Vehicle relay and installation method of electronic components thereof

A technology of automotive relays and electronic components, applied in relays, electrical components, circuits, etc., can solve problems such as welding difficulties and virtual welding phenomena that cannot be effectively solved, hidden dangers of product reliability, and insufficient vibration resistance, and achieve good fixing effects. Improve product quality and finished product pass rate, use reliable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

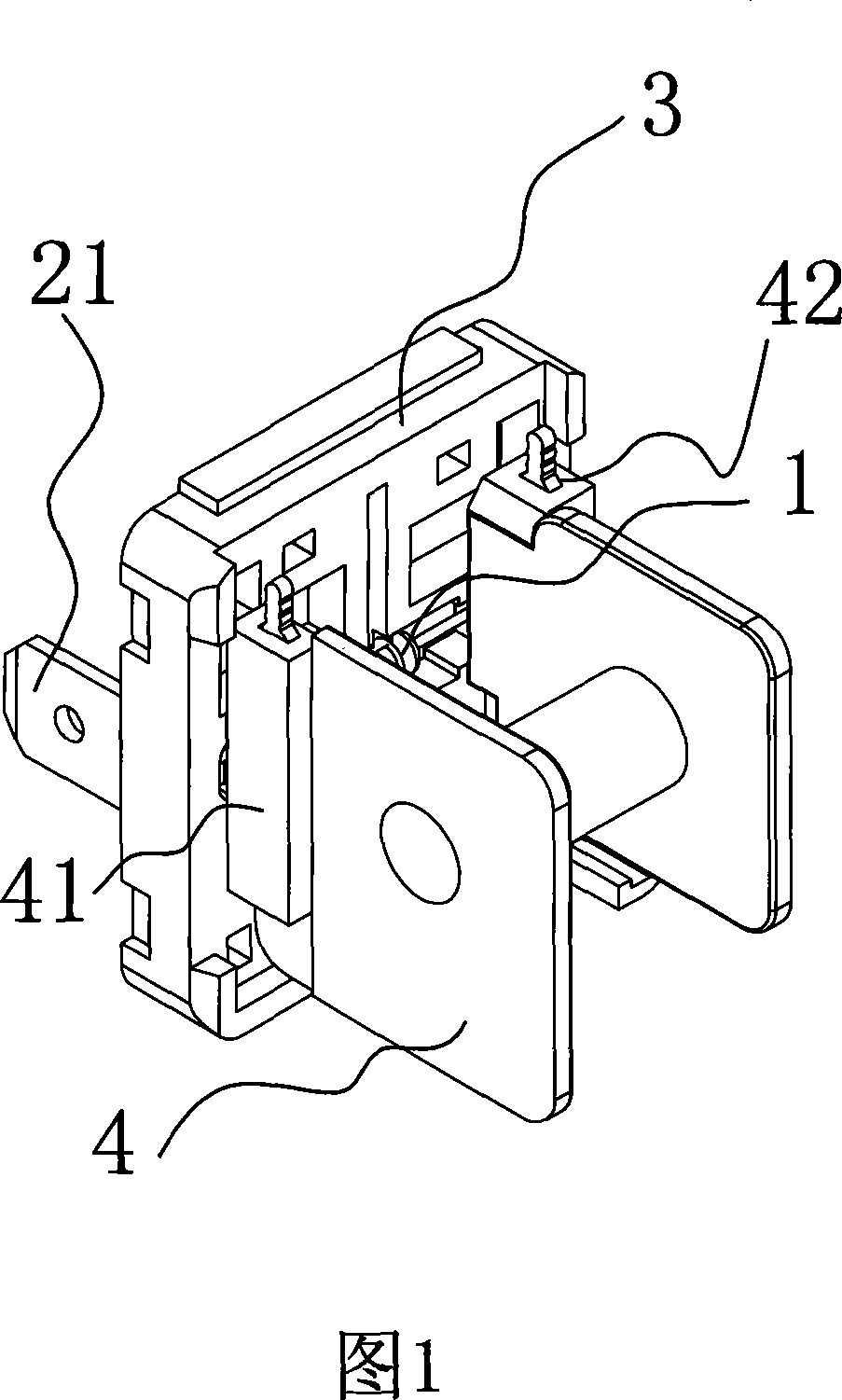

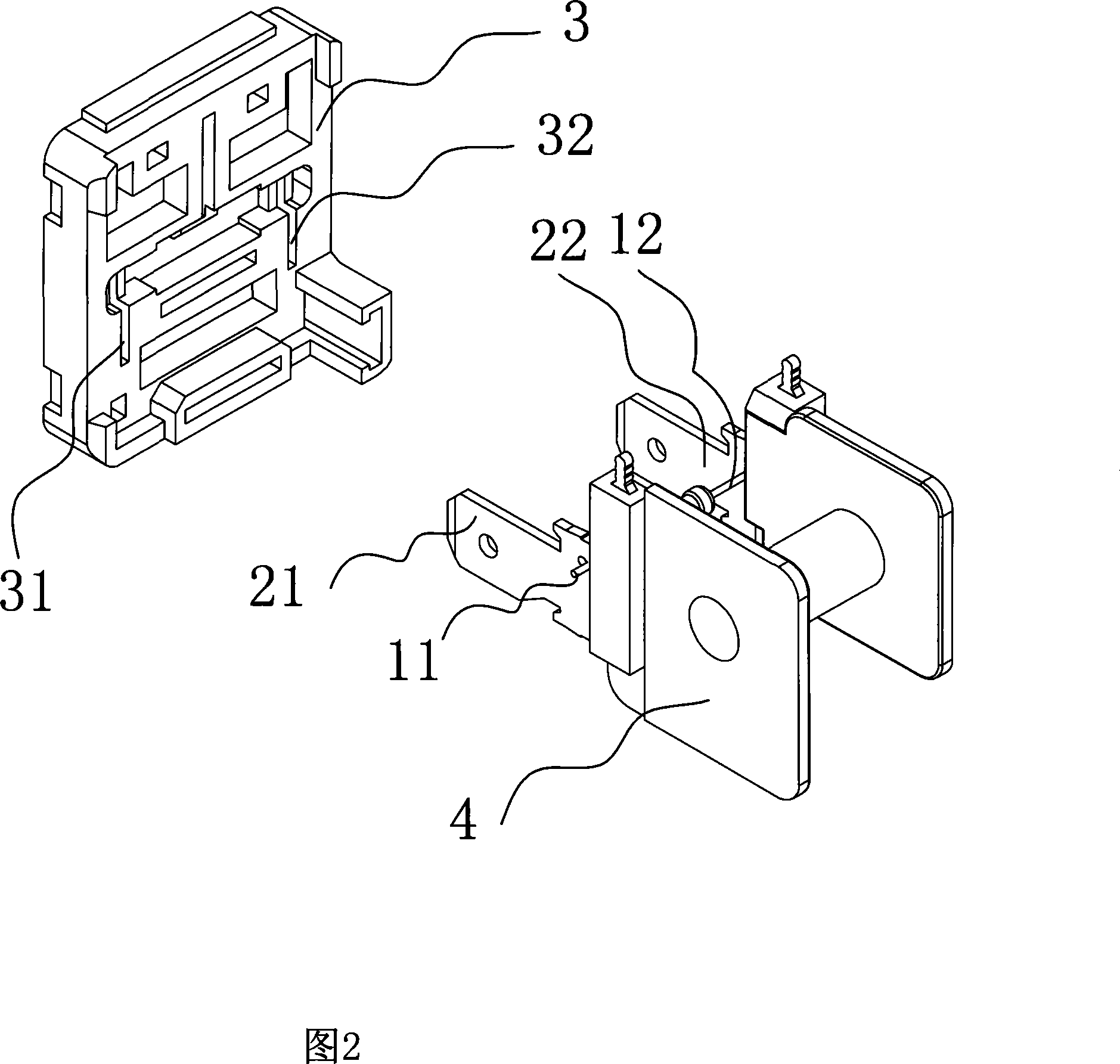

[0014] As shown in Fig. 1 and Fig. 2, the parts of the automotive relay involved in the present invention include a coil frame 4, a lead sheet 21, a lead sheet 22, an electronic component 1, a base 3, and the lead sheet 21 and the lead sheet 22 are inserted into the coil frame 4 Among the fixing pieces 41 and 42, the electronic component 1 is fixed on the lead piece 21 and the lead piece 22.

