Novel connecting flange

A new type of flange connection technology, applied in the direction of flange connection, pipe/pipe joint/pipe fittings, through components, etc., can solve the problems of waste of resources, increase the cost of flange use, etc., to improve sealing, improve service life, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

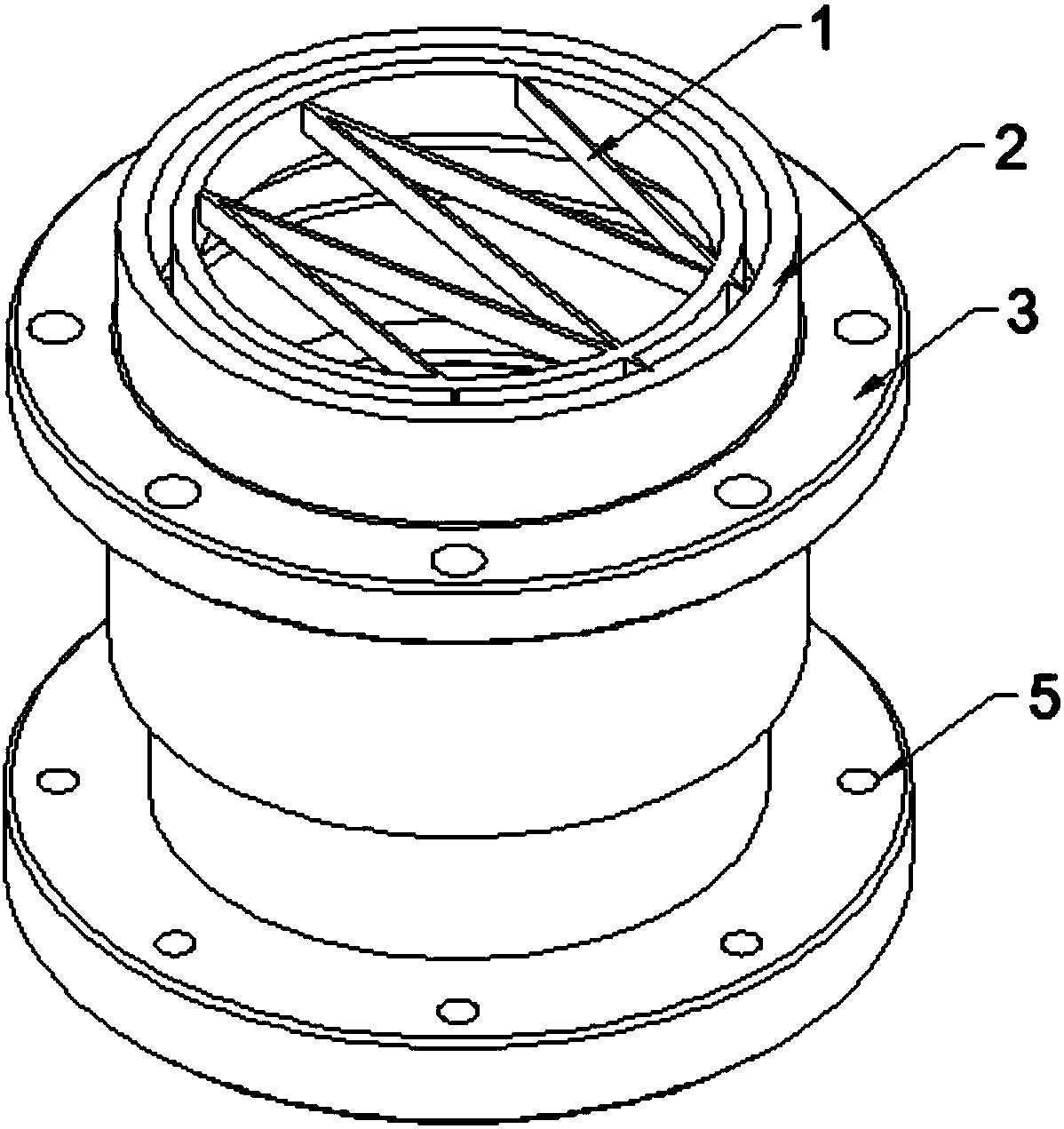

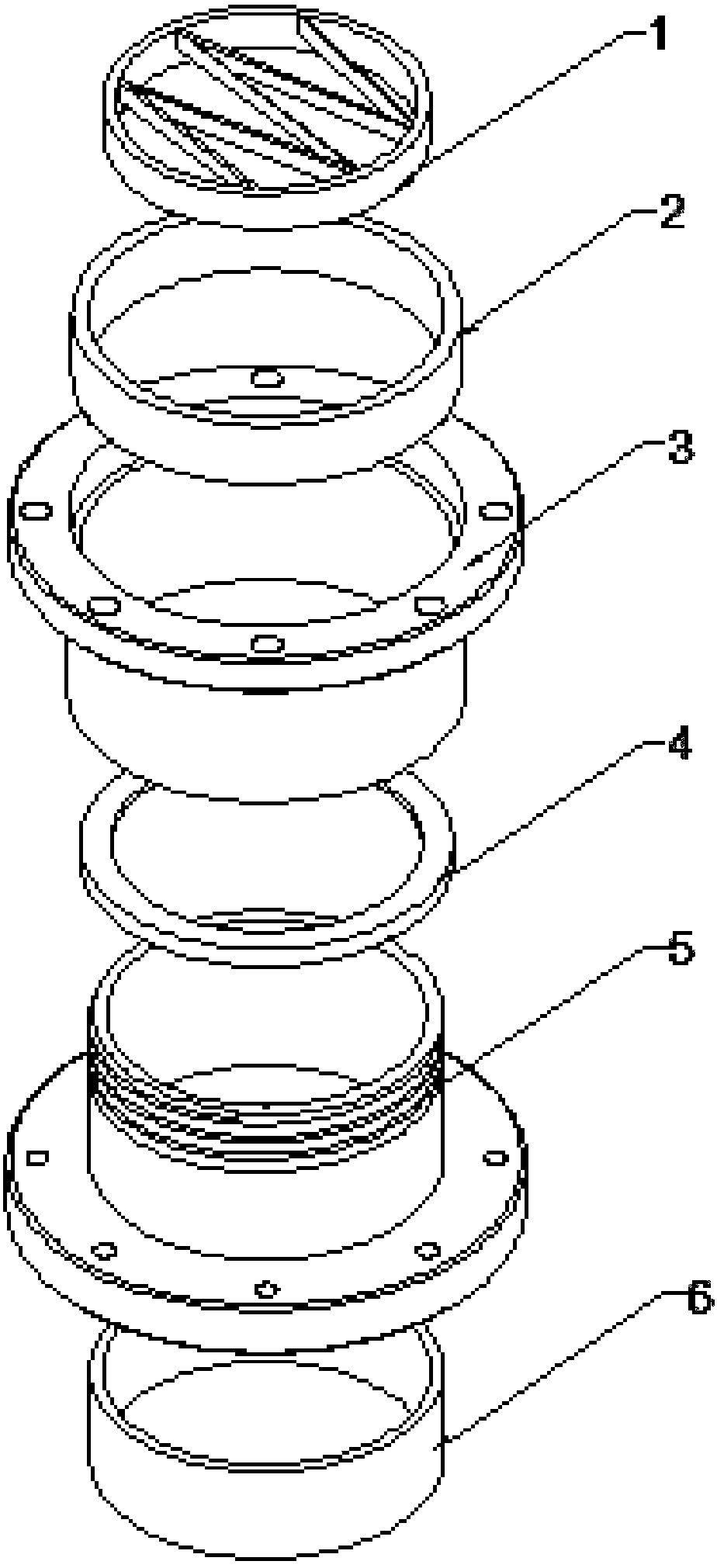

[0018] Such as Figure 1-2 As shown, a novel connection flange of the present invention includes a first connection end 3 and a second connection end 5, and the first connection end 3 and the second connection end 5 both include flanges and are compatible with the method. The blue plate is welded and fixed to the connecting pipe. The two connecting pipes are fixed by threaded connection. The two connection ends are designed to be threaded so that they can be disassembled, so that when one connection end of the flange is damaged and cannot be used, the other connection end can be disassembled. Come, and then assemble it with a new connecting end for use. This design makes the assembly and disassembly of the flange more flexible and convenient, and further endows the flange with the feature of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com