Patents

Literature

138 results about "Lead sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lead sheet or fake sheet is a form of musical notation that specifies the essential elements of a popular song: the melody, lyrics and harmony. The melody is written in modern Western music notation, the lyric is written as text below the staff and the harmony is specified with chord symbols above the staff.

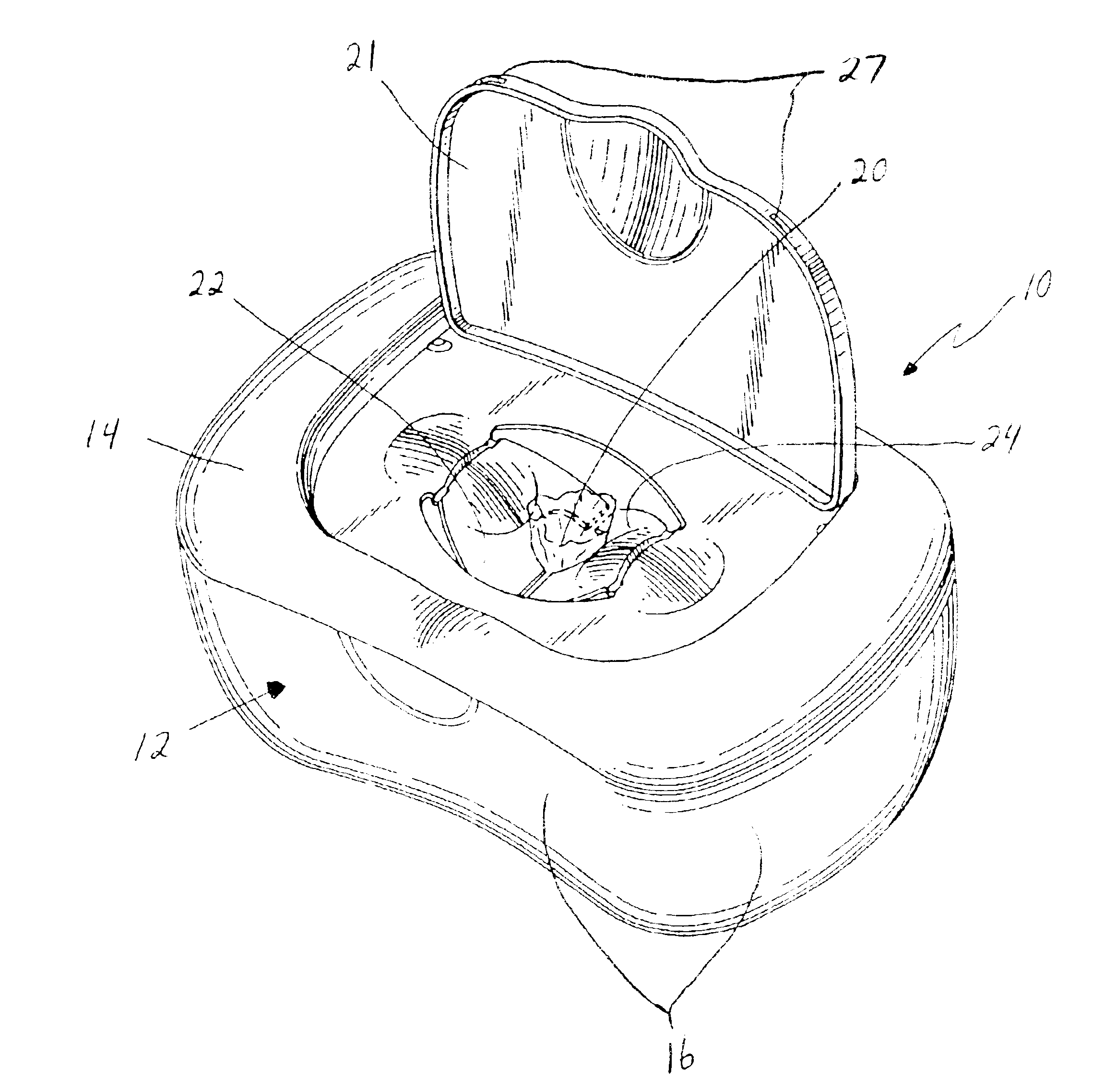

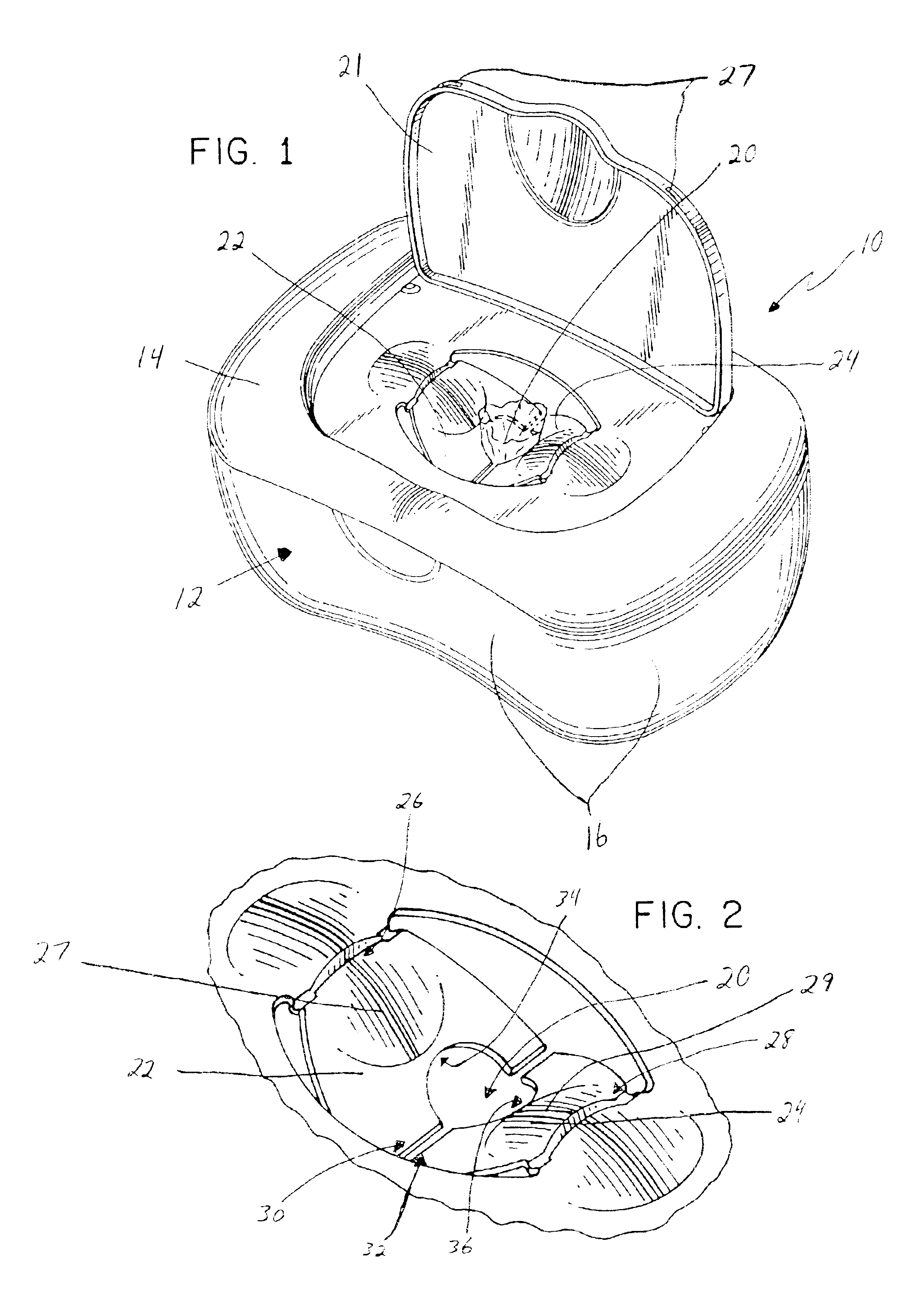

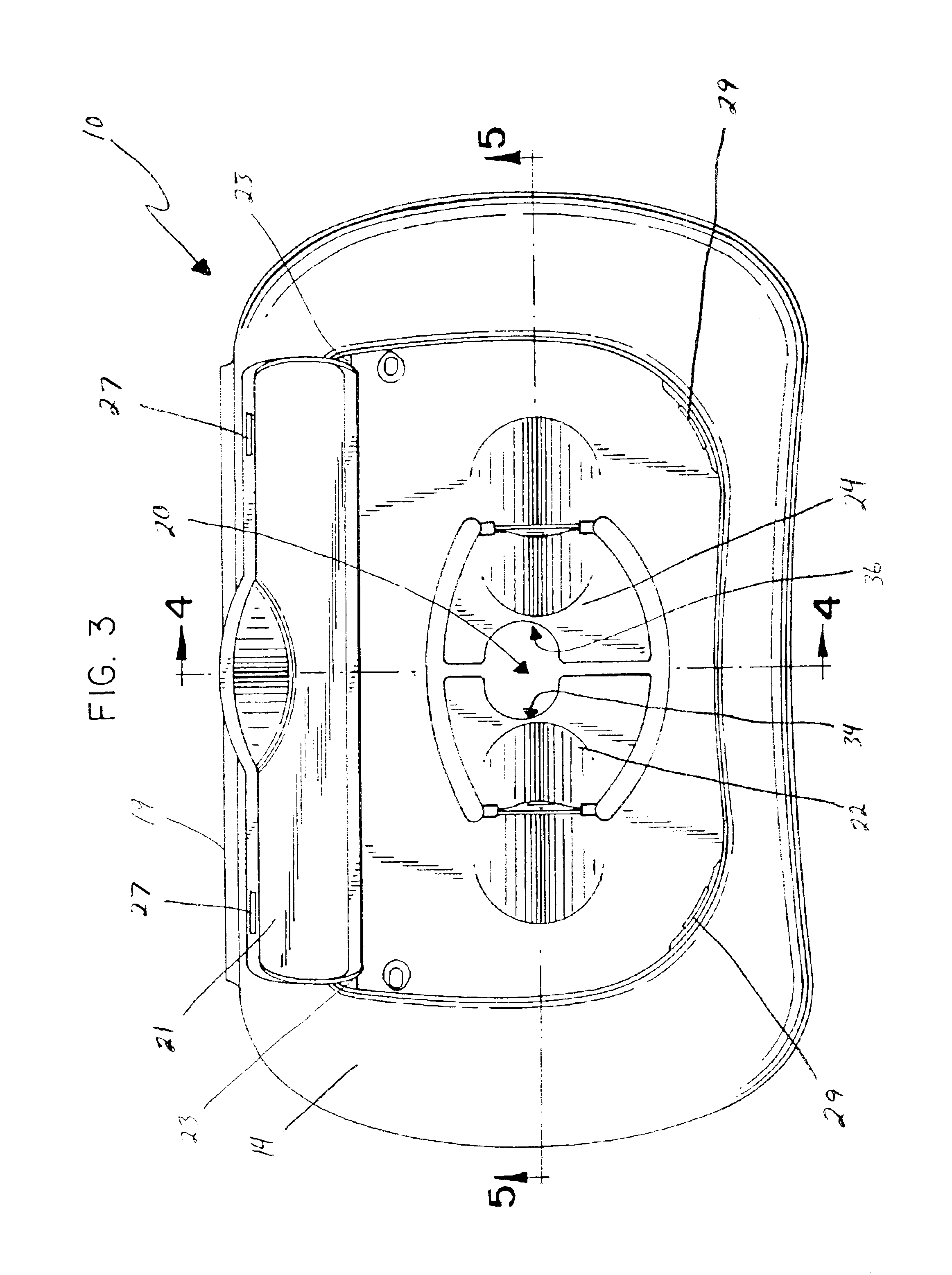

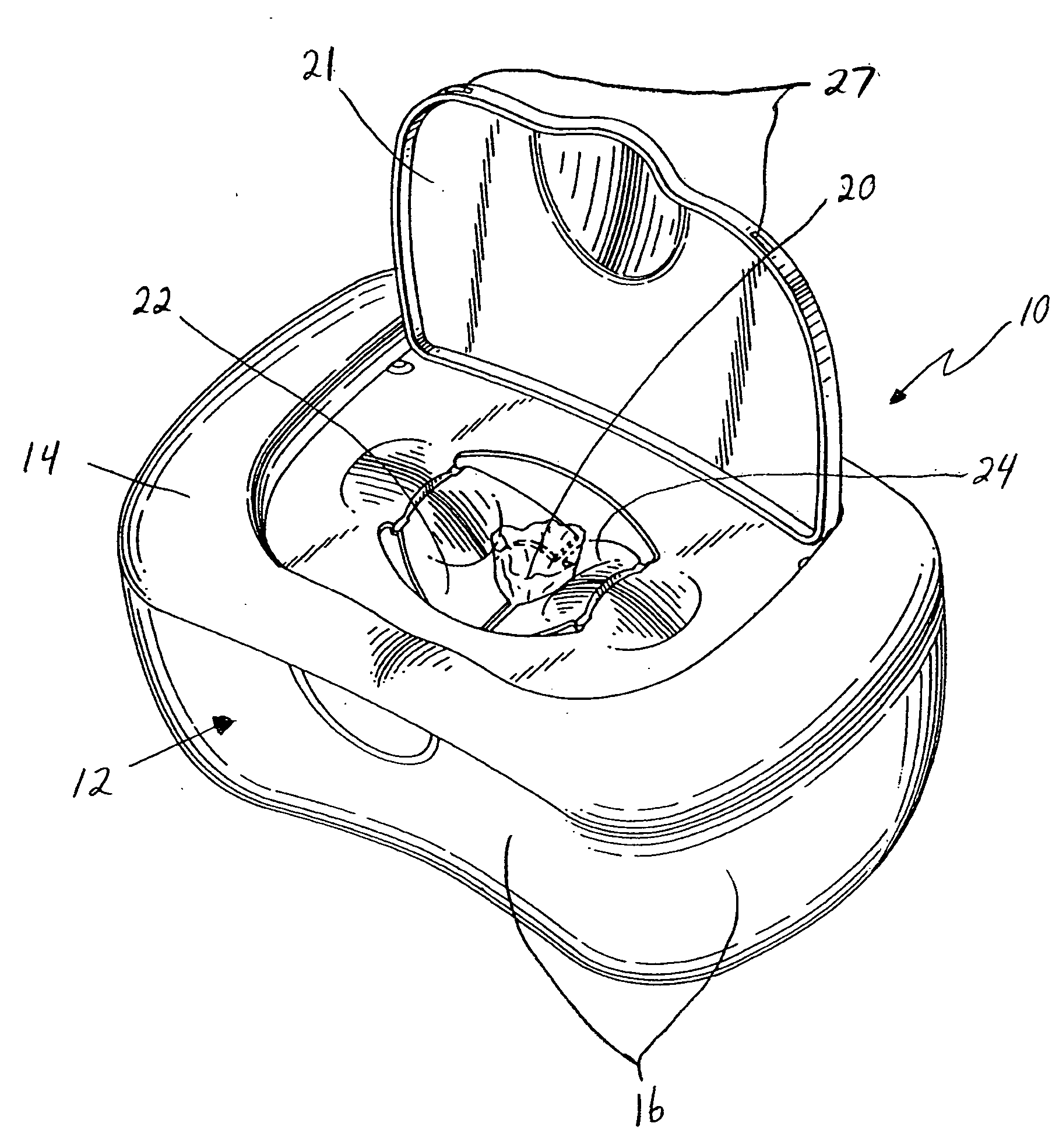

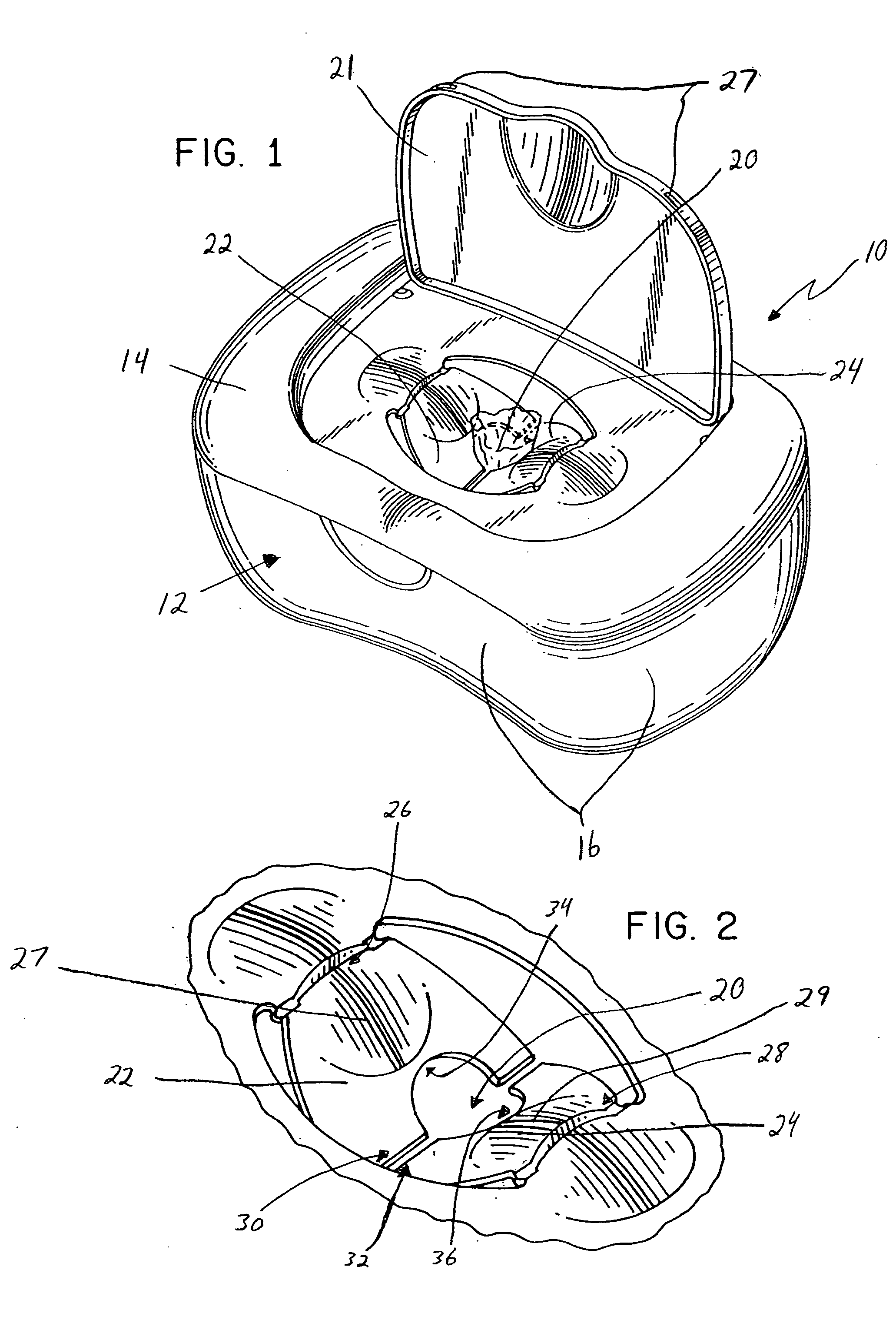

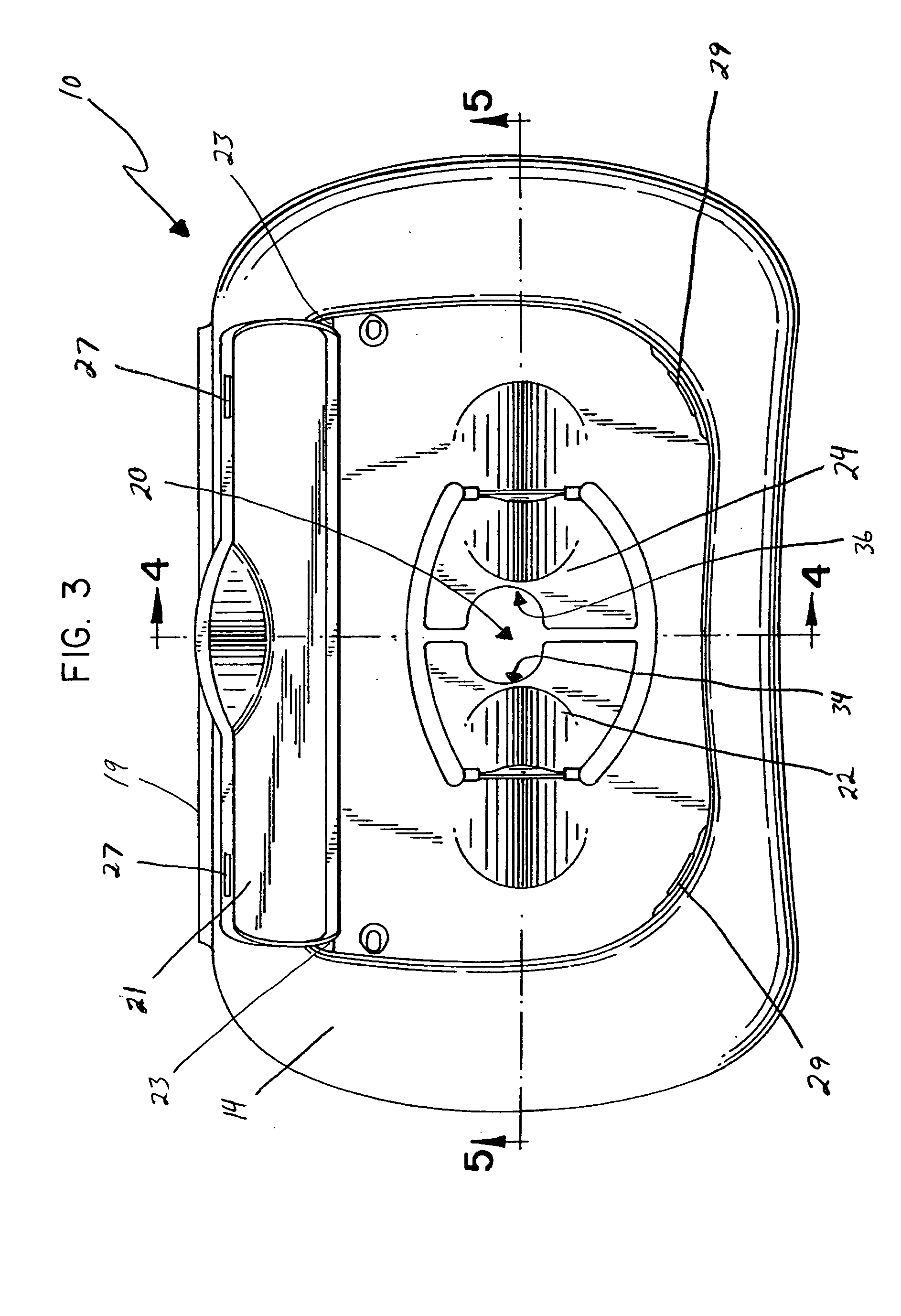

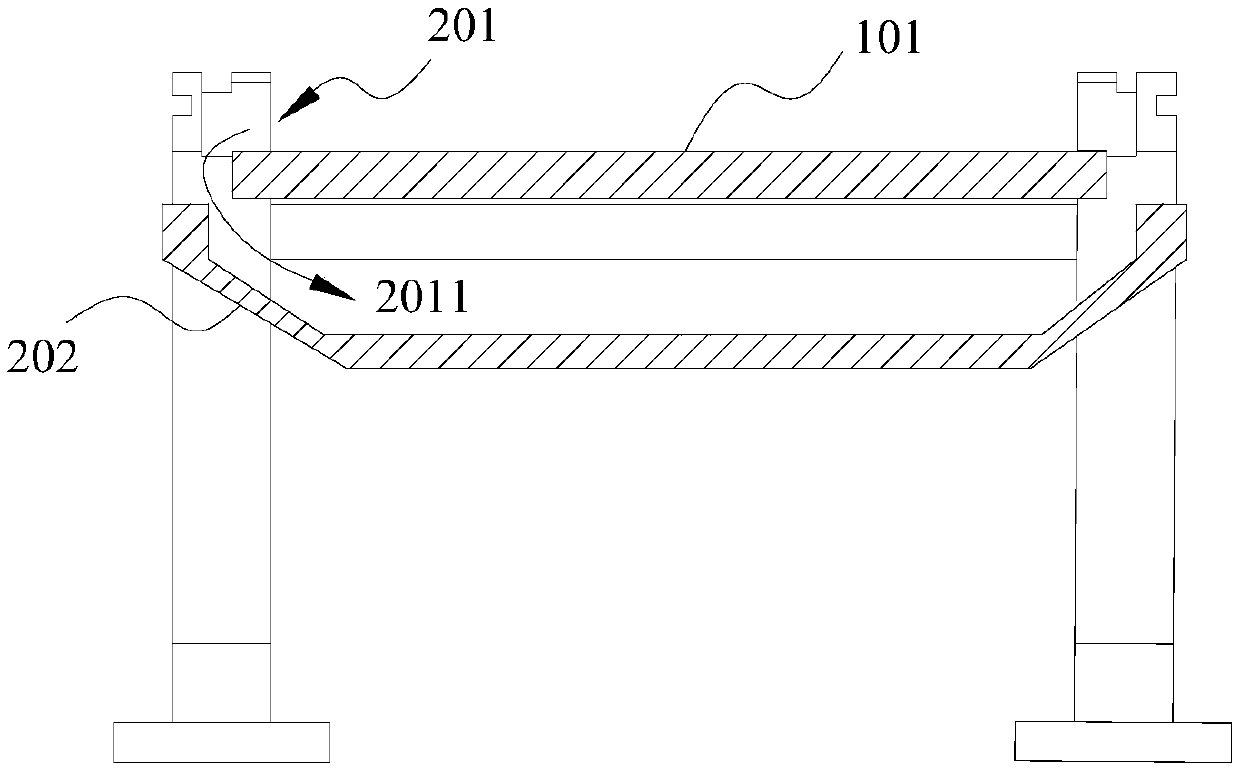

Refillable flexible sheet dispenser

InactiveUS6910579B2The process is convenient and fastEffective distributionContainers for flexible articlesOther accessoriesLead sheetEngineering

A flexible sheet container is provided that permits a user to quickly and easily feed a leading sheet. The container has a base portion that defines a storage area and a top covering the base portion. The top includes an opening into the storage area through which individual flexible sheets are dispensed. A pair of opposing flaps is pivotally attached to the top at their first ends and each extends toward the dispensing opening with its second end. The complementary second ends of the flaps together further define the dispensing opening while in a dispensing position. The flaps pivot inward toward the storage area to provide access through the opening into the storage area. As such, to feed a leading flexible sheet, a user may rotate the flaps inward, grab a leading flexible sheet, and pull it through the opening. During dispensing, the flaps rotate outward and retain subsequent sheets.

