Patents

Literature

43results about How to "Avoid Welding Phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

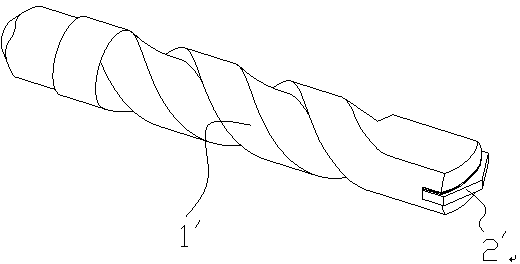

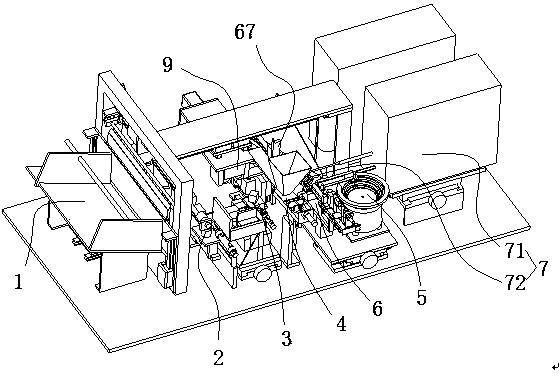

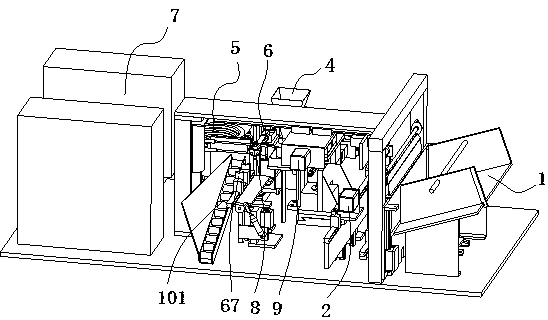

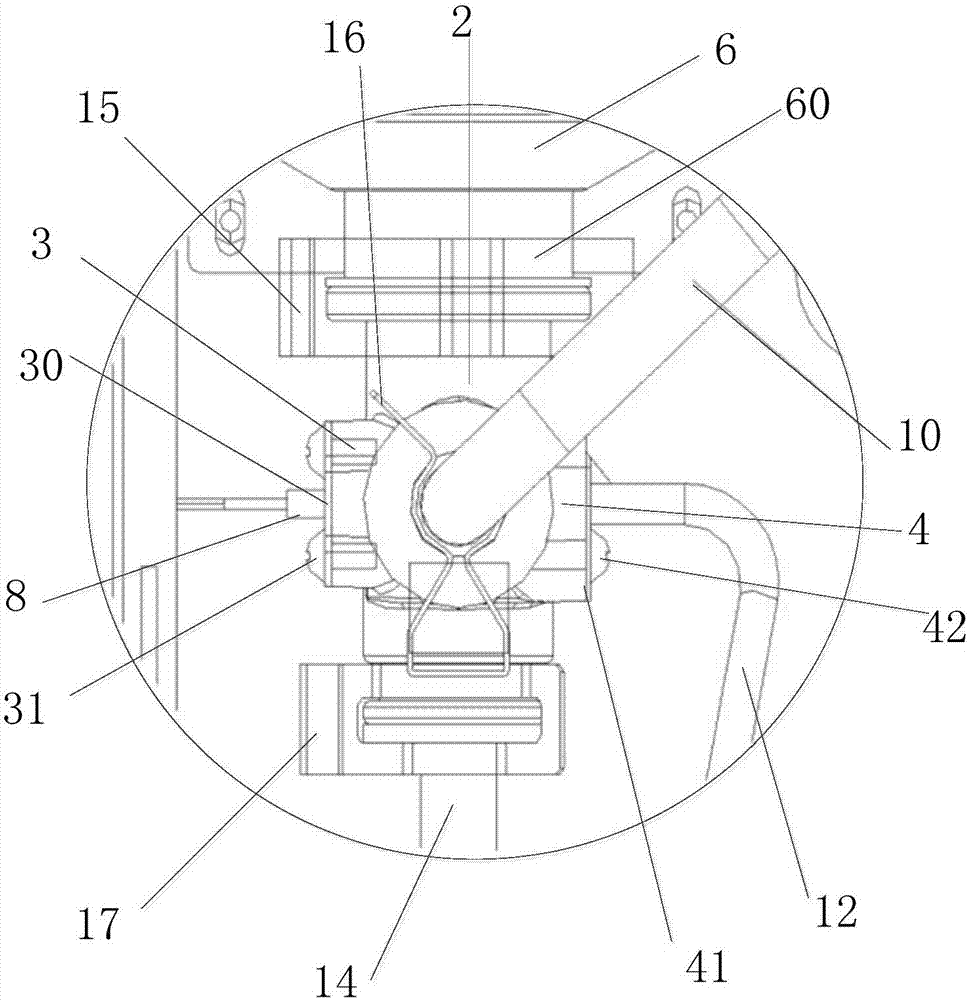

Automatic drill bit welding machine

ActiveCN104139236AImprove processing efficiencyReduce labor costsHigh frequency current welding apparatusAlloyCopper

The invention discloses an automatic drill bit welding machine. The automatic drill bit welding machine mainly comprises a drill bit body single feeding mechanism, a horizontal drill bit body notch aligning device, an automatic copper bar feeding device, a welding flux adding mechanism, an alloy sheet feeding mechanism, an accurate alloy sheet and drill bit body aligning mechanism, a high-frequency heating device and a post-welding alloy sheet calibrating device, all of which are in linkage with one another. The post-welding alloy sheet calibrating device comprises a calibration clamping port capable of being opened and closed, the calibration clamping port is composed of a left clamping plate and a right clamping plate, and the tail of the left clamping plate and the tail of the right clamping plate are respectively and movably installed on a linear guide rail, and are respectively and fixedly connected with a retractable power source body and a telescopic rod. The inner side of the head of the left clamping plate and the inner side of the head of the right clamping plate are provided with positioning sheets and calibration screws, and the difference value of the internal stretching length of the positioning sheets relative to the internal stretching length of the calibration screws is one second of the difference value of the total width of alloy sheets and the head of a drill bit body. The drill bit body and the alloy sheets can be automatically welded in the whole process, and the automatic drill bit welding machine has the advantages of being high in machining efficiency, good in welding quality and low in human cost.

Owner:乐清市长城工具有限公司

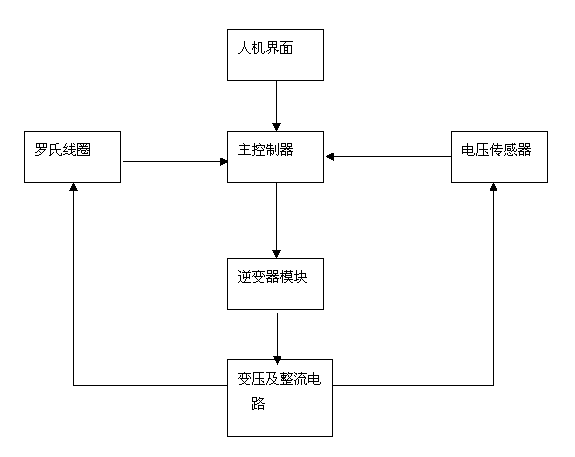

Welding method for intermediate frequency inverted resistance welding machine

ActiveCN103737166AImplement intelligent controlReduce volumeWelding electric supplyElectrical resistance and conductancePower flow

The invention discloses a welding method for an intermediate frequency inverted resistance welding machine. The intermediate frequency inverted resistance welding machine comprises a main controller, a human-computer interface, an inverter module, a voltage transforming and rectifying circuit, an electric current collecting device and a voltage sensor. According to the intermediate frequency inverted resistance welding machine, the working frequency of the system is 1800 HZ, the sampling frequency and the control accuracy are improved unprecedentedly, meanwhile the welding transformer size is reduced, welding parameters are adjusted according to actual conditions of contact resistors to be performed point welding, the electric current and the time are intelligently controlled, and cold joints and the like are effectively avoided.

