Piston type axial flow pressure regulator

A piston type, pressure regulator technology, applied in the valve's device for absorbing fluid energy, functional valve type, valve details, etc., can solve the erosion of the throttling part, easy to be damaged by erosion, increase the difficulty of spring manufacturing and production Cost and other issues, to achieve the effect of slowing down strong impact force, prolonging working life, and improving pressure-transformation smoothness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

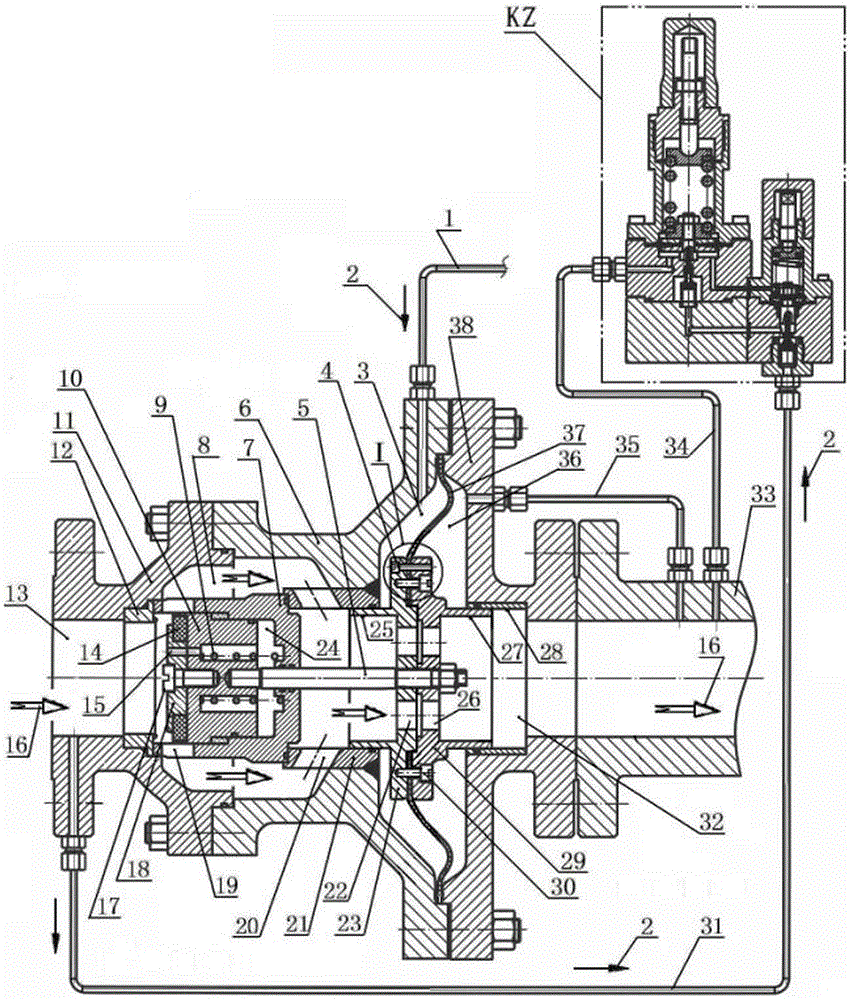

[0030] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0031] The piston type axial flow pressure regulator proposed by the present invention is mainly composed of an axial flow regulating valve, a pressure regulating controller KZ and a front pressure signal pipe 31 connected thereto, a rear pressure signal pipe 34, a main regulating signal pipe 1, a backflow Tube 35 is composed.

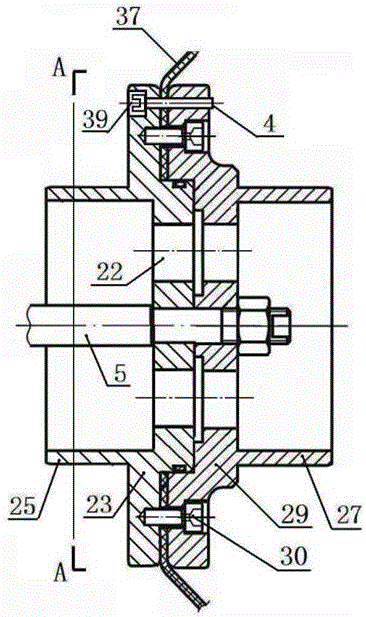

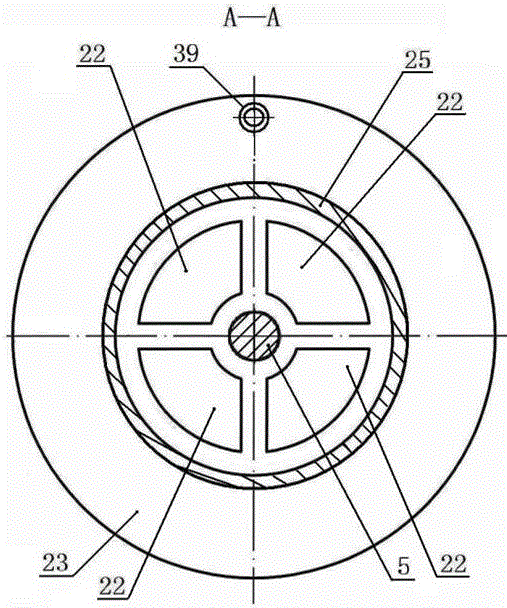

[0032] The axial flow regulating valve is mainly composed of a main valve body 6, a left valve body 11 installed at both ends of the main valve body 6, a right valve cover 38, a valve seat 12 and a valve sleeve 21 fitted in the main valve body 6, Between the valve seat 12 and the valve sleeve 21, the fixed embedded cylinder liner 7 is divided into an annular axial flow passage 8, and a set of throttle windows 19 communicated with the inlet end of the annular axial flow passage 8 is arranged on the wall of the cylinder liner 7, A set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com