Owner:GPCP IP HLDG LLC +1

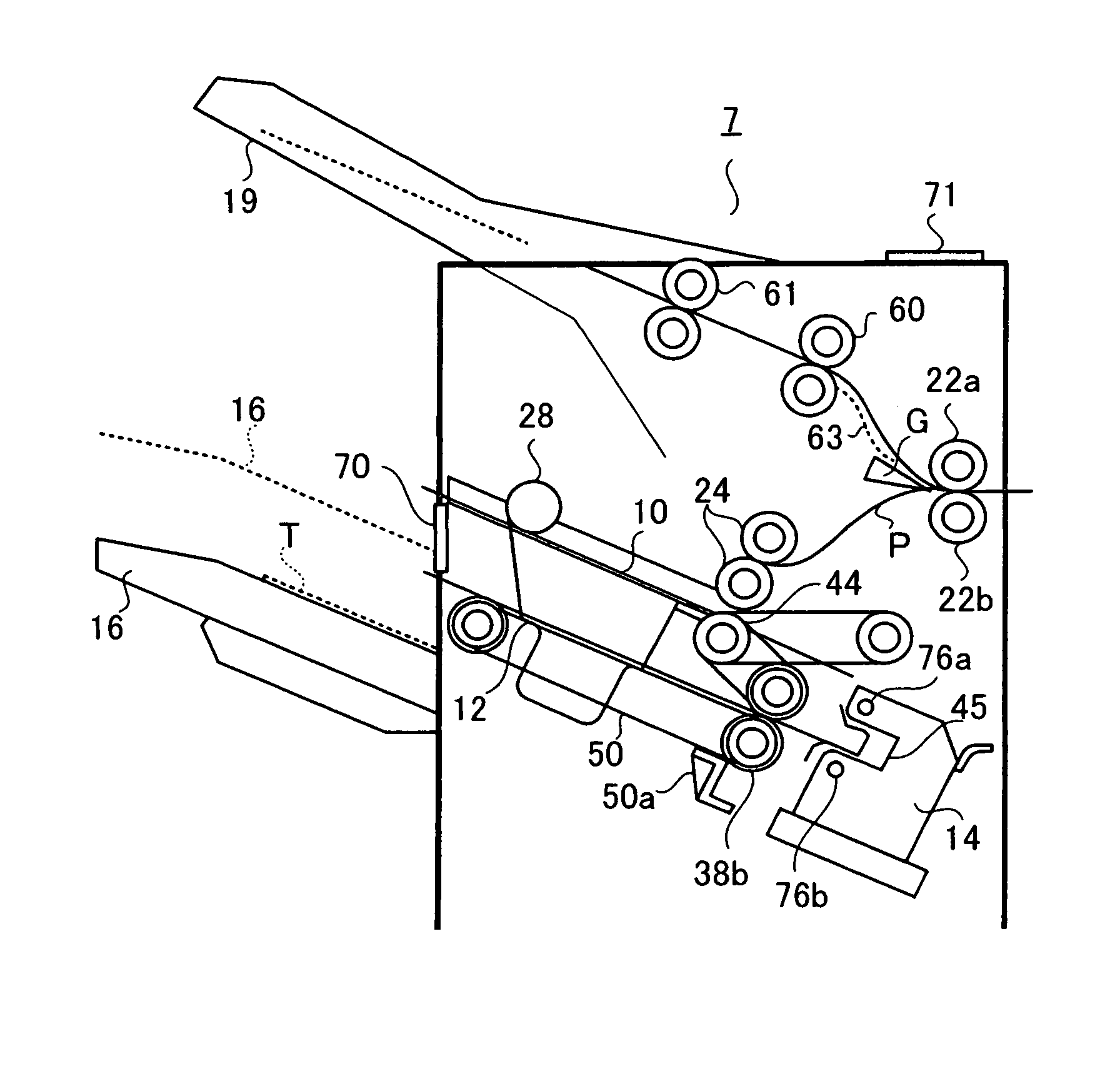

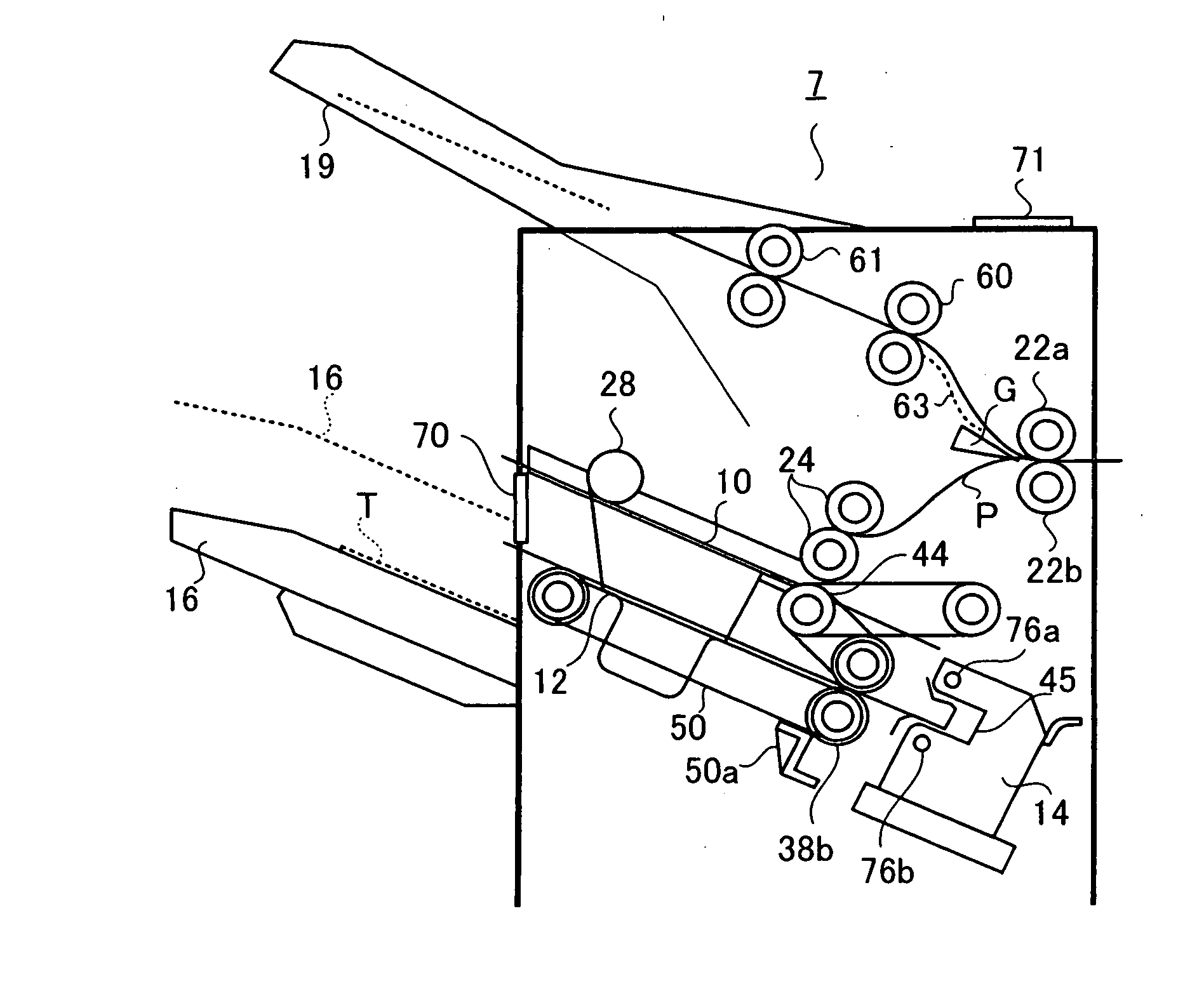

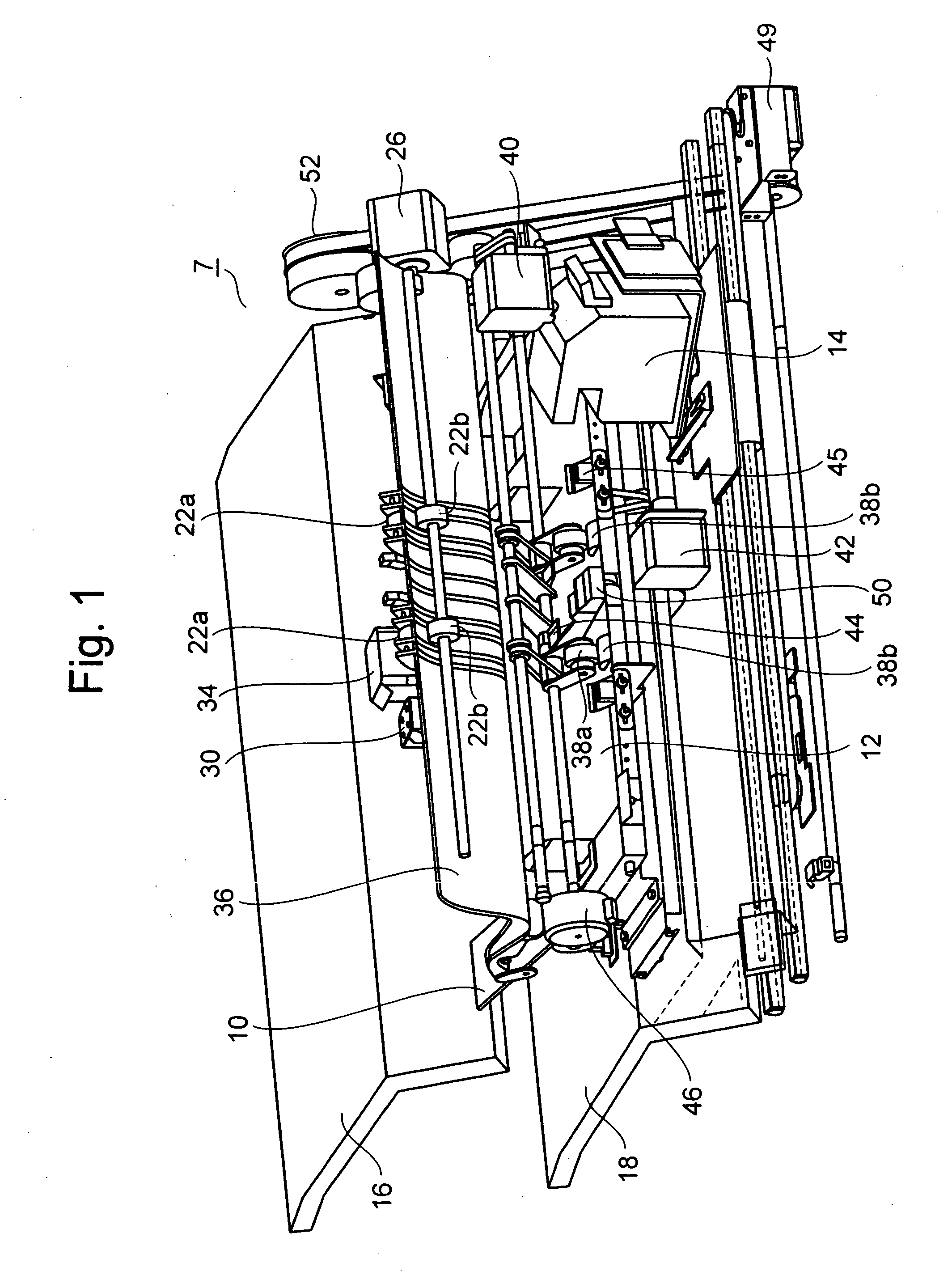

Sheet finishing apparatus

A sheet finishing apparatus of the present invention includes a gate for conveying sheets of paper ejected from an image forming apparatus by switching to a first conveying path requiring post processing or to a second conveying path requiring no post processing and a manual introduction unit for post-processing the sheets of paper conveyed via the first conveying path by a processing mechanism and ejecting them to a first paper ejection tray and manually leading sheets of paper requiring post processing to the processing mechanism, and when the post process is executed in a manual mode, switches the gate to the second conveying path, and when sheets of paper are taken in from the image forming apparatus, ejects the sheets of paper to a second paper ejection tray via the second conveying path.

