Refined screening machine for metallurgical machining non-ferrous metals

A non-ferrous metal, mechanical processing technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of screening errors, local depressions, improper material discharge, etc., to ensure the effectiveness of steering, improve support stability, avoid The effect of compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

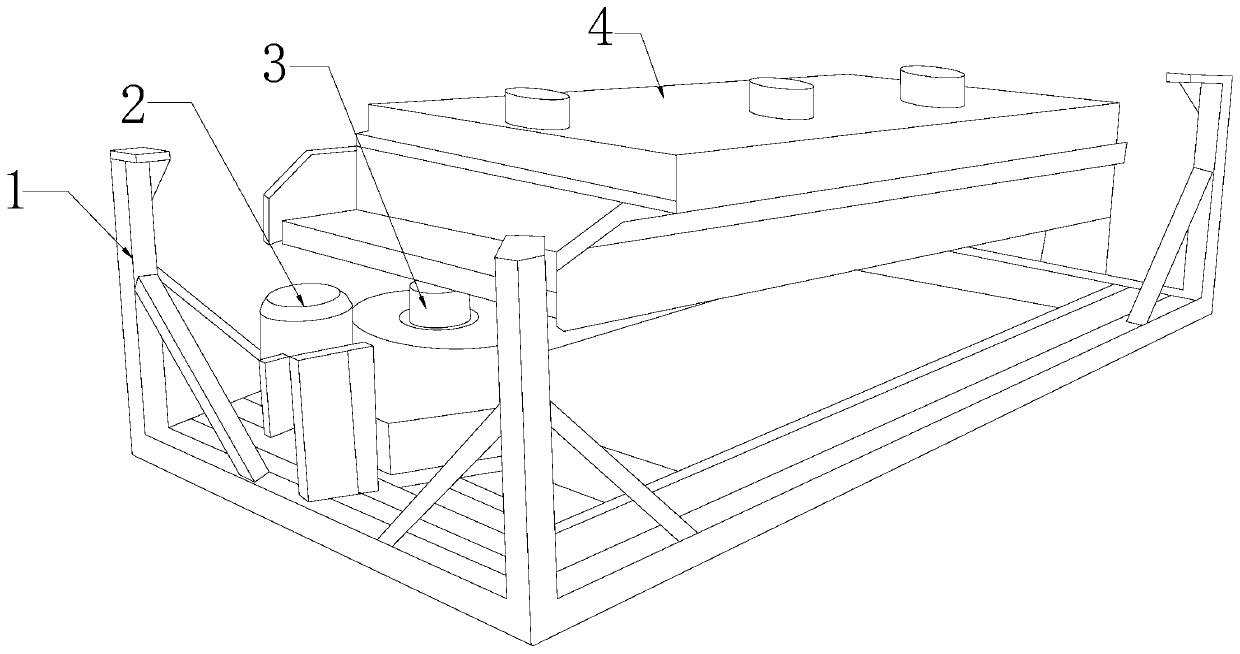

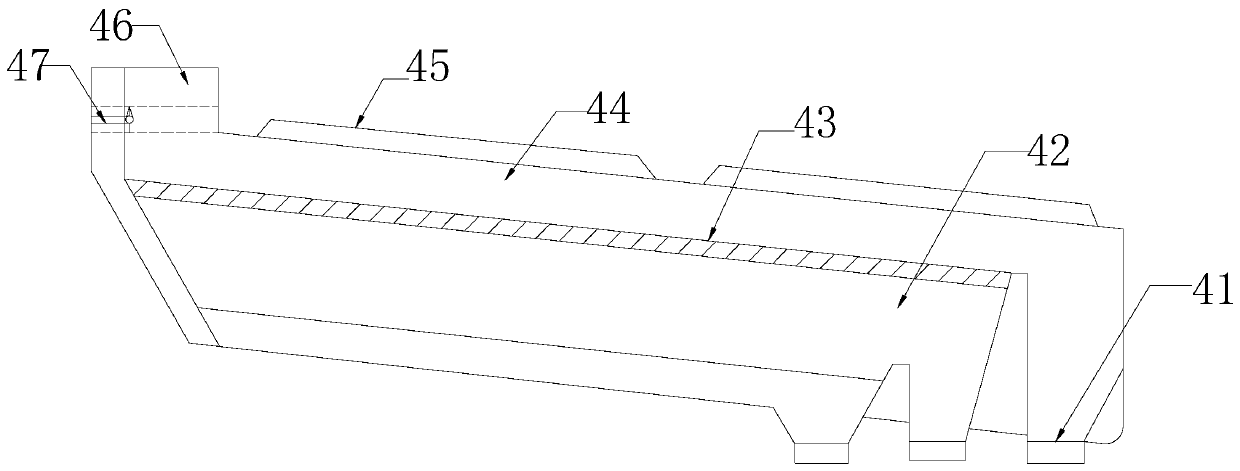

[0030] Such as Figure 1-Figure 4 As shown, the present invention provides a refining and screening machine for metallurgical machining of non-ferrous metals. Its structure includes a support frame 1, a driver 2, a transmission 3, and a screen box 4. The drive 2 and the transmission 3 are installed on the support frame 1. , the driver 2 and the driver 3 are driven and matched with the screen box 4, and the inside of the screen box 4 is provided with a discharge port 41, a first distribution tank 42, a screening plate 43, a second distribution tank 44, and a housing 45. Feed port 46, buffer mechanism 47, buffer mechanism 47 is provided inside the feed port 46, and screening plate 43 is installed horizontally between the first distribution tank 42 and the second distribution tank 44, The transmission end of the screening plate 43 is electrically connected to the driver 3, the first distribution tank 42 and the second distribution tank 44 are fixed with a discharge port 41, and t...