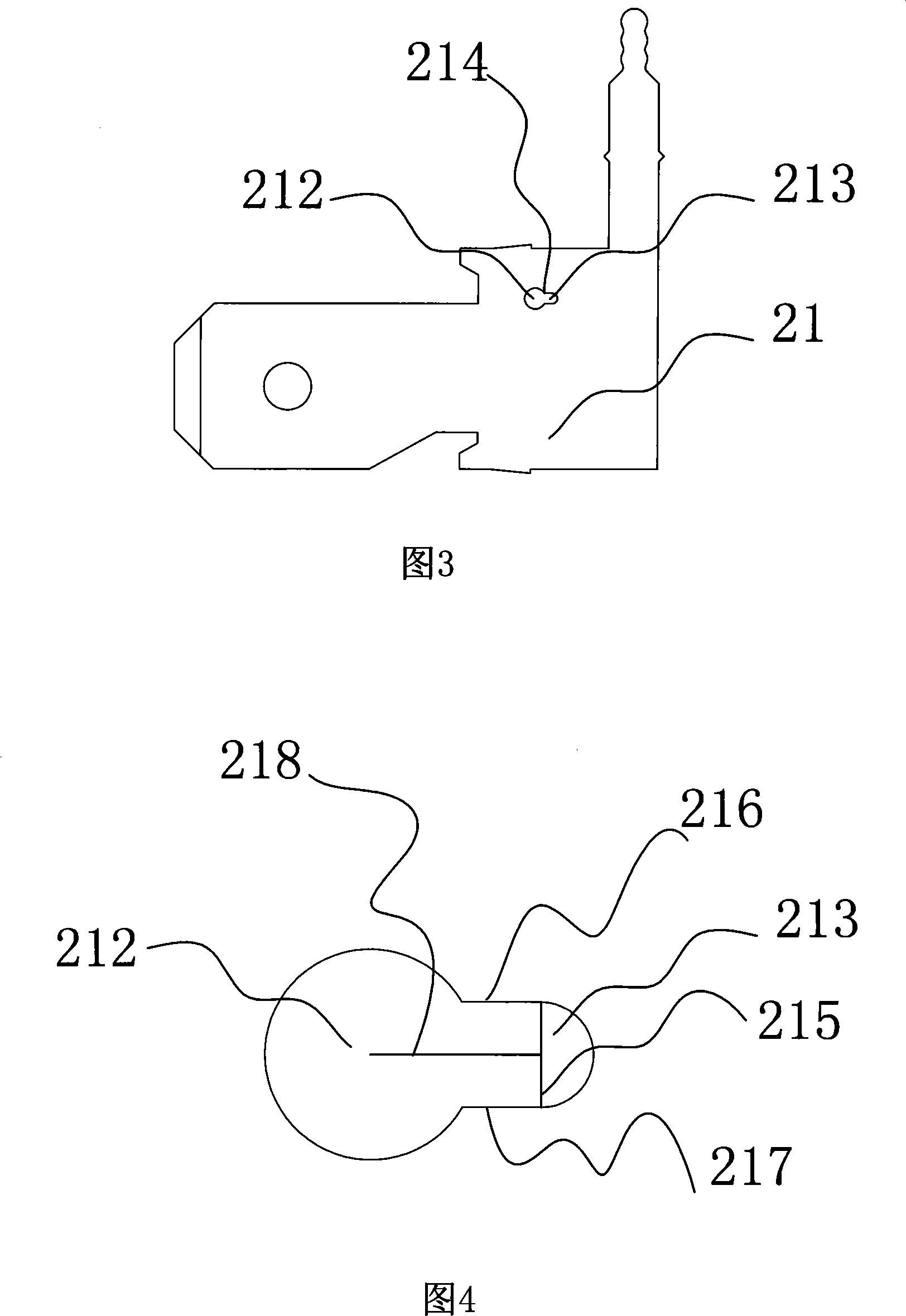

[0015] There is a hole 214 at the place where the above-mentioned lead piece 21 is installed with the electronic components, which is composed of a large hole 212 and a small hole 213 connected. To pass through it conveniently, a small hole 213 smaller than 20% of the diameter of the lead-out end of the electronic component is opened in front of the large hole 212, so that the lead-out end 11 is firmly embedded therein, as shown in FIG. 3 .

[0016] Abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com