Pneumatic encapsulating head applied for enclosing aerosol valve

An aerosol and potting technology, which is applied in the field of aerosol pressure filling and sealing equipment, can solve the problems of low product quality, poor sealing effect, bending and deformation of the cylinder shaft, etc., and achieve the best effect, sealing diameter and Depth parameter controls the effect of stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

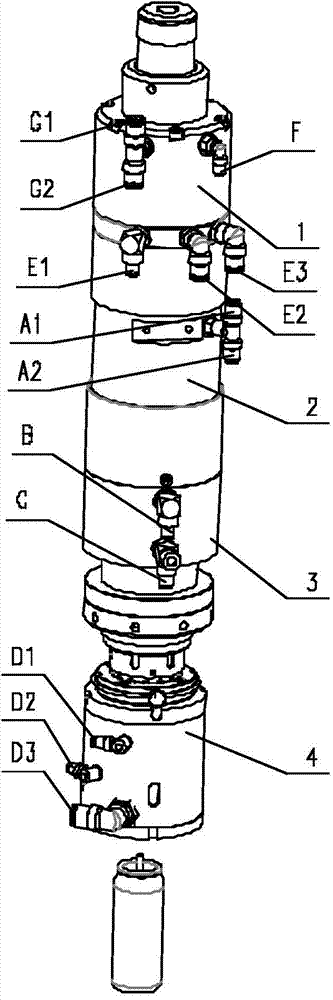

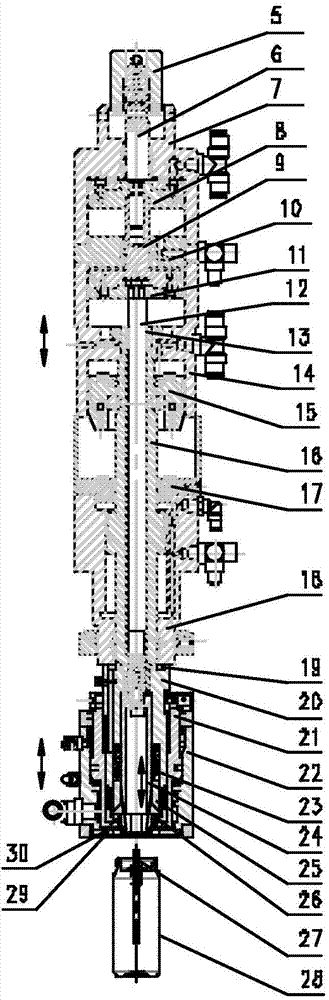

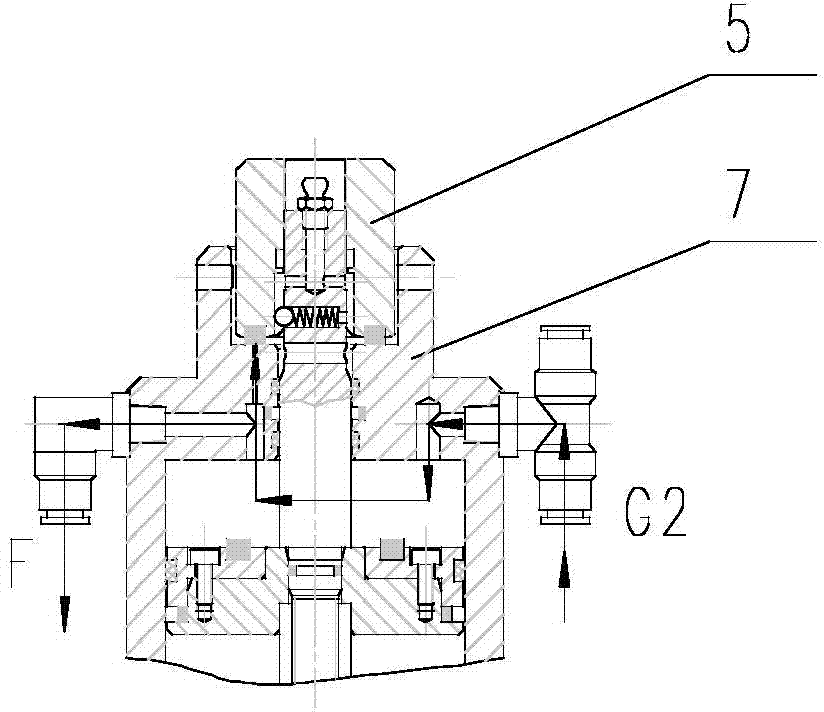

[0027] A pneumatic filling head for aerosol valve sealing, the present invention is characterized in that a sealing cylinder 1, a buffer cylinder 2, a positioning pressure cylinder 3, and a vacuuming cylinder 4 are respectively arranged in the filling head from top to bottom There are four cylinders in total; the push claw mechanism is set at the lower part of the vacuum pumping cylinder 4; the air pressure of the four cylinders in the filling head is controlled by the air control valve, so that the cylinders move step by step, and gradually complete air cushioning, downward positioning, slow pressurization, A cycle of vacuuming the original solution to defoam, seal and seal, and resetting the filling head realizes the sealing of the valve on the top of the aerosol tank and the inner wall of the tank;

[0028] The sealing cylinder 1, the buffer cylinder 2, the positioning pressure cylinder 3 and the vacuum cylinder 4 are respectively equipped with quick-change joints connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com