Owner:TOSHIBA TEC KK

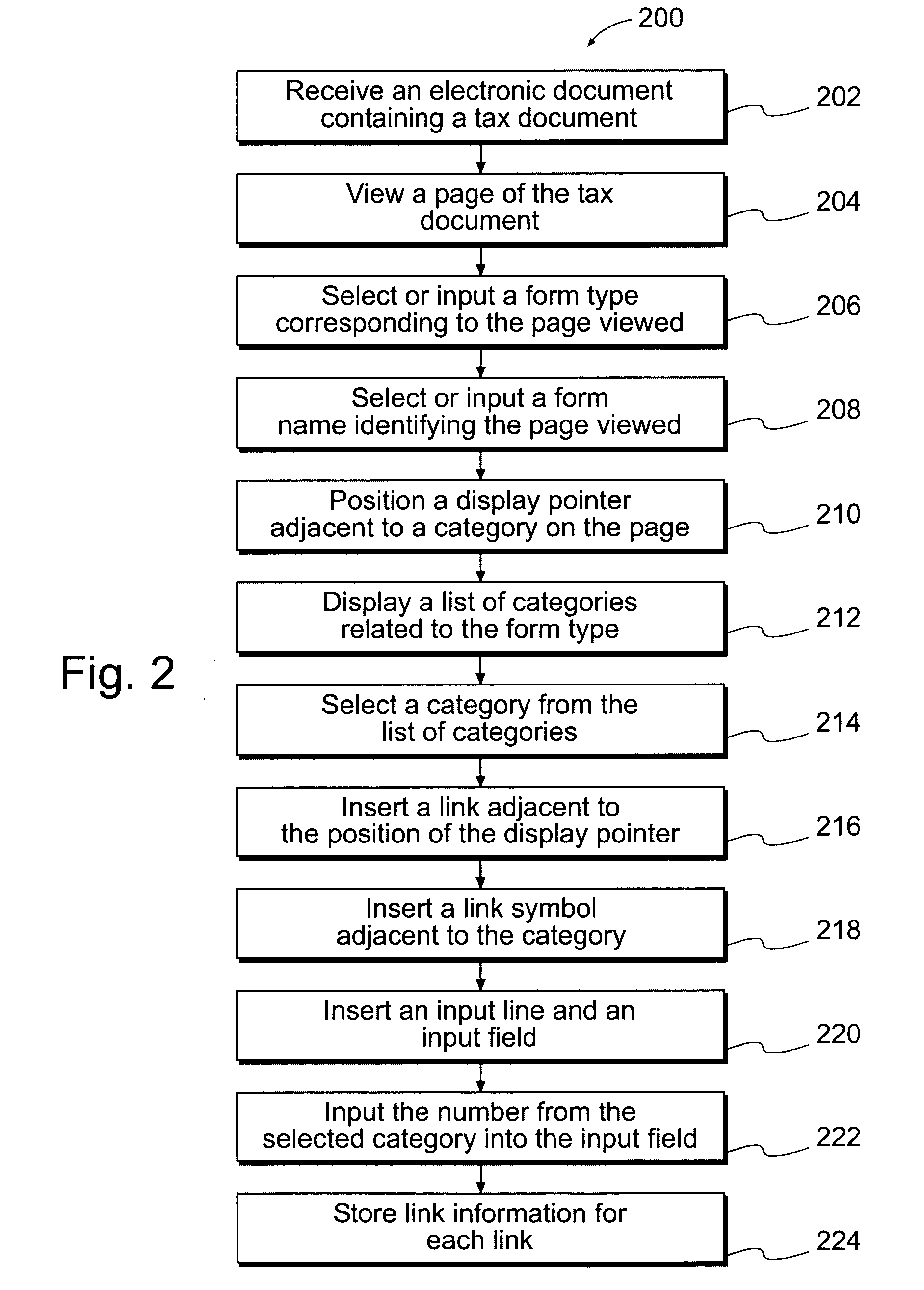

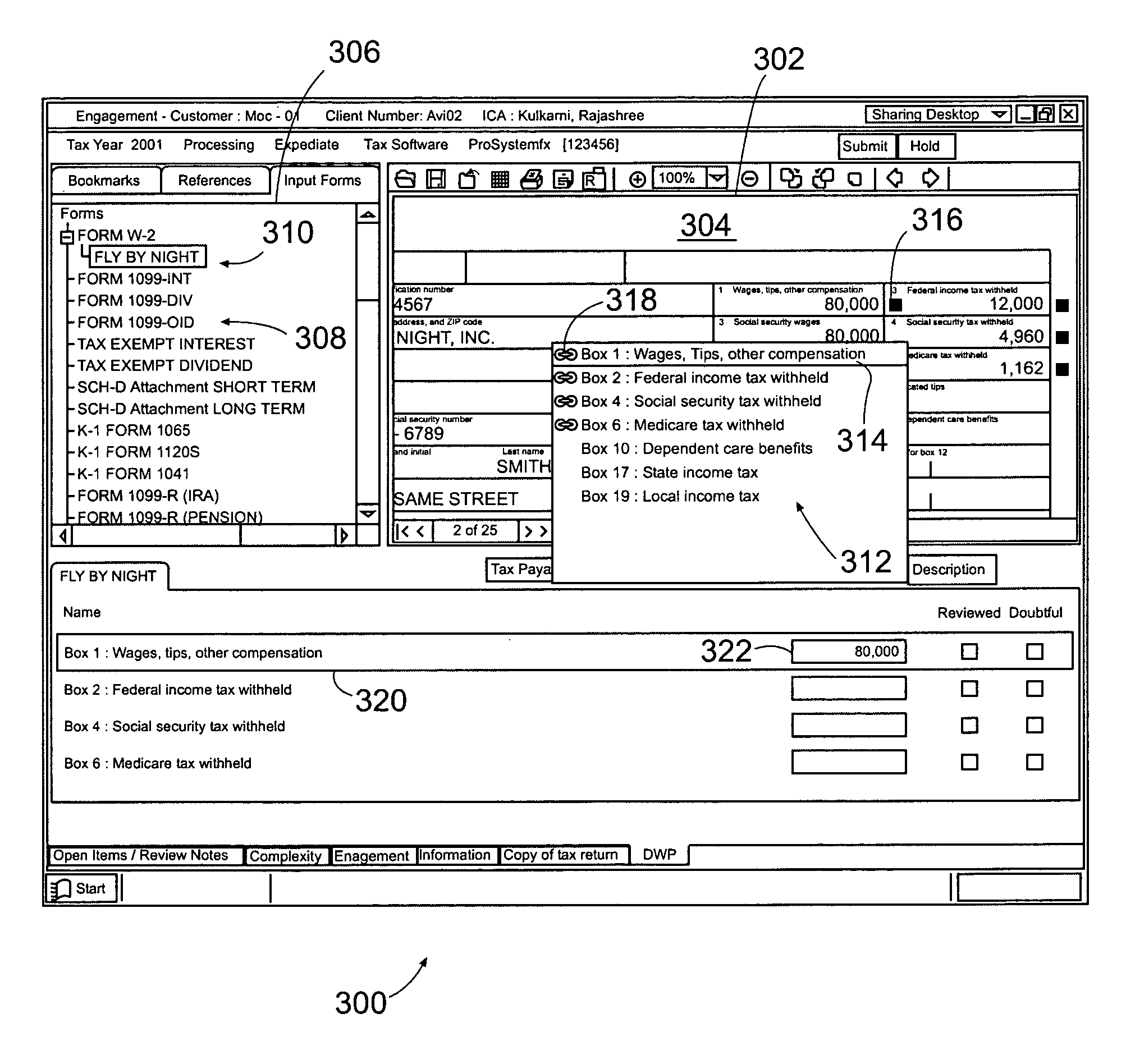

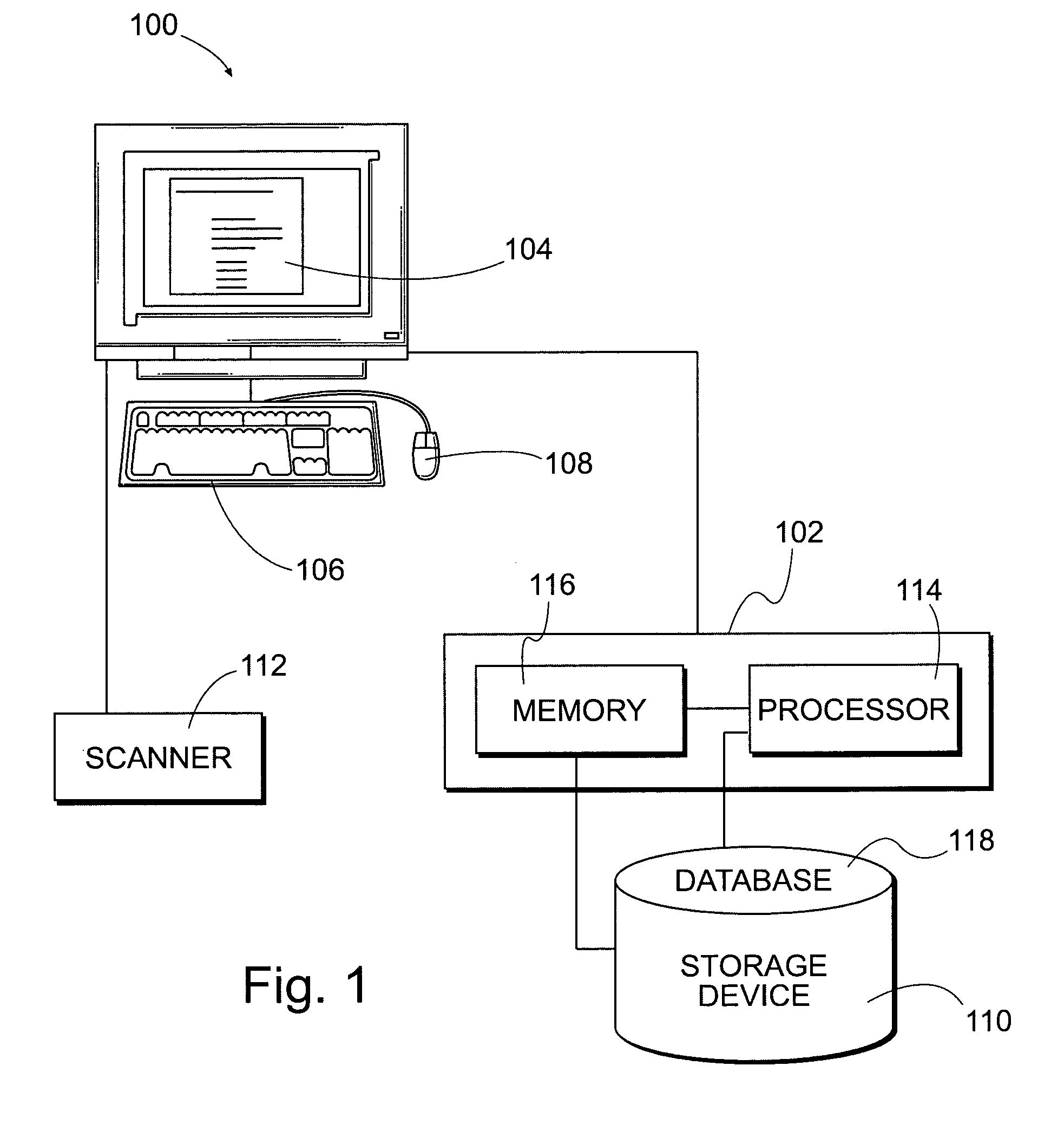

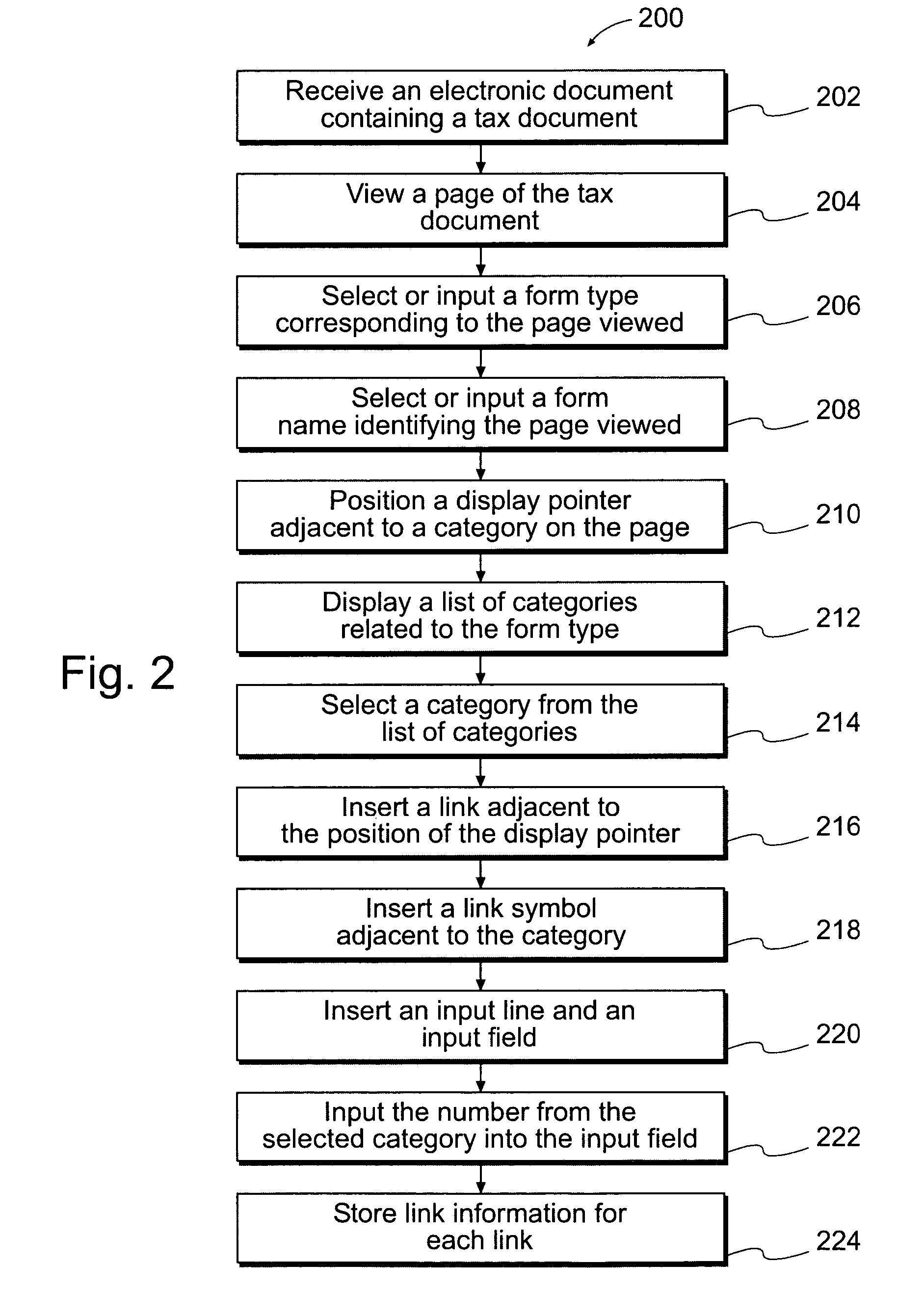

System and method for creating cross-reference links, tables and lead sheets for tax return documents