Owner:JIANGSU CEMT ENERGY EQUIP

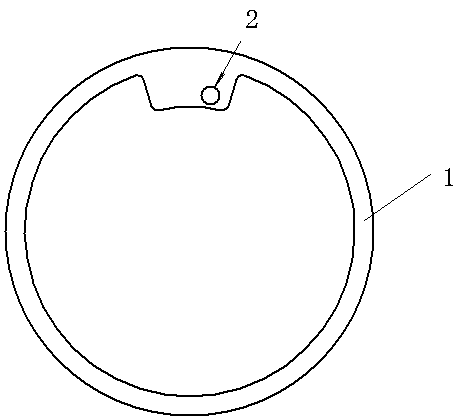

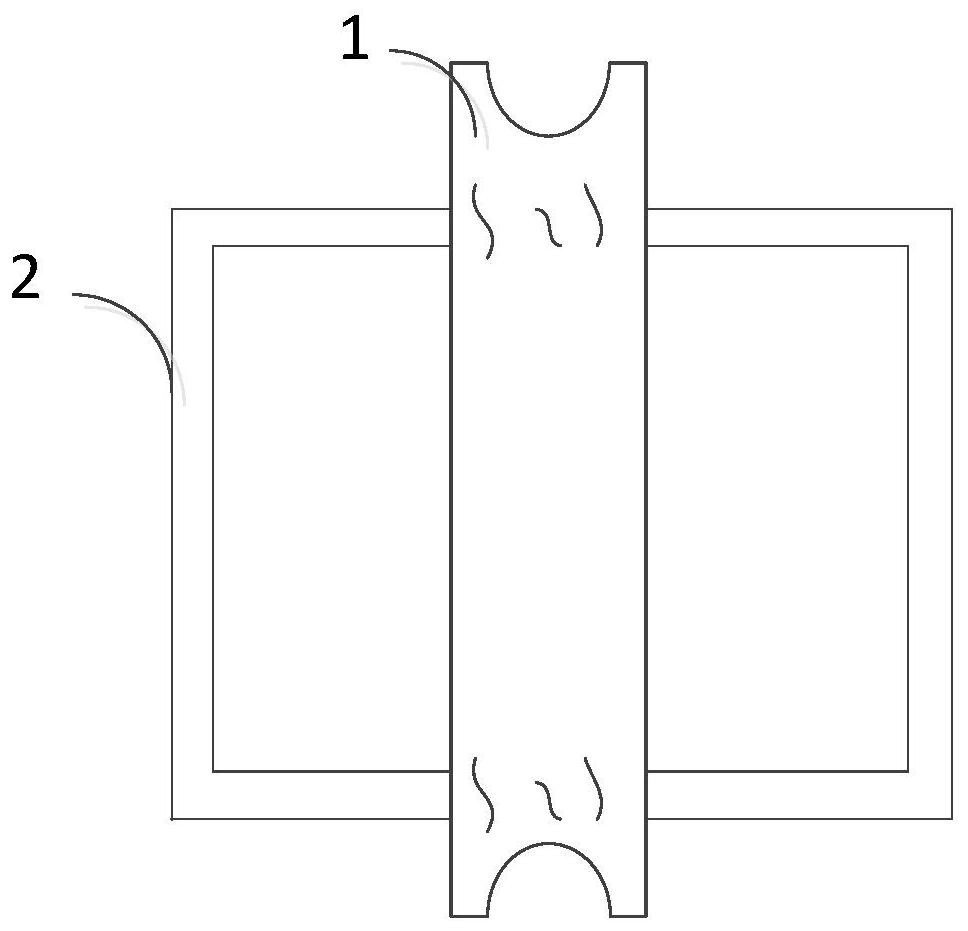

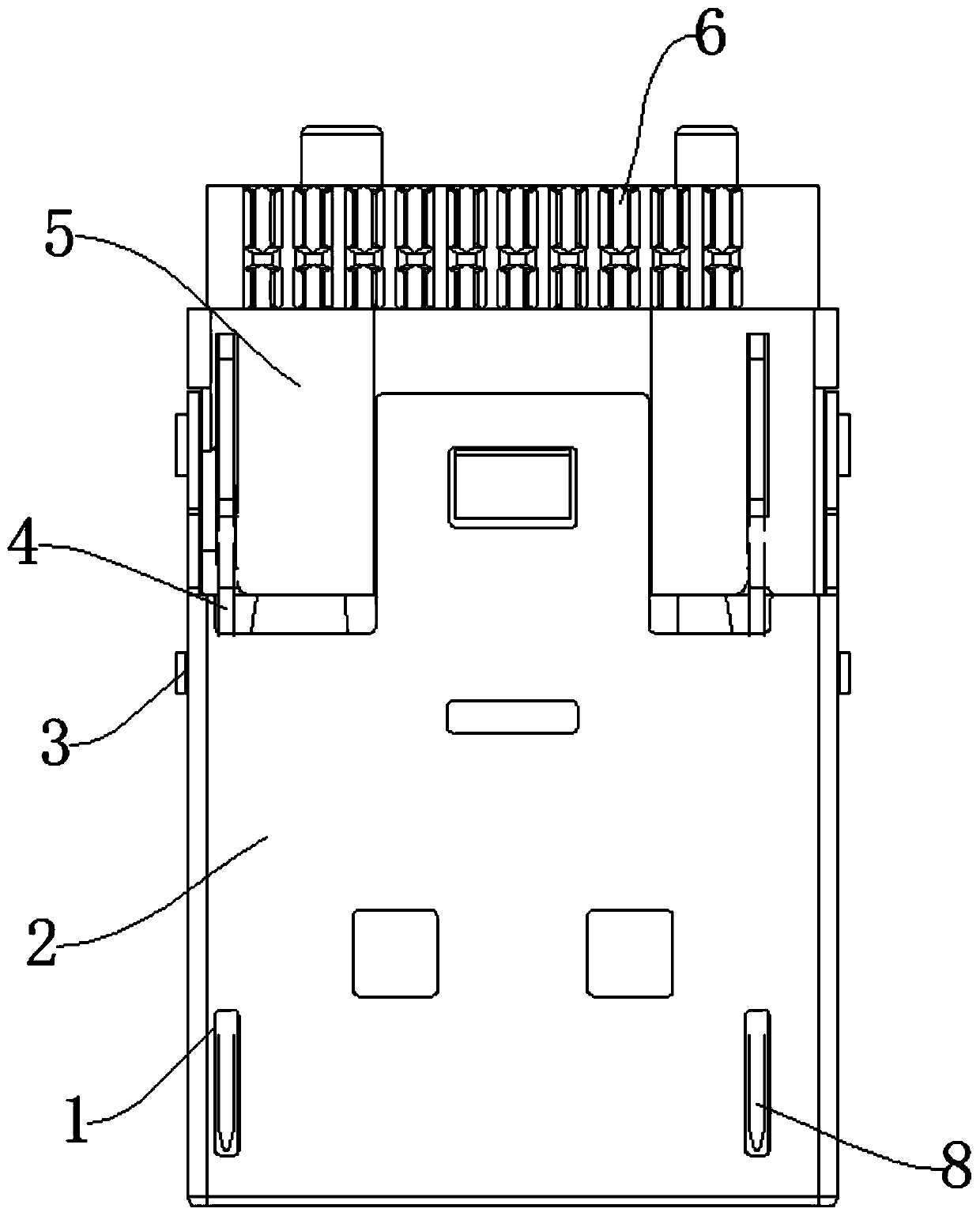

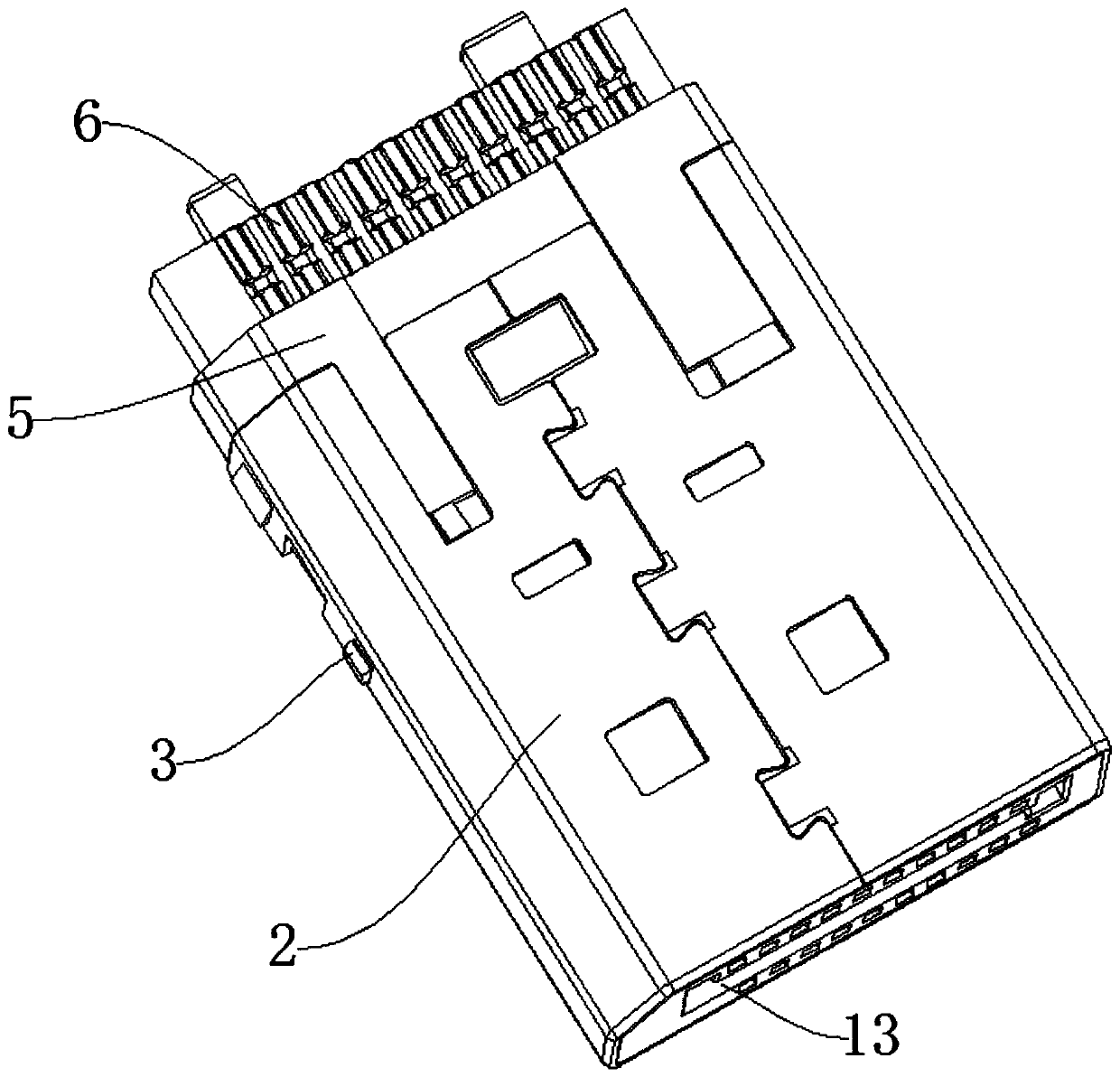

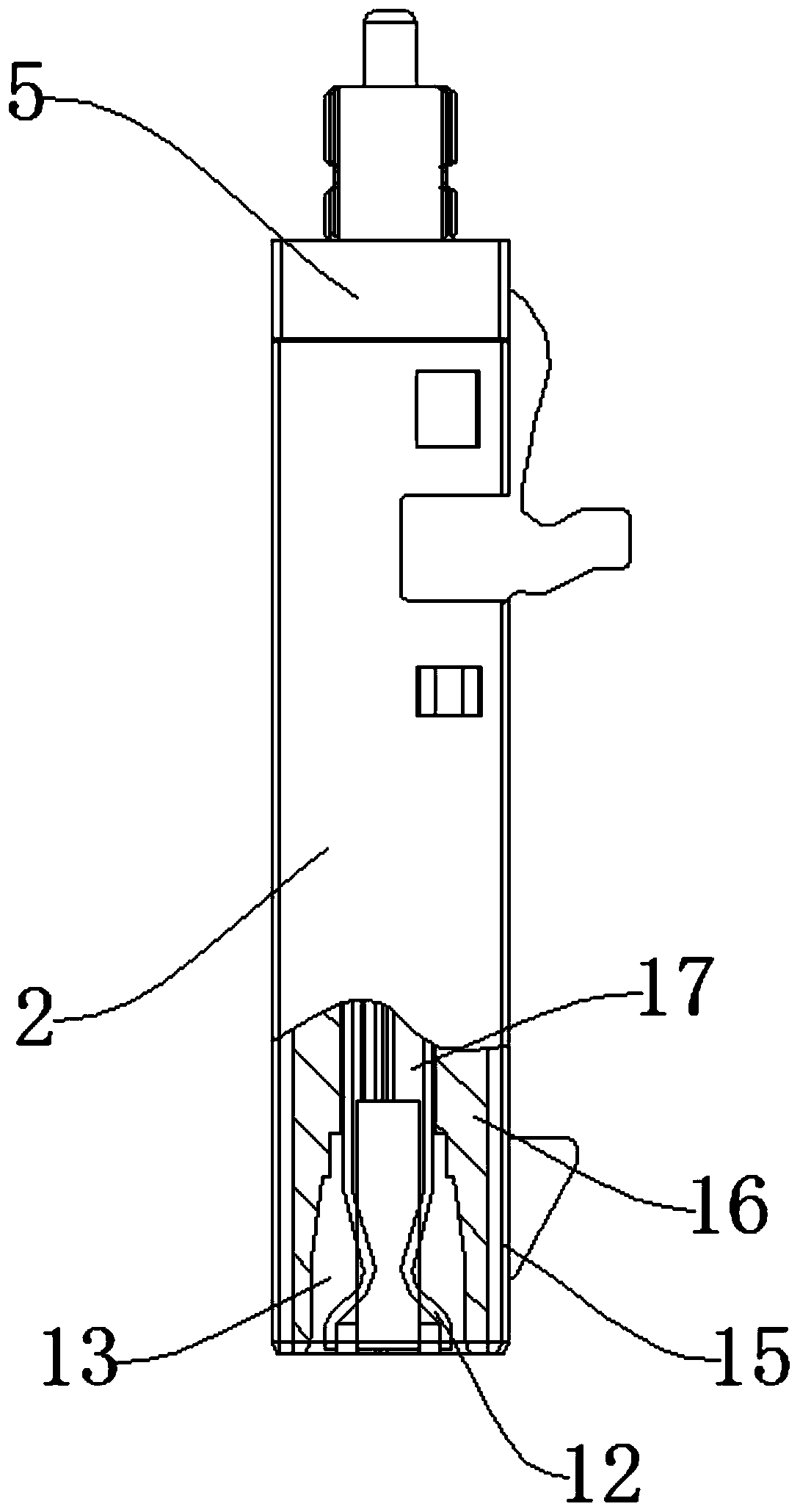

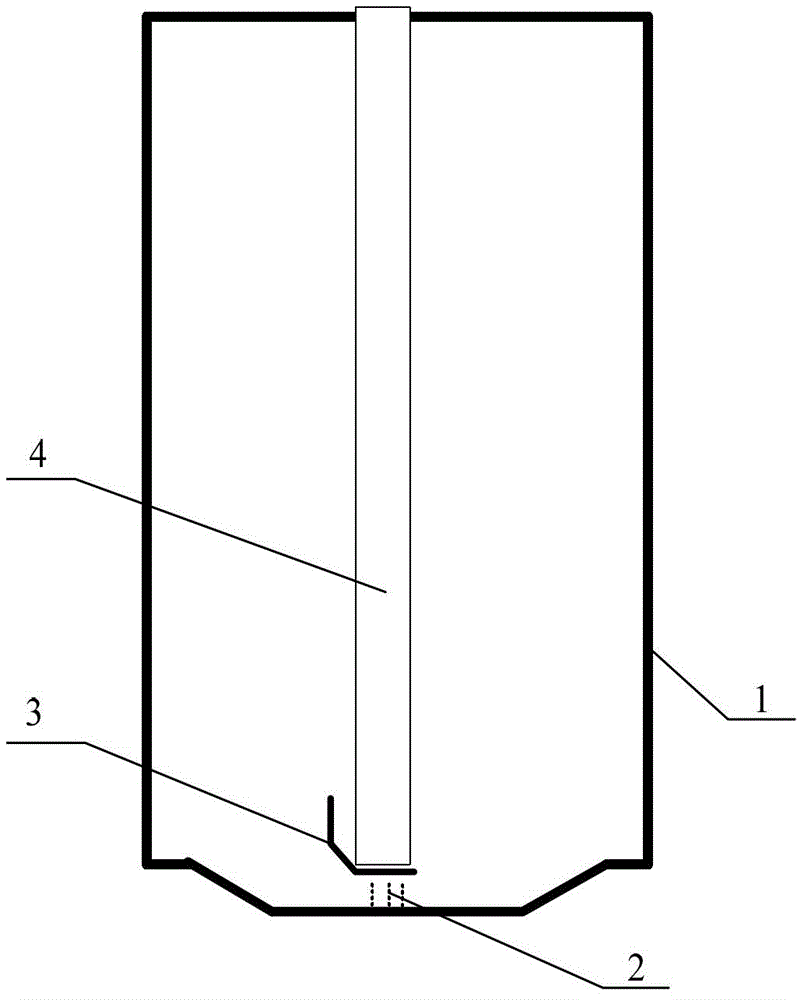

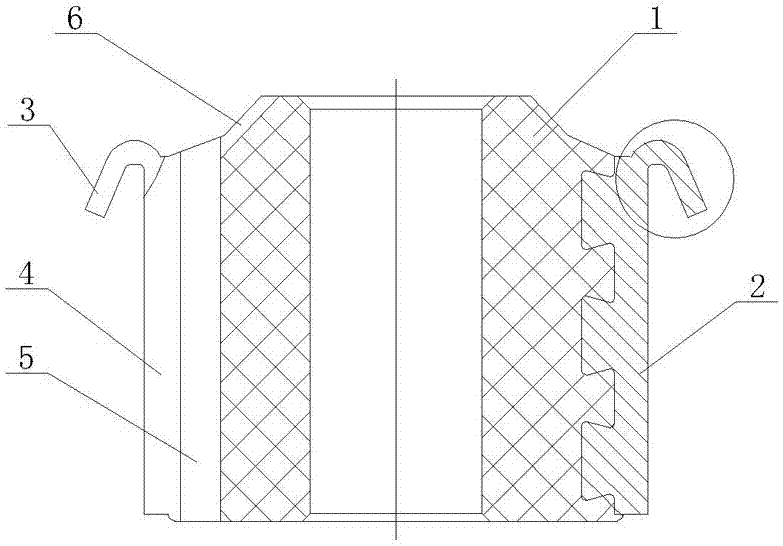

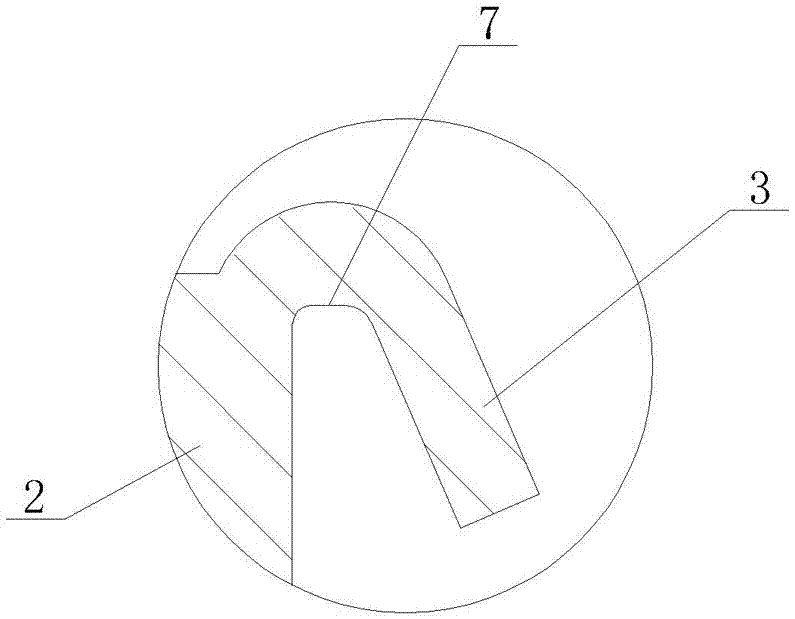

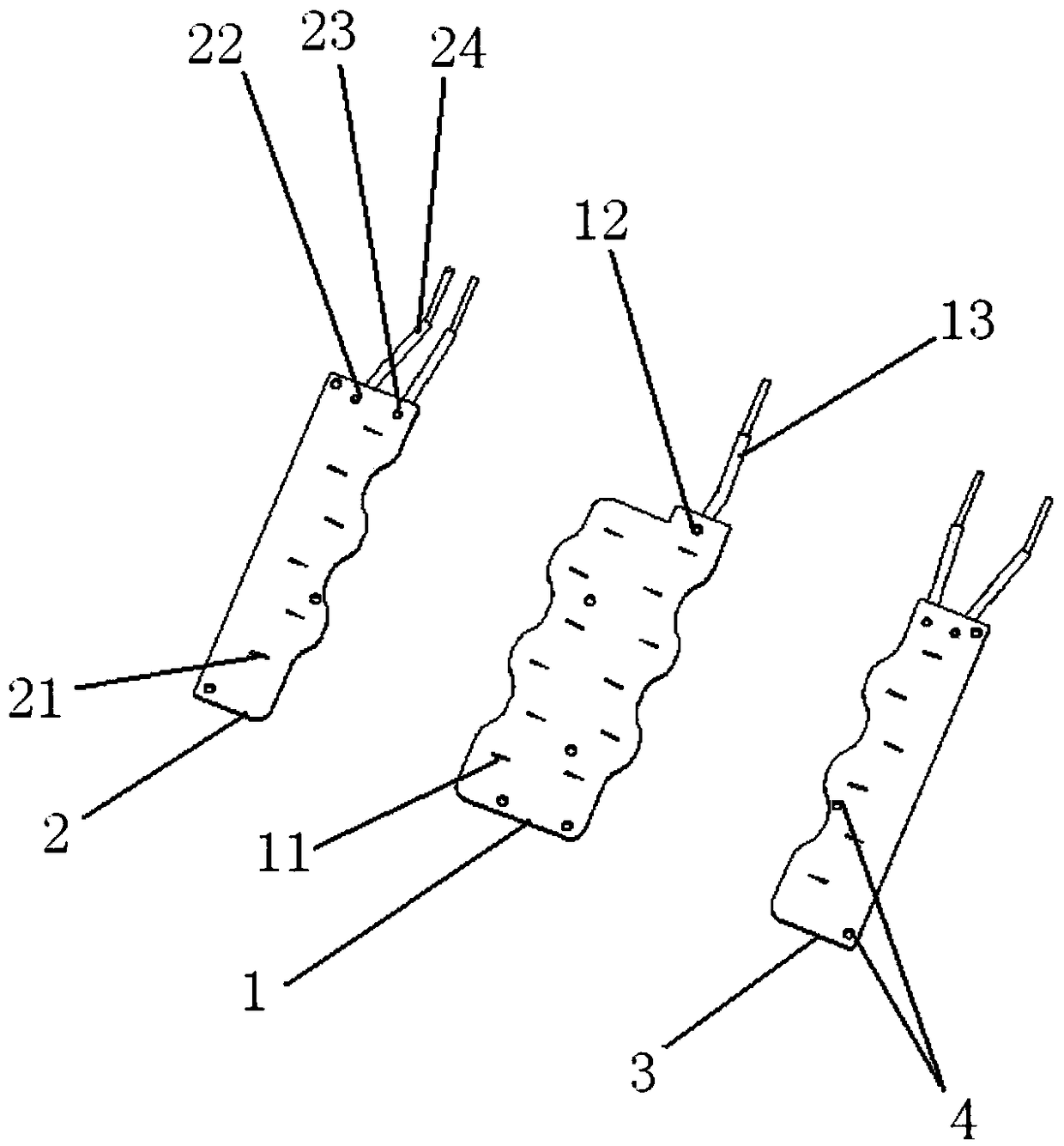

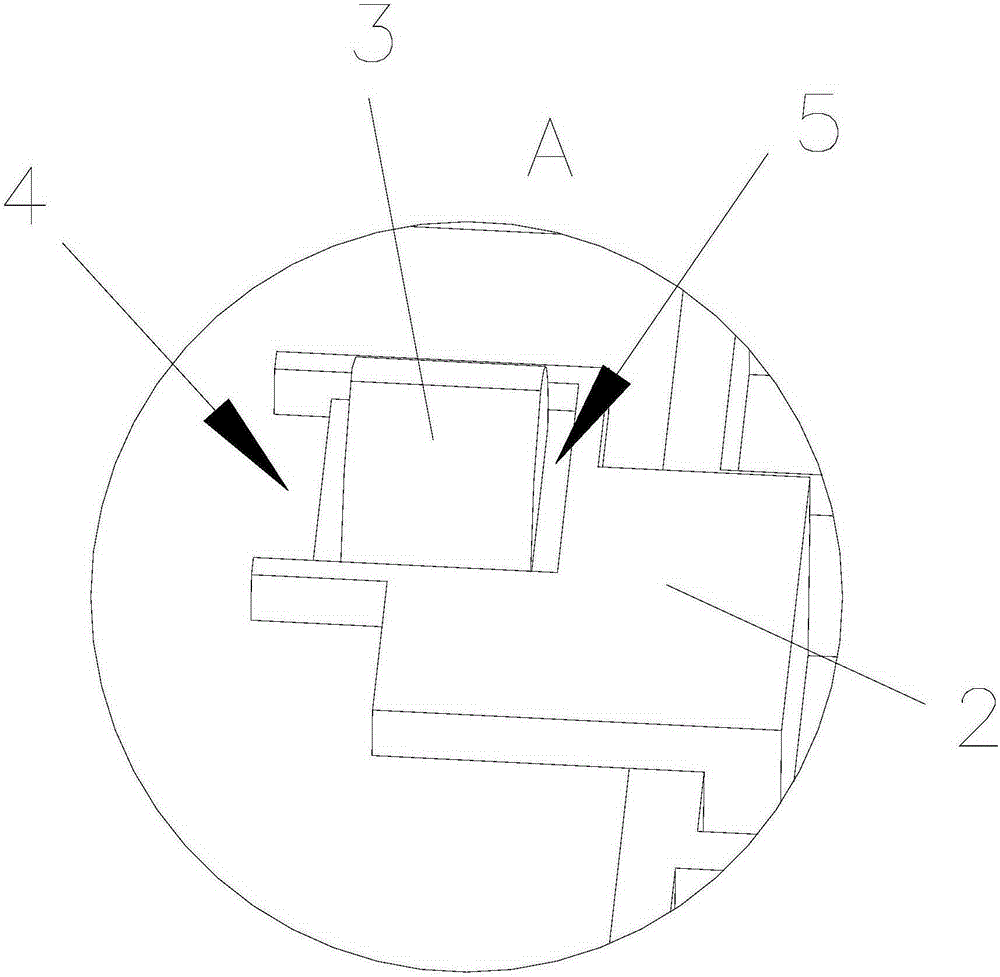

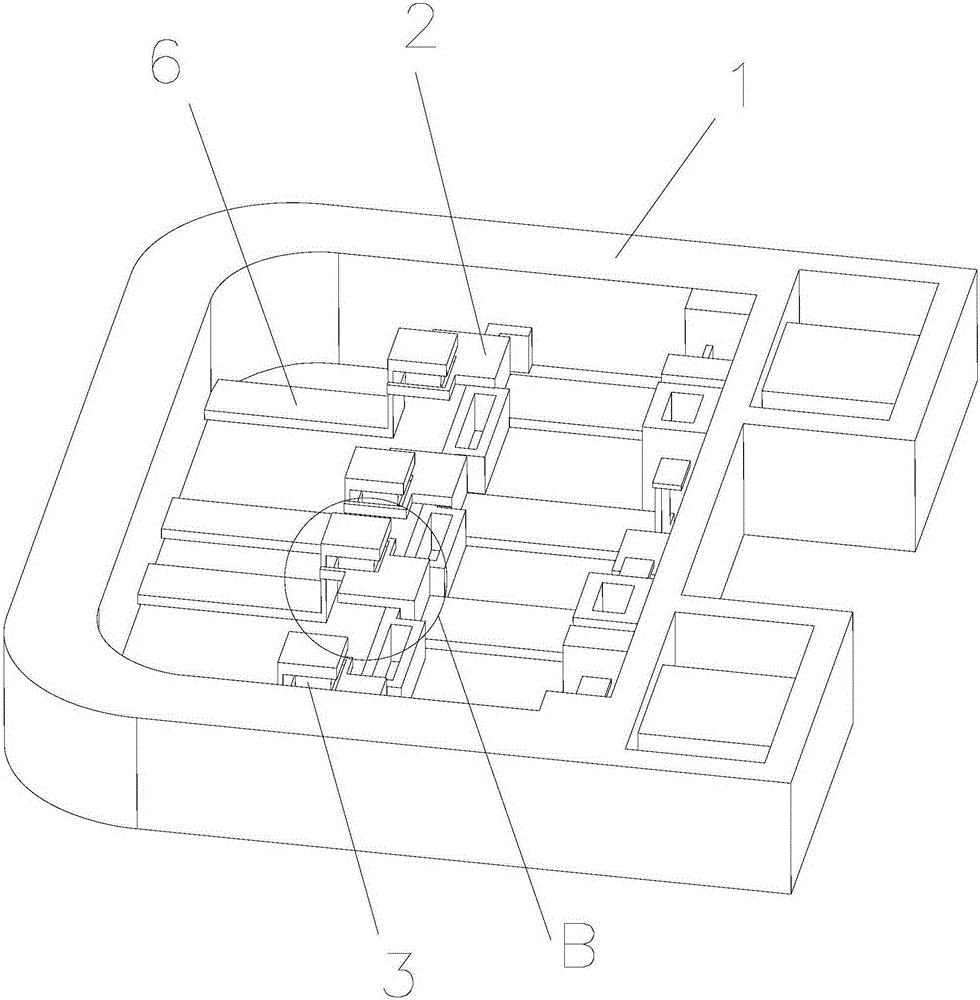

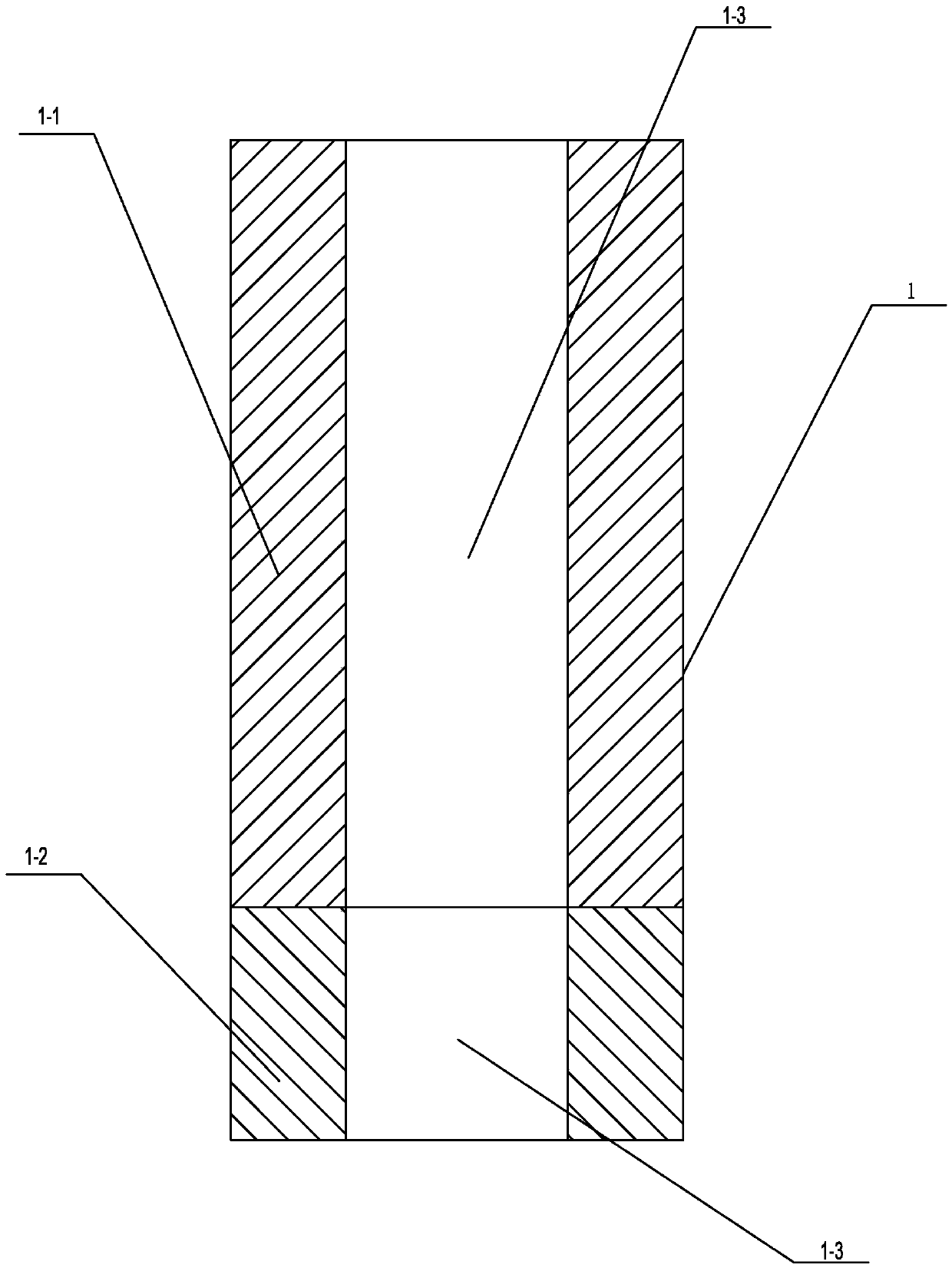

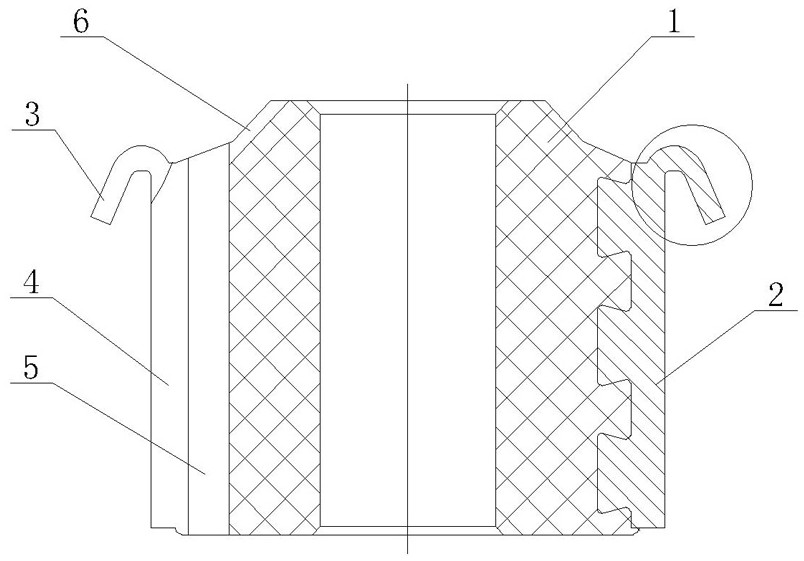

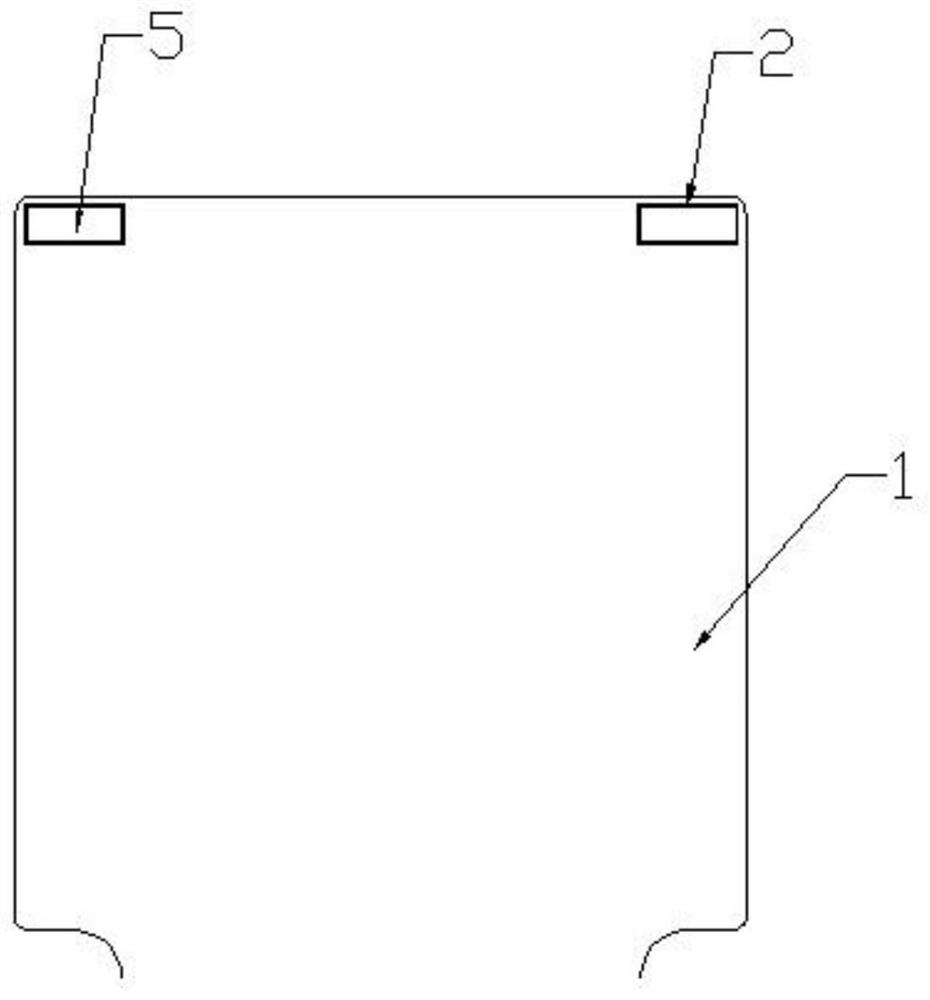

Tab welding structure and tab welding method of flexibly packaged lithium ion power battery

InactiveCN107452934APrevent splashAvoid high self-dischargeCell component detailsPower batteryInternal resistance

The invention relates to the preparation technical field of a lithium ion battery, and discloses a tab welding structure and a tab welding method of a flexibly packaged lithium ion power battery. The tab welding structure comprises a current collector (1) and a concave type tab welding block; the concave type tab welding block comprises a tab upper welding leg (2), a tab lower welding leg (3), a tab main body (4) and tab rubber blocks (5); the tab upper welding leg and the tab lower welding leg are fixed at the same end of the tab main body, and the tab upper welding leg and the tab lower welding leg and one end of the tab main body form a groove; the tab rubber blocks are arranged on the upper and lower end planes of the tab main body; and the current collector is welded to the groove. By virtue of the tab welding structure and the tab welding method provided by the invention, the welding area can be doubled and welding strength can be improved; and in addition, a phenomenon of cold solder joint can be avoided, the battery internal resistance can be lowered, the battery energy loss can be lowered, and safety in the welding process can be improved.

Owner:WANXIANG 123 CO LTD +1

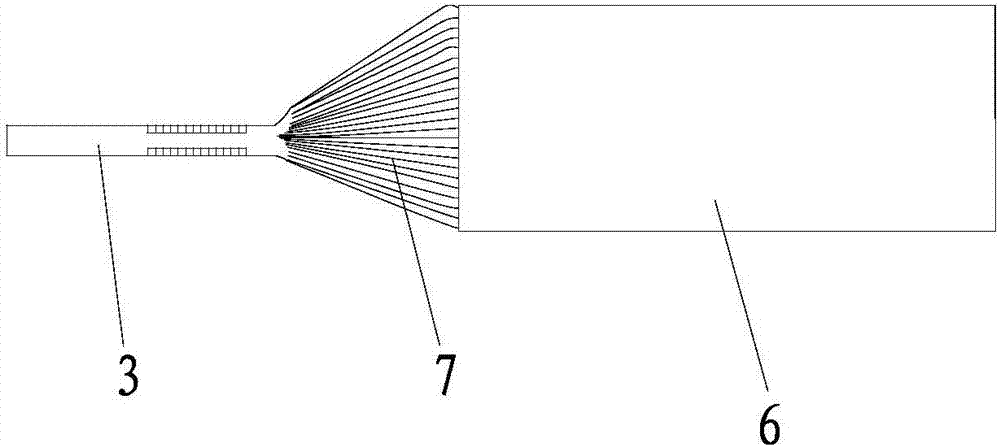

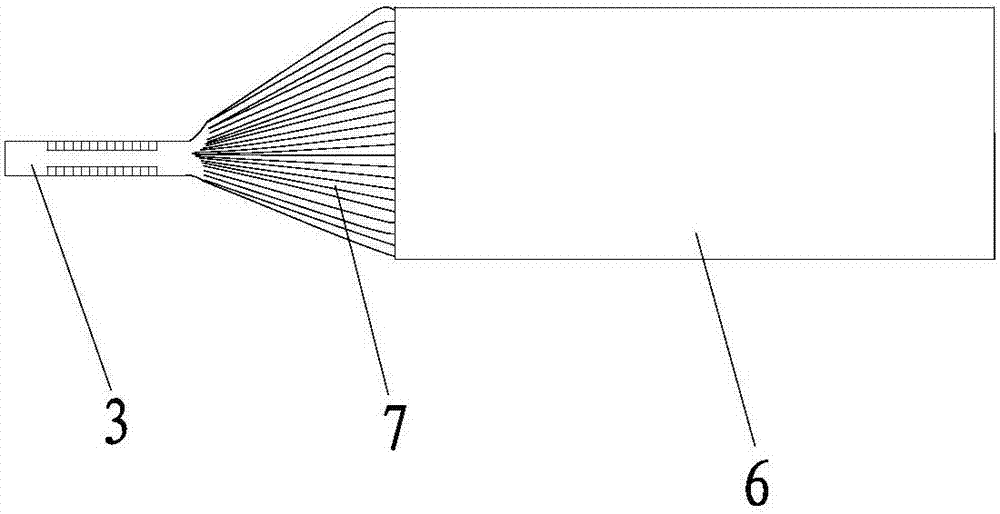

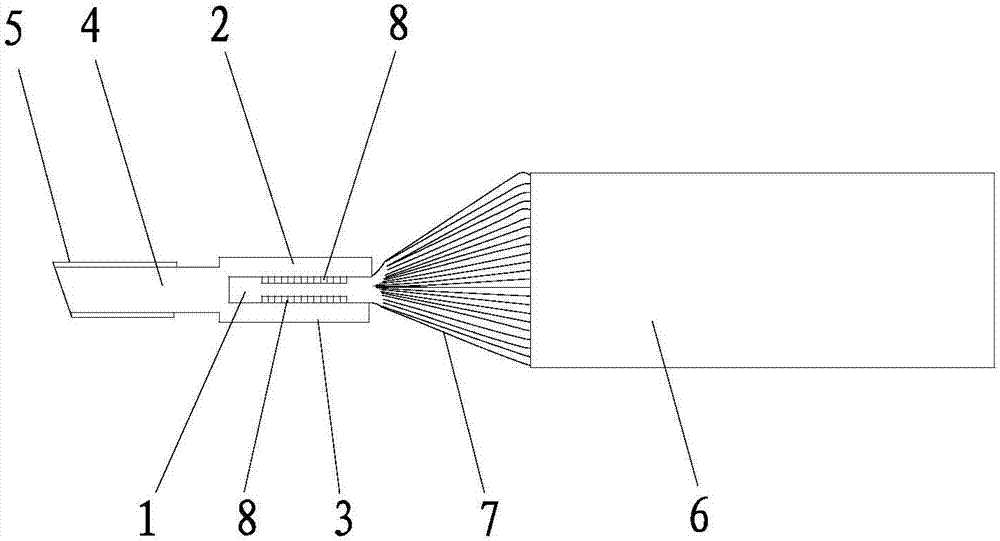

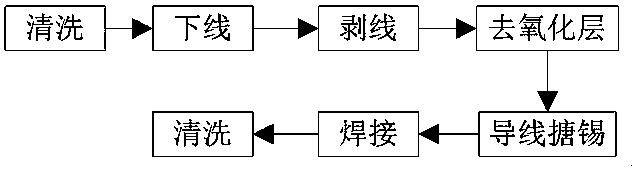

Draw welding method for micro-miniature conduction slip ring

InactiveCN107732629ASimple structureImprove performanceSlip-rings manufactureEngineeringUltimate tensile strength

The invention provides a draw welding method for a micro-miniature conduction slip ring. The method includes the steps of cleaning, thread feeding, thread stripping, oxide layer removing, wire tin hotdip coating, welding, cleaning, drying and the like, and then the satisfactory ring piece of wire welding is obtained. The method solves the problem that the welding quality of the micro-miniature conduction slip ring is not good. By using the method, the welding area can be enlarged, the welding quality and reliability of the ring piece can be improved, the intensity of a welding spot can be enhanced, the welding efficiency can be improved, virtual welding phenomena can be avoided at the same time, and the whole performance of the conduction slip ring can be obviously improved. The method further has the advantages of effectively improving the pouring yield of the micro-miniature conduction slip ring, reducing waste and lowering the production cost. The method solves the problem that thewelding quality of the micro-miniature conduction slip ring is not good, and is suitable for the production of the high-accuracy micro-miniature conduction slip ring.

Owner:JIUJIANG JINGDA MEASUREMENT TECH

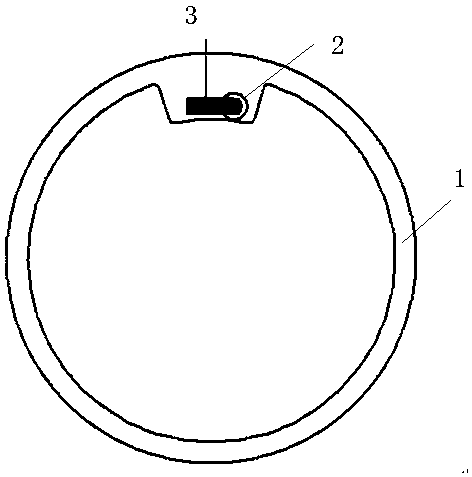

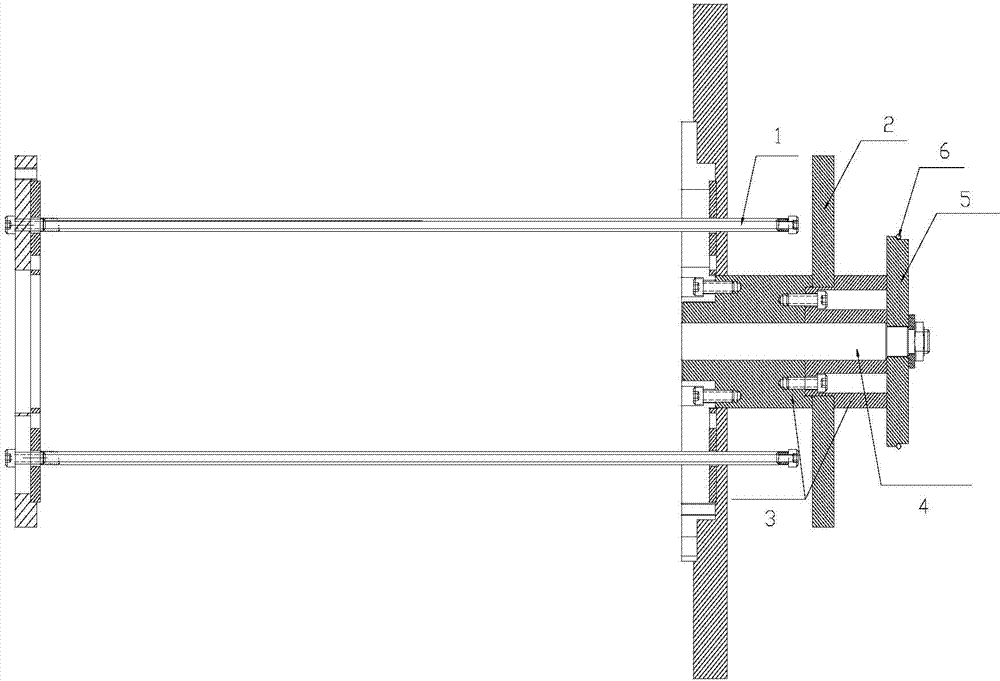

Welding method and device of frame support rings of bag type dust collector

The invention relates to a welding method and a device of frame support rings of a bag type dust collector. After longitudinal steel wires are straightened, the steel wires are inserted into welding equipment according to the number of frame longitudinal steel wires; support rings are put in to perform the spot welding connection with the longitudinal steel wires; and the radial expansion force is applied to the support rings before the welding, so that all the welding points of the support rings and the multiple longitudinal ribs are fully contacted. Compared with the prior art, the welding method and device can prevent the pseudo soldering phenomenon of synchronous welding of multiple points caused by the size errors of the support rings and devices for supporting the support rings.

