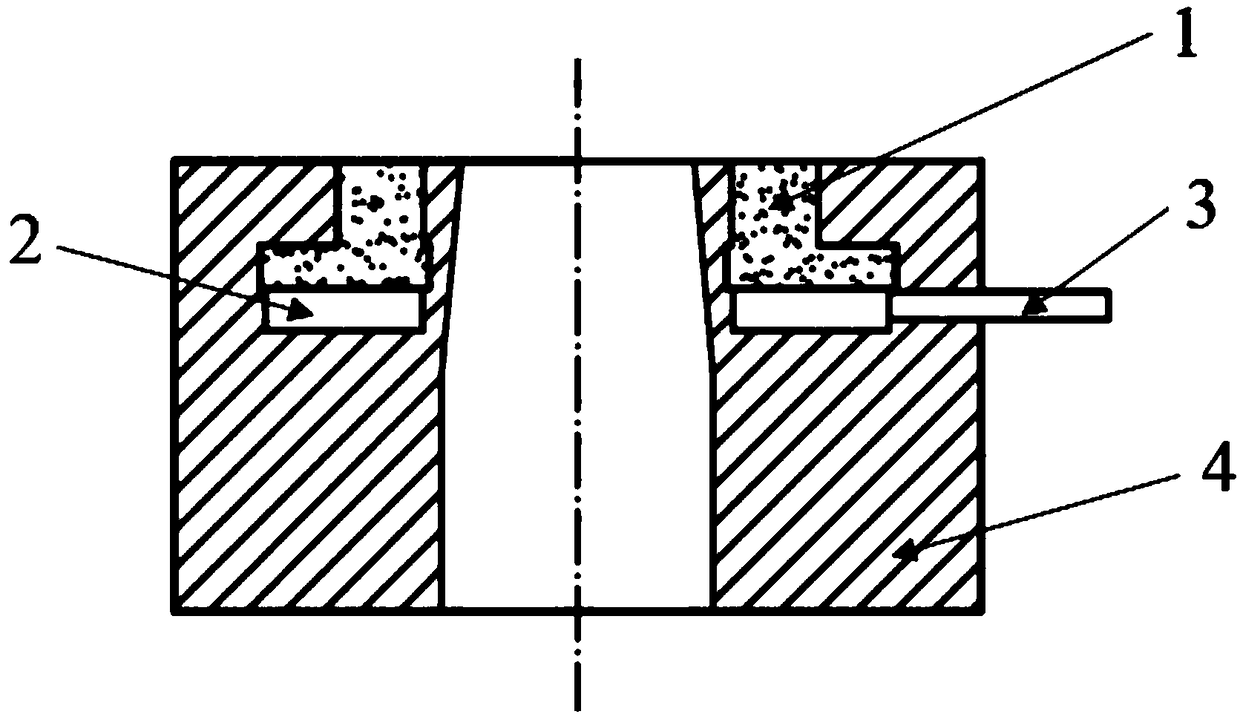

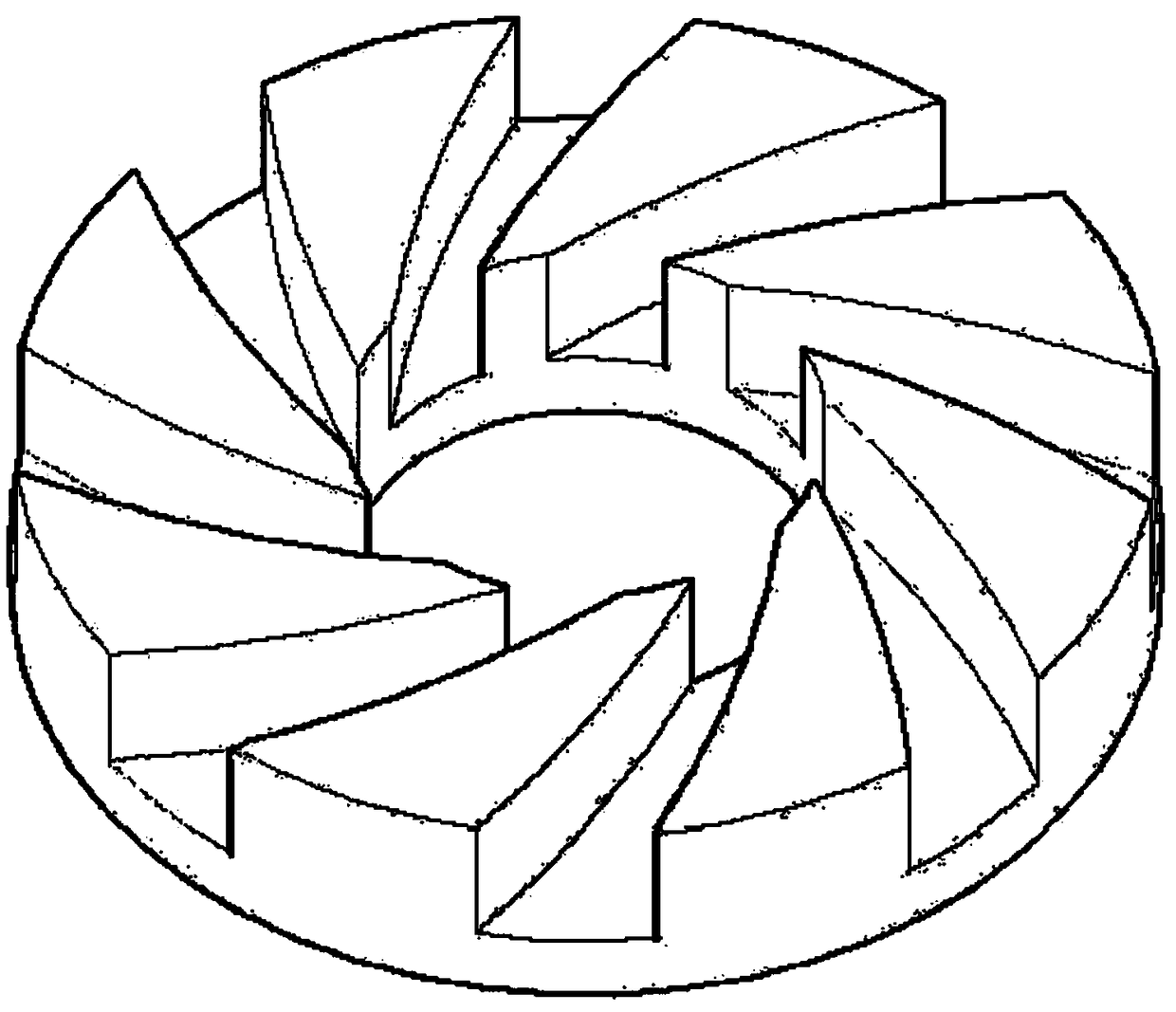

[0044] Such as Figure 1-Figure 3 As shown, Embodiment 1 of the present invention discloses a pneumatic swirl upper nozzle seat brick for continuous casting tundish, including the upper nozzle seat brick body 4, air-permeable brick 1, air chamber 2 and air intake pipe 3; The upper part is equipped with a breathable brick 1, and the breathable brick 1 is placed in the body 4 of the upper nozzle seat brick. The breathable brick 1 is a diffused breathable brick, including an integrally formed upper fan-shaped breathable part and a lower ring-shaped breathable part. , the lower circular part plays the role of uniform air pressure and gas connection, and the non-permeable gap between the fan-shaped permeable bricks forms a spiral liquid steel swirl channel; the annular air chamber 2 is located at the lower circular part of the permeable brick 1 and Between the upper nozzle block body 4, the air chamber 2 is located at the bottom of the breathable ring and communicates with the brea...

Embodiment 2

[0051] Such as Figure 4-Figure 6 As shown, Embodiment 2 of the present invention discloses a pneumatic swirl upper nozzle seat brick for continuous casting tundish, including an upper nozzle seat brick body 4, a breathable brick 1, an air chamber 2 and an air intake pipe 3; the upper nozzle seat The upper part of the brick is equipped with a breathable brick 1, and the breathable brick 1 is placed in the brick body 4 of the upper nozzle seat. The lower circular part plays the role of uniform air pressure and gas connection, and the non-permeable gap between the fan-shaped permeable bricks forms a spiral molten steel swirling channel; the annular air chamber 2 is located between the lower circular part of the permeable brick 1 and the upper water Between the mouth block body 4, the air chamber 2 is located at the bottom of the air-permeable ring and communicates with the air-permeable brick 1. The air chamber 2 is connected with an air inlet pipe 3. One end of the air inlet pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com