Owner:SUREPREP

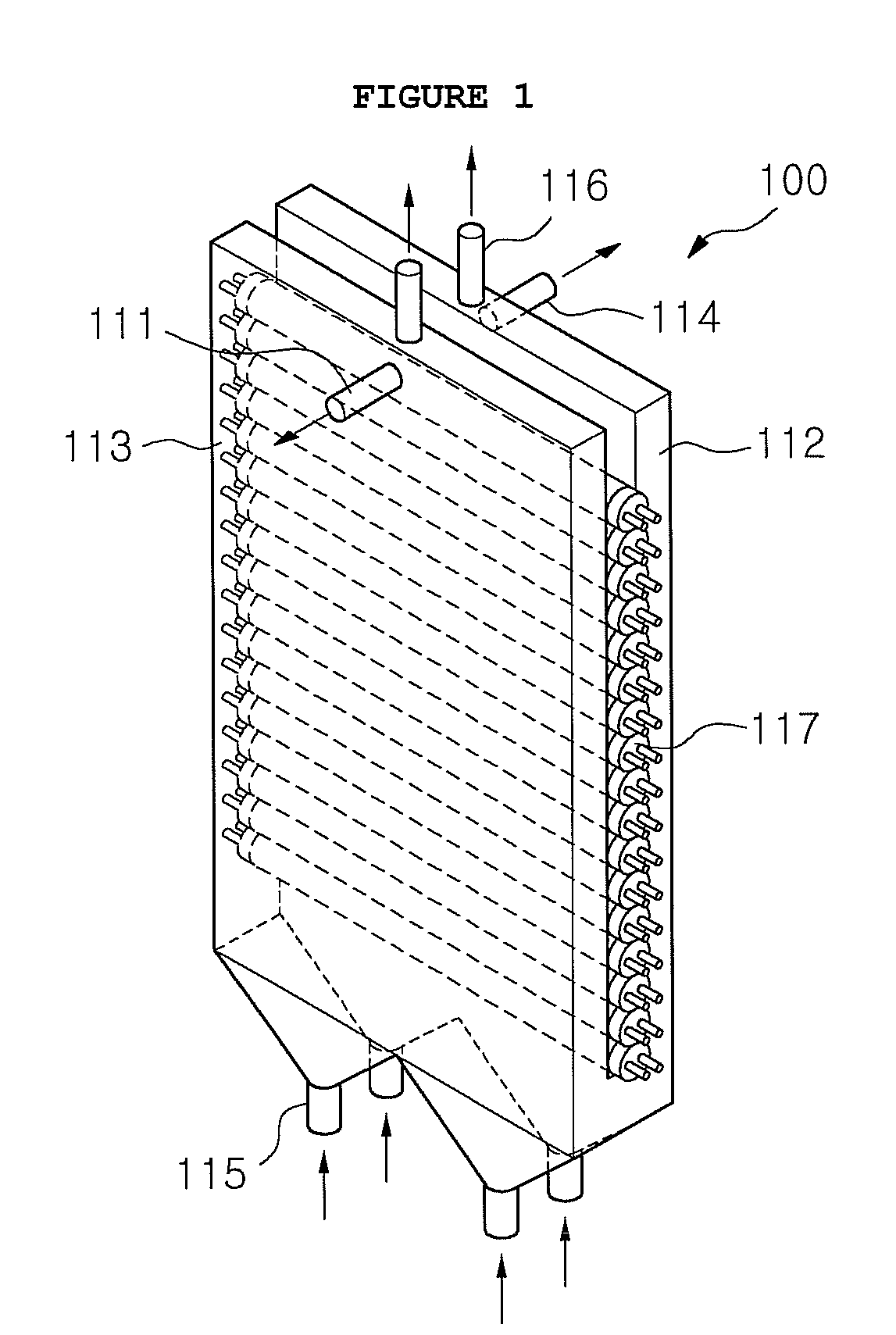

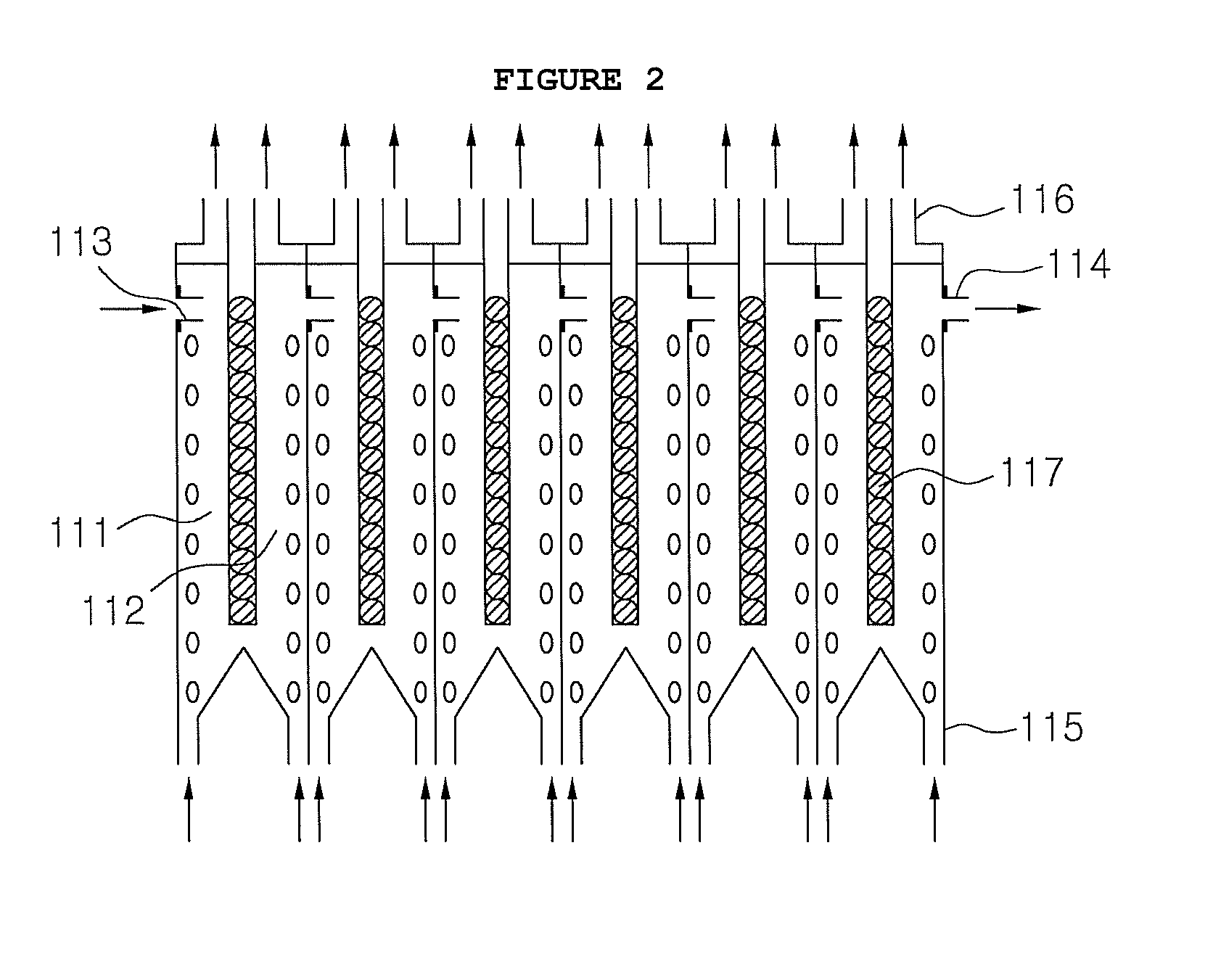

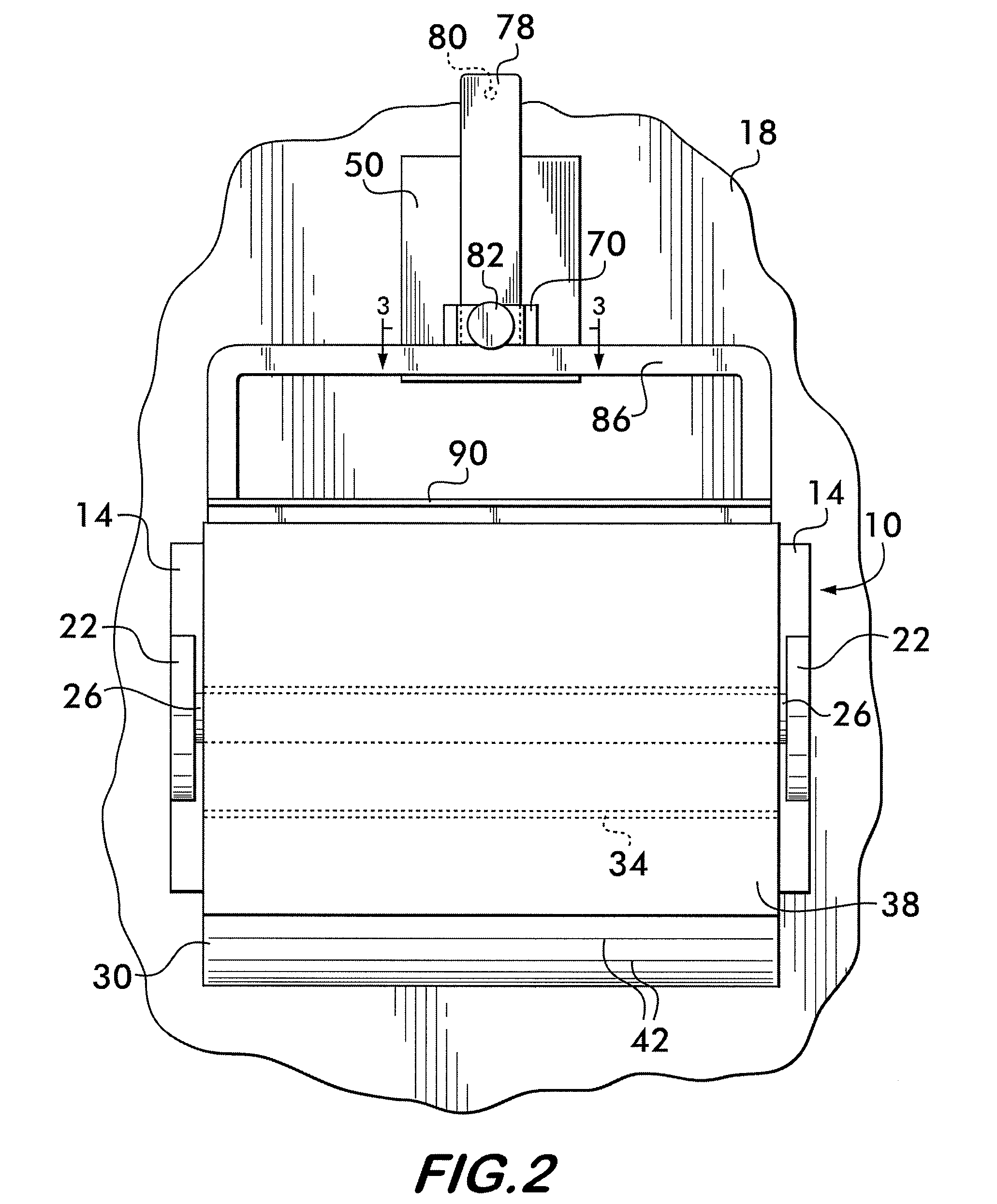

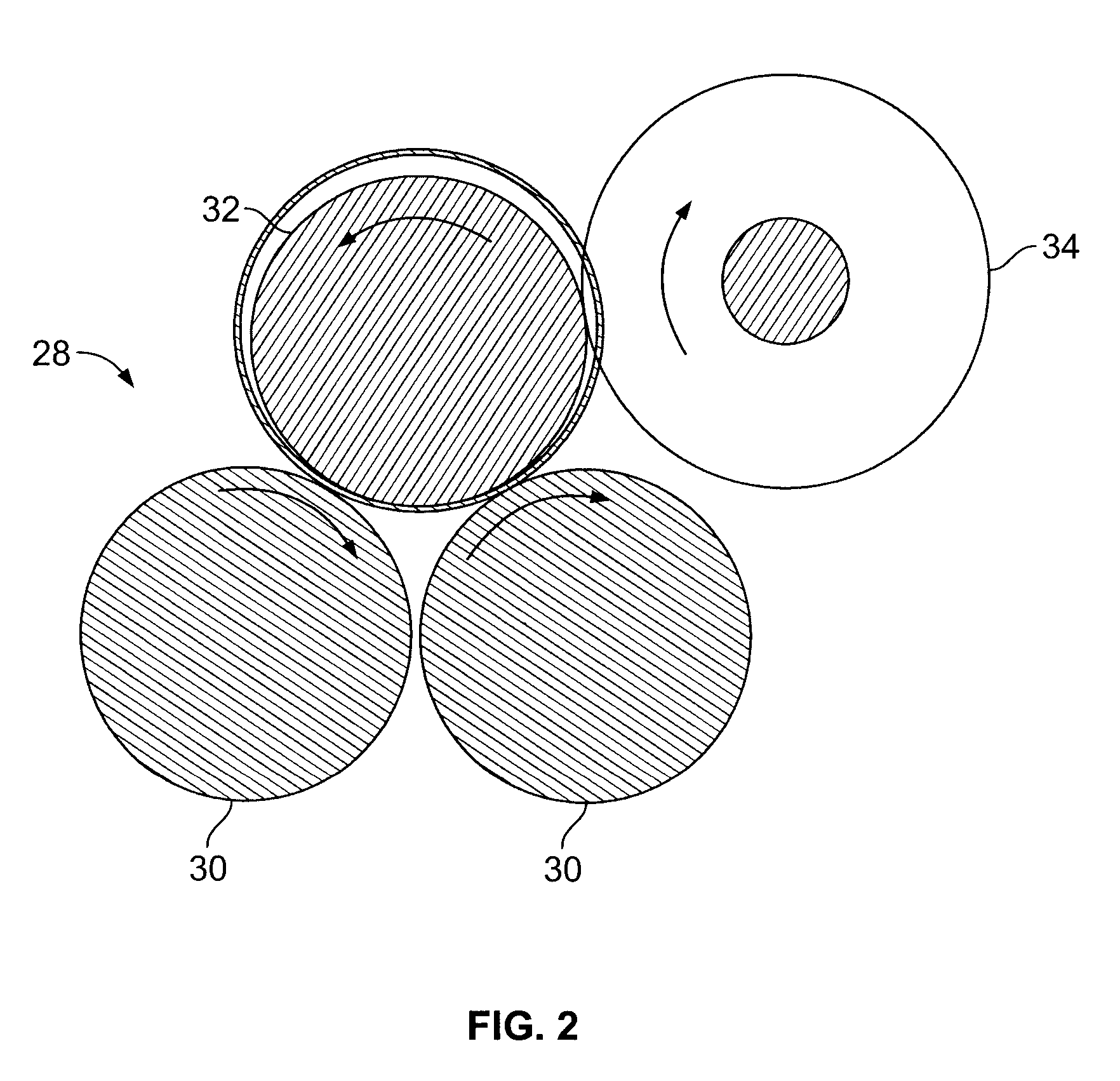

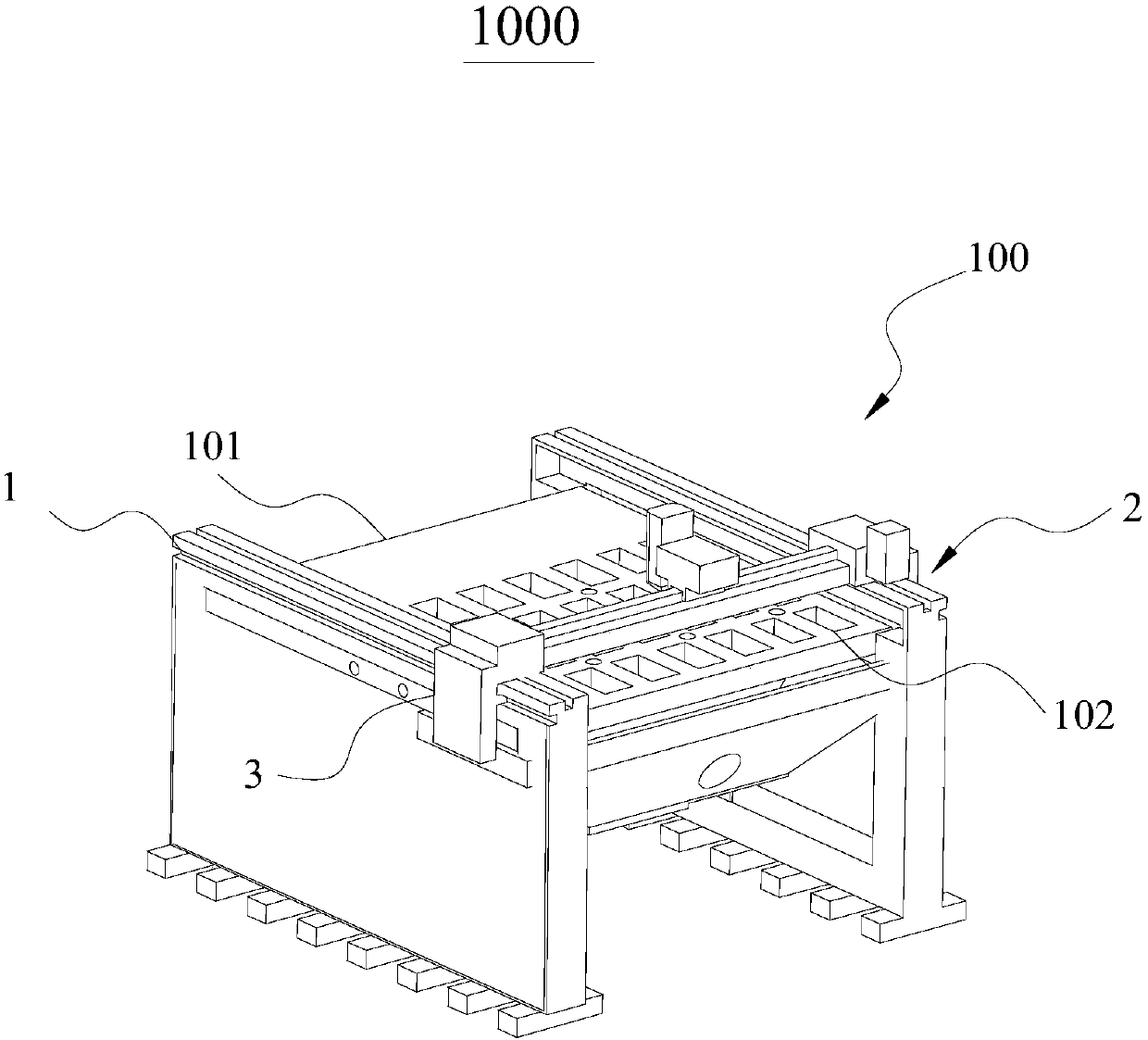

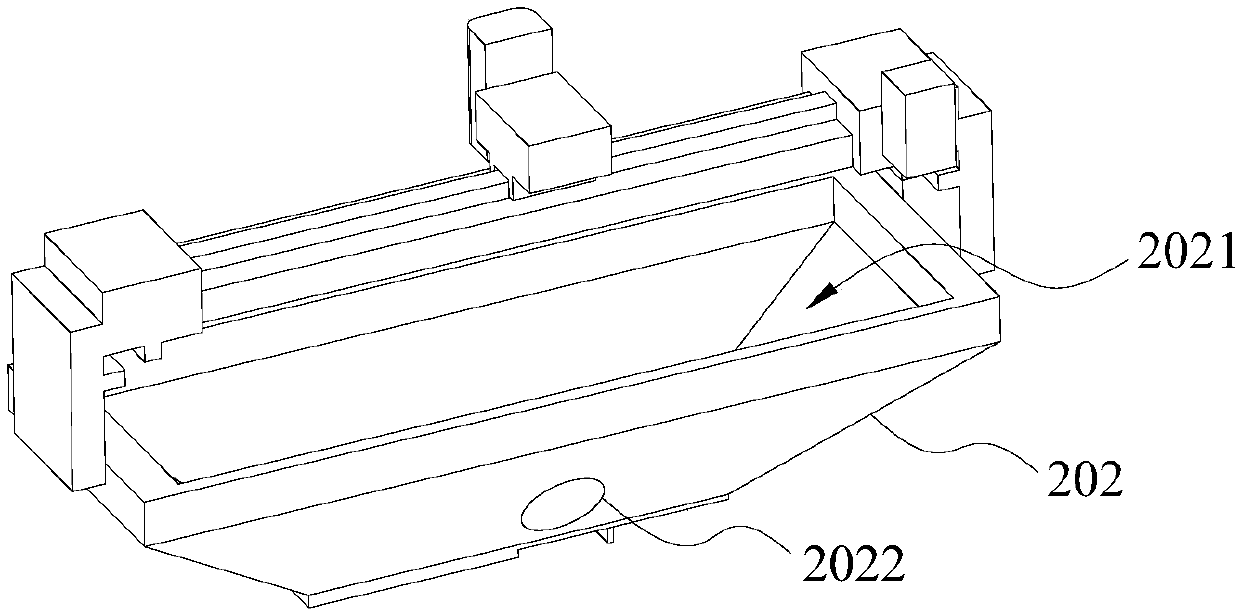

Photobioreactor for large-scale culture of microalgal

InactiveUS20100323436A1Facilitate scaling-upImprove productivityBioreactor/fermenter combinationsBiological substance pretreatmentsInterior spaceLead sheet

A photobioreactor for a large-scale microalgal culture. The photobioreactor includes a plurality of surface-light-source assemblies using a light emitting diode (LED) element, an organic light emitting diode (OLED) element, or a flexible LED sheet as a light source. The surface-light-source assemblies have the shape of a flat plate or a cylinder, are installed at predetermined intervals in the interior space of a reaction tank having the shape of a cube or a cylinder, and emit light for culturing microalgae in an internally illuminated fashion. Here, the surface-light-source assemblies are installed in such a manner that they are alternately in contact with first and second walls of the reaction tank disposed in parallel to each other in a symmetrical shape, and serve as partitions that portion the interior space of the reaction tank and increase a flow distance of gas.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