Owner:上海袋式除尘配件有限公司

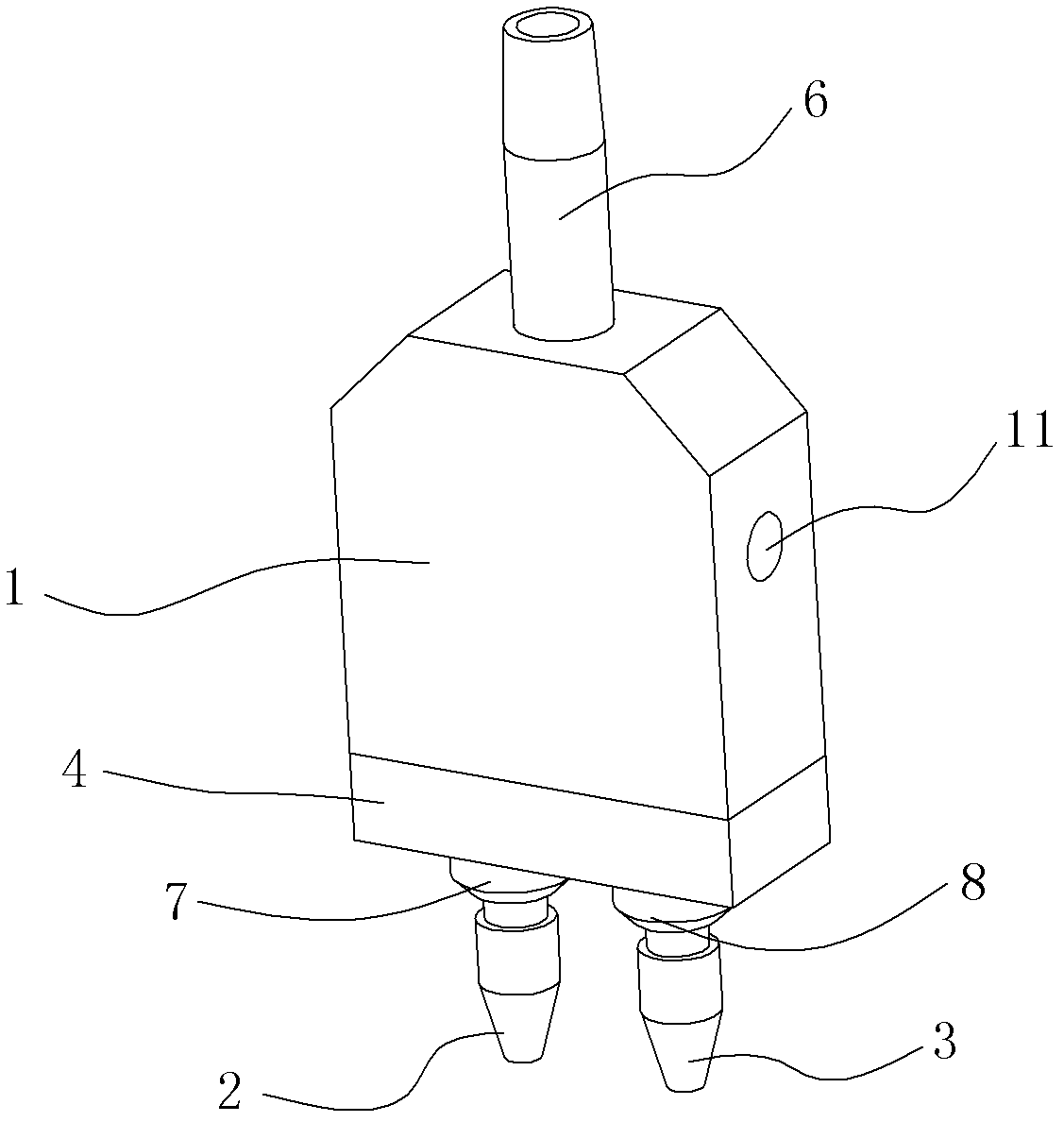

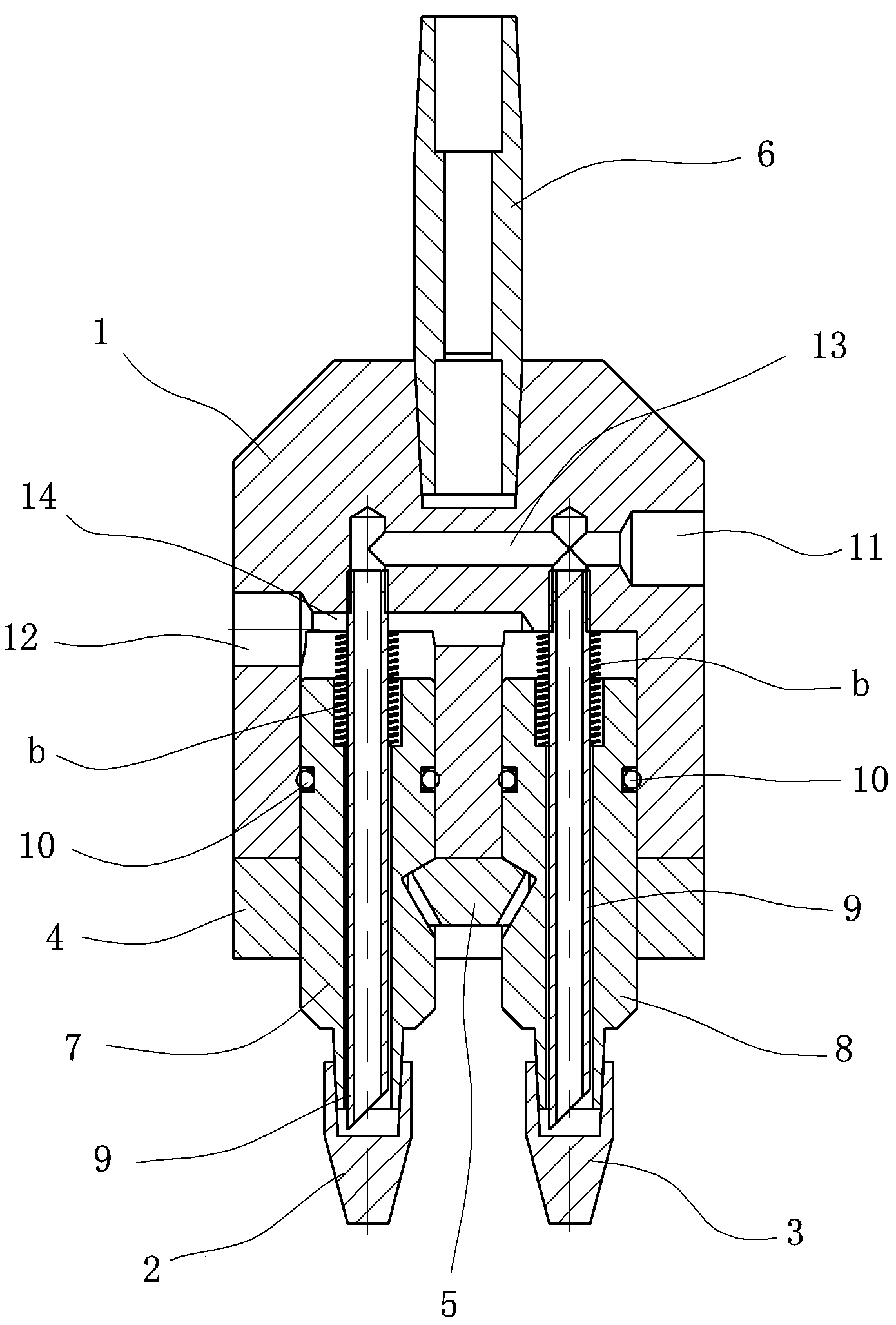

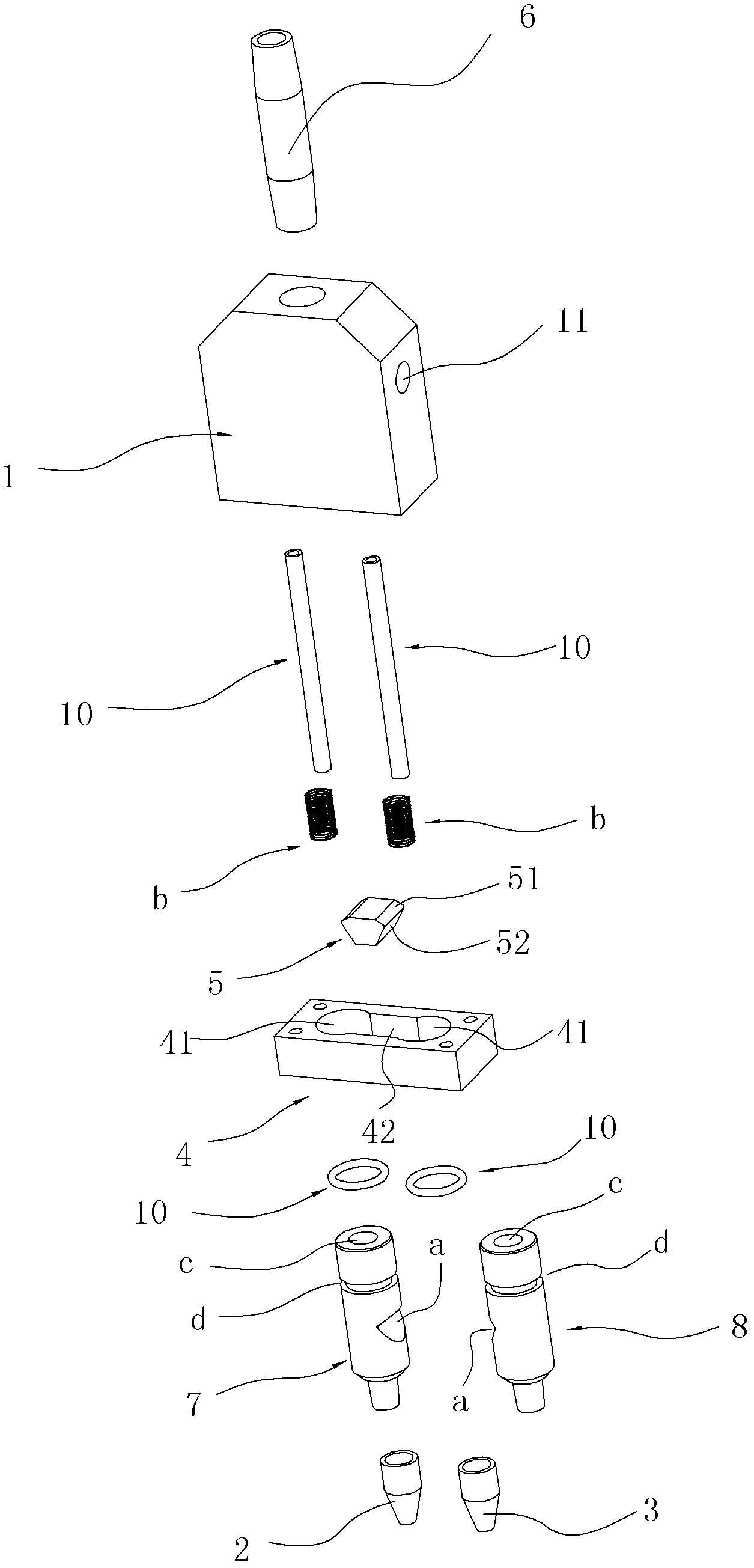

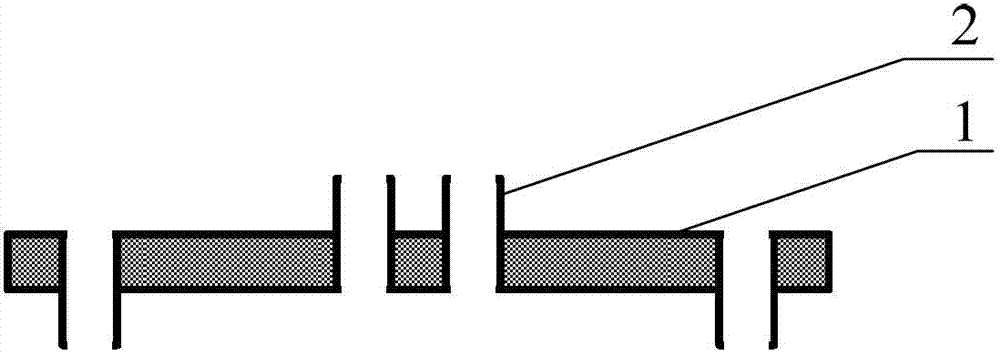

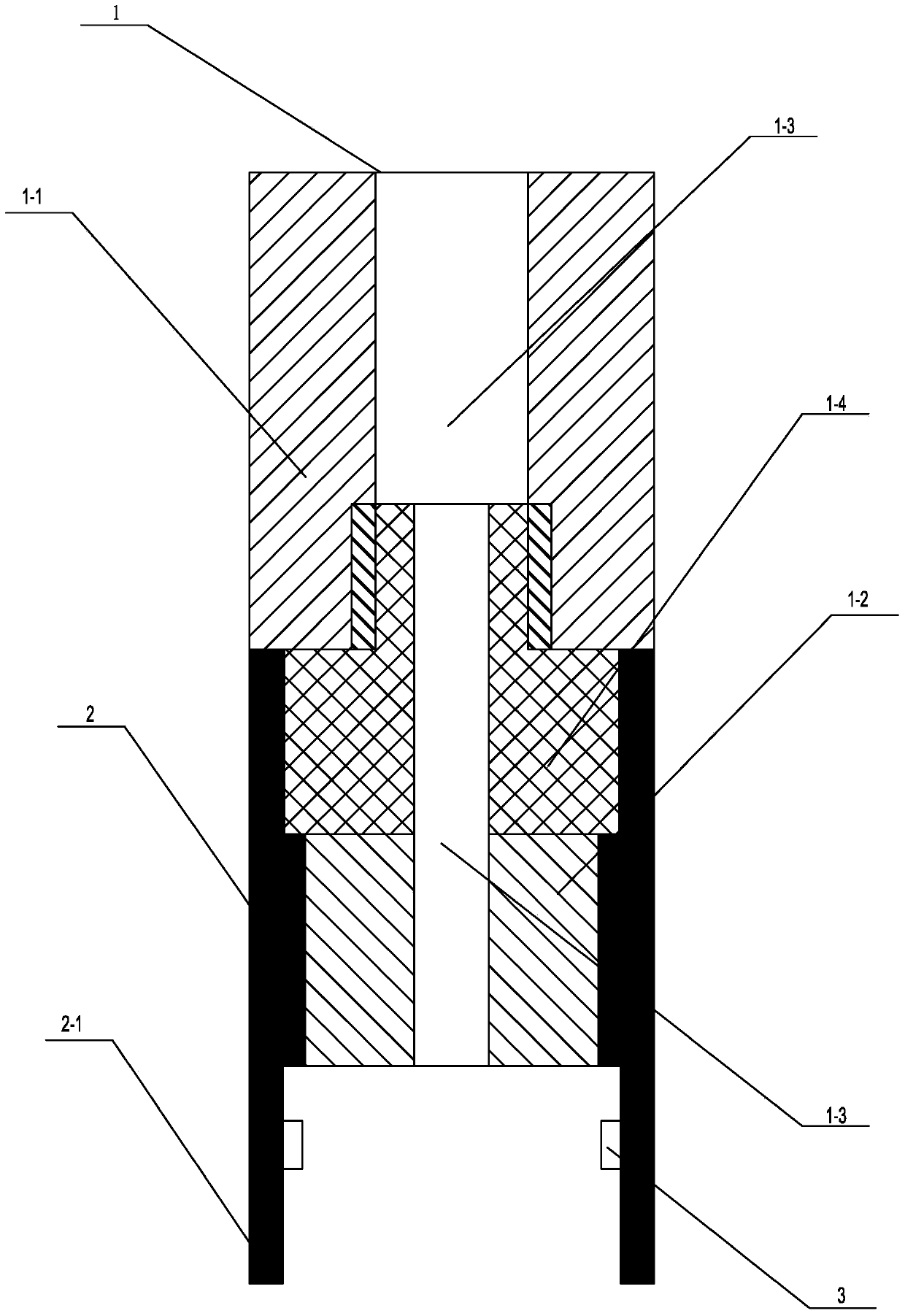

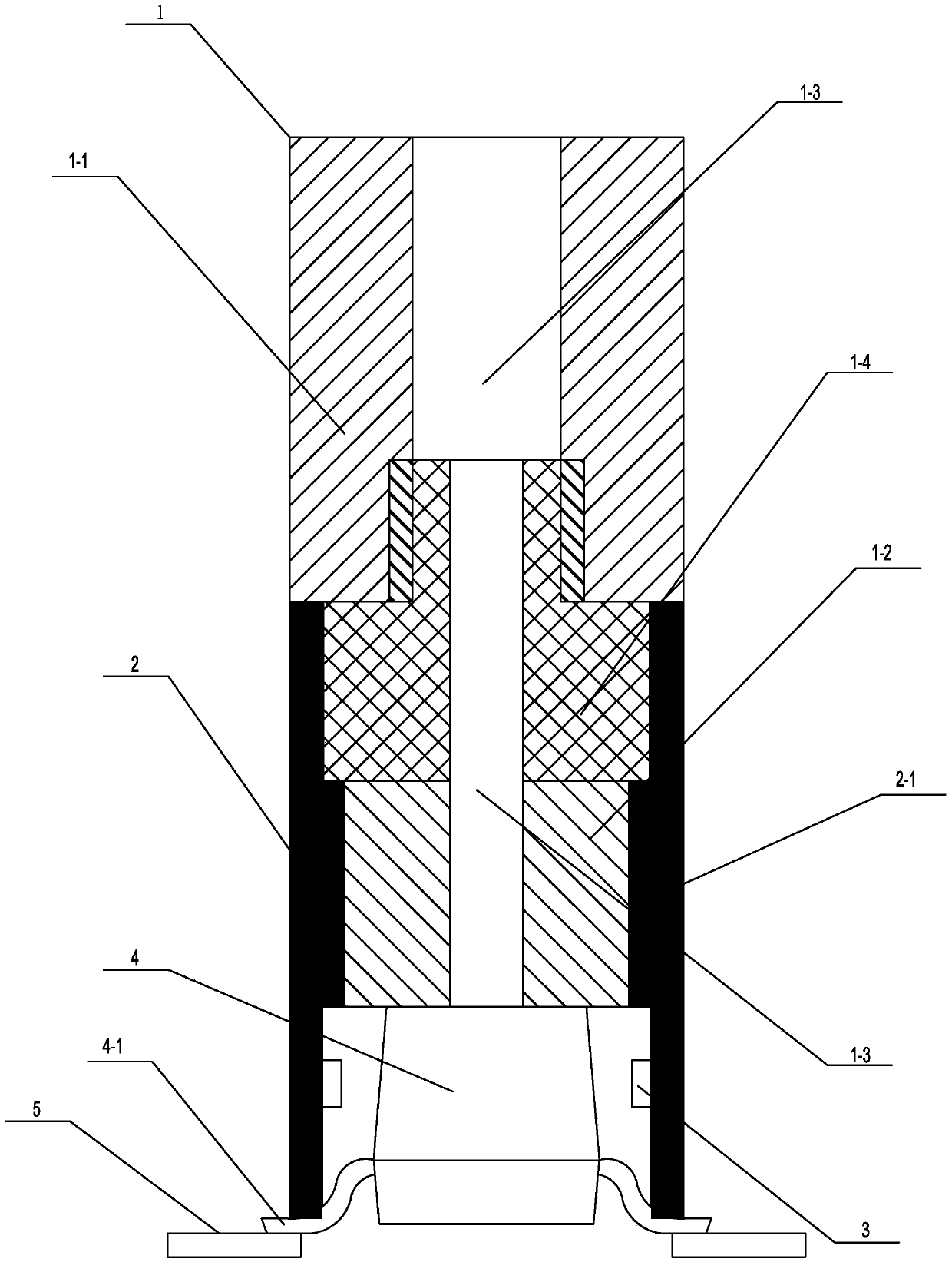

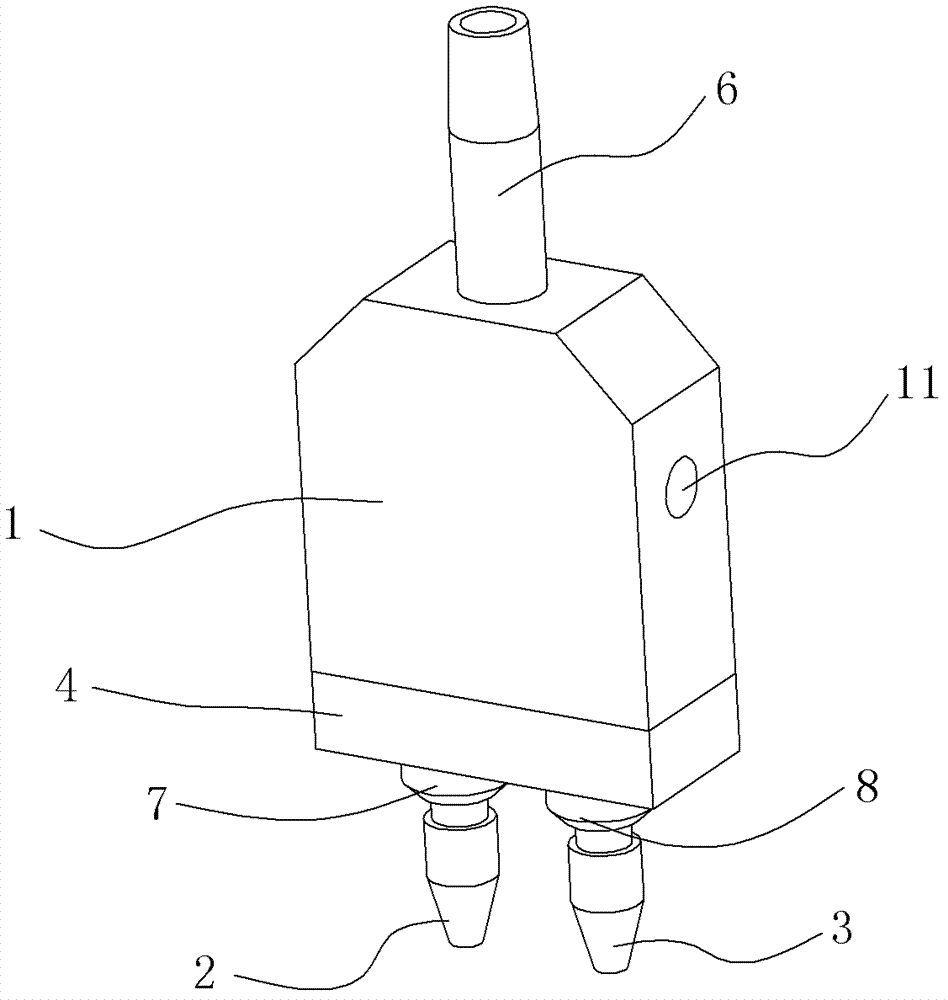

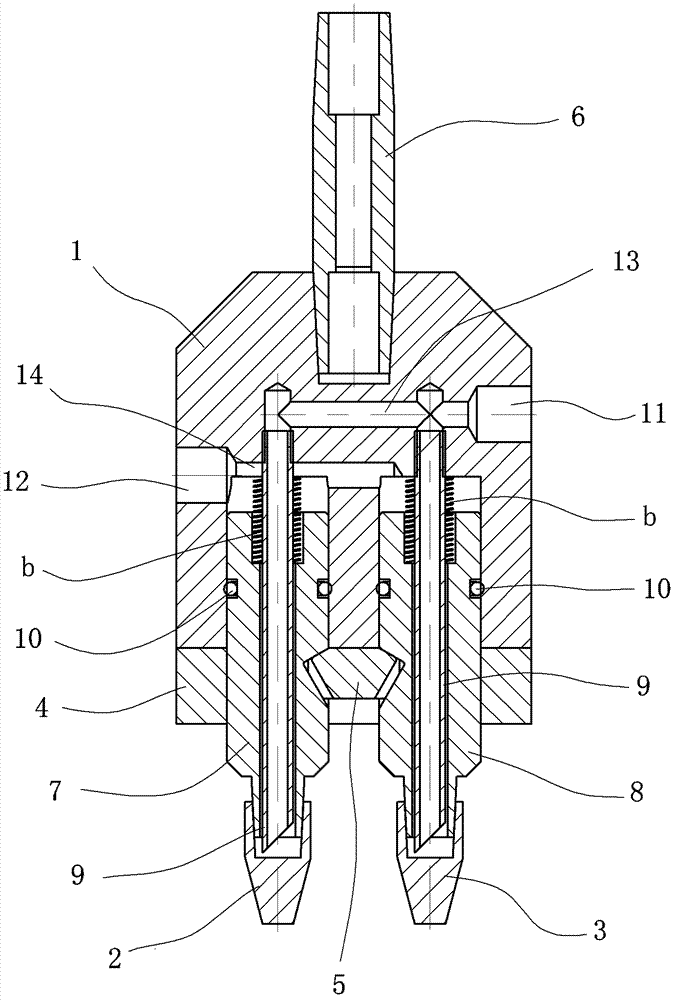

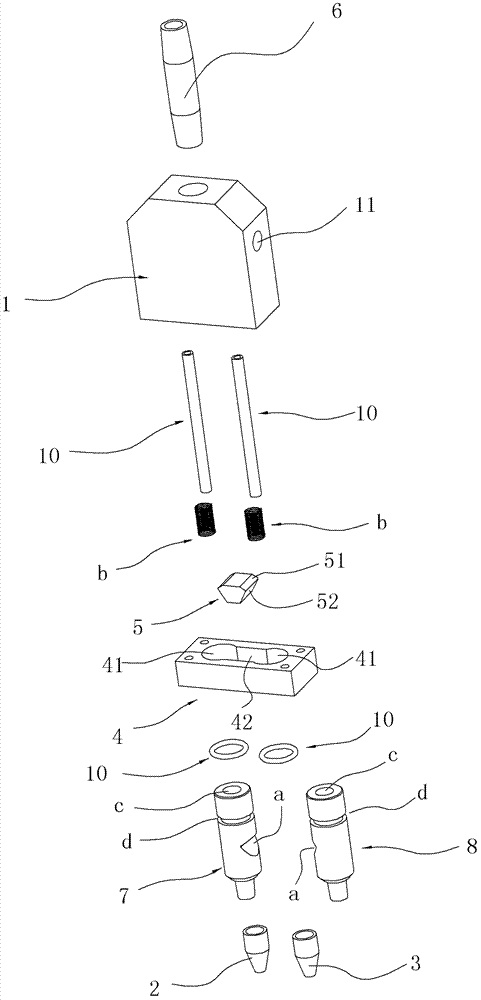

Duplex spot welding electrode

ActiveCN102581463AReduce the number of repairsAvoid Welding PhenomenonElectrode featuresNatural stateEngineering

The invention relates to a duplex spot welding electrode. Improvements are made on the basis of an electrode holder, a first electrode, a second electrode, a first guide pillar and a second guide pillar, namely an auxiliary block is fixed on the bottom surface of the electrode holder; two through holes are arranged in the auxiliary block; a sunken groove is arranged on the upper part of the auxiliary block, and is communicated with the two through holes; a sliding block is positioned in the sunken groove; each of the two lateral surfaces of the sliding block is provided with a downwardly inclined surface; a groove matched with the corresponding downwardly inclined surface of the sliding block is arranged on the lateral surface of each of the first and second guide pillars; a spring is arranged in each of mounting holes, and makes each of the first and second electrodes always tend to be exposed out of the electrode holder; and each spring is in a natural state, the sliding block is pressed against the grooves on the first and second guide pillars, and a gap is formed between the downwardly inclined surface on each of the two sides of the sliding block and each groove. The two electrodes can float and be automatically leveled, so that the two electrodes contact a workpiece with the same force, a pseudo soldering phenomenon is avoided, the number of overhauling times of the abraded electrode is decreased, the use cost is decreased, and the welding efficiency is improved.

