Solar photovoltaic assembly wiring box convenient to fix and reliable to weld

A solar photovoltaic and junction box technology, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of welding points falling off, circuit interruption, welding tape and metal sheet virtual welding, etc., to achieve firm welding, reduce probability, avoid The effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

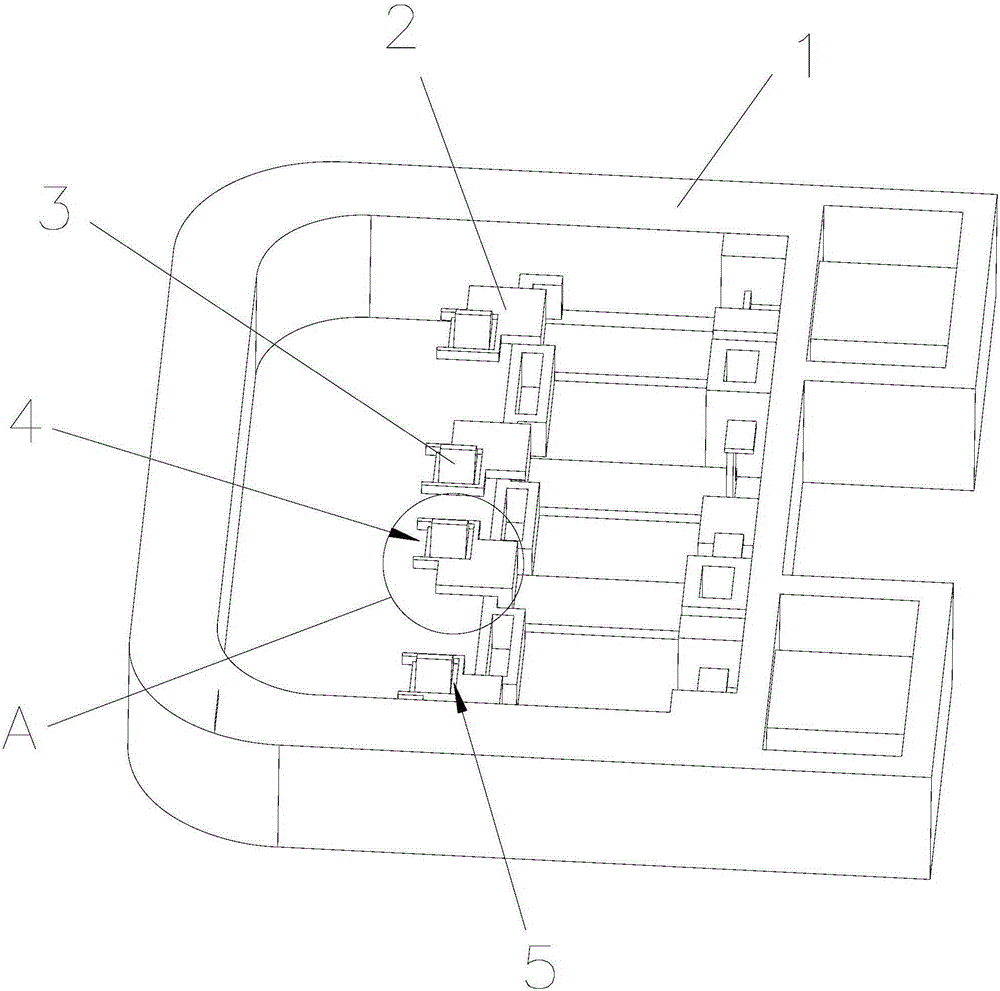

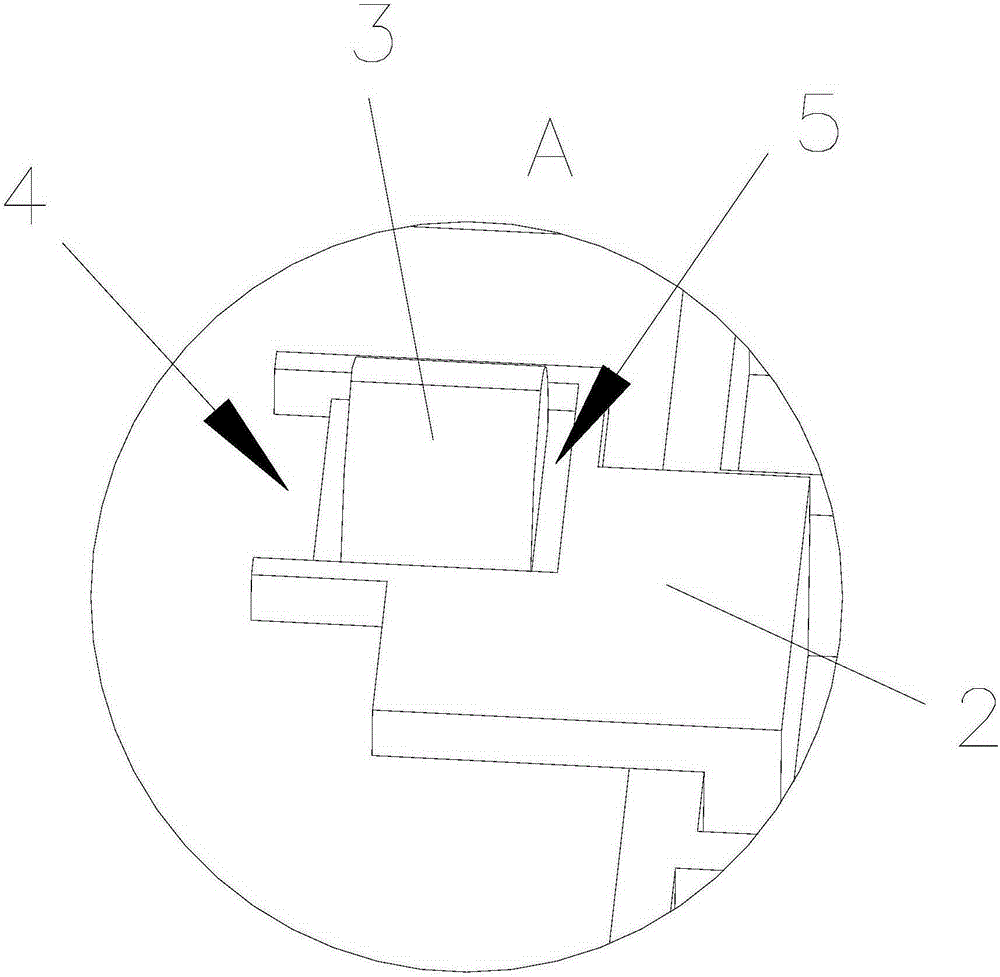

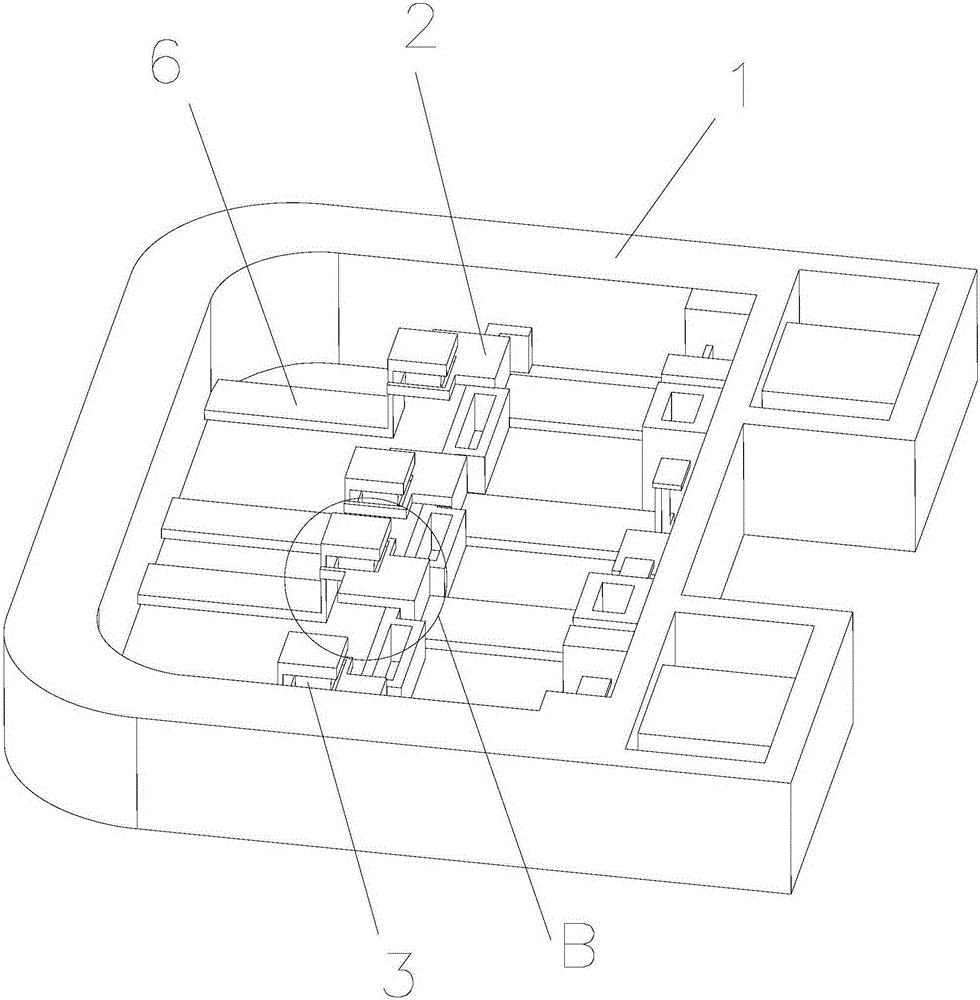

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] like Figure 1-4 The solar photovoltaic module junction box shown is convenient for fixing and reliable welding, including a junction box body 1, a metal sheet lead-out line 2 is provided inside the junction box body 1, and a groove 5 and an opening 4 are provided at the front end of the metal sheet lead-out line 2 , the opening 4 is located at the front end of the groove 5 .

[0018] During the welding process, the solder in the solder joint 3 tends to flow from both sides and the opposite side to the lead-out wire 2 of the metal sheet. In order to prevent false welding, the lead-out wire 2 of the metal sheet is provided with a groove 5 whose depth is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com