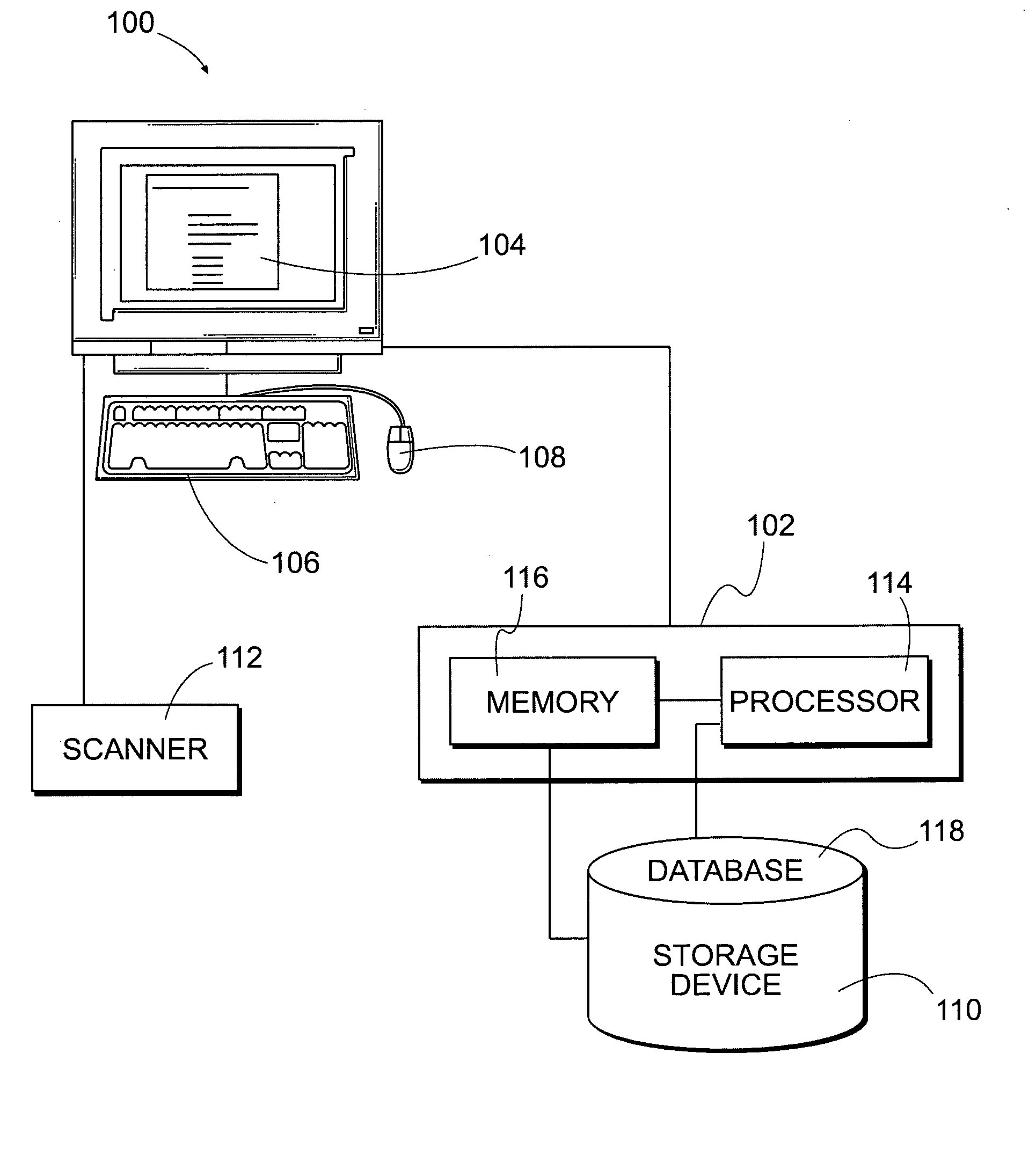

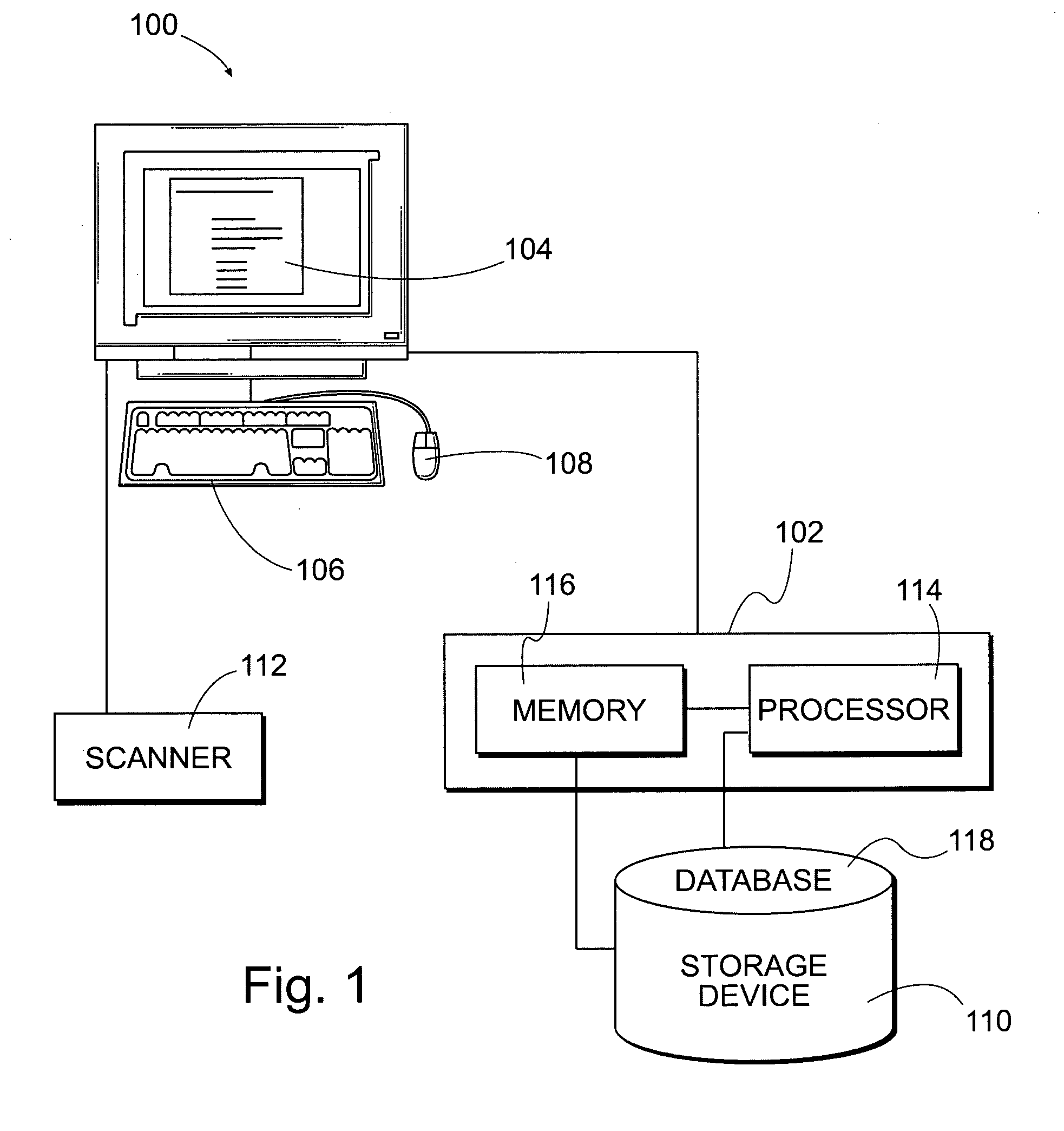

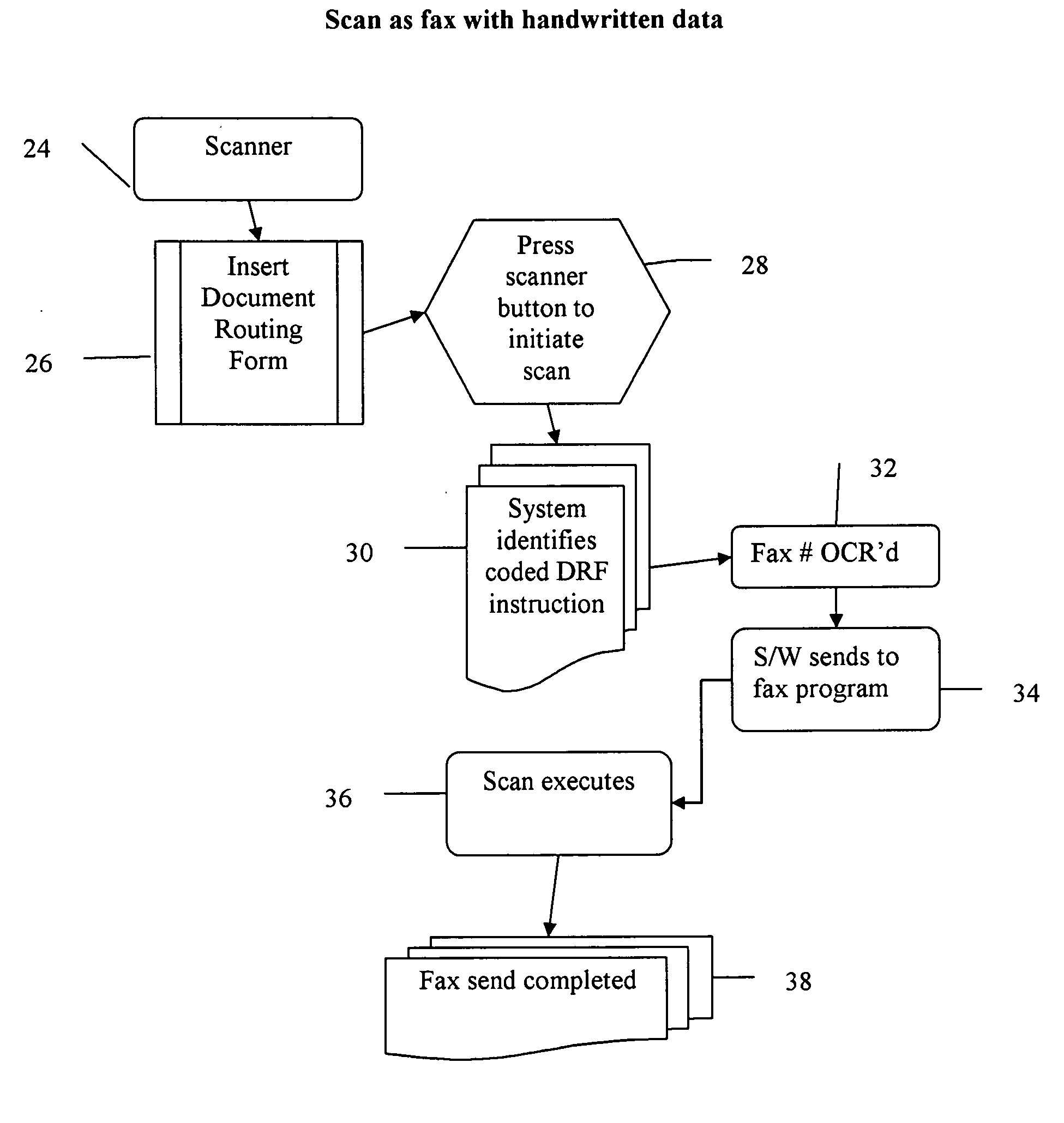

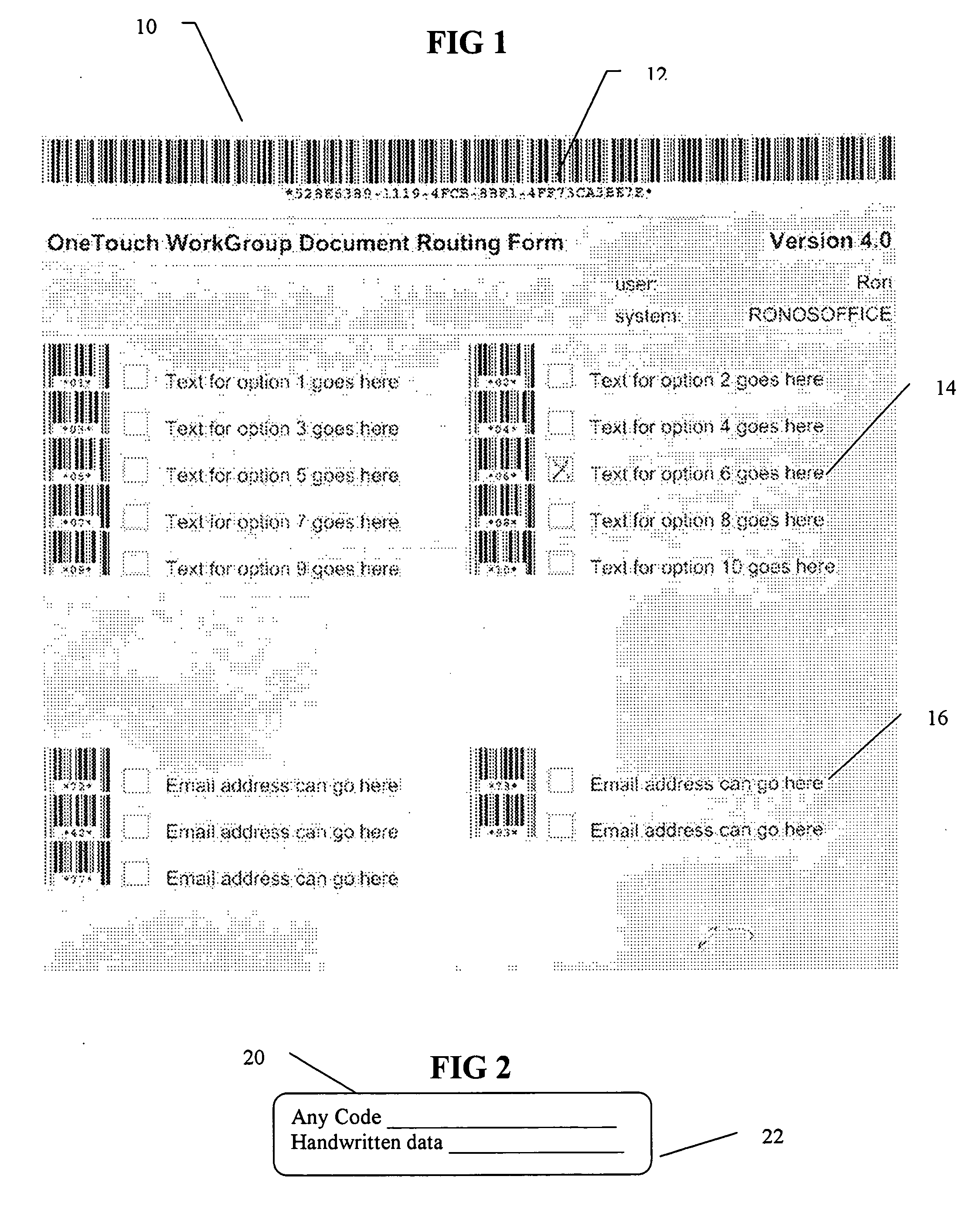

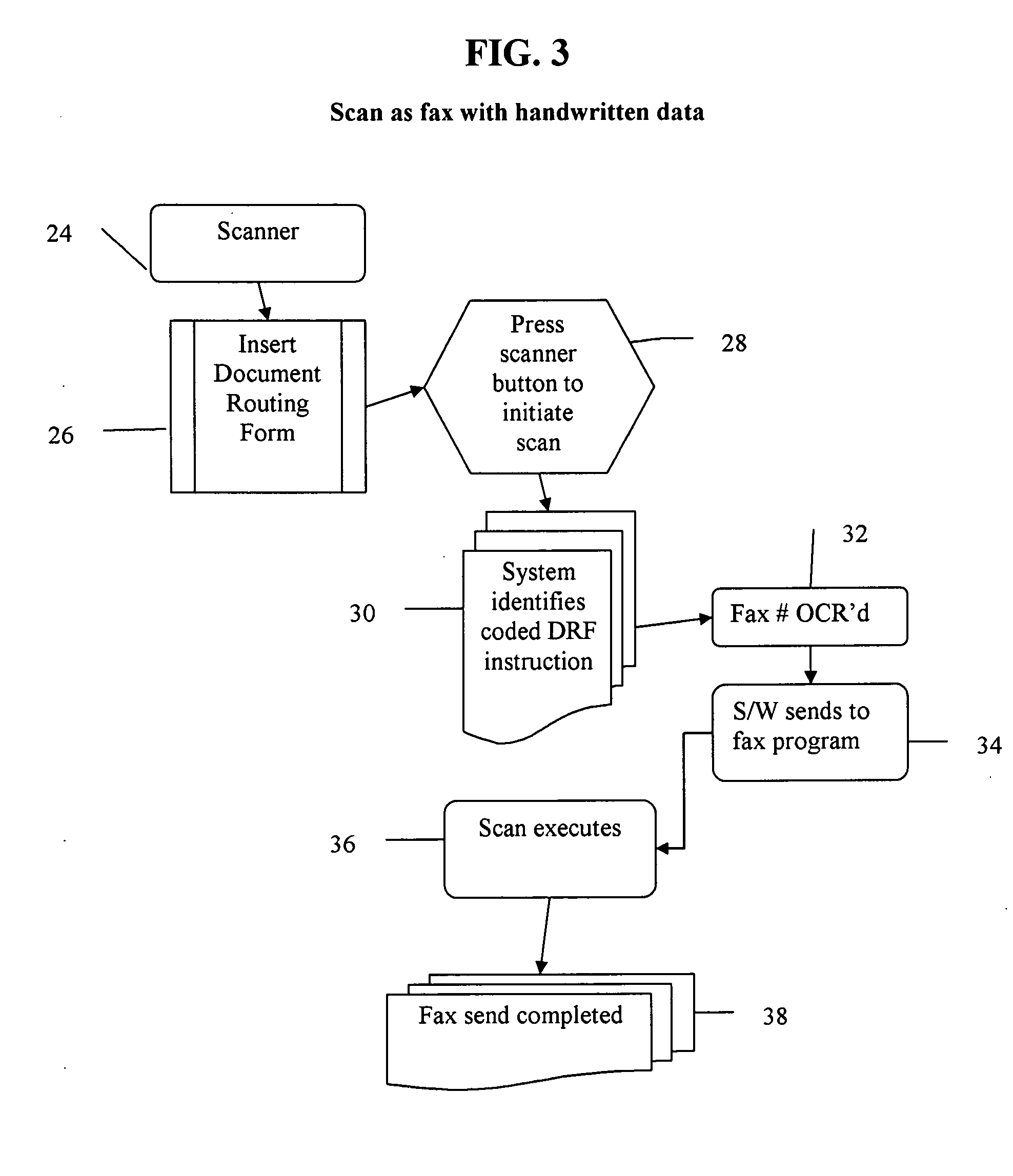

Document routing method for utilizing paper medium to direct outcome of scanned documents and software therefor

InactiveUS20050195447A1Easy to routeEasy retrievalCommerceSpecial data processing applicationsLead sheetData retrieval

The invention claimed is a method for creating and utilizing a paper intermediary, ideally termed a document routing form, to serve as a lead sheet to a set of documents to be scanned on a scanner connected to a computer, or a computer connected to a workgroup. Computer readable data, such as bar code, printed on the routing form serve as data instructions to the inventive software to process a set of scanned documents in a variety of end outcome options. The document routing forms may be printed on an 8.5 by 11 inch sheet of paper, or on an adhesive type label, and contain selection options that determine an outcome to documents scanned. Options for end outcomes may include processing the scan as an email, a fax, or being sent to a User's electronic archive. The inventive software facilitates data retrieval from a secondary source such as a User's electronic archive to be utilized in the outcome process. The inventive method also allows for a combination of encoded data and hand written data to be read from a document routing form, and processed by a secondary program such as an email or fax program.

Owner:VISIONEER INC

Method for manufacturing lead-carbon ultracapacitor battery cathode

ActiveCN101667637AIncrease specific energyImprove discharge capacityElectrochemical generatorsElectrode manufacturing processesCapacitanceActivated carbon

The invention discloses a method for manufacturing a lead-carbon ultracapacitor battery cathode, comprising the following steps: active substances taking lead powder as a main component and active substances taking active carbon as a main component are respectively coated on different areas of an electrode matrix, and then are dried to obtain the lead-carbon ultracapacitor battery cathode. The invention provides a manufacturing technology of lead-carbon ultracapacitor battery cathode, which takes a pure lead sheet or lead alloy sheet as a matrix, and adopts the active carbon and the lead powder as active substances. Compared with the cathode taking the pure active carbon as cathode active substance, the cathode piece manufactured by the method can greatly improve discharge capacity of thelead-carbon ultracapacitor batteries, the specific energy can reach more than 16wh / kg, the cycle life can reach more than 1500 times, working potential window can reach 2.0V, and the cost is only onethird to one fifth of that of the current inorganic system carbon-carbon symmetric form and nickel electrode-carbon mixed alkaline system.

