Ore conveying hopper based on the reinforcing plates

A technology of reinforcing plates and hoppers, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as limiting ore mining efficiency, high unloading costs, and high labor intensity, so as to achieve strong popularization and improved use Longevity and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and drawings.

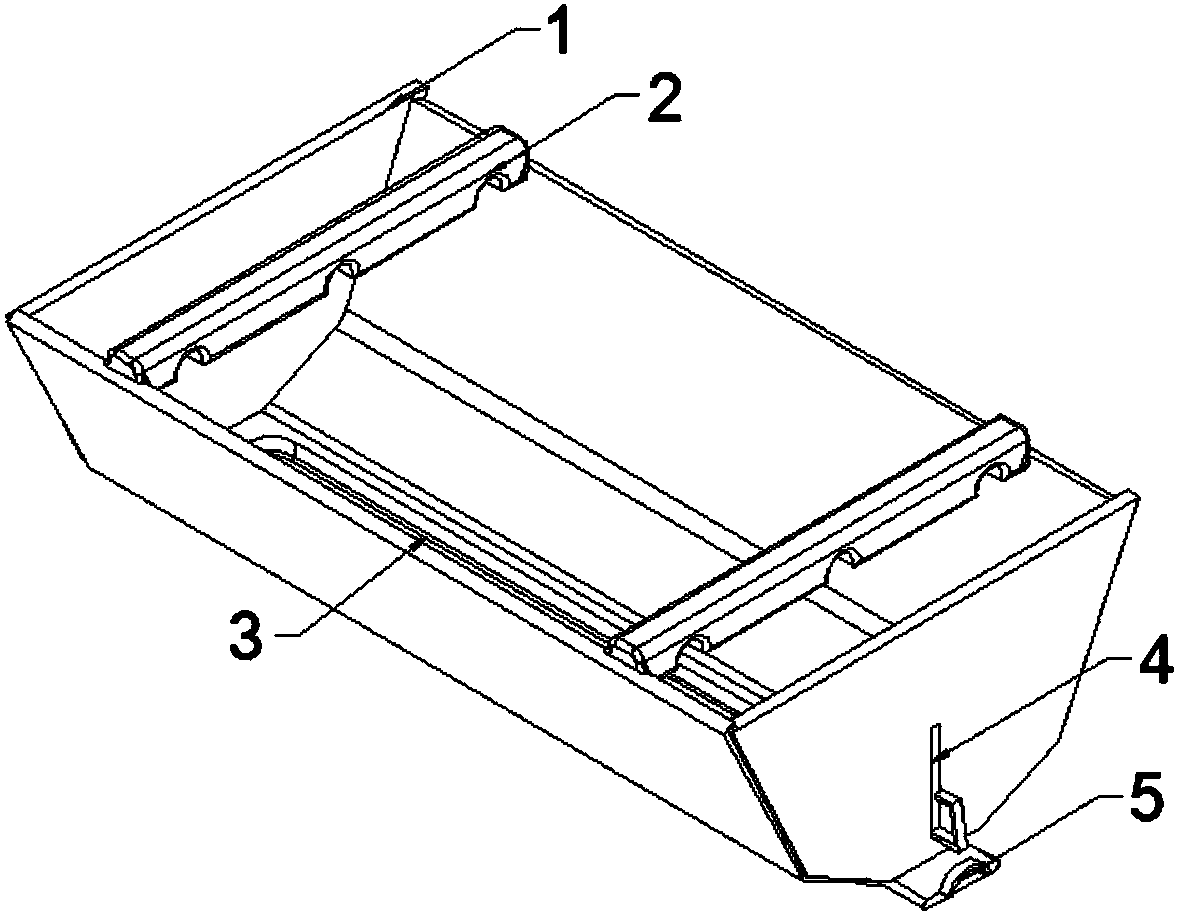

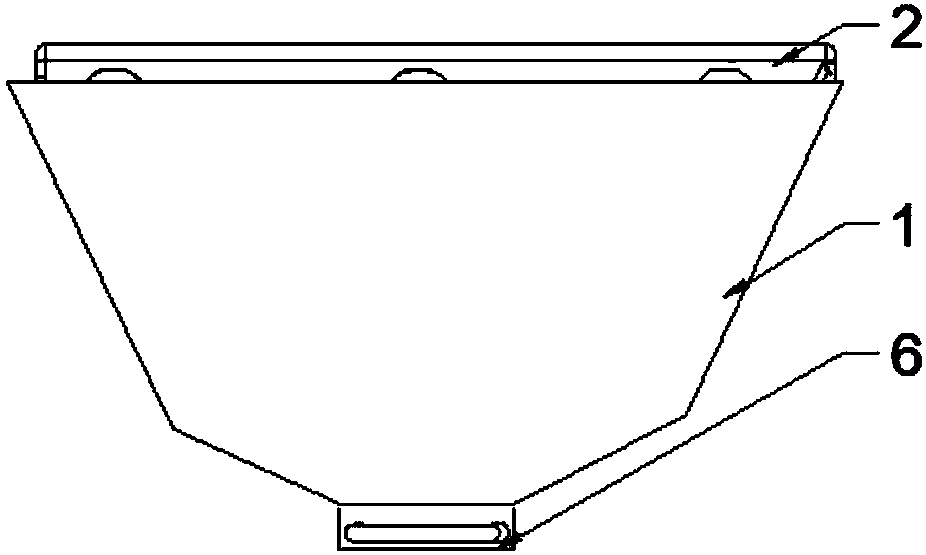

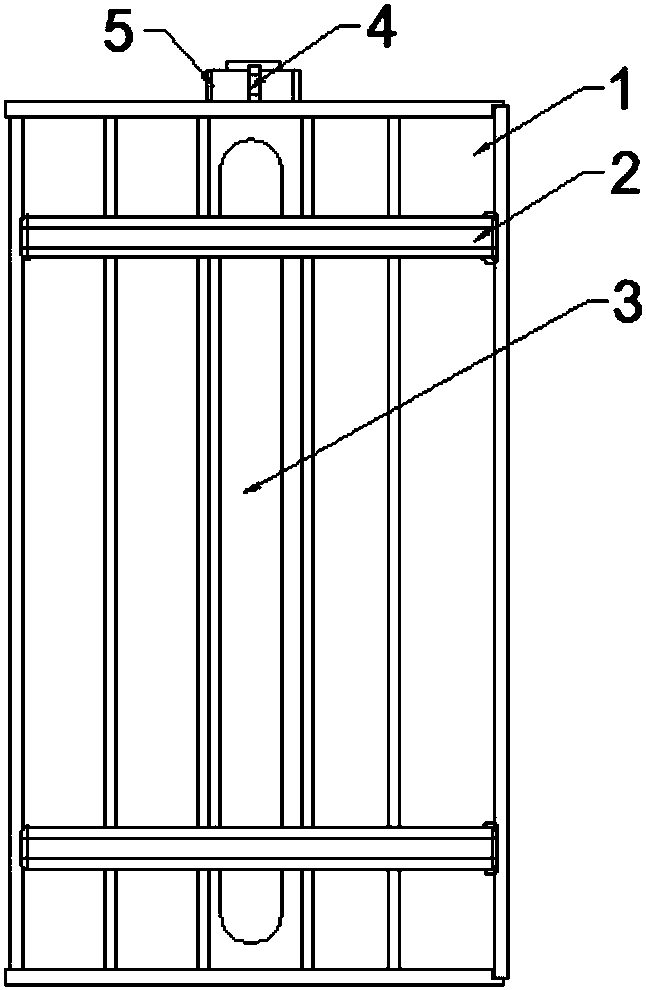

[0020] Such as Figure 1-4 As shown, a reinforced plate-based ore transportation hopper of the present invention includes a hopper main body including a hopper wall 1 and a connecting rod 2 fixedly connected to the upper end of the hopper wall 1. The connecting rod 2 is provided with a groove for installing the transportation rope, and the edge of the groove is provided with rounded corners. This enables the hopper to maintain good stability during transportation, and avoids large shaking that may cause ore to fall from the hopper.

[0021] By setting rounded corners on the edge of the groove, the friction between the groove and the rope is reduced, so as to achieve the purpose of promoting the smooth transportation of the hopper on the rope.

[0022] The hopper wall 1 includes a bottom plate and a side plate conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com