Owner:北京敏实汽车零部件有限公司

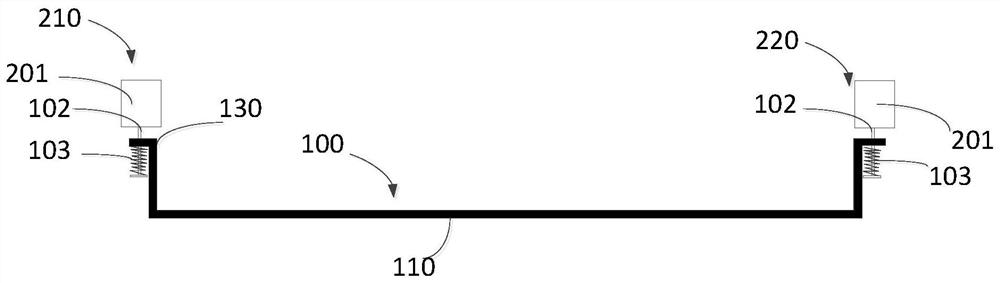

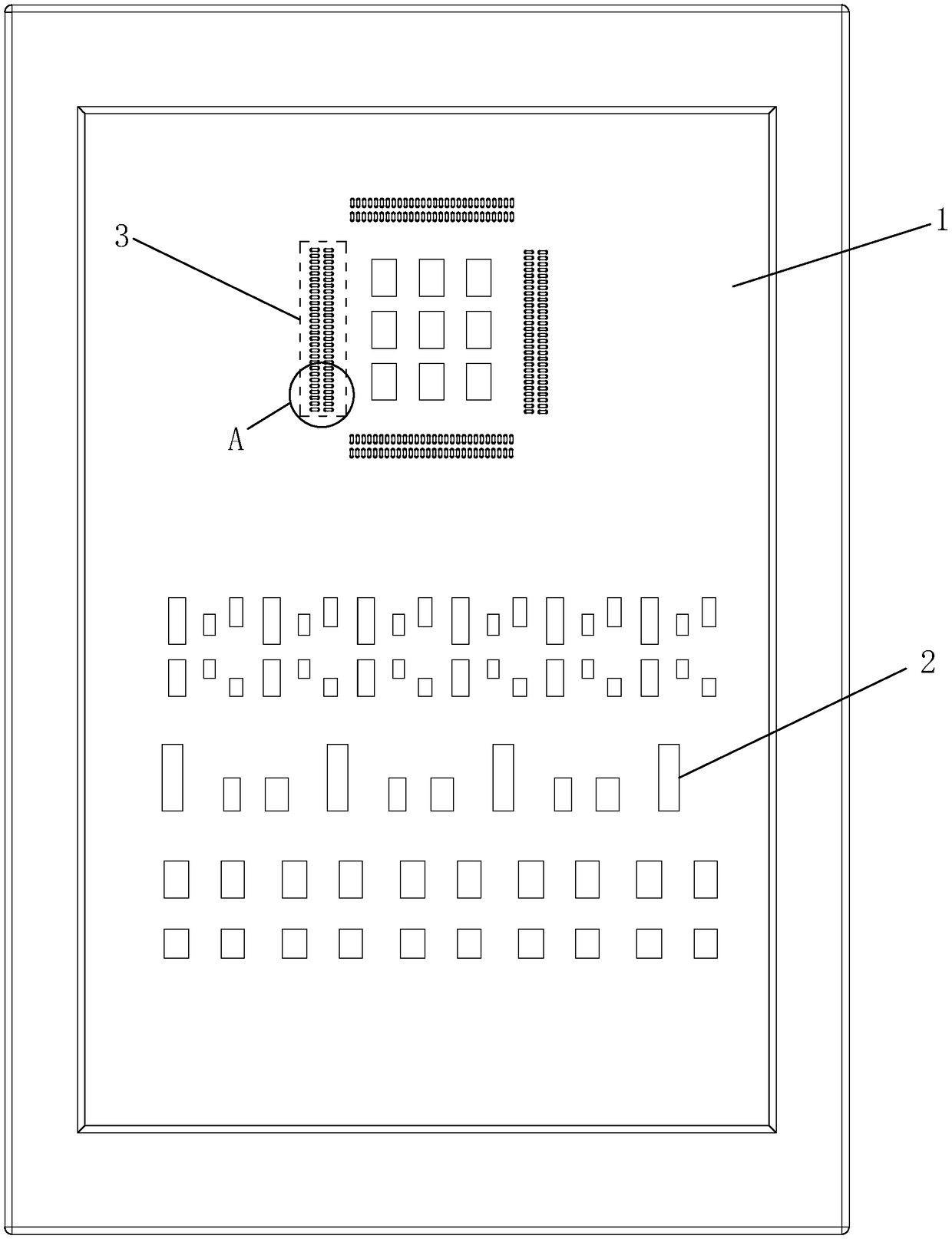

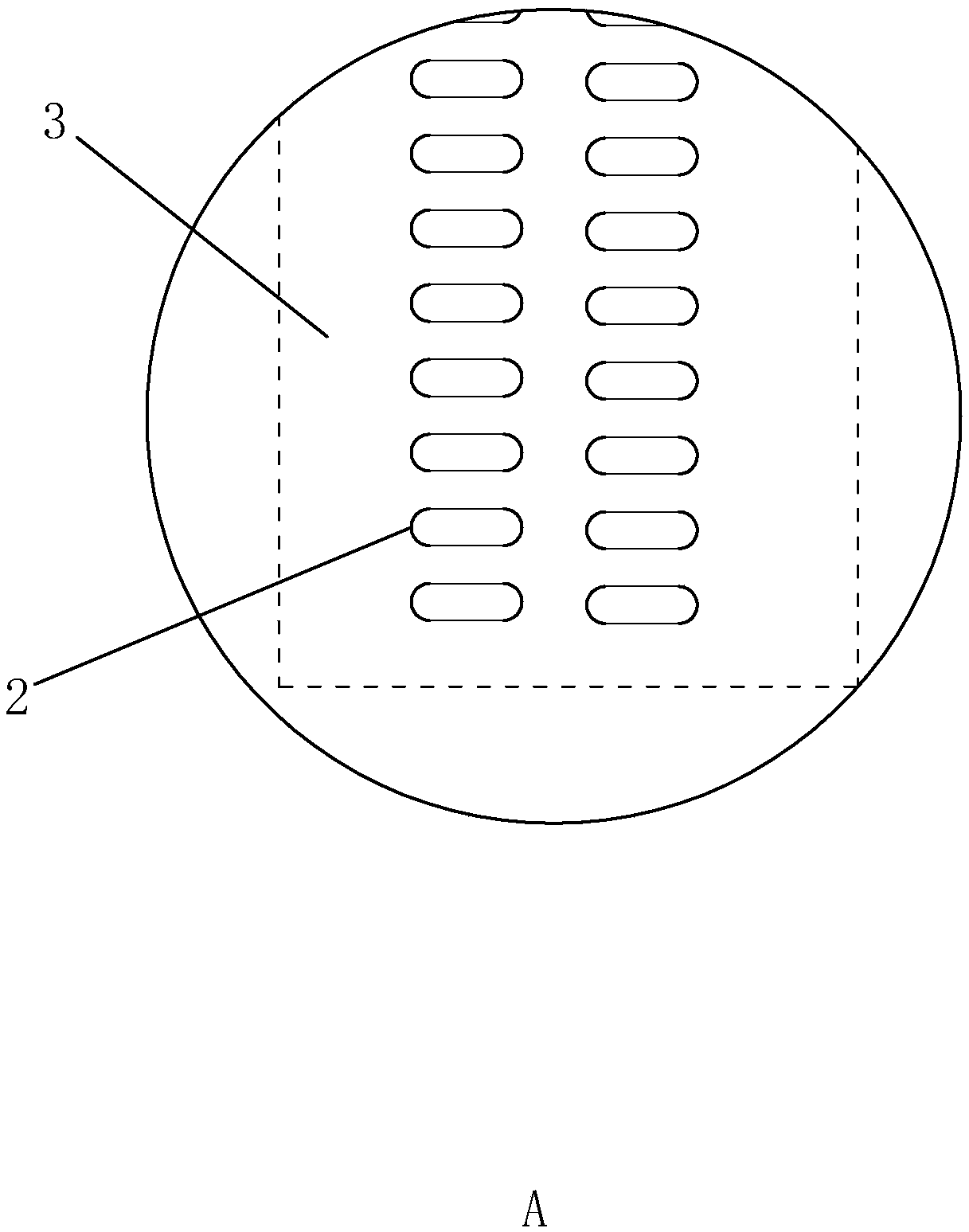

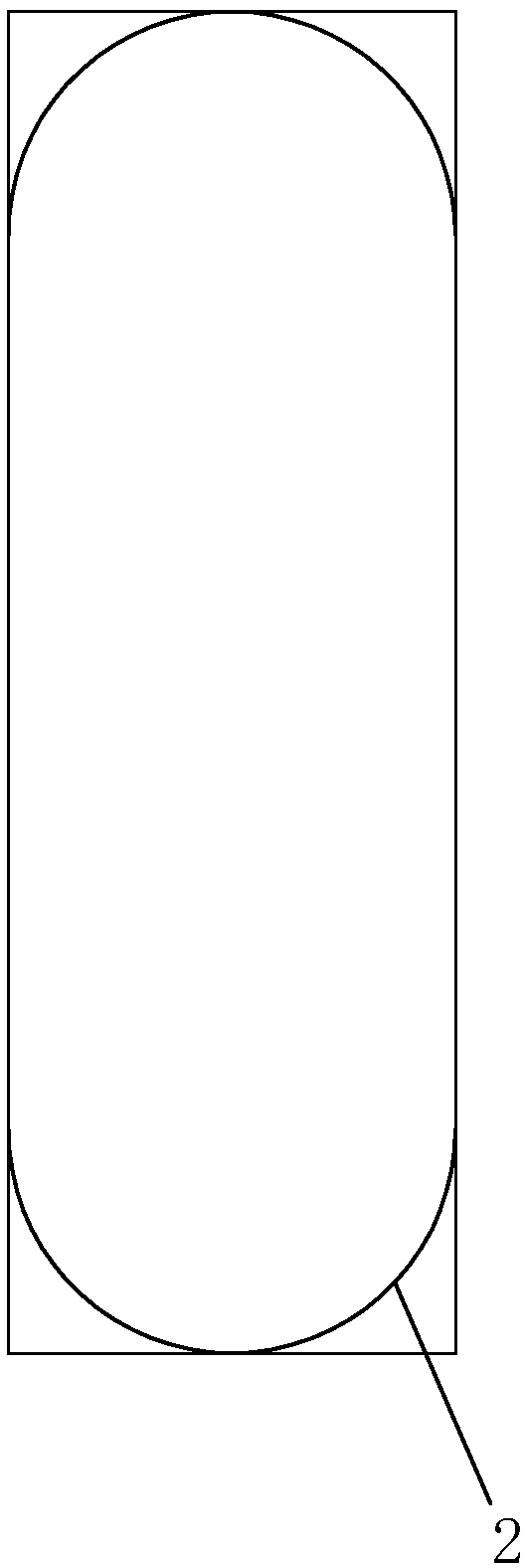

Mask plate net stretching assembly, net stretching device and net stretching method

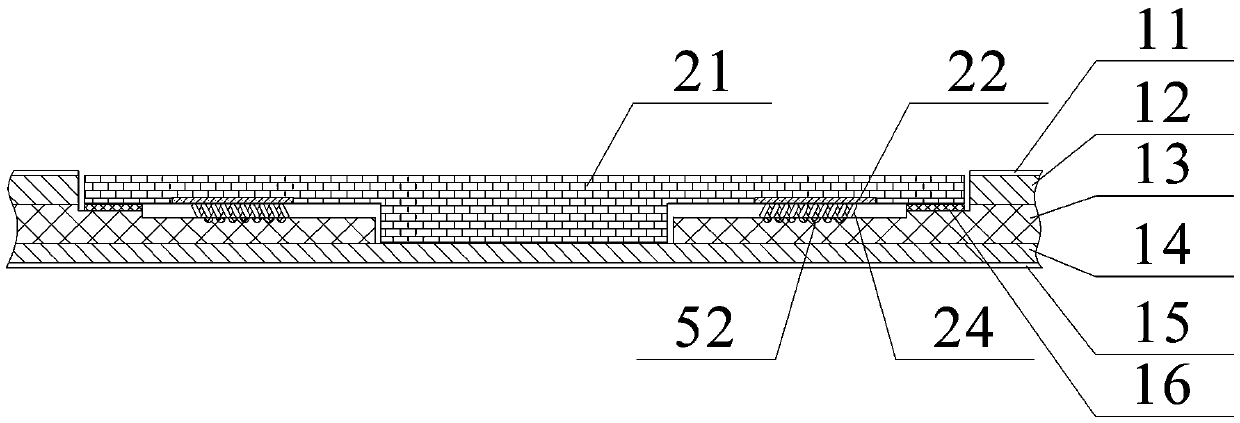

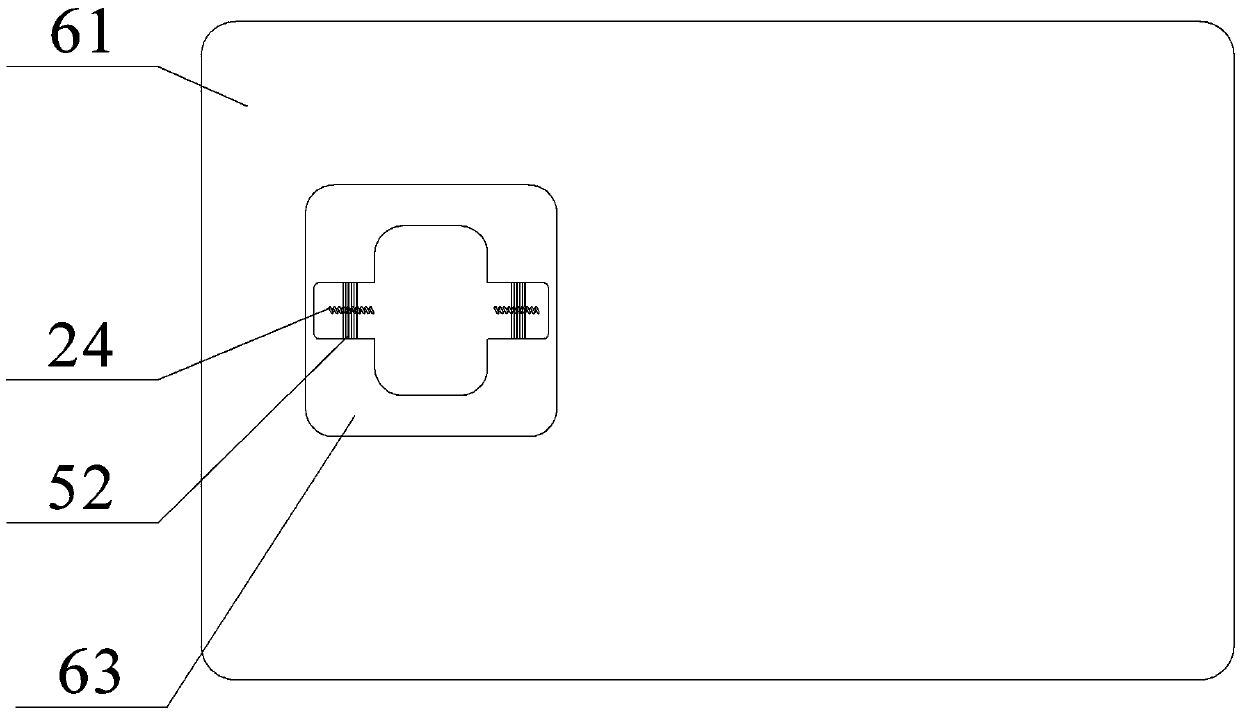

PendingCN111952485AImprove problems such as short service lifeAvoid Welding PhenomenonVacuum evaporation coatingSolid-state devicesStructural engineeringMechanical engineering

The invention provides a mask plate net stretching assembly, a net stretching device and a net stretching method, the mask plate net stretching assembly, the net stretching device and the net stretching method are used for stretching a mask plate on a mask frame, the mask plate comprises two welding areas located at the two opposite ends of the mask plate, each welding area comprises a first faceand a second face which are opposite, and the mask frame comprises two opposite first side edges; the first surface is attached to the surface of the first side edge of the mask frame; the mask platenet stretching assembly comprises a main frame which comprises a pressing plane used for pressing a second face of a welding area and a back face opposite to the pressing plane, and a hollow area penetrating through the pressing plane and the back face is arranged in the middle of the main frame; and the force application structure is arranged on the main frame and applies a first pressing actingforce and a second pressing acting force to the two opposite ends of the main frame correspondingly, and the directions of the first pressing acting force and the second pressing acting force are perpendicular to the pressing plane and are the same. According to the mask plate net stretching assembly, the net stretching device and the net stretching method provided by the invention, defects causedby wrinkles of mask plate net stretching can be overcome.

