Preparation method of spray granulation Fe-Al2O3 spraying composite powder

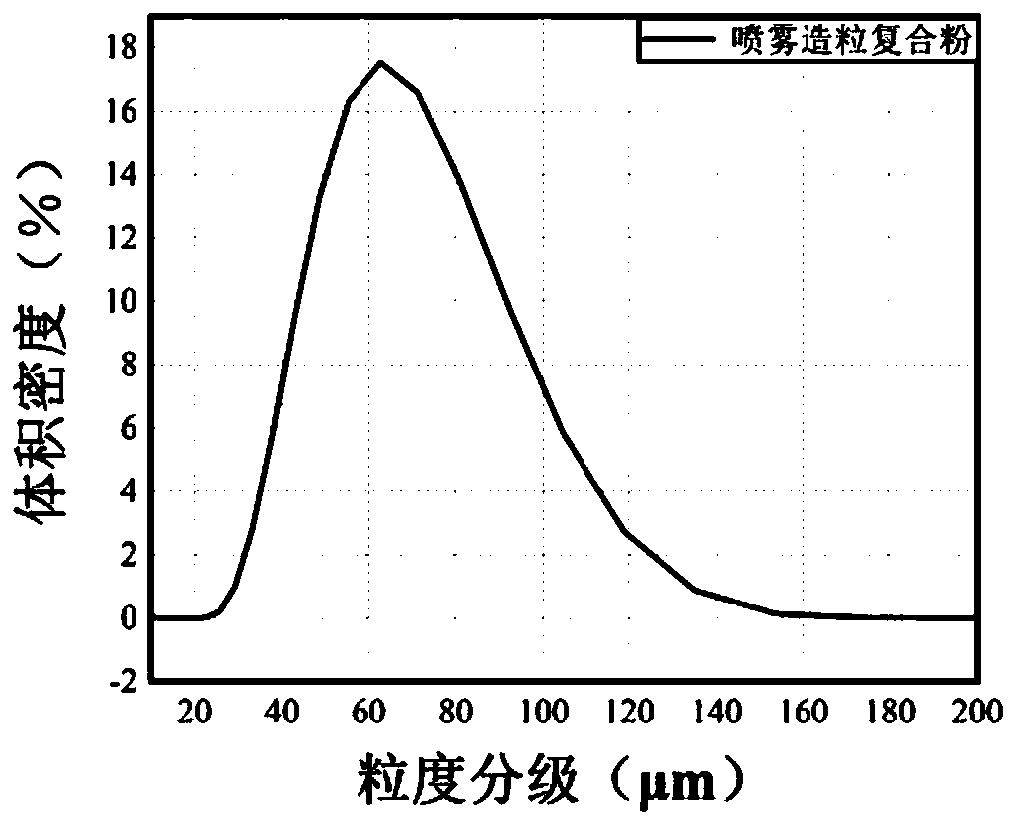

A fe-al2o3, spray granulation technology, applied in the direction of coating, molten spraying, metal material coating technology, etc., can solve the problems of high cost, complicated preparation process, not good enough oxidation resistance, etc., to achieve compactness Good, uniform particle size distribution, excellent chemical stability and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1, slurry preparation:

[0025] Take 300g of ultrafine Fe powder and 1200g of ultrafine Al 2 o 3 Put the powder into a 10L roller milling tank, add 45g of binder PEI and 15g of defoamer, and add zirconia balls with diameters of 5mm and 10mm and a total weight of 3120g, and finally add 1560g of deionized water as a solvent , followed by ball milling for stirring and dispersing, the stirring time is 6 hours, and then the spray granulation slurry (viscosity 0.133Pa.s) is obtained.

[0026] The SEM morphology of the original powder used in this embodiment is as follows figure 1 As shown, it can be seen that the shape of the original powder is irregular, the particle size is small, and the distribution is uneven, so it cannot be used as a spray powder.

[0027] Step 2, spray granulation:

[0028] Use centrifugal spray granulation machine to carry out spray granulation to the slurry obtained above. Before granulation, heat the machine to 245°C, then control the inlet...

Embodiment 2

[0033] Step 1, slurry preparation:

[0034] Get 950g of ultrafine Fe powder and 2800g of ultrafine Al 2 o 3 Put the powder into a 10L roller mill jar, add 112.5g of binder PEI and 37.5g of defoamer, add zirconia balls with diameters of 5mm and 10mm, and a total weight of 7800g, and finally add 3900g of deionized water As a solvent, it was then dispersed by ball milling for 8 hours to obtain a spray granulation slurry (viscosity of 0.133 Pa.s).

[0035] The SEM morphology of the original powder used in this embodiment is as follows figure 1 As shown, it can be seen that the shape of the original powder is irregular, the particle size is small, and the distribution is uneven, so it cannot be used as a spray powder.

[0036] Step 2, spray granulation:

[0037] Use a centrifugal spray granulation machine to spray and granulate the slurry obtained above. Before granulation, the machine is heated to 240°C, and then the air inlet temperature is controlled at 260°C during the gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com