Embodiment 2

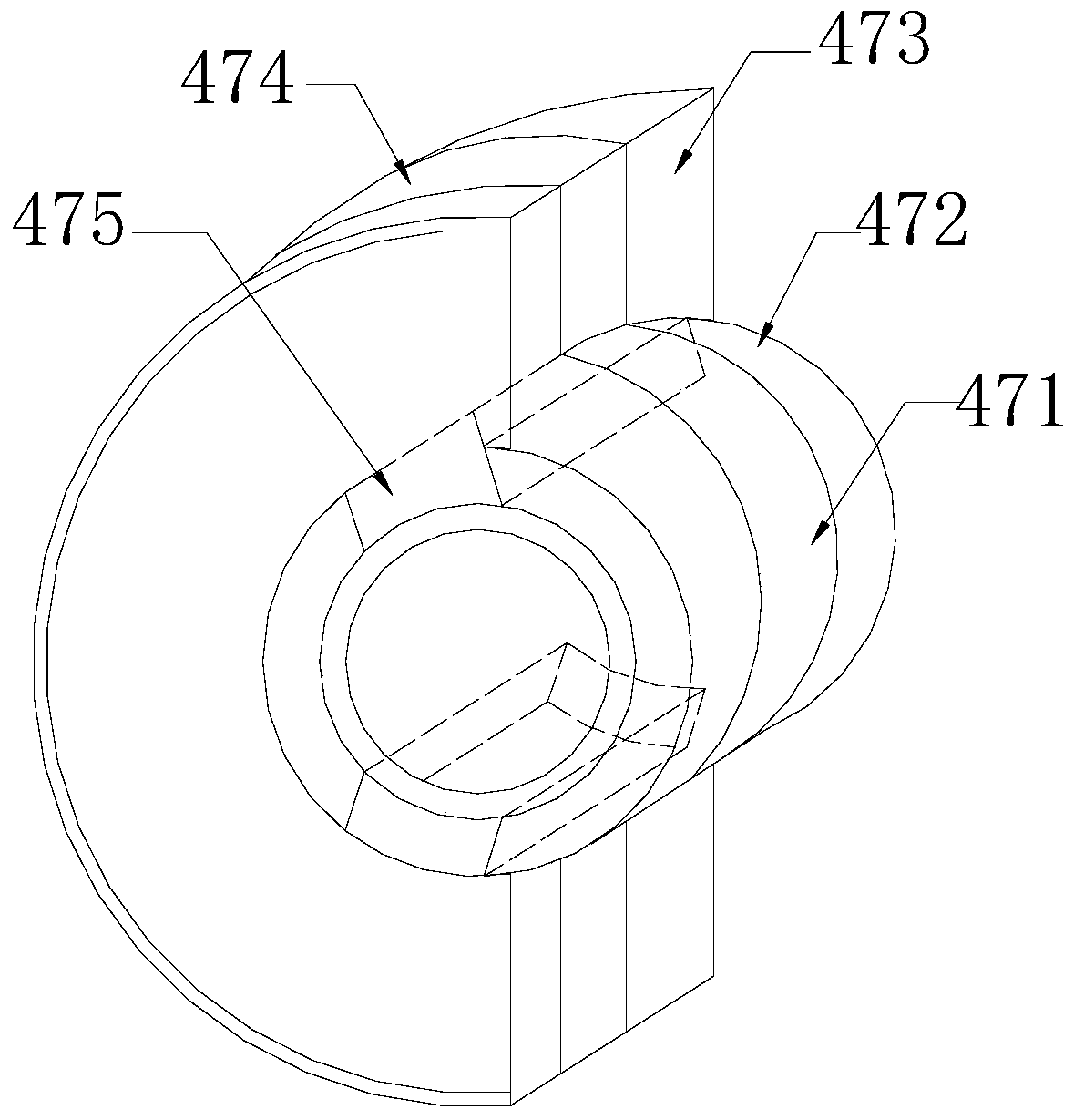

[0032] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, through the mutual cooperation of the following structural components, the receiving seat 473 includes a first bottom block 73a, an installation shaft 73b, a support mechanism 73c, a fixed rod 73d, and a second bottom block 73e, the The upper end of the first bottom block 73a is fixed with the second bottom block 73e, the support mechanism 73c is vertically fixed on the second bottom block 73e through the fixing rod 73d, the installation shaft 73b is fixed on the surface of the support shaft 472, and is distributed on On both sides of the turntable 471, the supporting mechanism 73c is composed of a bracket 3c1, a pressing bar 3c2, a connecting shaft 3c3, and a joint piece 3c4. The bracket 3c1 and the pressing bar 3c2 are movably connected by guide wheels, and the pressing bar 3c2 is connected relative to the joint. One end of the bracket 3c1 is welded with a connecting shaft 3c3, the connecting shaft 3c3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com