Owner:BOE TECH GRP CO LTD +1

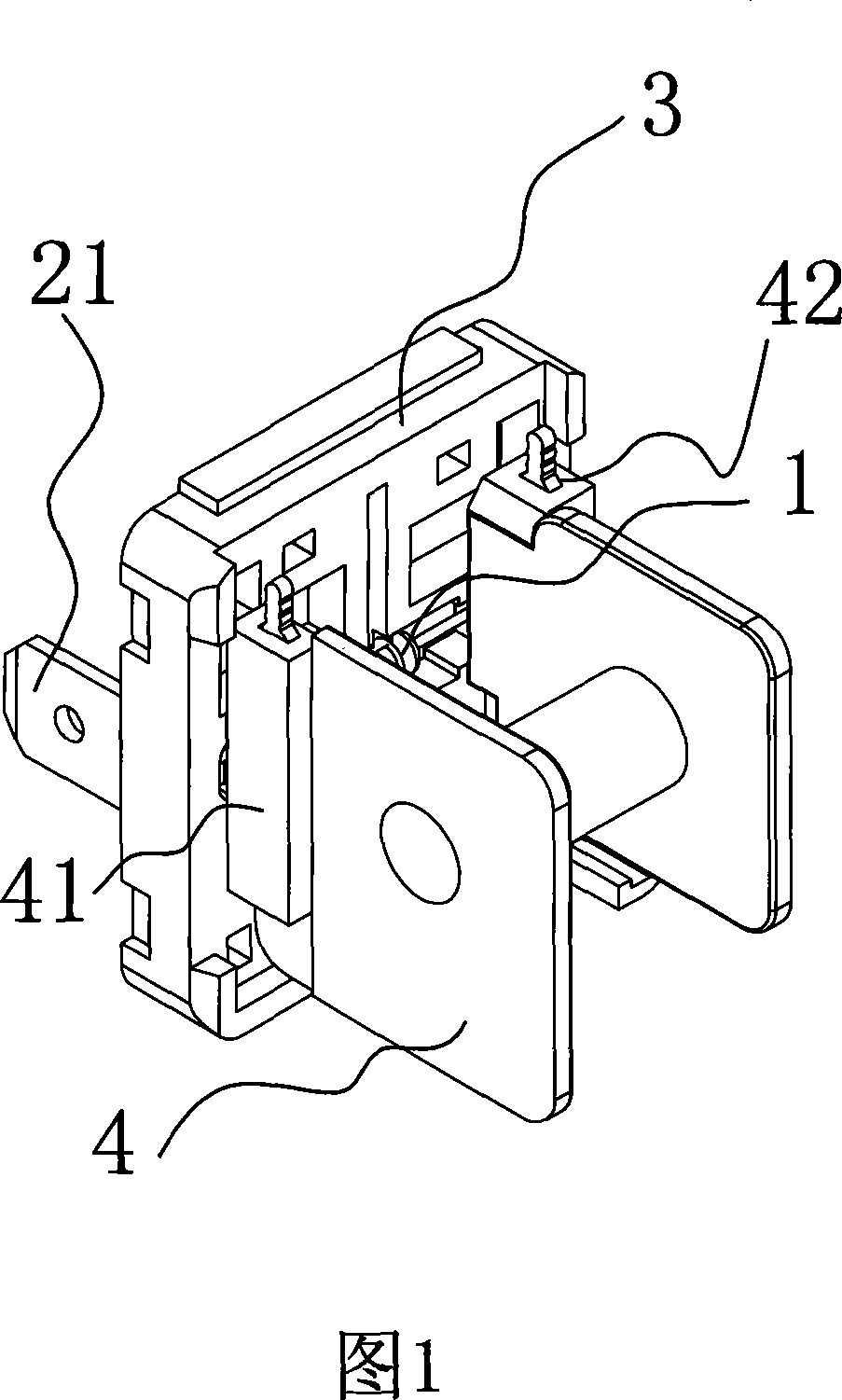

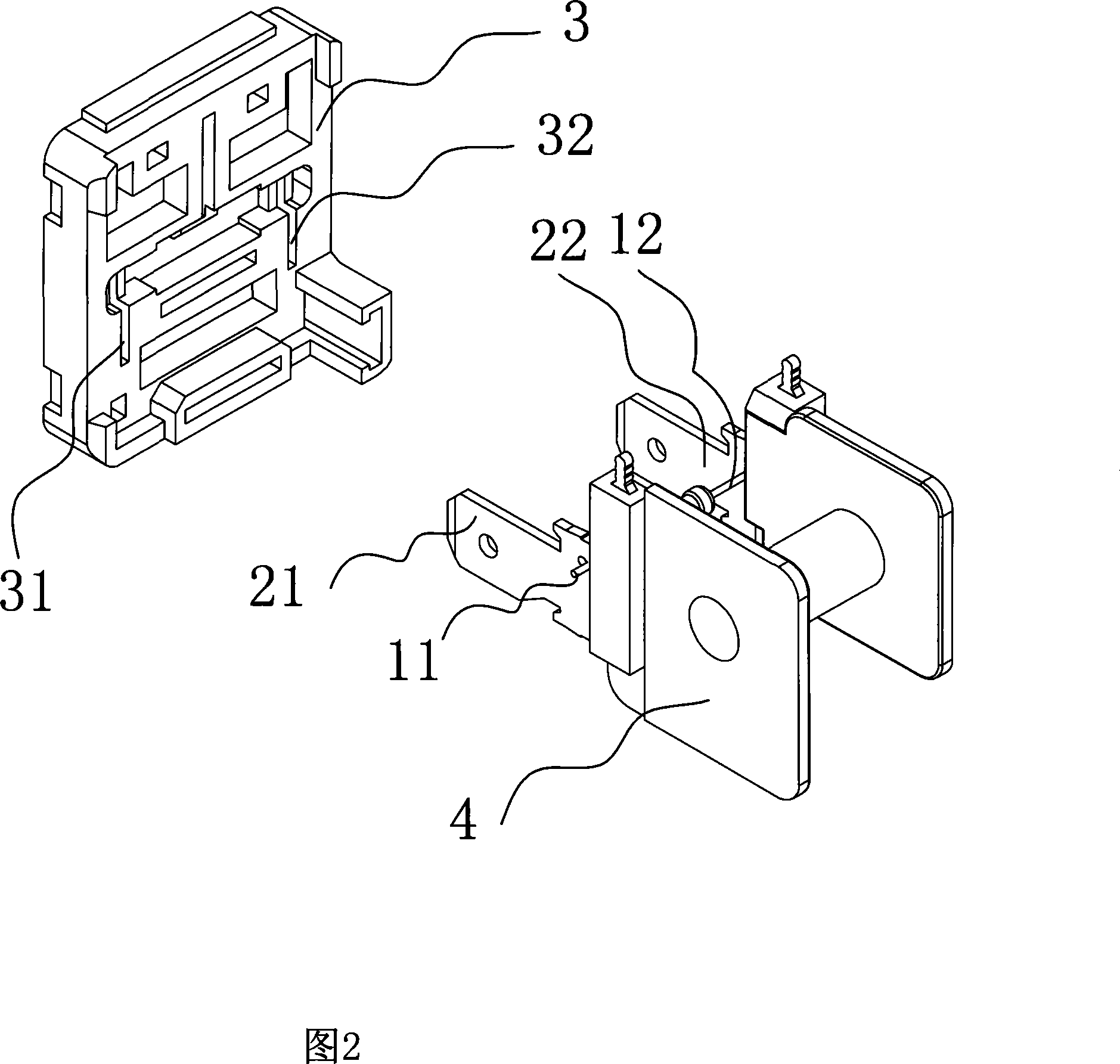

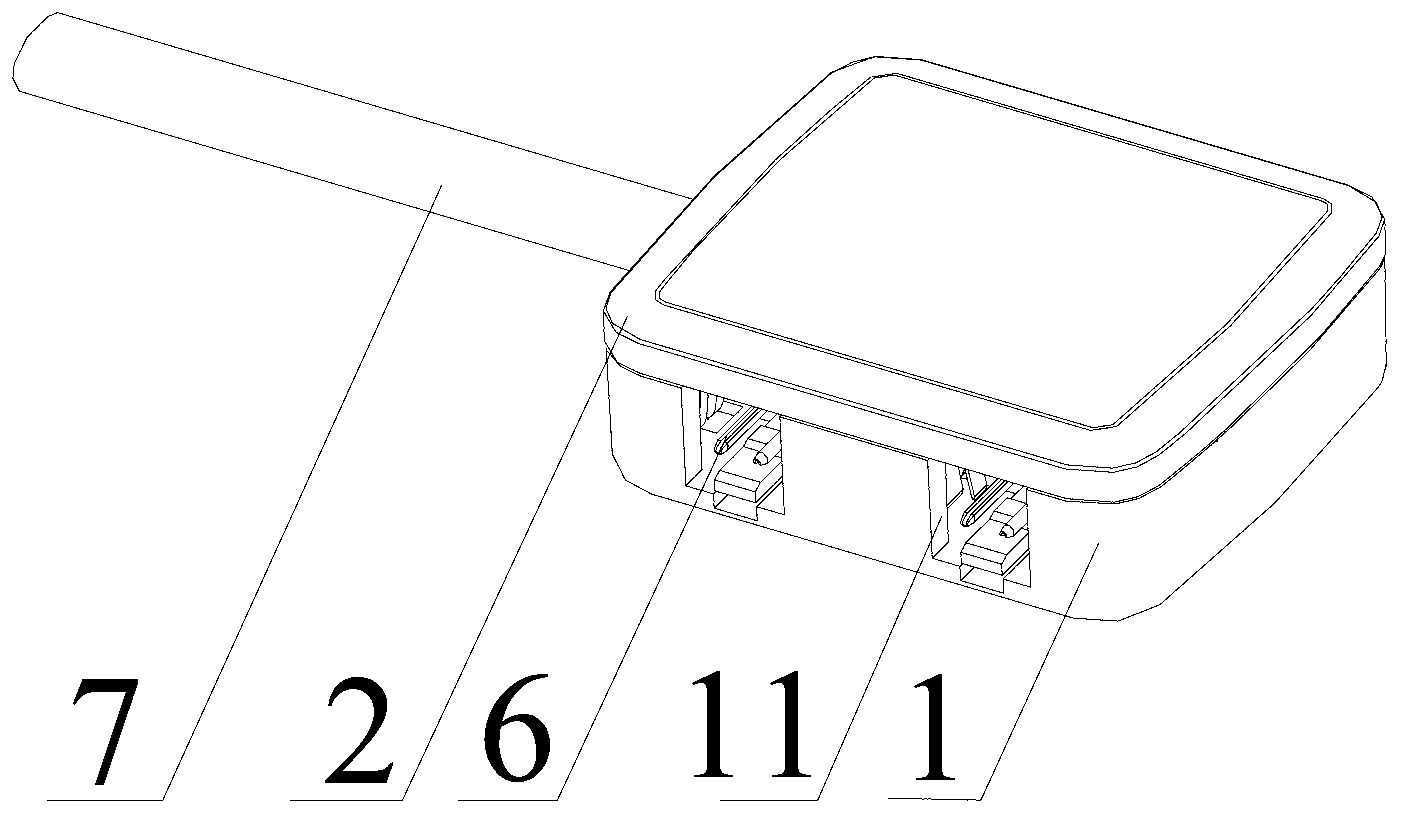

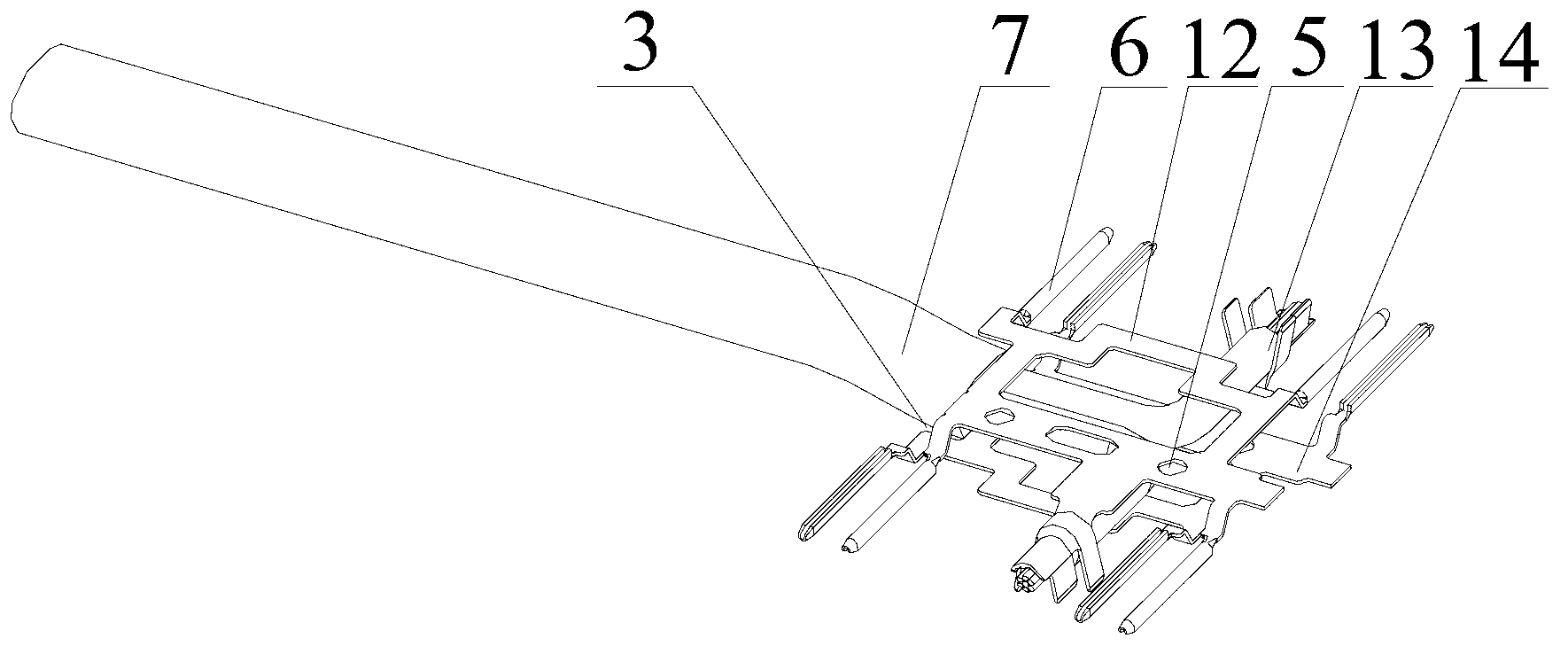

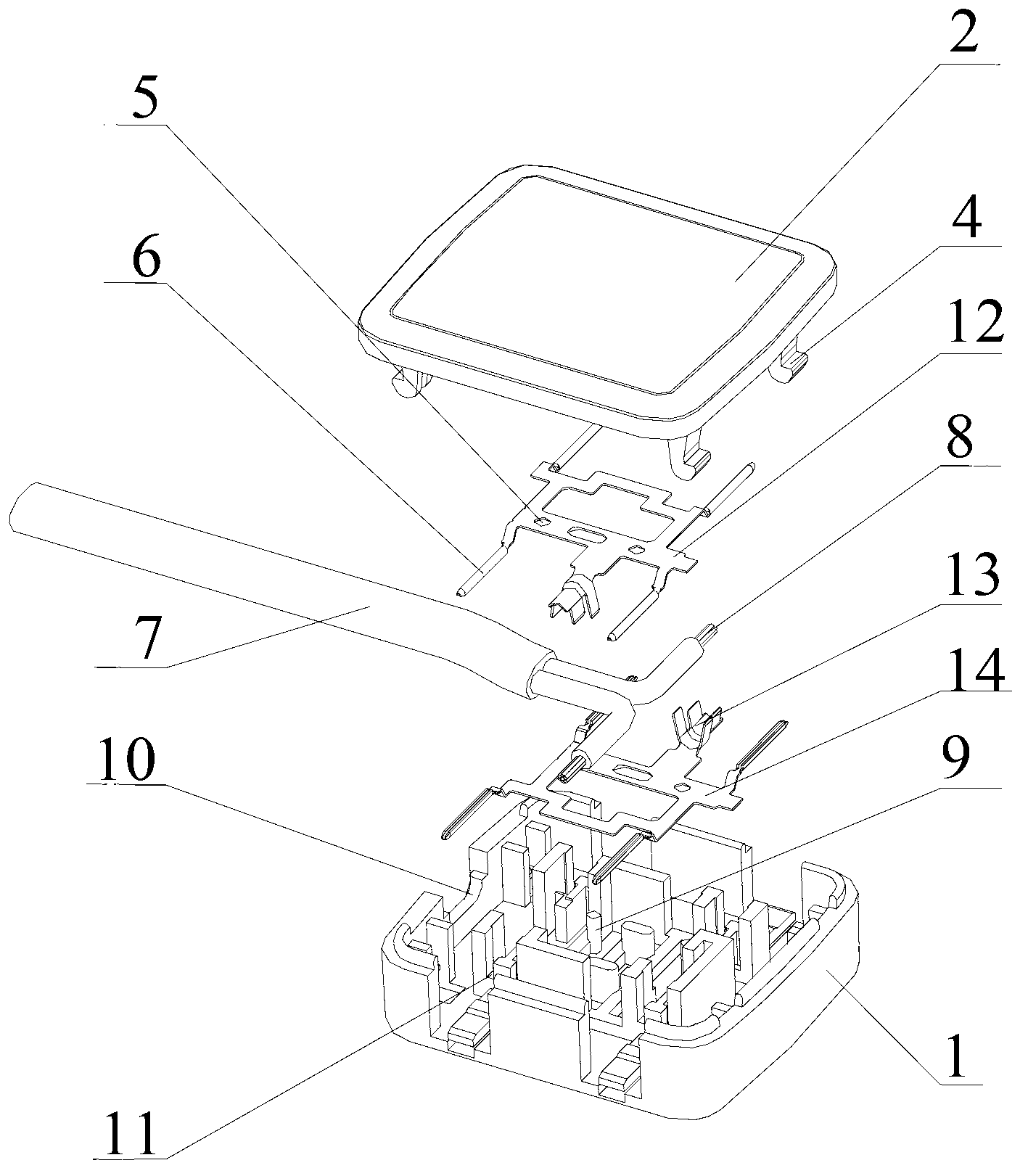

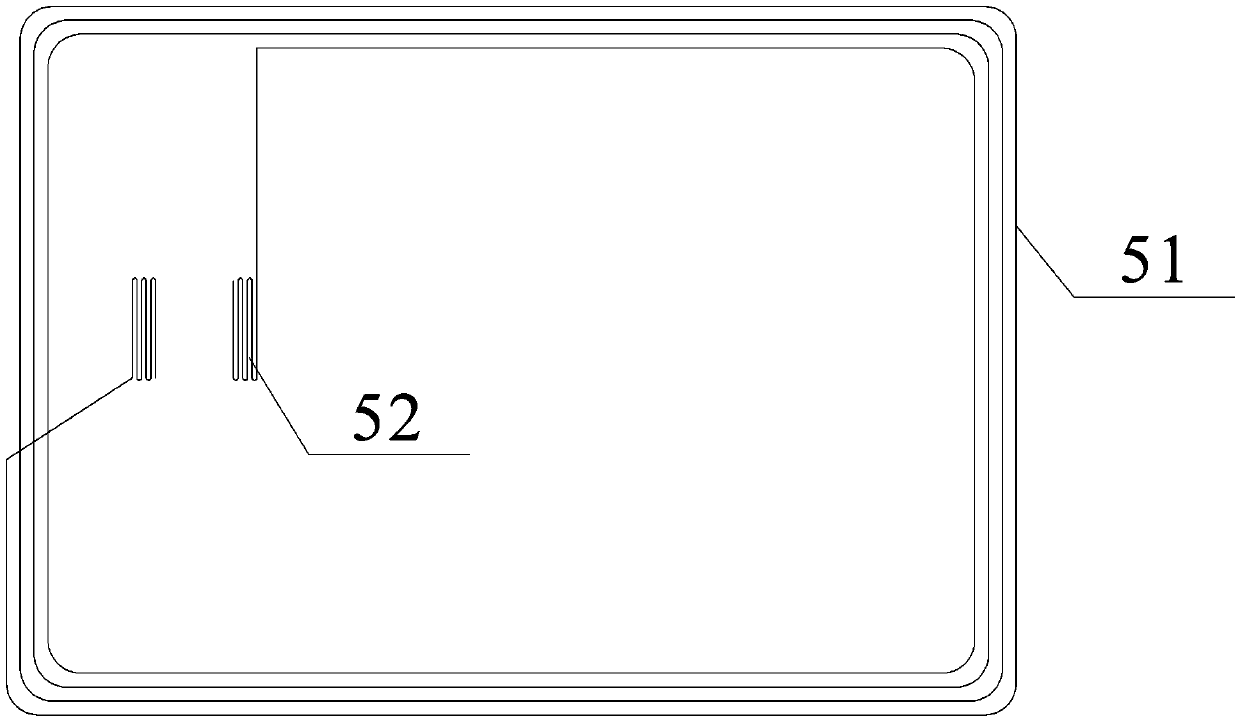

Vehicle relay and installation method of electronic components thereof

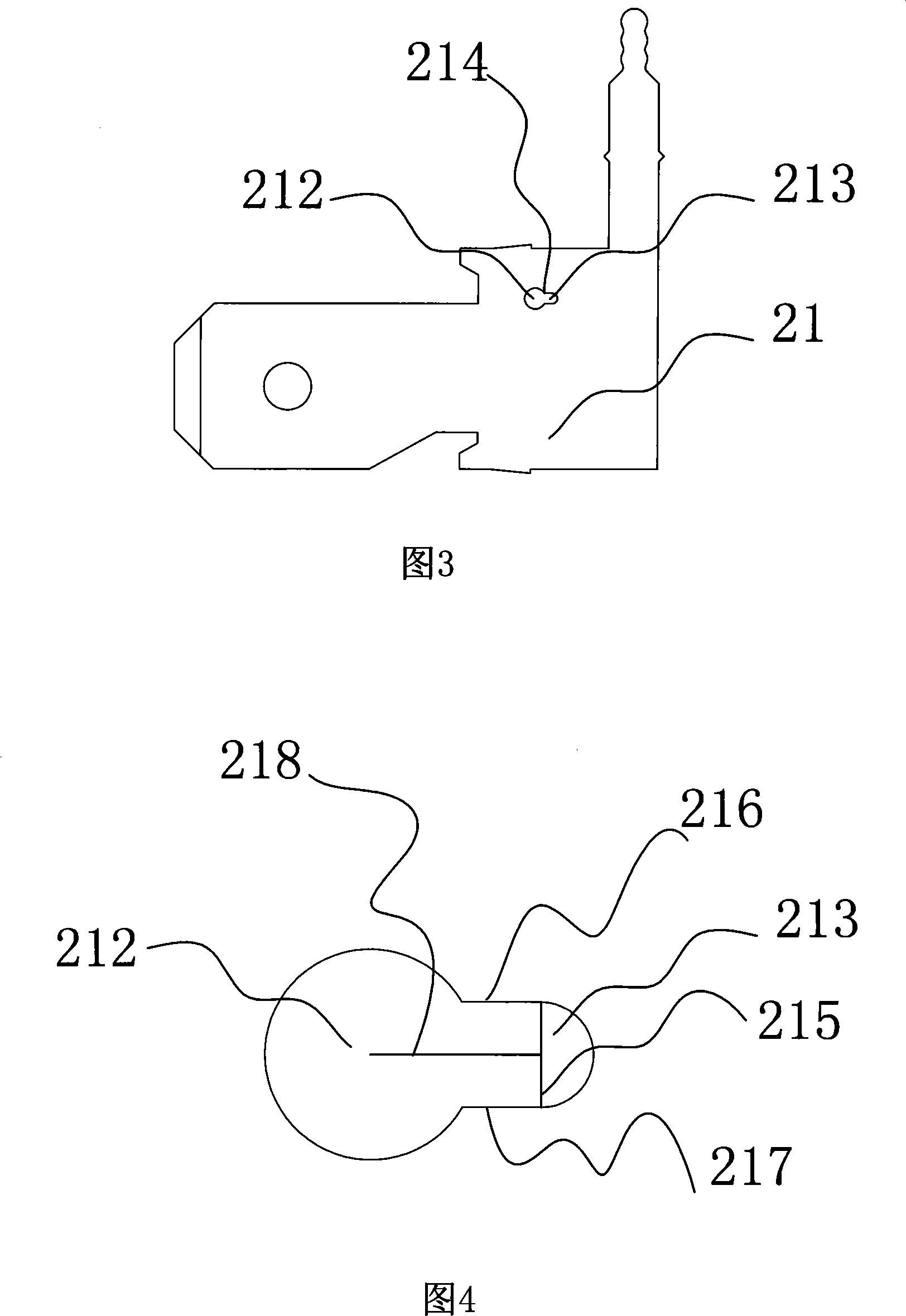

ActiveCN101226853AReasonable structural designEasy to installRelay bases/casings/coversSolderingSmall hole

Disclosed is a car relay, which comprises a foundation, an electronic element, a pair of parallel coil lead chips, wherein the parallel coil lead chips are respectively inserted in a coil former, the lead chip is opened a hole which is larger than the diameter of the leading-out end of the electronic element, a hole smaller than the leading-out end of the electronic element is provided in the front of the hole, the two holes are connected mutually, the leading-out end of the electronic end is positioned in the bigger hole of the lead chip, the lead chip is inserted in the foundation, the leading-out end of the electronic element is inserted in the smaller hole from the bigger hole by the foundation. The invention additionally provides the corresponding installment method. The invention has the advantages of reasonable structural design, convenient installment and good fixing effect, which resolves problems of poor soldering in welding process of lead chips and difficult welding caused by small volume of relays and small installment space, greatly increases working efficiency, and the car relay can bear certain vibration, increase product quality and finished product percent of pass, and has reliable and stable usage and long service life.

Owner:NINGBO YINZHOU YONGLIN ELECTRON ELECTRICAL EQUIP

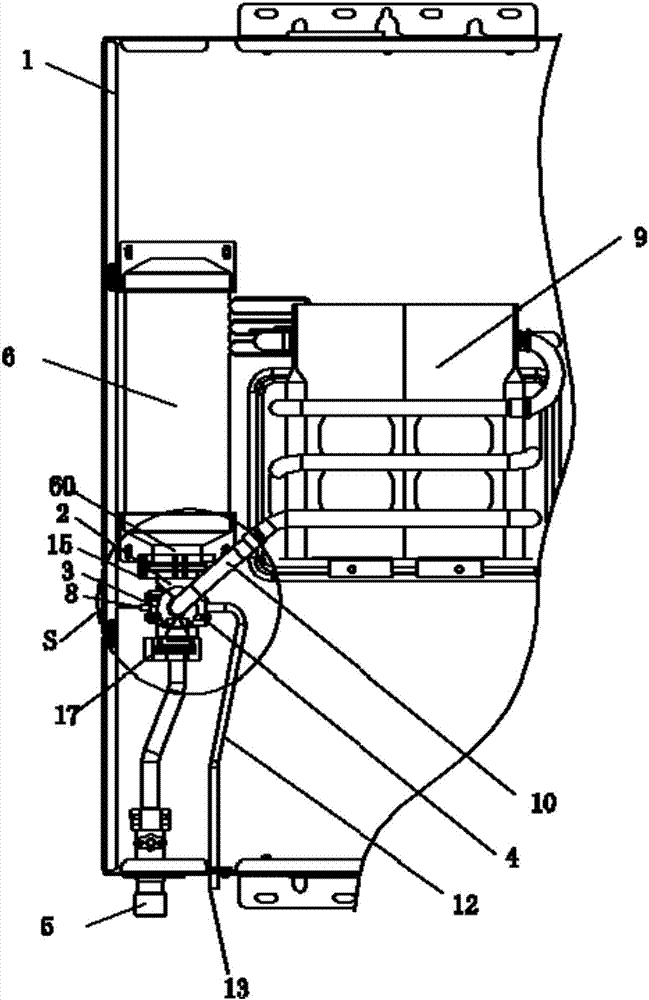

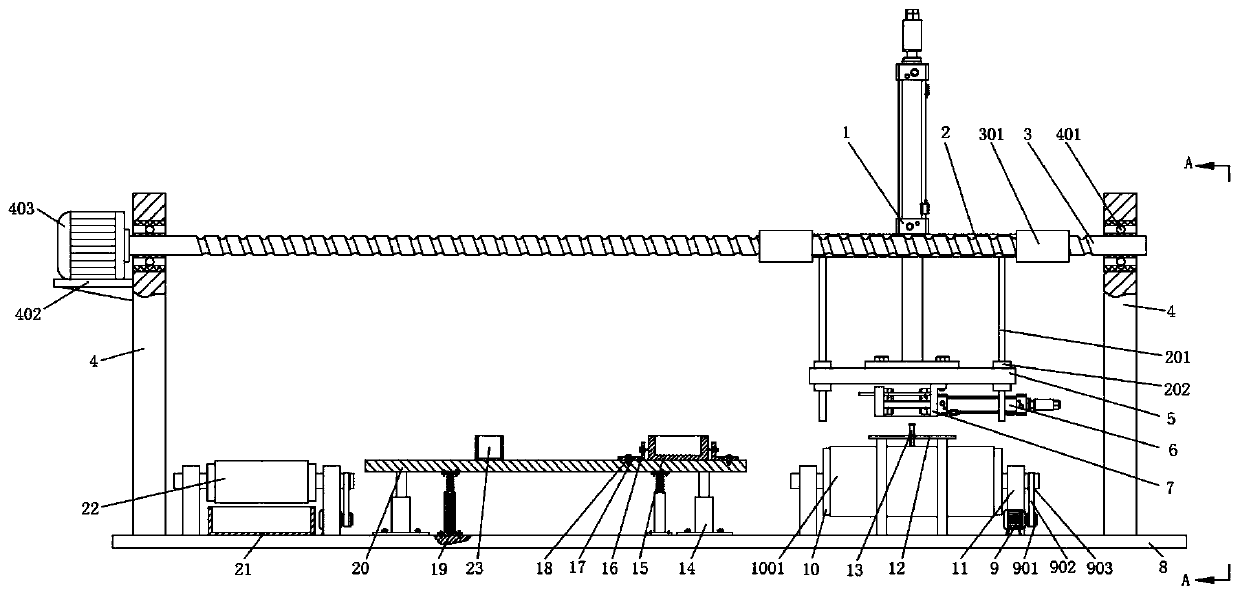

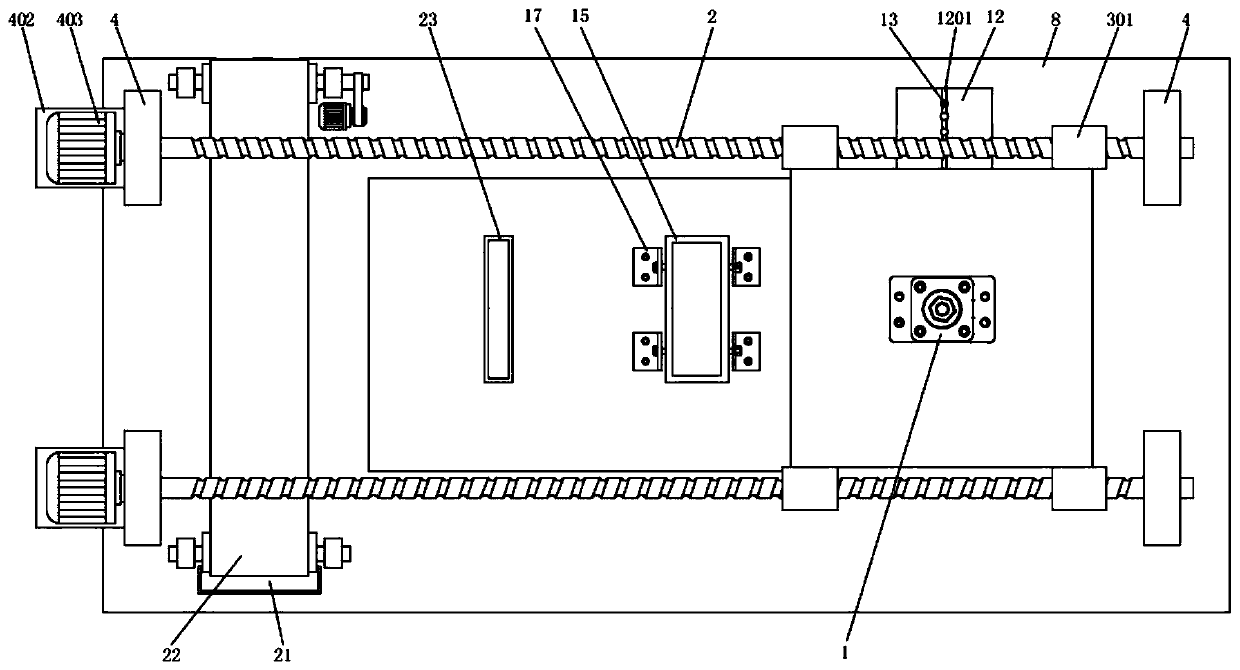

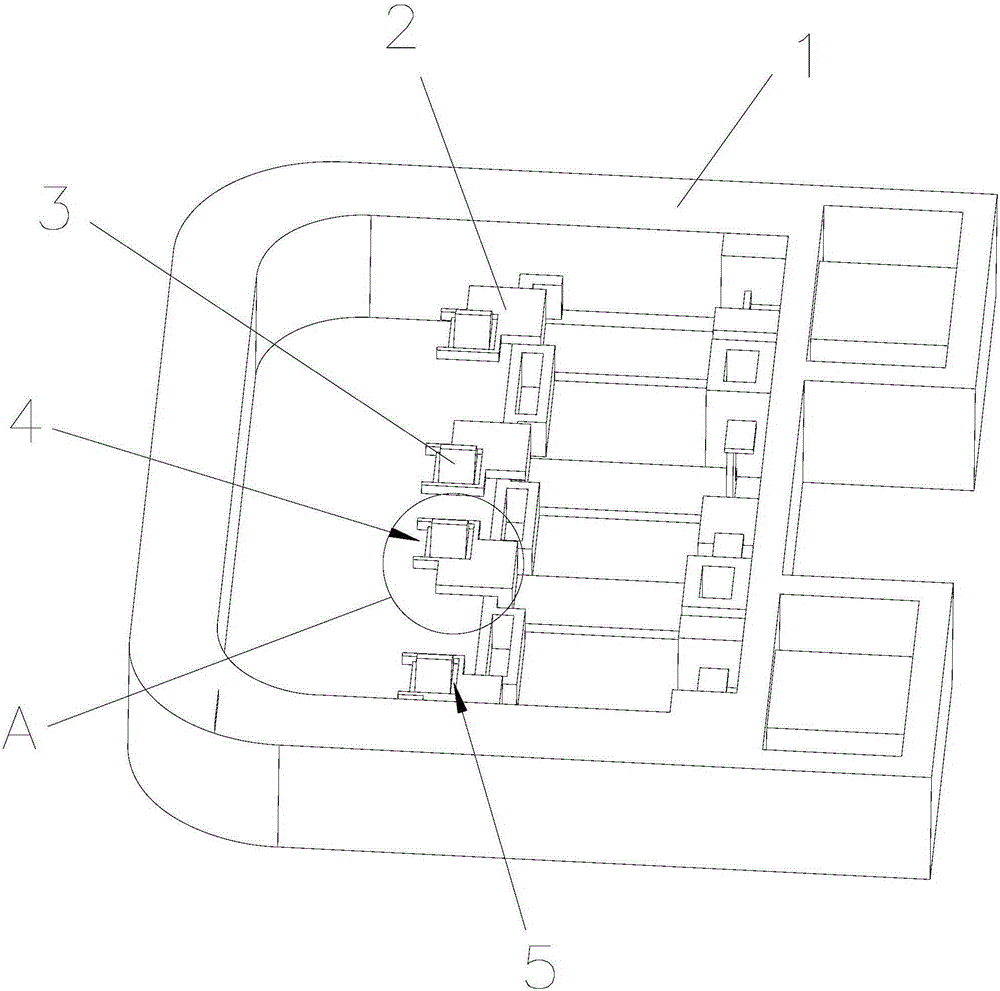

Automatic lead welding equipment for junction box of solar panel

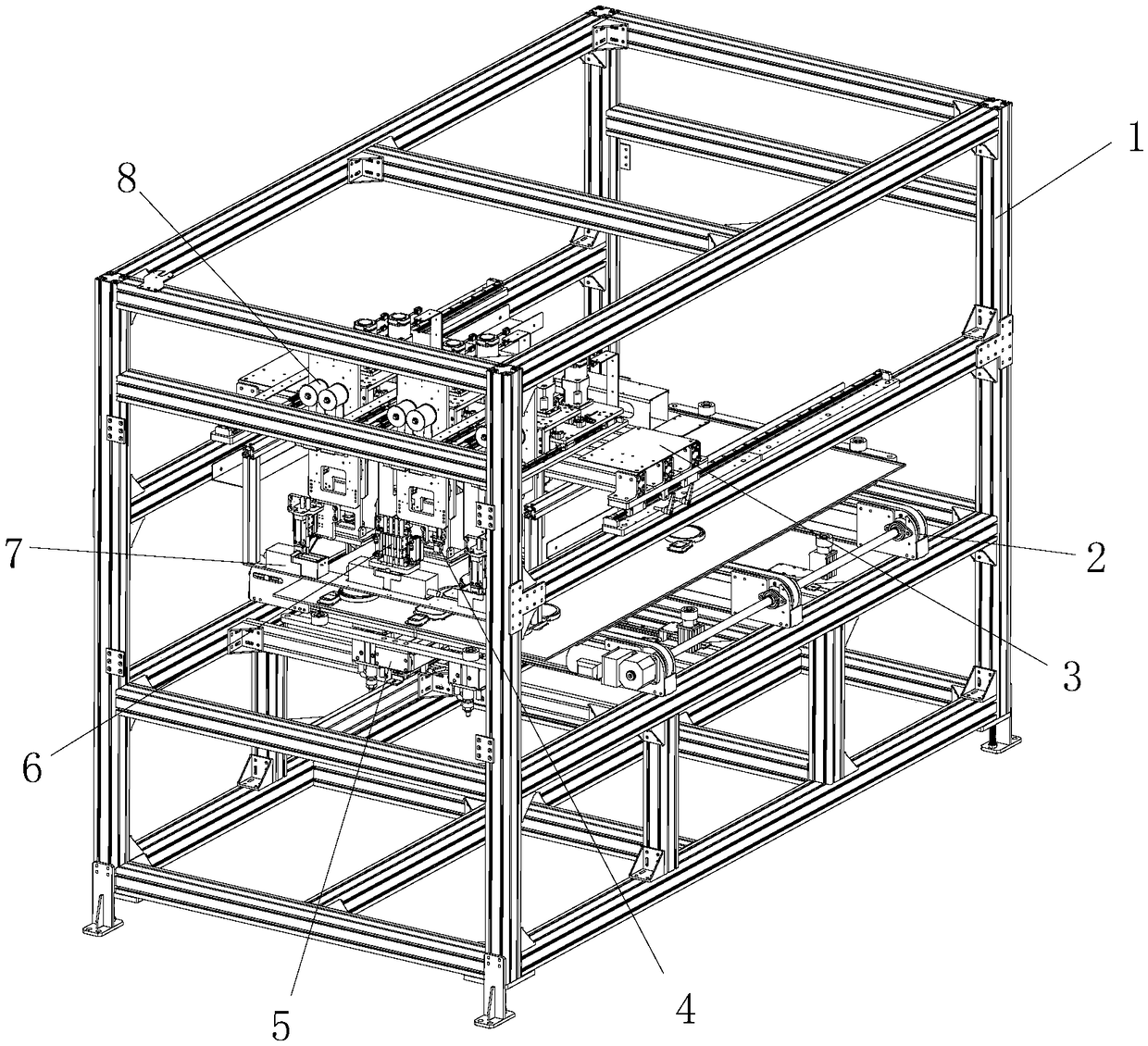

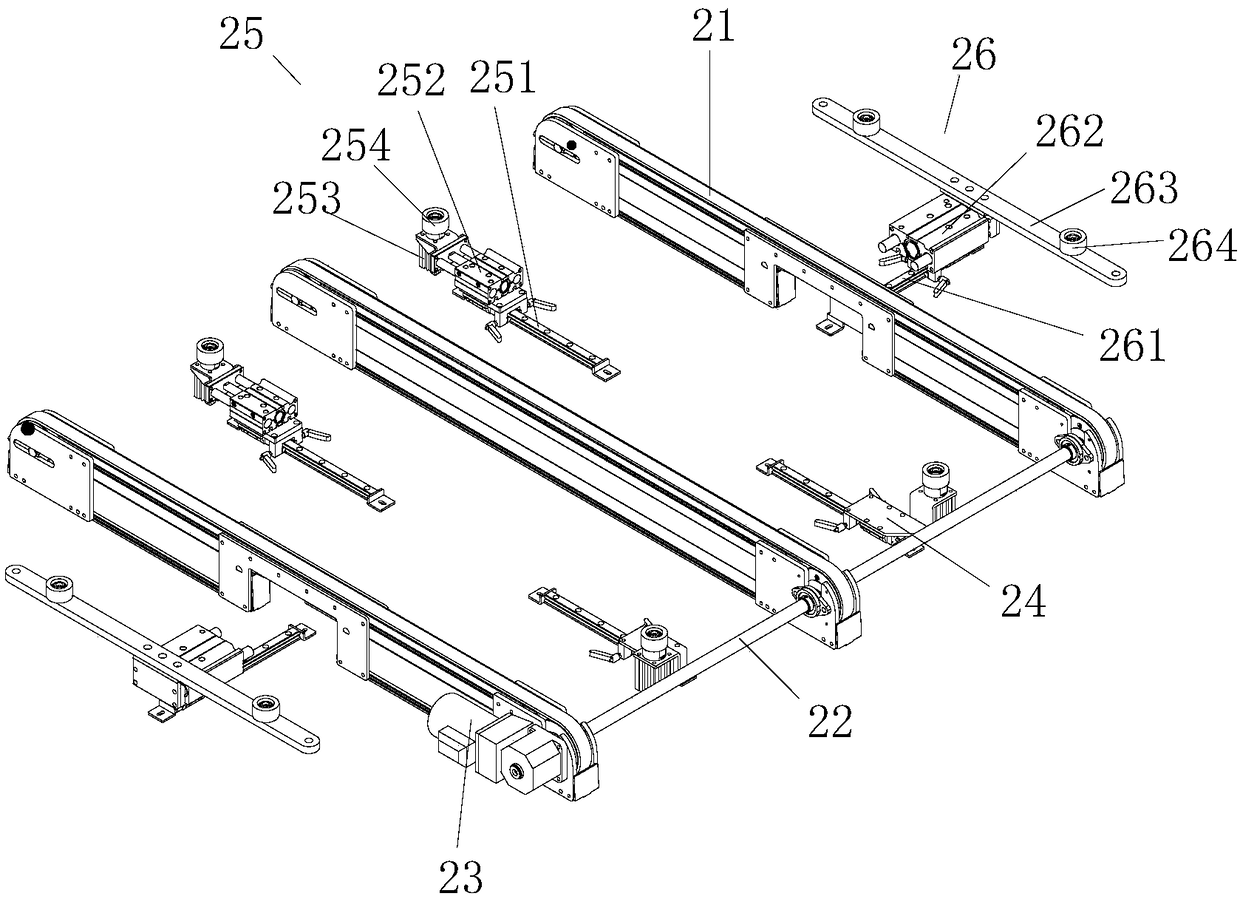

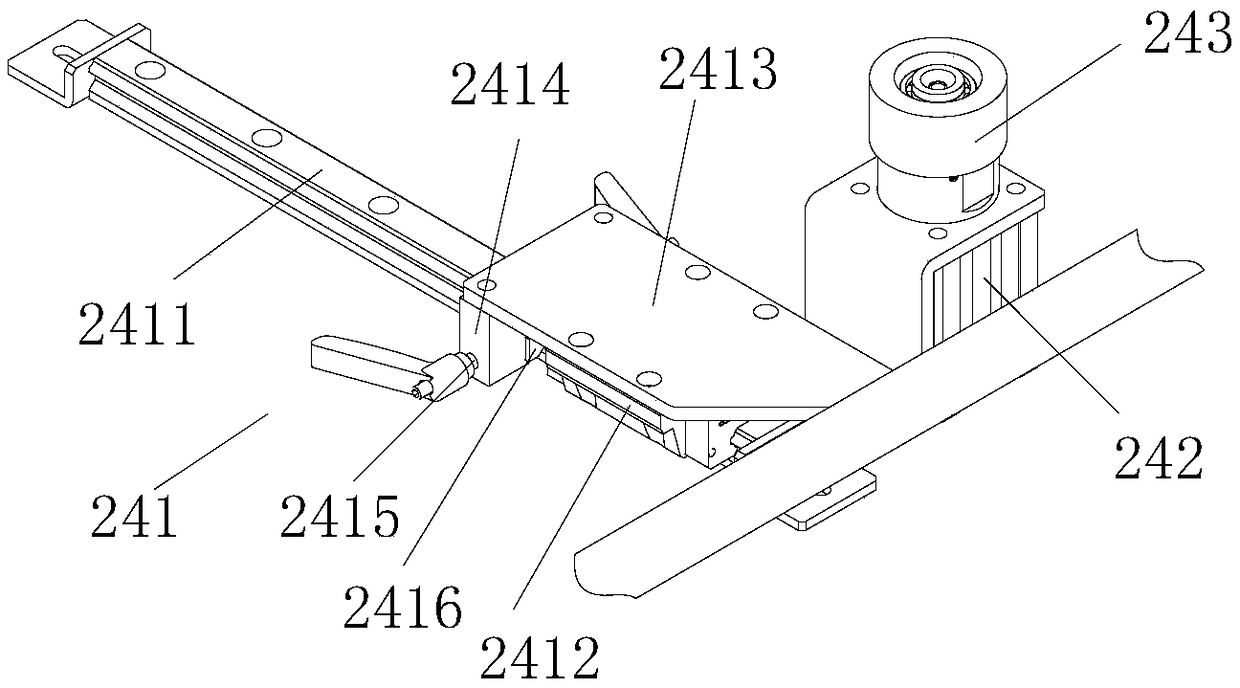

PendingCN109226924ACompact structureRun smoothlySoldering ironSoldering auxillary devicesSurface plateWelding

The invention discloses automatic lead welding equipment for a junction box of a solar panel. The automatic lead welding equipment for the junction box of the solar panel comprises a rack, a transmission device, an auxiliary supporting device, a moving platform, a horizontal guide mechanism, a Z-axis guide mechanism, a welding head mechanism and a pressing device, and the auxiliary supporting device, the transmission device and the moving platform are fixed to the rack from top to bottom in sequence; the horizontal guide mechanism is installed on a moving shelf of the moving platform, the Z-axis guide mechanism is installed on a Y-direction guide assembly push plate of the horizontal guide mechanism, the welding head mechanism is installed on a Z-direction guide assembly push plate of theZ-axis guide mechanism, and the pressing device is installed on a locating plate of the Z-axis guide mechanism. Through the mode, the automatic lead welding equipment is compact in structure and steady in running, a floating assembly sufficiently guarantees the welding quality, and the pesudo welding phenomenon generated during welding is avoided; a welding pencil cleaning device conducts automatic cleaning, the cleanliness of the welding position is guaranteed, the cleaning time is saved, and the welding quality is also guaranteed.

Owner:苏州晟成智能装备有限公司

Voltage-withstanding motor end cover and manufacturing method thereof

PendingCN111600415AImprove structural strengthImprove pressure resistanceSupports/enclosures/casingsElectric machineStructural engineering

The invention discloses a voltage-withstanding motor end cover and a manufacturing method thereof. Which comprises a body, wherein the body comprises a bearing chamber and a mounting base, a mountinghole is formed in the center of the mounting base, the bearing chamber is located above the mounting hole, the bearing chamber comprises a cylindrical cavity and a bearing hole, the bearing hole is formed in the top of the cavity, the bearing hole and the mounting hole are concentrically formed, and reinforcing assemblies are further circumferentially distributed on the outer side wall of the bearing chamber and fixedly connected with the mounting base; the method comprises the following steps: a, early-stage preparation; b, assembling a bearing chamber and a clamping part; c, connection between the bearing chamber and the mounting base; d, overturning the mounting base; and e, the clamping part is installed. Through the arrangement of the reinforcing assembly, the structural strength of connection between the bearing chamber and the mounting base is improved, so that the pressure resistance of the motor is improved, the motor is prevented from being damaged, and the service life of the motor is prolonged.

Owner:SHENGZHOU ZHENGDE ELECTRIC MOTOR CO LTD

A technology for bon a dual-row QFN integrated circuit

InactiveCN109152231AReduce volumeIncrease the tin climb heightPrinted circuit assemblingConductive pattern formationPeak valueEngineering

The invention relates to a welding process of a dual-row QFN integrated circuit, Circuit board weld field, The process comprises the following steps: S1) screen printing: brushing solder paste on thebonding pad of the circuit board by a screen printer, wherein the ratio of the area of the aperture in the fine pitch area to the area of the bonding pad of the circuit board is 0.85 to 0.95, the thickness of the steel plate is 0.09 to 0.11 mm, and the ratio of the thickness of the fine pitch area to the thickness of the steel plate is 0.85 to 0.95; The printing speed of screen printer is 30-40mm / s, the pressure of front and back scraper is 2.5-3.5 kg, the demoulding length is 1.4-1.6 mm, and the demoulding speed is 0.4-0.6 mm / s. 2) mount: mounting with a mount machine; S3) reflow soldering: reflow soldering is carried out by using a reflow soldering equipment, wherein the temperature peak value of the reflow soldering is 240 + / - 5 DEG C, the reflow time when the temperature is higher than217 DEG C is 30 to 60 seconds, and the temperature rise slope is less than or equal to 3 DEG C / s; S4) testing: testing the soldering quality and assembly quality of the assembled circuit board; S5) repairing: repairing the circuit board which is detected to be out of order, so as to improve the qualification rate of the double-row QFN integrated circuit.

Owner:成都京蓉伟业电子有限公司

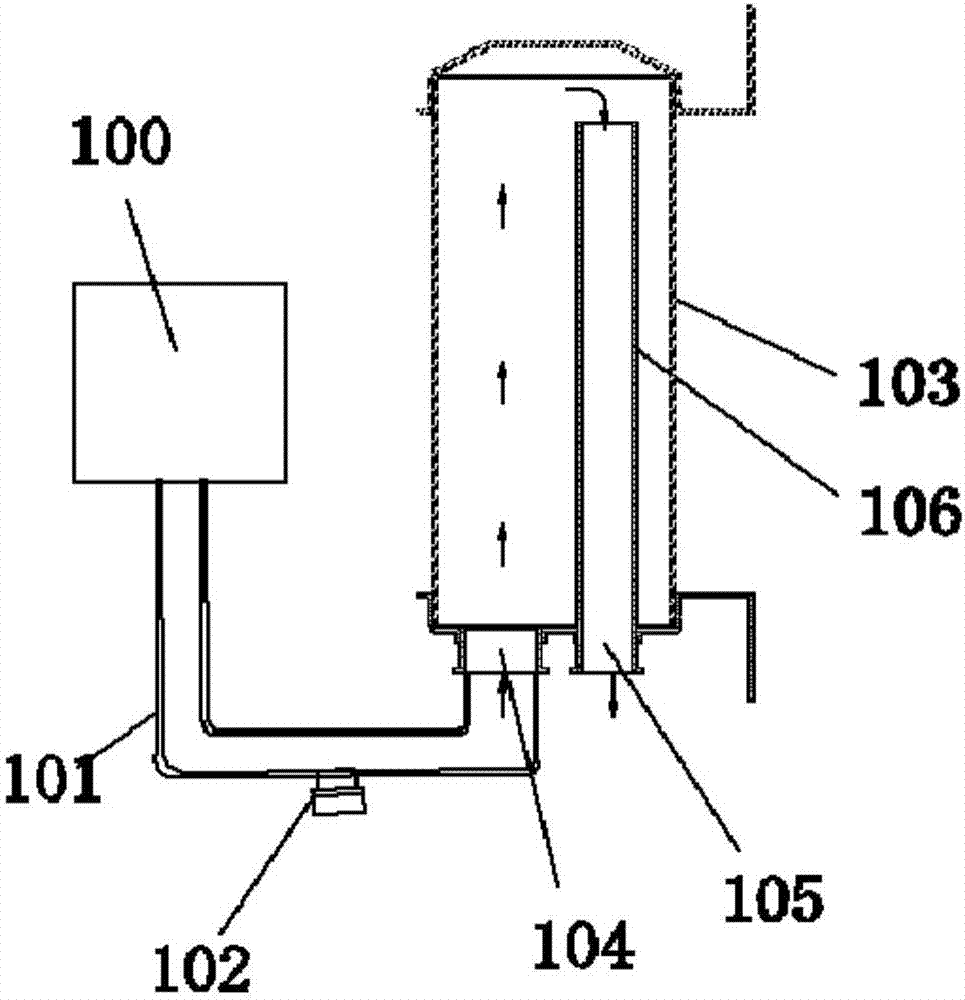

Water inlet and outlet connector and water heater

ActiveCN107166732AReduce the risk of water leakageReduce molding difficultyFluid heatersWater storageWater leakage

The invention discloses a water inlet and outlet connector. The water inlet and outlet connector comprises a connector main body and a temperature probe fixing base, wherein the connector main body is of a hollow structure, and the temperature probe fixing base and the connector main body are integrally formed; the connector main body is provided with a first pipe section, a second pipe section and a branch pipe section which communicate with one another; the pipe end of the first pipe section is provided with a first connector body; a first connecting hole communicating with the interior of the connector main body is formed in the first connector body; the pipe end of the second pipe section is provided with a second connector body; a second connecting hole communicating with the interior of the connector main body is formed in the second connector body; the pipe end of the branch pipe section is provided with a third connector body; a third connecting hole communicating with the interior of the connector main body is formed in the third connector body; and a temperature probe mounting hole communicating with the interior of the connector main body is formed in the temperature probe fixing base. The invention further provides a water heater. According to the water inlet and outlet connector and the water heater, the water leakage hidden danger of the water heater can be reduced, the reliability of the water heater can be improved, and the level of the forming difficulty of a water storage container of the water heater can be lowered.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

High-fidelity high-definition DP connector

PendingCN111430943AIncrease contact areaGuarantee welding qualityCoupling device detailsSoldered/welded conductive connectionsEngineeringStructural engineering

The invention discloses a high-fidelity and high-definition DP connector. The connector comprises a female connector and a male connector, a metal shell is arranged outside the female joint; a rubbercore is arranged in the metal shell; a mounting groove is formed in the outer end part of the female joint; a PIN terminal is arranged in the mounting groove; wherein the end part of the PIN terminalis provided with a lead, two sides of the female joint are provided with antiskid bulges, the female joint is internally provided with a through hole, the through hole is internally provided with a hook, the outer wall of the female joint is provided with a buckle, the other end of the female joint is provided with the male joint, and the outer wall of the end part of the male joint is provided with a fixing groove. The connector has the advantages that the U-shaped groove structure increases the contact area of the rubber core and the wire during welding, the soldering tin layer can avoid insufficient soldering, the welding quality of the wire is guaranteed, the data transmission quality is guaranteed, the hook design can conveniently connect and separate the male connector and the femaleconnector, and the connector is simple and convenient to use.

Owner:中山立杰精密器材有限公司

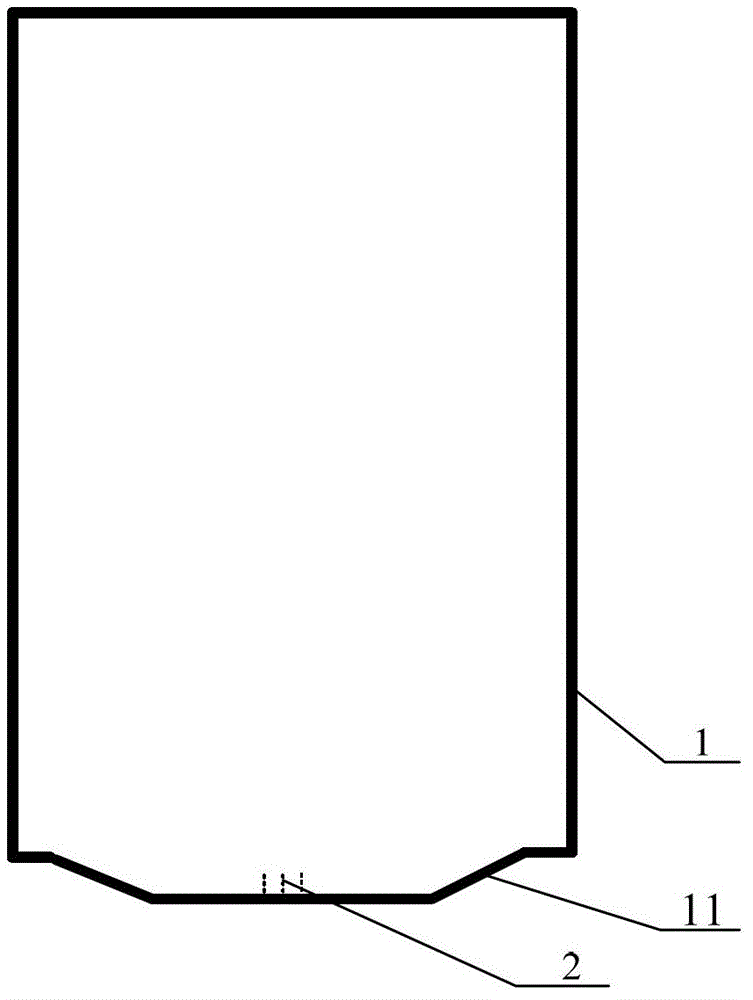

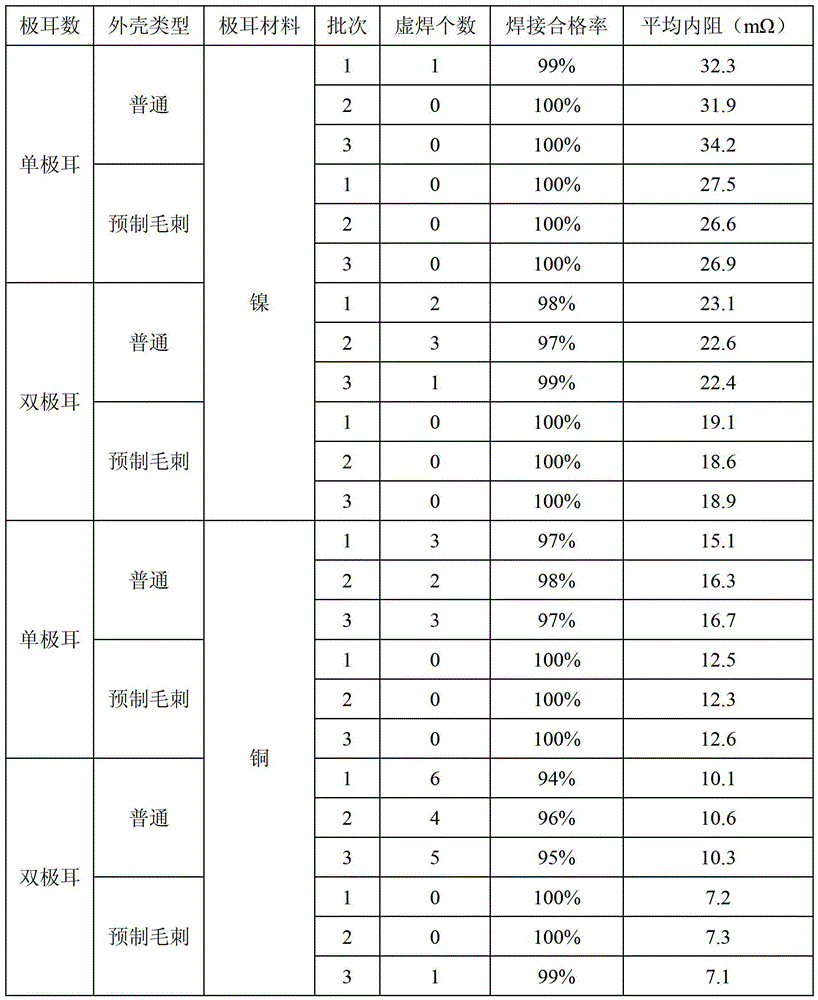

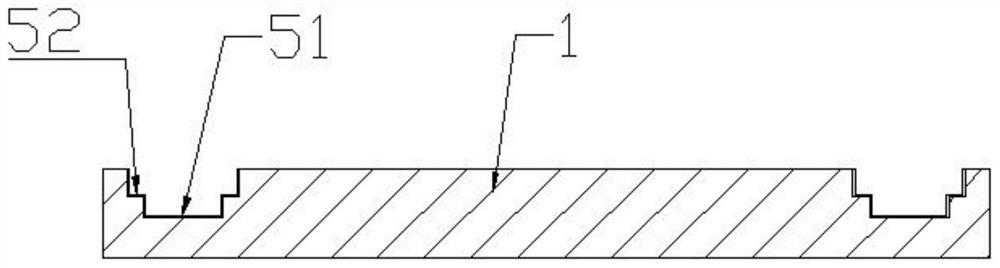

Lithium ion battery case with prefabricated burrs on bottom and lithium ion battery preparation method

InactiveCN103151473AEliminate virtual solderingAvoid Welding PhenomenonFinal product manufactureCell component detailsPunchingInternal resistance

The invention discloses a lithium ion battery case with prefabricated burrs on the bottom. The lithium ion battery case comprises a lithium ion battery case; and burrs are formed on one side of the bottom of the lithium ion battery case for being connected with tabs. By arranging the burrs on the bottom of the lithium ion battery case, cold solder occurring in the welding process of a multi-tab point bottom can be obviated effectively, and the welding strength between the lithium ion battery case and the multi-tab point bottom can be enhanced, thereby effectively reducing internal resistance and improving point bottom reliability of the lithium ion battery. The invention also discloses a lithium ion battery preparation method, which comprises the steps of prefabricating concave holes at the top end of a punch of a forming mold, molding by deep punching to obtain the lithium ion battery case with the prefabricated burrs, welding the lithium ion battery case with the tab point bottom, and carrying out subsequent treatment to obtain a lithium ion battery. The yield of the lithium ion battery can be improved greatly.

Owner:浙江铁鹰新能源科技有限公司

Tin soldering device for I-shaped inductor processing

InactiveCN110948077AAvoid pinchingPrevent the phenomenon of false weldingWelding/soldering/cutting articlesMetal working apparatusEngineeringInductor

The invention discloses a tin soldering device for I-shaped inductor processing. The device comprises a baseplate, wherein four supports are disposed at a fixed interval on the top of the baseplate; alead screw is disposed horizontally and horizontally disposed inside the supports in a rotatable manner; lead screw nuts are disposed at an interval on the lead screw; a supporting table is fixedly disposed on a side end of the lead screw nuts; a lifting air cylinder is disposed at the center of the upper surface of the supporting table; a telescopic end of the lifting air cylinder passes throughthe supporting table downwards and is fixedly connected to a lifting table; and a clamping mechanism is disposed on the lower surface of the lifting table. The device disclosed by the invention has the beneficial effects that tin soaking can be conducted on multiple I-shaped inductors at a time; during material fetching, clamping damage to the I-shaped inductors can be effectively prevented; processing quality and production efficiency are increased; and insufficient soldering caused by decrease of a soldering flux or a tin liquid can be prevented.

Owner:湖南碧建精密机械有限公司

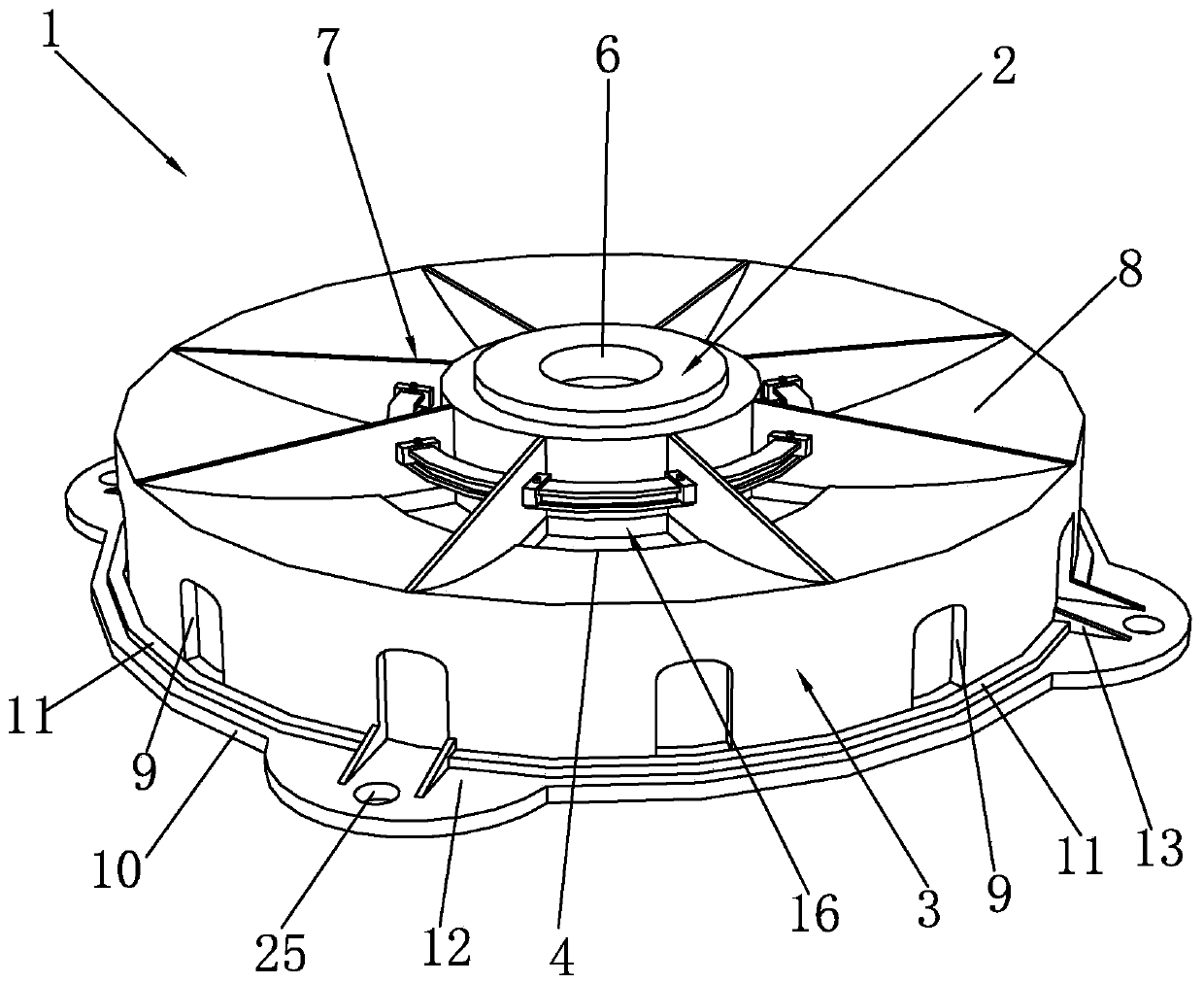

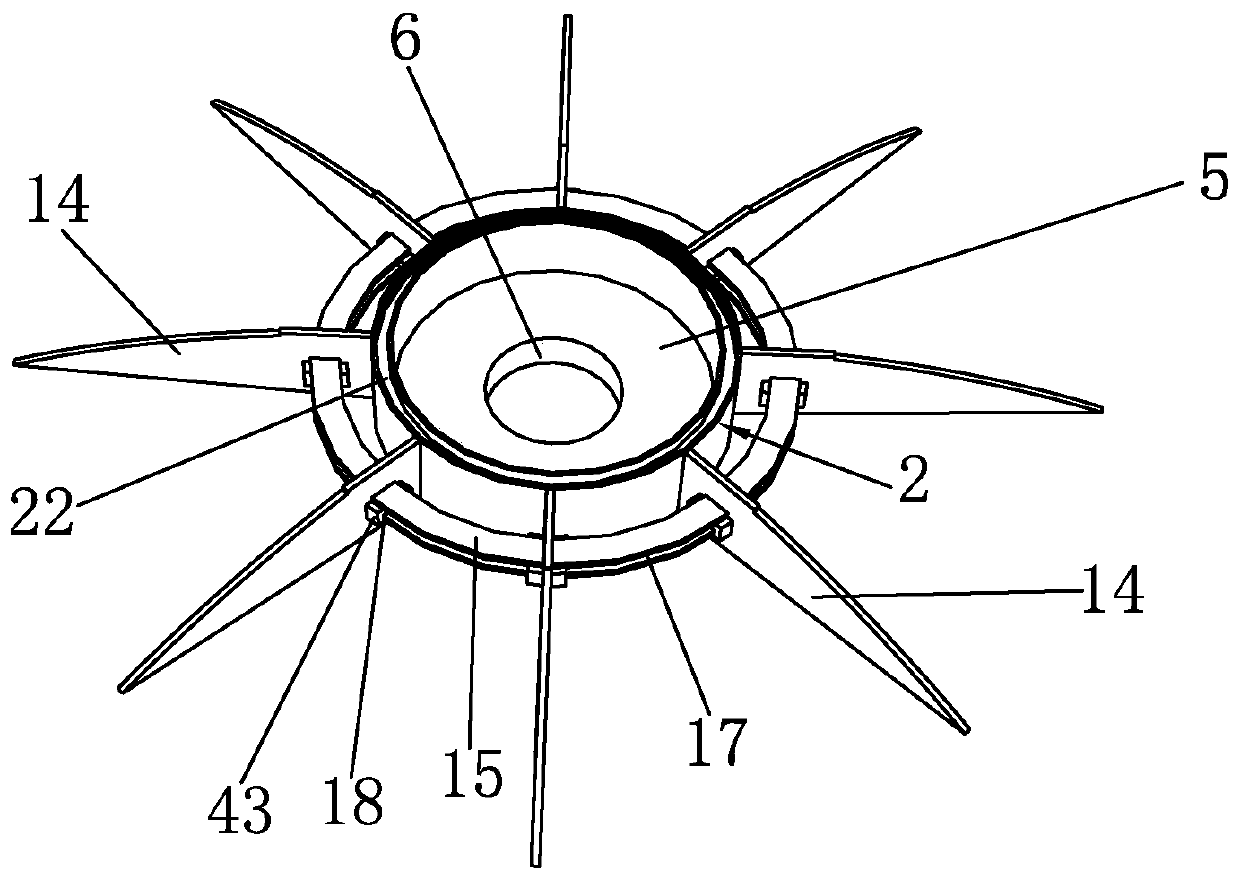

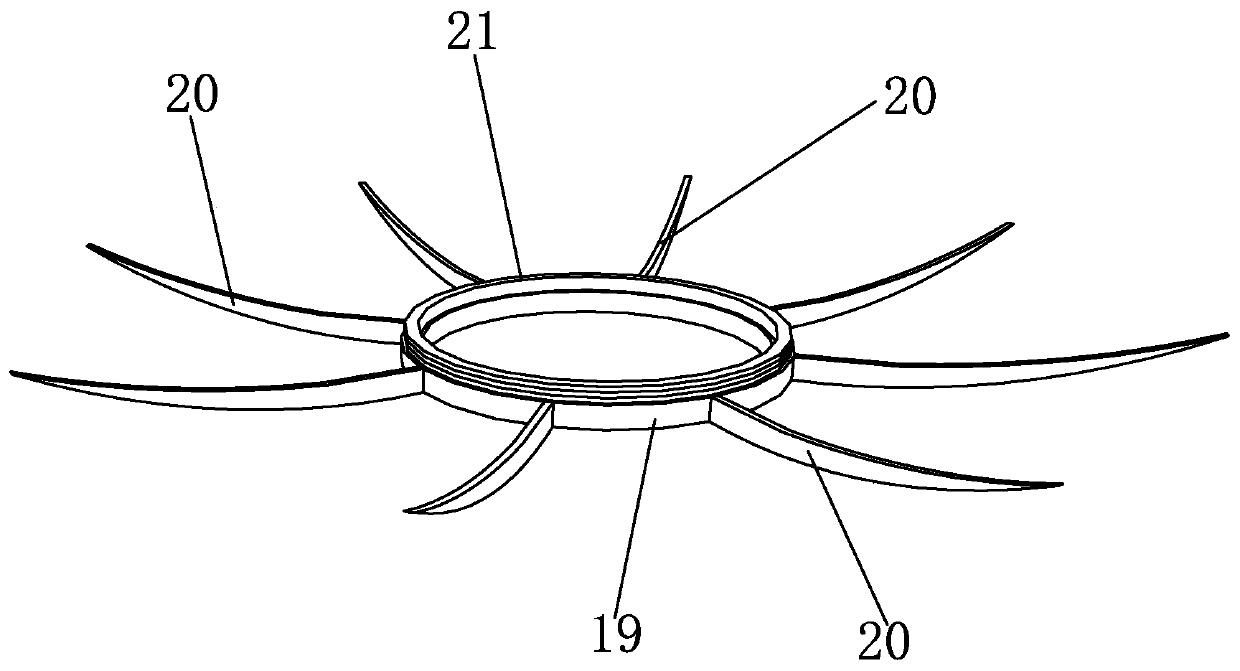

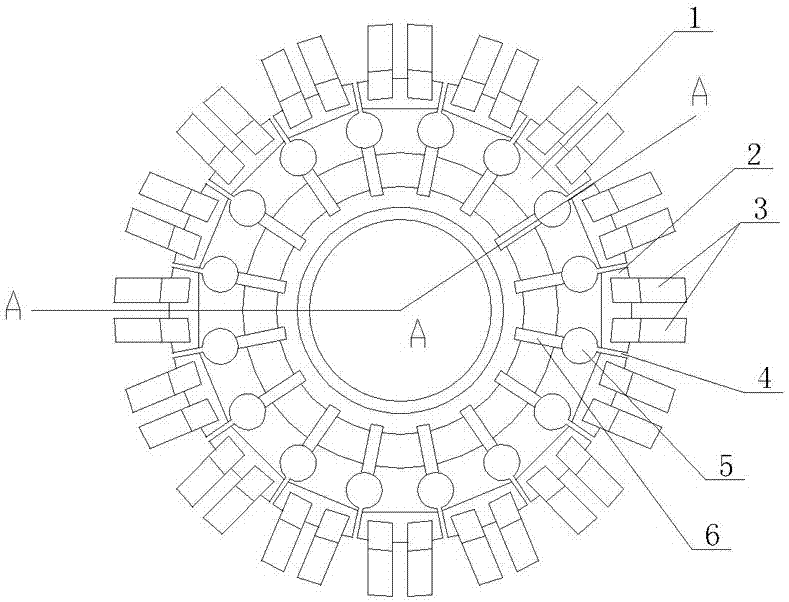

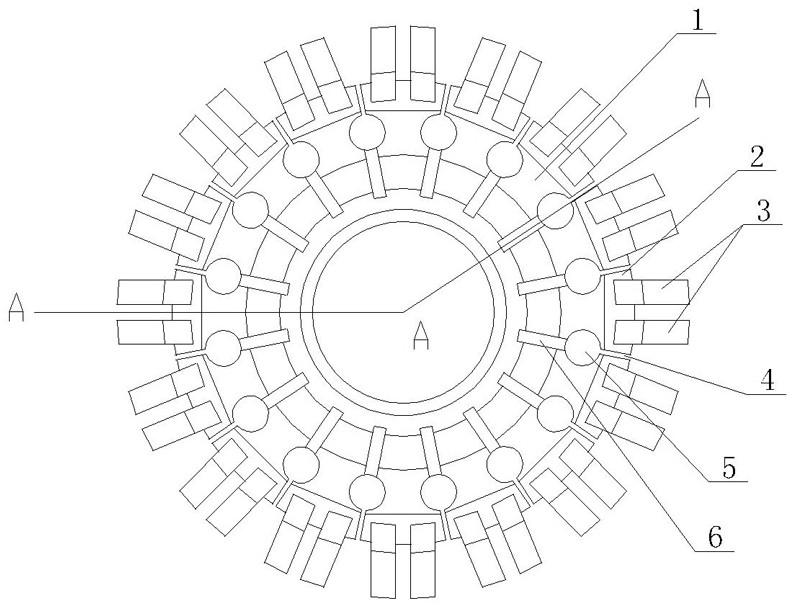

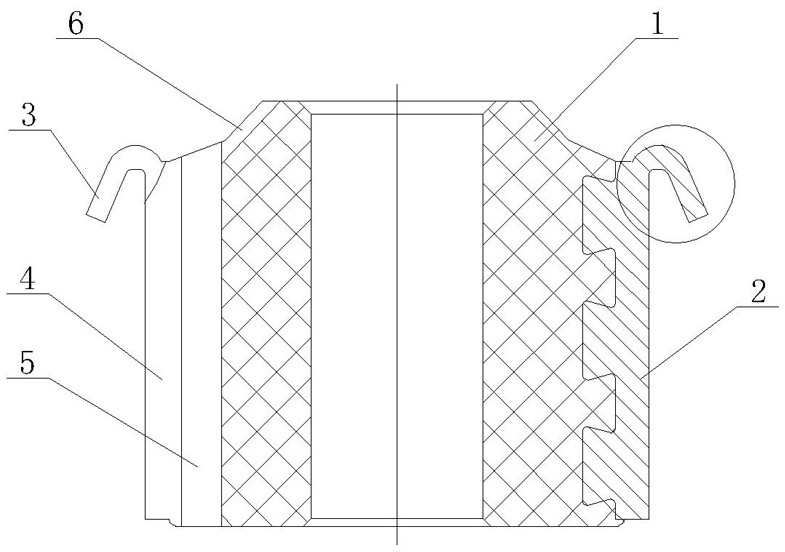

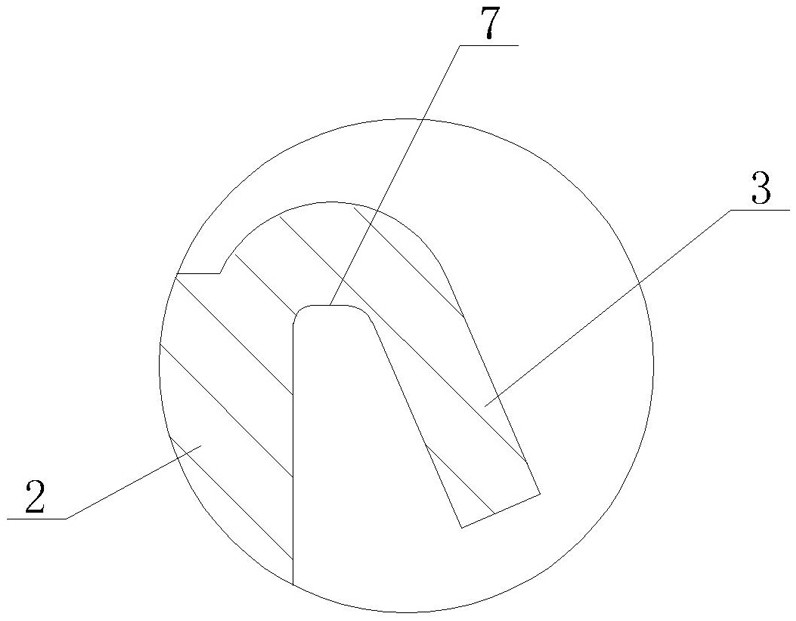

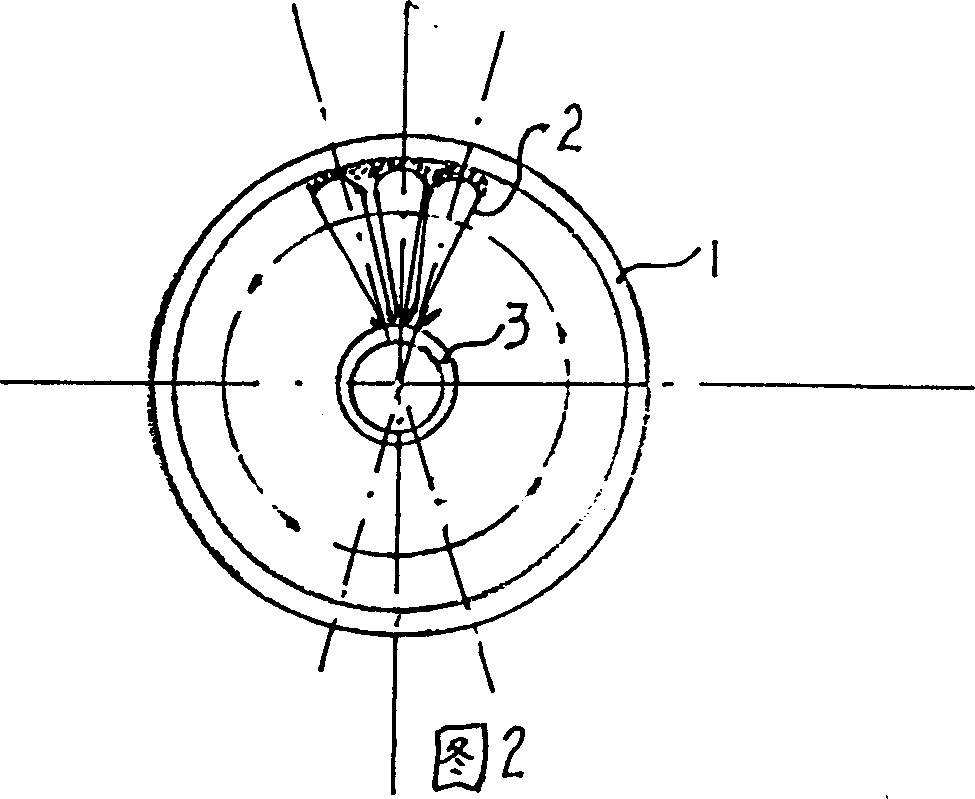

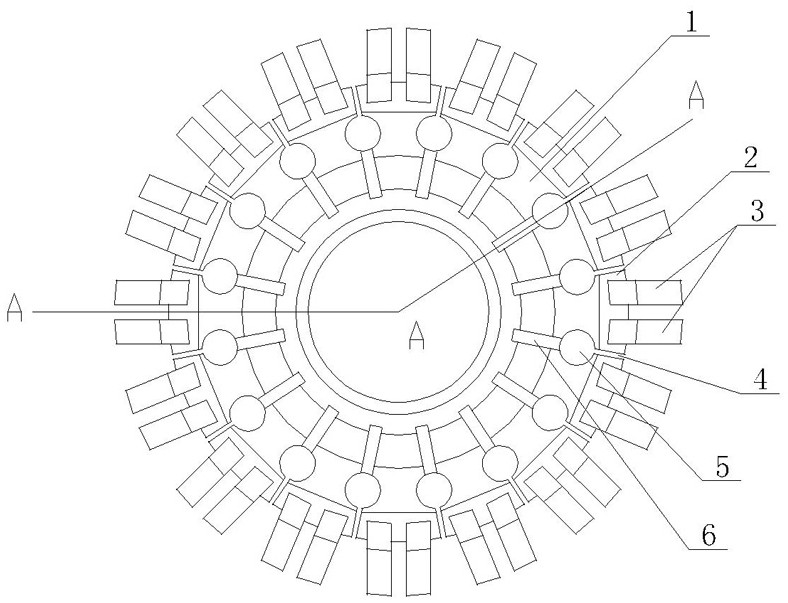

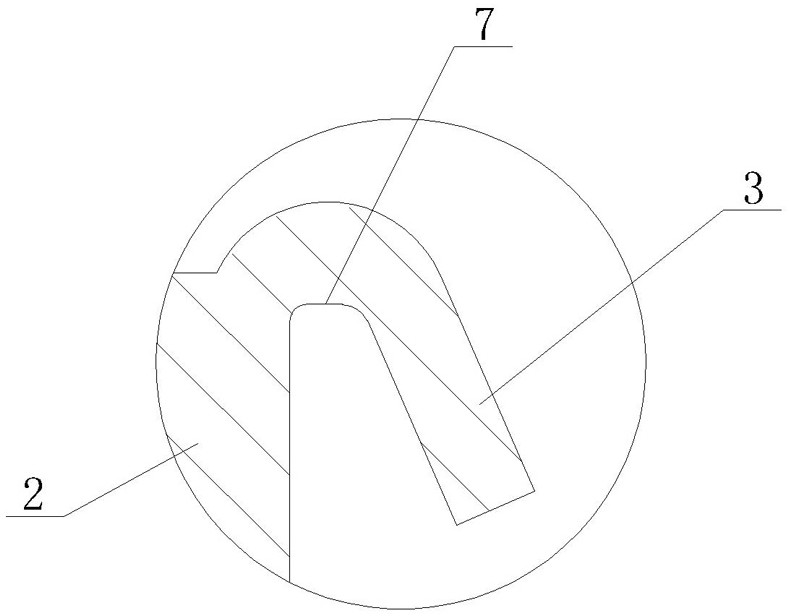

Hook type commutator

ActiveCN107968303AIncrease contact areaImprove bending strengthRotary current collectorDynamoelectric machine connectorsEngineeringElectrical and Electronics engineering

The invention discloses a hook type commutator. The hook type commutator comprises a substrate and commutator segments which are uniformly arranged on the outer circumference of the substrate, whereininsulation slots are formed among adjacent commutator segments for insulating. The hook type commutator is characterized in that the commutator segments have dual-hook designs; the top of each commutator segment is provided with two bonding wire hooks; the two bonding wire hooks are arranged side by side at a certain distance along the circumferential direction of each commutator segment; and molded surfaces of which two ends assume R angles and the middles are straight lines are molded on the tops of the hooks on inner sides of the bonding wire hooks. Through adoption of the hook type commutator, the problems of carbon deposition and pseudo soldering in the commutator can be solved completely, so that the two main factors of motor damage are eliminated; the service life of a motor is greatly prolonged and effectively ensured; and the production cost is low.

Owner:瑞安博宇科技股份有限公司

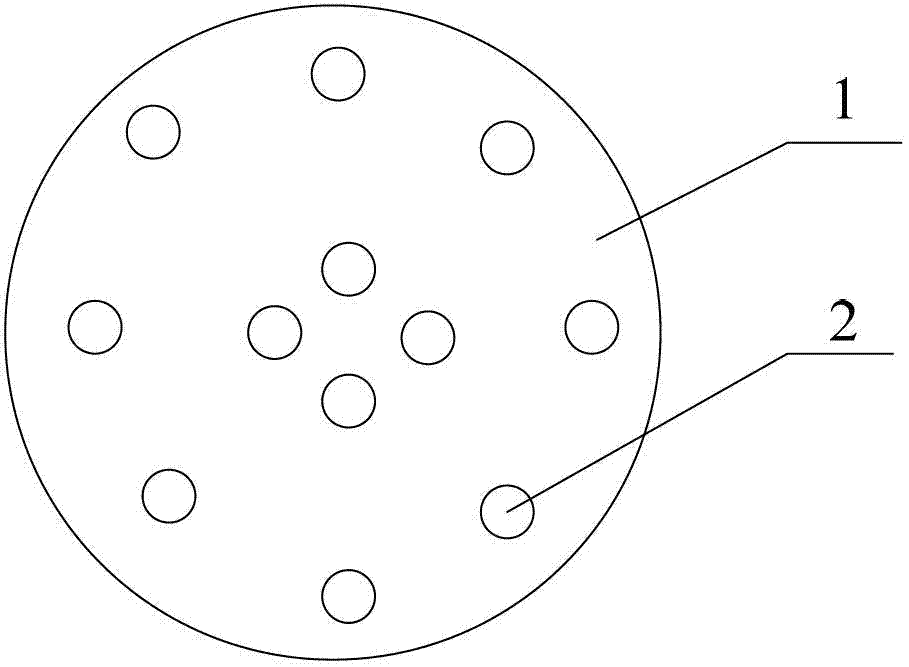

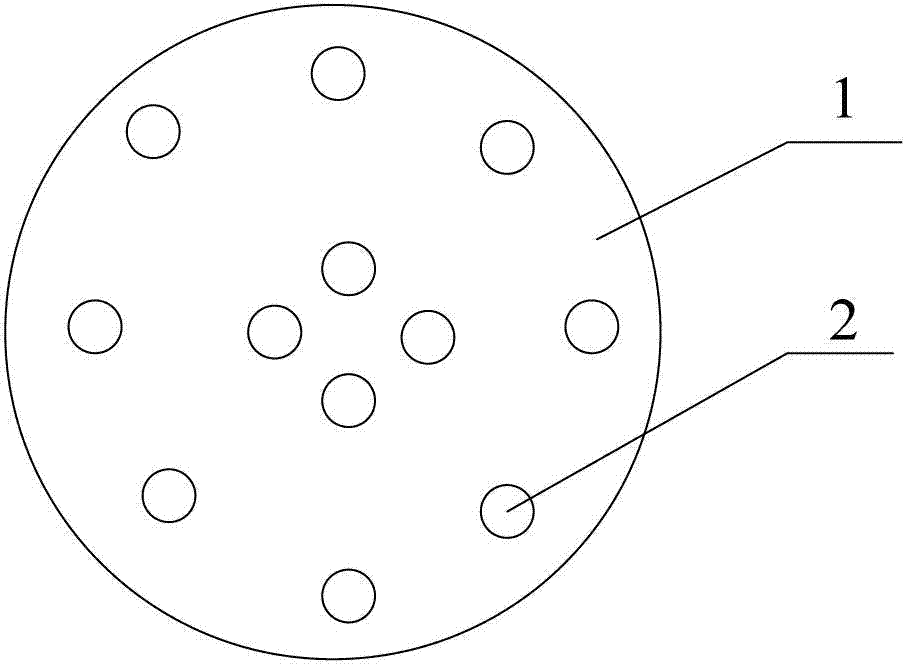

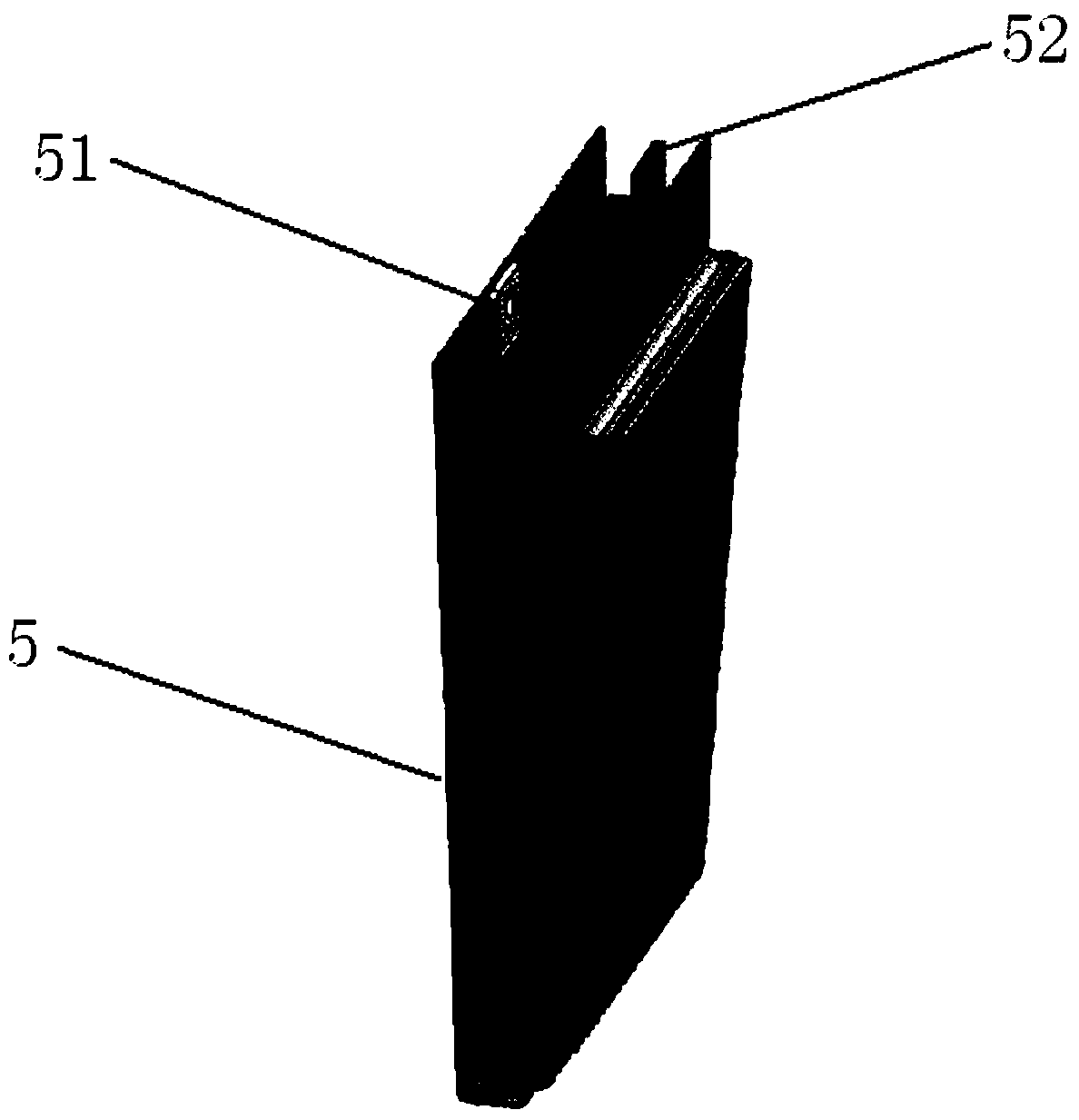

Lithium ion battery point bottom connecting piece and preparation method of lithium ion battery

InactiveCN103117370AAvoid Welding PhenomenonReduce virtual solderingCell component detailsInternal resistanceEngineering

The invention discloses an lithium ion battery point bottom connecting piece, which comprises a connecting substrate and burrs arranged at both sides of the connecting substrate. According to the invention, as burrs are arranged at the upper and lower surfaces of the connecting substrate, a large current generated in a welding process is discharged through the burrs, which can be effectively melted instantly, and electrode tabs and the lithium ion battery point bottom connecting piece, as well as the lithium ion battery point bottom connecting piece and the bottom of a lithium ion battery housing are firmly fused together, thus effectively overcoming the false welding phenomenon, improving the welding strength, and reducing the internal resistance, so the lithium ion battery point bottom connecting piece is highly efficient and reliable in performance. The invention also discloses a preparation method of a lithium ion battery. A nickel plated steel band is processed by a mechanical stamping method to form burrs on two surfaces; then stamping is carried out to obtain the lithium ion battery point bottom connecting piece; and then point bottom welding is carried out, and subsequent processing is performed to obtain a lithium ion battery, thereby greatly improving the yield.

Owner:浙江吉能电池科技有限公司

PCB composite board for PTC heater

PendingCN108832068AEasy to dissipate heatReduce electromagnetic interferenceSoldered/welded conductive connectionsCell component detailsElectrical and Electronics engineeringWelding

The invention discloses a PCB composite board for a PTC heater. The PCB composite board comprises a positive plate and a negative plate, wherein the positive plate is provided with a plurality of positive pole jacks, and the negative plate is provided with a plurality of negative pole jacks; the end part of the positive plate is provided with a positive wire welding end, and the end part of the negative plate is provided with a negative wire welding end; the positive wire welding end and the plurality of positive pole jacks are electrically connected through a positive printed circuit on the positive plate; the negative wire welding end and the plurality of negative pole jacks are electrically connected through a negative printed circuit on the negative plate; and the positive plate and the negative plate do not contact with each other. The PCB composite board provided by the invention improves the technical problems of poor heat dissipation performance, low safety, low yield and the like of conventional PCB boards, and has the characteristics of simple structure, good heat dissipation performance, high qualified rate of welding, good safety performance and the like.

Owner:芜湖黑特新能源汽车科技有限公司

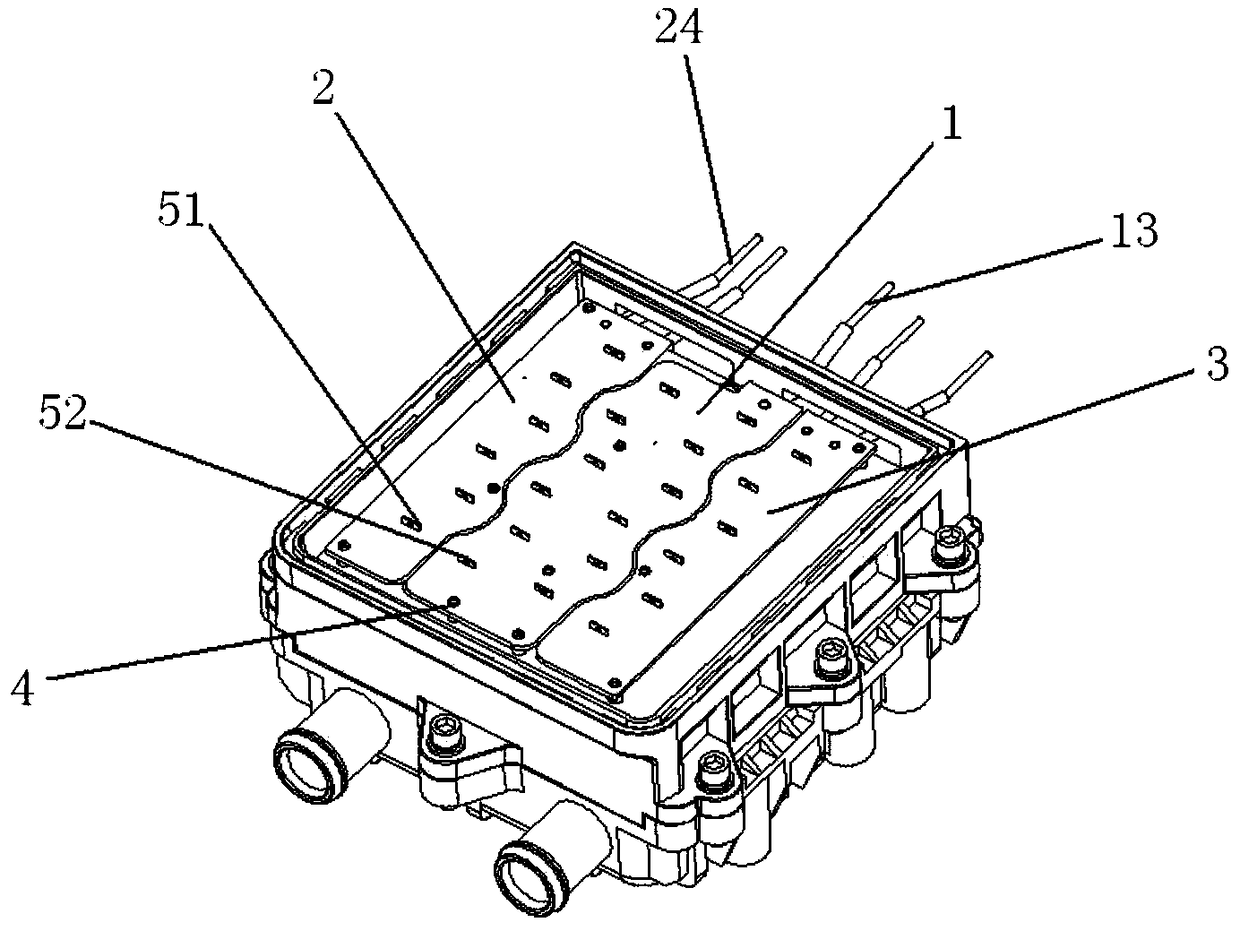

Solar photovoltaic assembly wiring box convenient to fix and reliable to weld

InactiveCN105187008AReduce the effective contact areaAvoid Welding PhenomenonPhotovoltaicsPhotovoltaic energy generationEngineeringTin

The invention relates to a solar photovoltaic assembly wiring box convenient to fix and reliable to weld. The solar photovoltaic assembly wiring box convenient to fix and reliable to weld comprises a wiring box body, wherein a metal piece leading-out wire is arranged in the wiring box body; the front end of the metal piece leading-out wire is provided with a groove and an opening; the opening is formed in the front end of the groove. The solar photovoltaic assembly wiring box convenient to fix and reliable to weld can be used for conveniently and fast clamping a welding belt at the opening of the metal piece leading-out wire for fixing the welding belt, so that the reduction of the effective contact area of the metal piece leading-out wire, caused by left-ring skewing of welding belt during welding, can be limited, and the rate that the welding belt breaks away from the metal piece leading-out wire is reduced; melt welding tin is encircled in the groove, and an insufficient welding phenomenon generated by a fact that the welding tin is melt to flow out from the periphery of the plane of the metal piece leading-out wire is avoided; one edge of the groove is communicated with the opening, the melt tin only can flow out from the opening end of the groove to be connected with the welding belt pasted on the opening end, so that the relatively reliable welding is achieved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

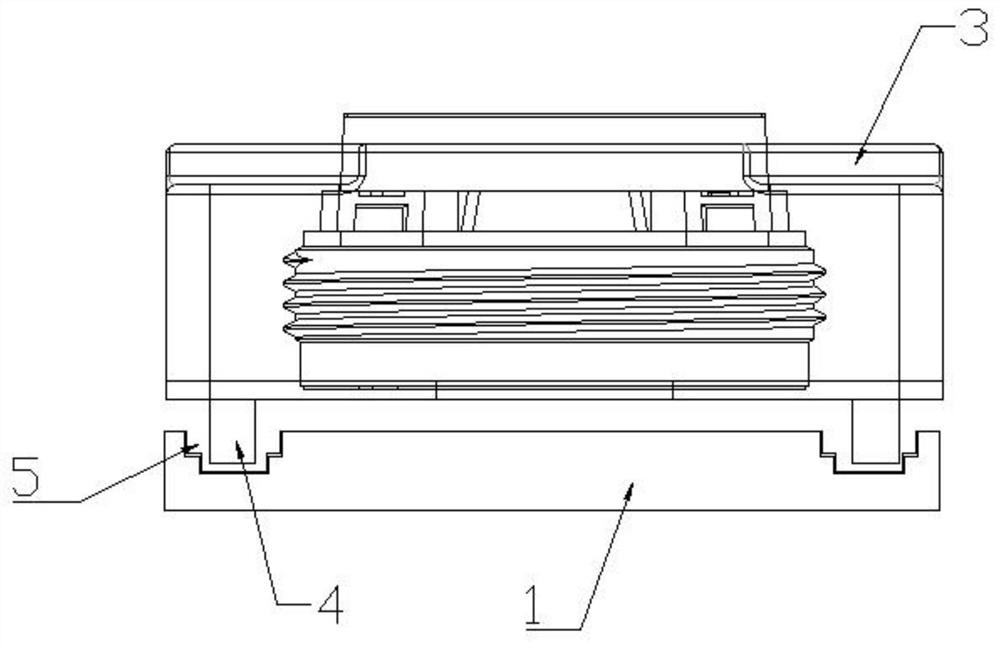

Suction nozzle for testing sorting machine

The invention discloses a suction nozzle for a testing sorting machine. The suction nozzle comprises a suction nozzle body, which comprises a suction nozzle rod and a suction nozzle head, wherein vacuum runners are formed in the centers of the suction nozzle rod and the suction nozzle head; a detachable positioning protecting device is arranged on the suction nozzle body and comprises positioning protecting rods which are arranged on the two sides of the suction nozzle body and are parallel to the suction nozzle body. The suction nozzle for the testing sorting machine is simple in structure and easy to manufacture; the pin transformation of a semiconductor device is effectively avoided; the suction nozzle rod is connected with the suction nozzle head through a connector; the suction nozzle has the advantages of short repairing time, high product quality, and the like, and the long service life of the suction nozzle head is long; the suction nozzle is worthy of wide popularization.

Owner:GUILIN STRONG MICROELECTRONICS

A hook type commutator

ActiveCN107968303BIncrease contact areaImprove bending strengthRotary current collectorDynamoelectric machine connectorsElectric machineCarbon deposit

The invention discloses a hook-type commutator, which comprises a base body and commutation segments uniformly arranged on the outer circumference of the base body, insulating grooves are provided between adjacent commutation segments for insulation, and the feature is that the commutation segments have double hooks Design, there are two welding wire hooks on the top of each commutator piece, and the two welding wire hooks are arranged side by side along the circumferential direction of the commutator piece and separated from each other by a certain distance; the inner side of the welding wire hook is formed at the top of the hook. Forming surface with R angle at both ends and straight line in the middle. The invention can completely solve the problems of carbon deposition and virtual welding in the commutator, thereby eliminating the two most important factors of motor damage, greatly improving and effectively ensuring the service life of the motor, and low production cost.

Owner:瑞安博宇科技股份有限公司

A kind of photovoltaic ribbon and preparation method thereof

ActiveCN107591460BLow resistivityImprove conductivityPhotovoltaic energy generationSemiconductor devicesAlloySoldering

Owner:XIAN TELISON NEW MATERIAL

Power socket demultiplexer

InactiveCN102842770AReduce manufacturing costAvoid Welding PhenomenonCoupling contact membersRiveted connectionsSolderingPrinted circuit board

The invention relates to a power socket demultiplexer which comprises a base and a cover. The base is connected with the cover; a terminal riveting wire assembly is arranged in the base; the terminal riveting wire assembly comprises an upper terminal, a lower terminal and a wire; the front sides and the rear sides of the upper terminal and the lower terminal are respectively provided with a plurality of pairs of inserted pins; the upper terminal and the lower terminal are respectively provided with terminal wire riveting ports; the wire is connected with the corresponding terminal wire riveting ports; base inserted pin placement grooves are arranged at four edges of the base; a base wire outlet is arranged at the left side of the base; the inserted pins are positioned in the base inserted pin placement grooves; and the wire is positioned in the base wire outlet. The power socket demultiplexer has the beneficial effects that the unique terminal riveting wire structure assembly replaces a PCB (printed circuit board) assembly with a complex process, the production cost is reduced and the terminal is of an integrated structure, so that the pseudo soldering phenomenon which is possibly generated due to welding in the prior art is avoided and the excellent and stable conduction performance is ensured; and by the positioning matching of a terminal positioning hole and a base positioning pillar, the assembling process is simpler, the assembling effect is better and the quality is more stable.

Owner:NINGBO CONNFLY ELECTRONIC CO LTD

A welding method for dual-interface smart card

ActiveCN106670613BAvoid Welding PhenomenonImprove welding reliabilityWelding/soldering/cutting articlesMetal working apparatusSmart cardEngineering

Disclosed is a welding method of a dual-interface smart card. The dual-interface smart card comprises a metal antenna, a module groove and welding grooves. The welding method is characterized by comprising the steps that tinned wire tubes which are spiral through winding are placed in the two welding grooves respectively, wherein the thickness of a tinned layer on the surface of each tinned wire tube ranges from 0.05mm to 0.15mm; and the high temperature ranging from 180 DEG C to 190DEG C is applied to the surface of a dual-interface module, and the heat is transferred to the tinned wire tubes to melt soldering tin on the surfaces of the tinned wire tubes, so that connection between dual-interface module welding pads and an antenna welding pad is achieved. According to the welding method of the dual-interface smart card, due to the fact that the tinned wire tubes serve as welding intermediate media, the problems that in the prior art, the stability is low, the rejection rate is relatively high, and hot compression deformation is obvious in the dual-interface smart card production process are solved, the time of the whole welding process is short, welding spots formed after welding are smooth, and the smart card is low in card body deformation and more attractive in appearance.

Owner:SHANGHAI CHINA CARD SMART CARD CO LTD

Photovoltaic solder strip and preparation method therefor

ActiveCN107591460ALow resistivityImprove conductivityPhotovoltaic energy generationSemiconductor devicesSurface layerAlloy

The invention discloses a photovoltaic solder strip and a preparation method therefor. The photovoltaic solder strip comprises a base material and a tin lead alloy solder coated on the base material;and the tin lead alloy solder comprises 0.05-0.5% of copper, 0.1-1% of silver and 0.01-0.05% of phosphorus. By virtue of the copper, silver and phosphorus elements added to the tin lead alloy solder,the oxidization resistance, the wettability and release force intensity of the photovoltaic solder strip can be improved; meanwhile, the resistivity of the photovoltaic solder strip is lowered by 9.8%, equivalently, the power of a photovoltaic assembly is improved by about 0.8W, so that loss of photoelectric conversion efficiency caused by loss of resistance power can be lowered; the copper, silver and phosphorus elements have relatively high intermiscibility, so that corrosion of a tin liquid to the added copper and silver elements can be suppressed, and a phenomenon of insufficient solder ofthe battery piece can be avoided; the surface layer of the photovoltaic solder strip is rich in phosphorus-tin alloy, so that an effect of lowering the partial temperature of a soldering point in battery piece soldering also can be played, thereby facilitating soldering; and in addition, the photovoltaic solder strip has simple preparation method, low cost, easy operation and implementation, no environmental pollution, and convenience in realizing industrial production and application.

Owner:XIAN TELISON NEW MATERIAL

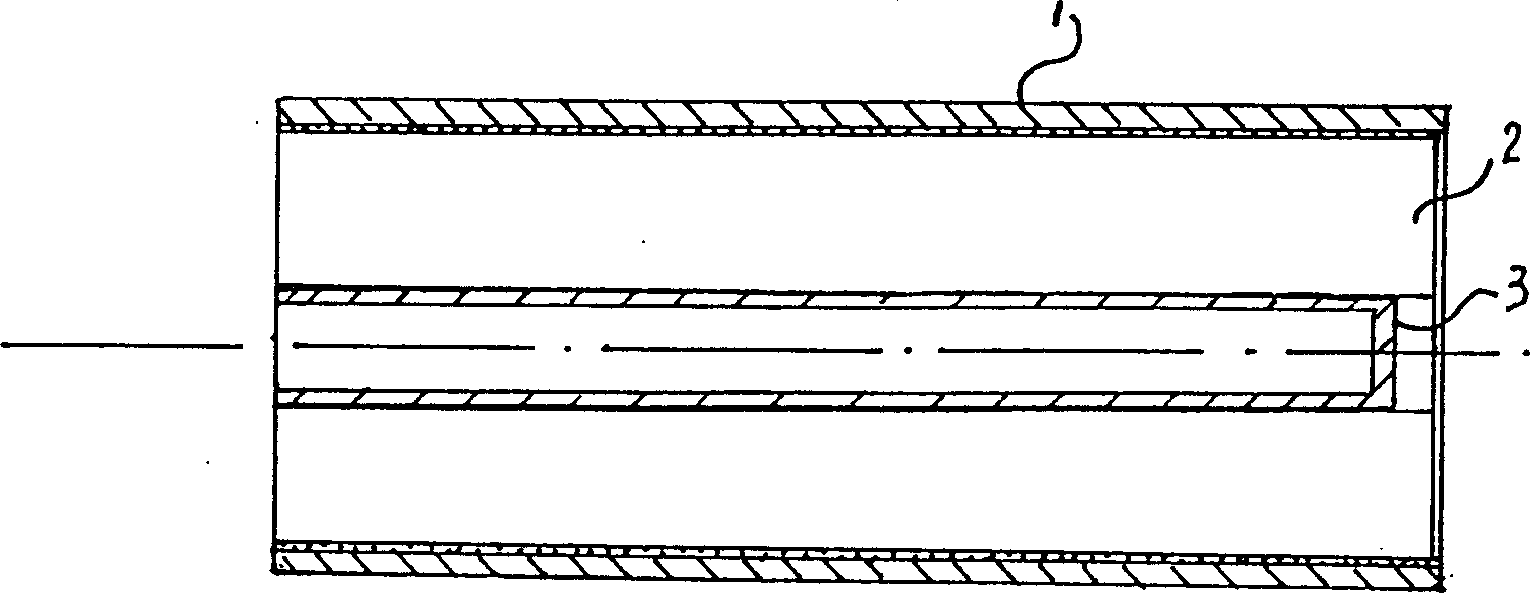

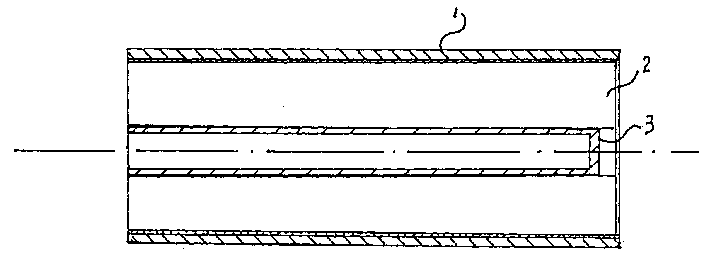

Method for manufacturing heat exchanging tube of heat exchanger

InactiveCN1141194CClose contactImprove heat transfer efficiencyIndirect heat exchangersTubular elementsEngineeringMachine tool

A method for making heat exchanging tube of heat exchanger includes cutting to obtain external tube, finned tube and core tube, welding the core tube in the finned tube, applying tin on the surface of finned tube, inserting it in external tube, reducing the diameter of end part of external tube, inserting it in a pipe reducing die, clamping one end of external tube by the chuck of machine-tool, pushing its another end by a pusher, and rotating the external tube which moving said pipe reducing die from one end to another end. Its advantages are high heat exchanging efficiency and high quality of product.

Owner:张书贵

hook commutator

ActiveCN107994434BImprove ventilationSolve the problem of carbon accumulationRotary current collectorElectric machineEngineering

The invention discloses a hook-type commutator, which includes a base body and commutation segments uniformly arranged on the outer circumference of the base body, insulating grooves are provided between adjacent commutation segments for insulation, and welding wire hooks are arranged on the top of the commutation segments , characterized in that: the inner side of the insulating groove is provided with an axial through groove, the axial through groove is arranged in the same direction as the insulating groove and runs through the upper and lower end faces of the base body, the upper end face of the base body has a slope, and a guide groove is opened on the slope to guide The upper end of the flow groove is open, and the lower end of the flow guide groove communicates with the axial through groove. The invention can completely solve the problems of carbon deposition and virtual welding in the commutator, thereby eliminating the two most important factors of motor damage, greatly improving and effectively ensuring the service life of the motor, and low production cost.

Owner:瑞安博宇科技股份有限公司

Duplex spot welding electrode

ActiveCN102581463BReduce the number of repairsAvoid Welding PhenomenonElectrode featuresNatural stateEngineering

The invention relates to a duplex spot welding electrode. Improvements are made on the basis of an electrode holder, a first electrode, a second electrode, a first guide pillar and a second guide pillar, namely an auxiliary block is fixed on the bottom surface of the electrode holder; two through holes are arranged in the auxiliary block; a sunken groove is arranged on the upper part of the auxiliary block, and is communicated with the two through holes; a sliding block is positioned in the sunken groove; each of the two lateral surfaces of the sliding block is provided with a downwardly inclined surface; a groove matched with the corresponding downwardly inclined surface of the sliding block is arranged on the lateral surface of each of the first and second guide pillars; a spring is arranged in each of mounting holes, and makes each of the first and second electrodes always tend to be exposed out of the electrode holder; and each spring is in a natural state, the sliding block is pressed against the grooves on the first and second guide pillars, and a gap is formed between the downwardly inclined surface on each of the two sides of the sliding block and each groove. The two electrodes can float and be automatically leveled, so that the two electrodes contact a workpiece with the same force, a pseudo soldering phenomenon is avoided, the number of overhauling times of the abraded electrode is decreased, the use cost is decreased, and the welding efficiency is improved.

Owner:北京敏实汽车零部件有限公司

Novel AF camera module motor PIN connection method

InactiveCN113542567APrevent overflowWill not cause a short circuitTelevision system detailsColor television detailsAdhesive glueCamera module

The invention discloses a novel AF camera module motor PIN connection method, which comprises the following steps: S1, hollowing the centers of VCM bonding pads on an FPC board to form a group of concave parts for the motor PINs on an AF camera module HOLDER to contact; S2, coating the surface of the motor PINs with a liquid conductive adhesive, and inserting the motor PINs into the concave parts of the VCM bonding pads; and S3, solidifying the liquid conductive adhesive by high-temperature heating to realize tight connection between the VCM bonding pads and the motor PINs. According to the method, the cost is saved, the rosin joints are avoided, and the product yield is improved. The hollowed-out bonding pads are designed in a stepped mode, excessive adhesive can overflow to the upper step of the hollowed-out bonding pads, and the conductive adhesive is prevented from overflowing to the board surface. The use amount of the conductive adhesive is controlled, the adhesive is drawn strictly according to the specified use amount, and excessive overflow of the conductive adhesive is prevented; and the FPC board surface around the bonding pads is coated with ink, so that the short circuit of the module cannot be caused even if a small amount of adhesive overflows.

Owner:武汉当代华路光电技术有限公司

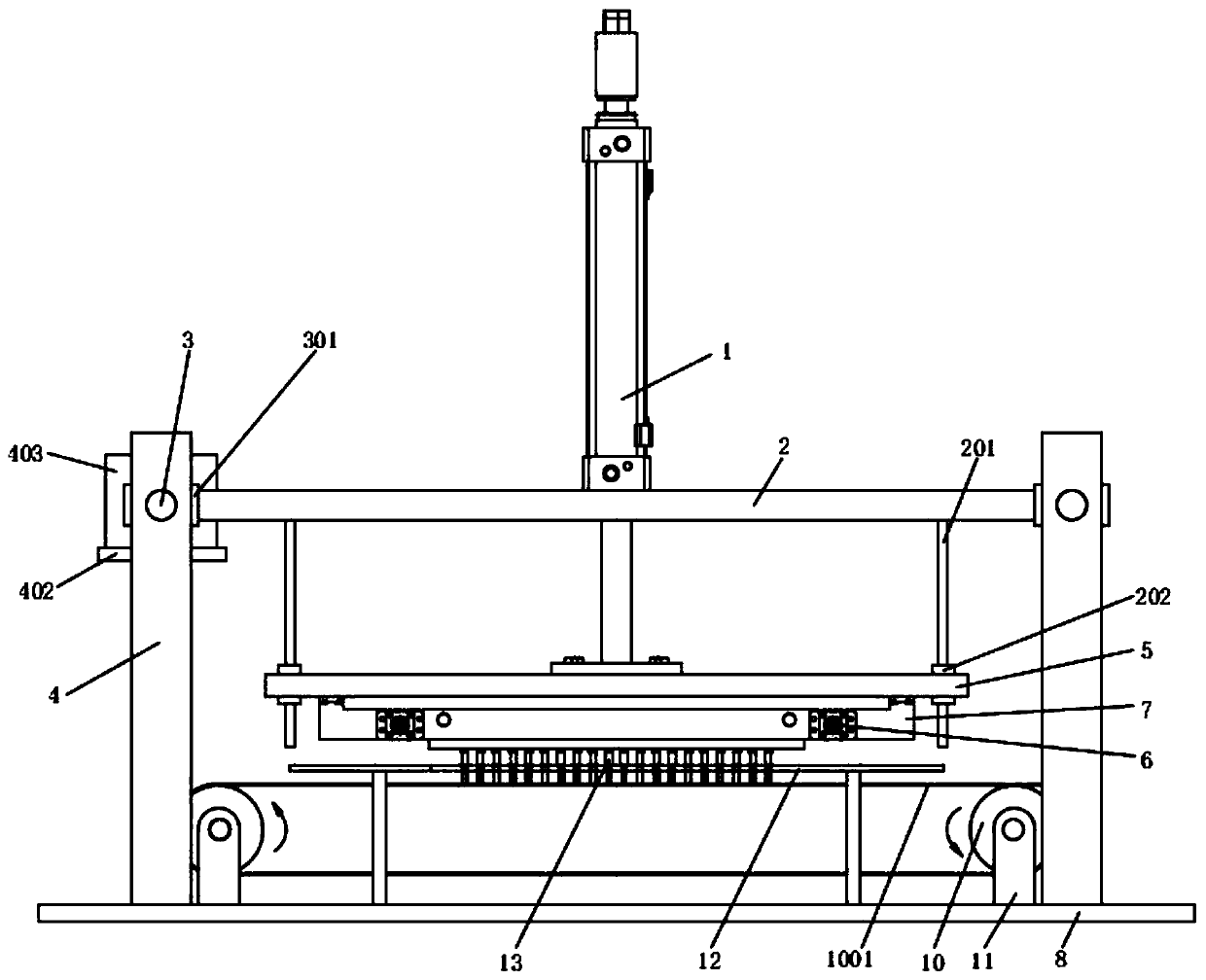

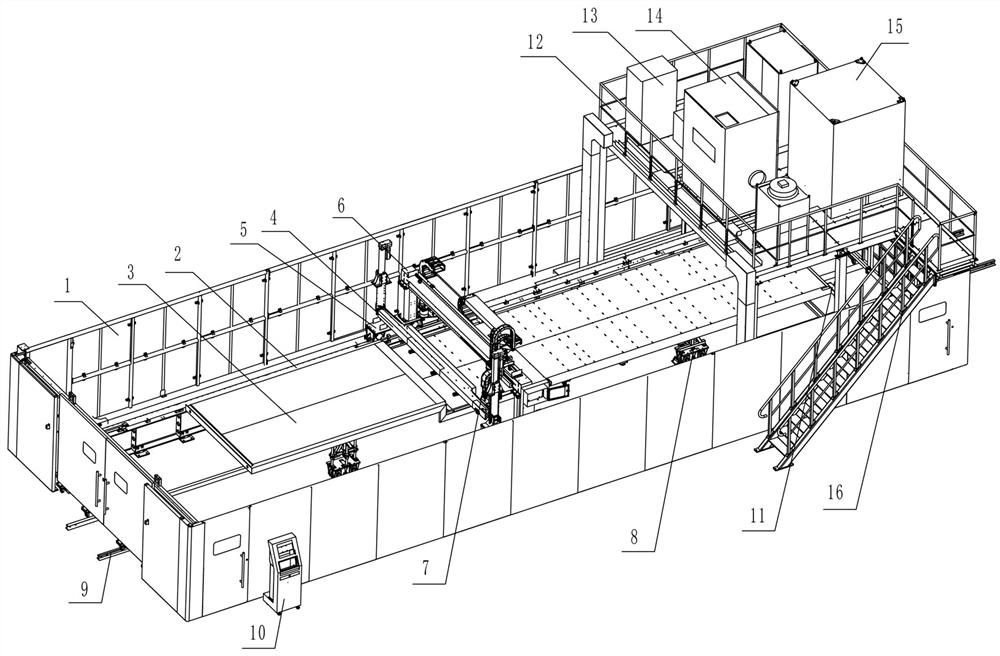

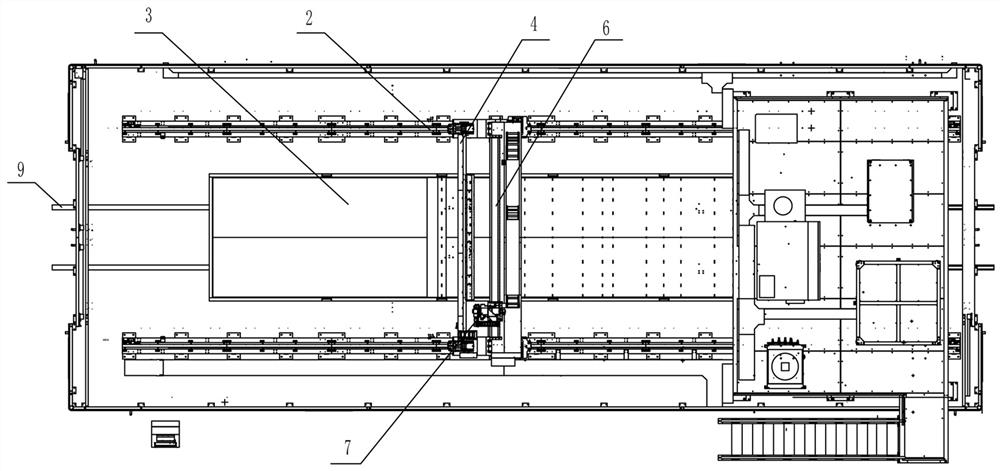

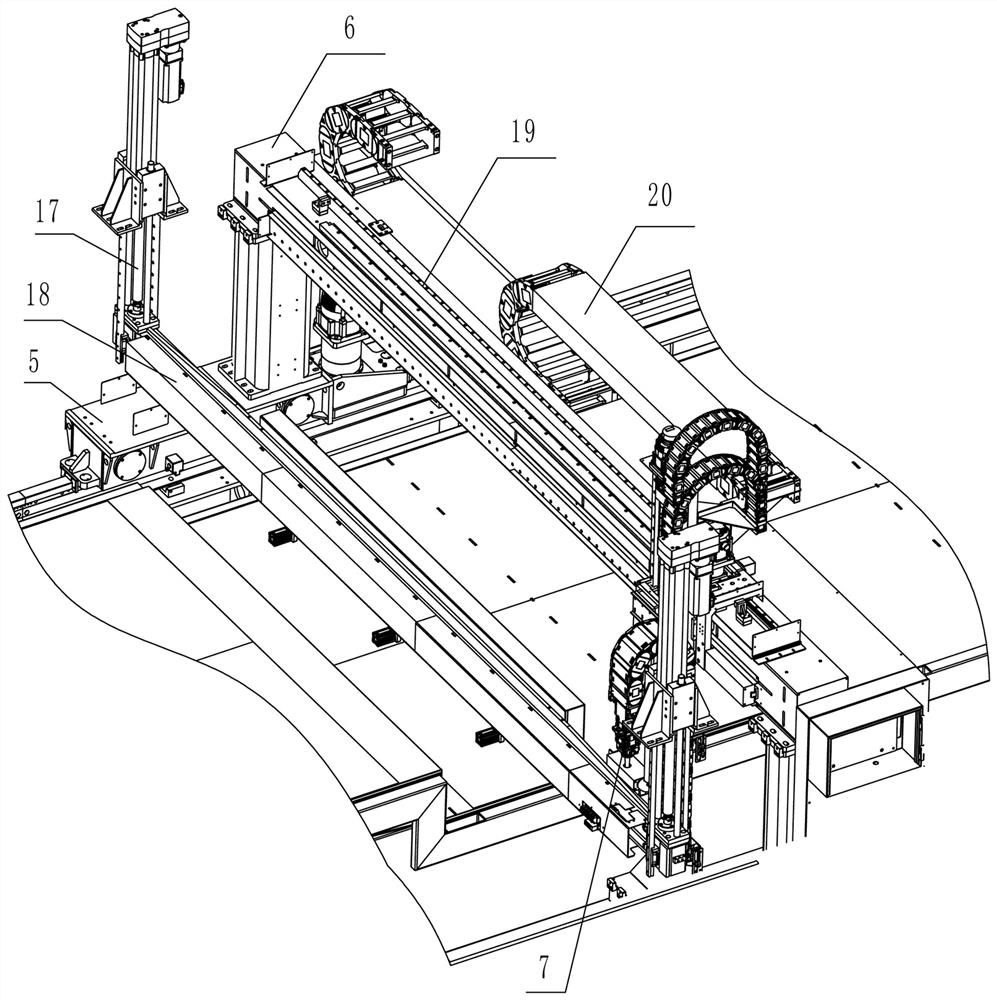

Semitrailer bottom plate laser welding equipment

PendingCN113681161AReduce gapAvoid Welding PhenomenonEngineering safety devicesLaser beam welding apparatusStructural engineeringMechanical engineering

The invention provides semitrailer bottom plate laser welding equipment. The semitrailer bottom plate laser welding equipment comprises a pair of lathe bed rails and a pair of trolley rails arranged between the lathe bed rails, a logistics trolley used for supporting a semitrailer bottom plate and a semitrailer frame is arranged on the trolley rails in a sliding mode; a pair of walking end beams are arranged on the lathe bed rails in a sliding mode, and a welding gantry beam and a lifting pressing mechanism used for fixing and pressing the semitrailer bottom plate are arranged between the two walking end beams; a welding head system capable of moving horizontally and going up and down is arranged on the welding gantry beam, and a flexible pressing wheel used for pressing the semitrailer bottom plate in a follow-up mode is arranged on the welding head system. According to the semitrailer bottom plate laser welding equipment, the gap between the semitrailer bottom plate and the semitrailer frame is reduced, laser self-fluxing penetration welding is achieved, the semitrailer frame and the bottom plate do not need to be turned over in the welding process, the labor intensity is reduced, and the production safety is improved.

Owner:ZHUMADIAN CIMC HUAJUN VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com