Owner:SHUANGDENG GRP

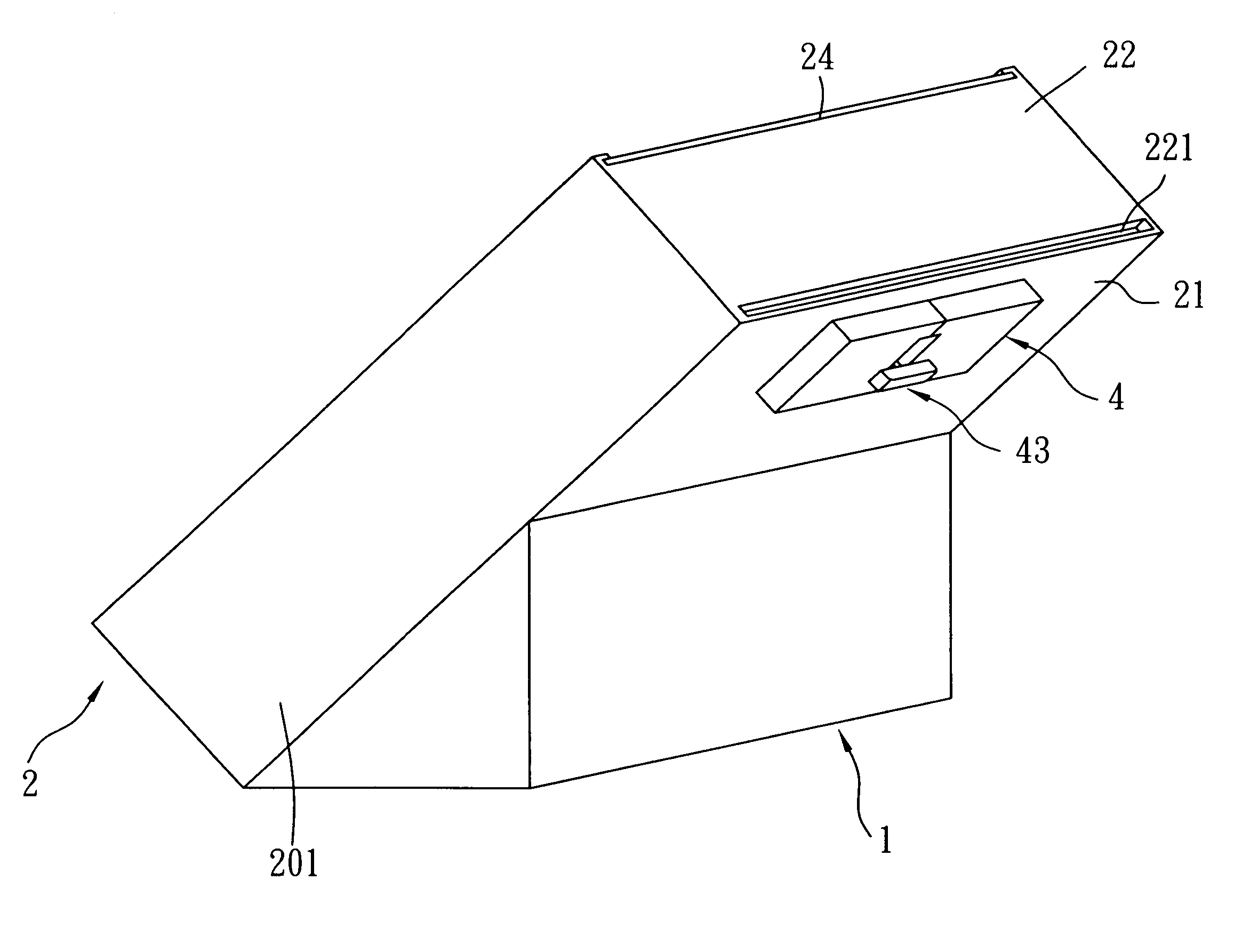

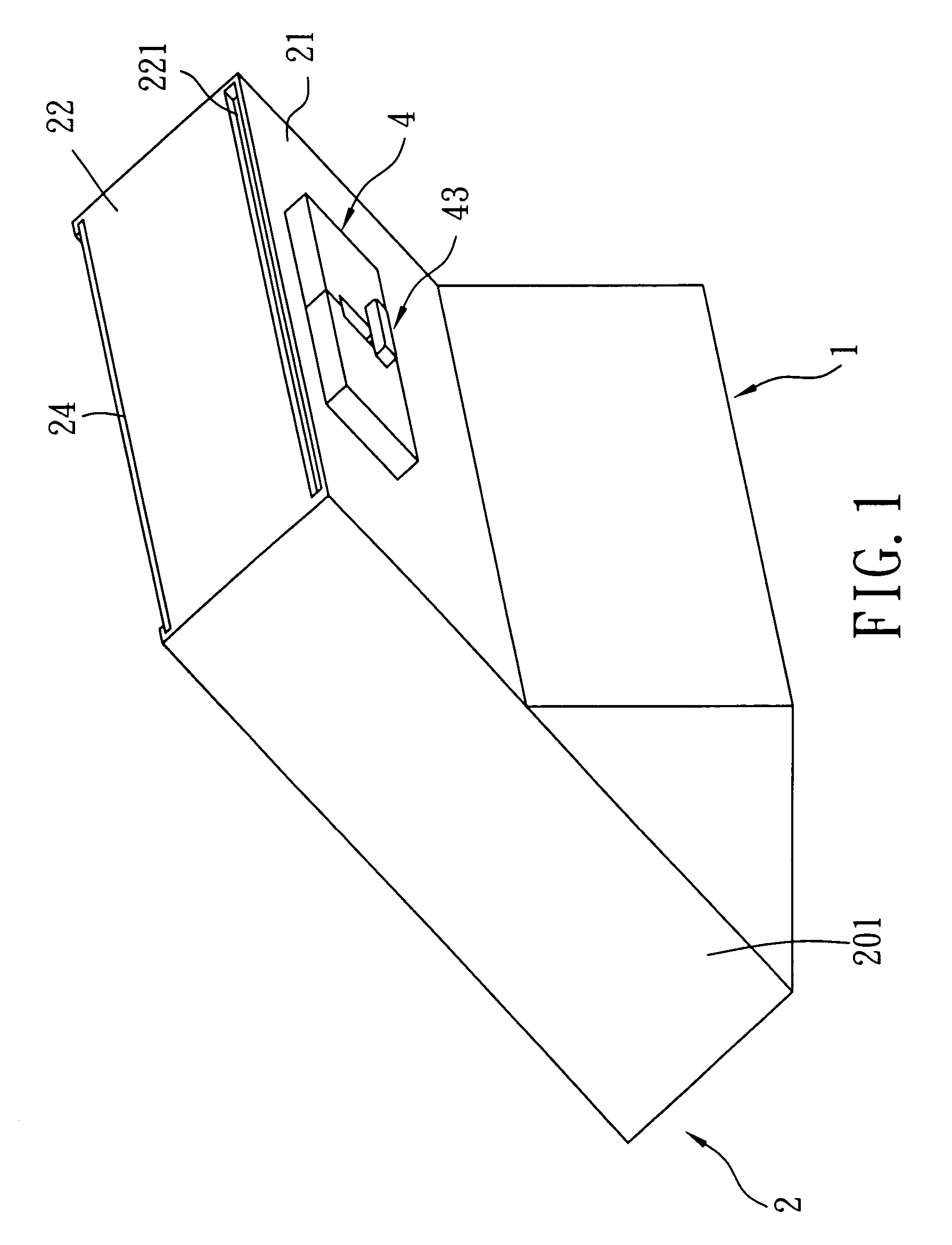

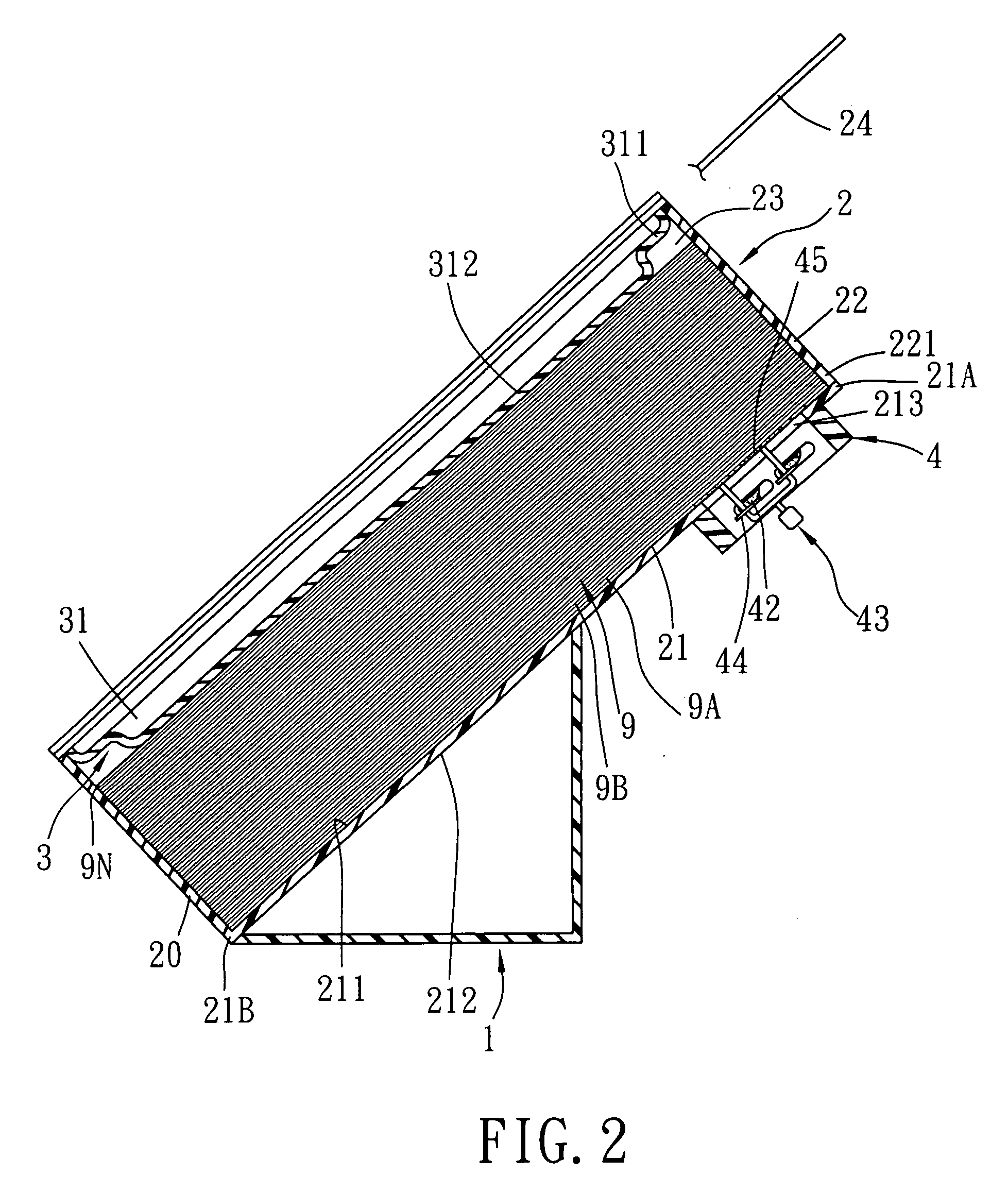

Refillable flexible sheet dispenser

InactiveUS20050236416A1The process is convenient and fastEffective distributionContainers for flexible articlesOther domestic articlesLead sheetMechanical engineering

A flexible sheet container is provided that permits a user to quickly and easily feed a leading sheet. The container has a base portion that defines a storage area and a top covering the base portion. The top includes an opening into the storage area through which individual flexible sheets are dispensed. A pair of opposing flaps is pivotally attached to the top at their first ends and each extends toward the dispensing opening with its second end. The complementary second ends of the flaps together further define the dispensing opening while in a dispensing position. The flaps pivot inward toward the storage area to provide access through the opening into the storage area. As such, to feed a leading flexible sheet, a user may rotate the flaps inward, grab a leading flexible sheet, and pull it through the opening. During dispensing, the flaps rotate outward and retain subsequent sheets.

Owner:GPCP IP HLDG LLC

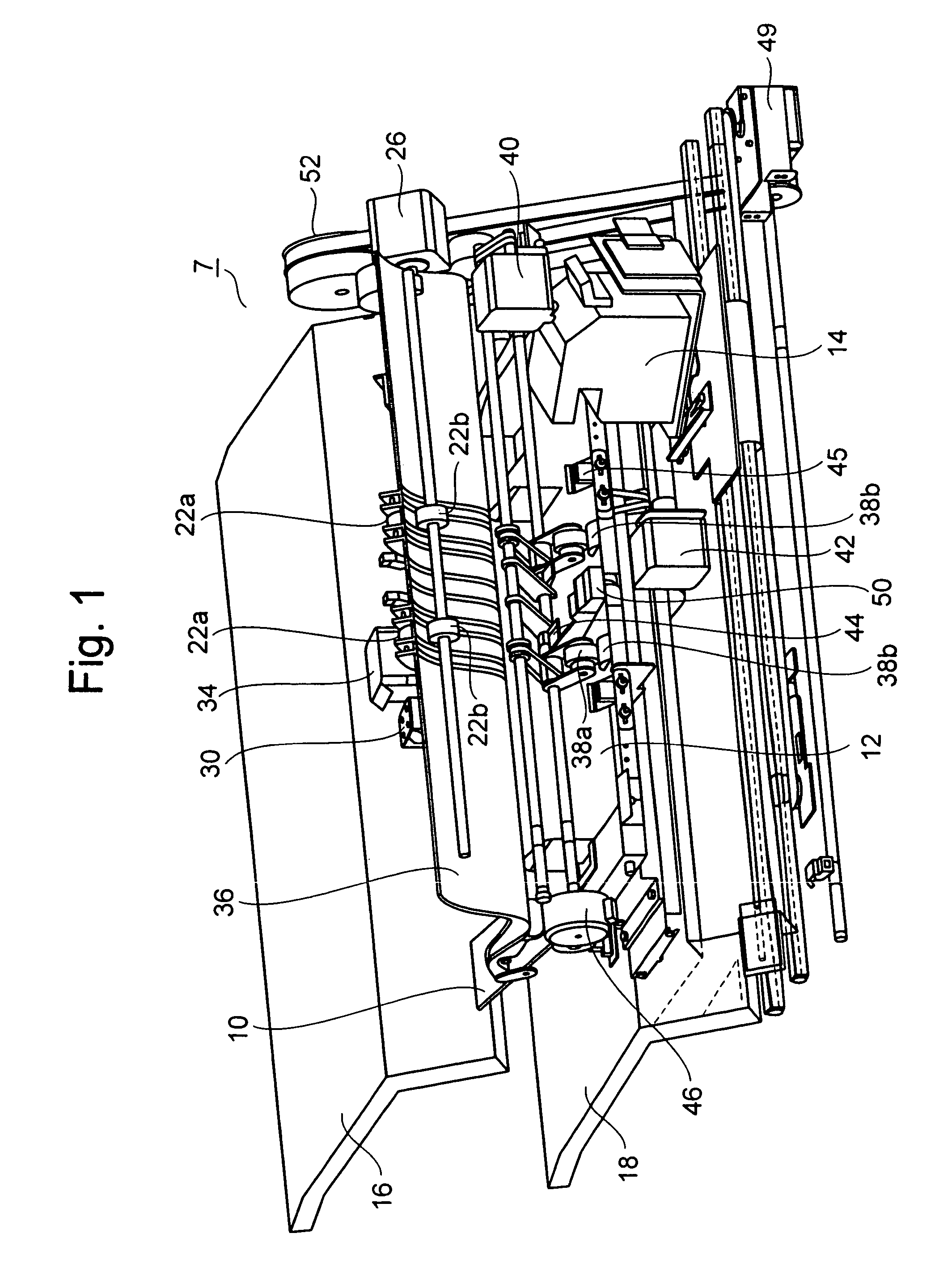

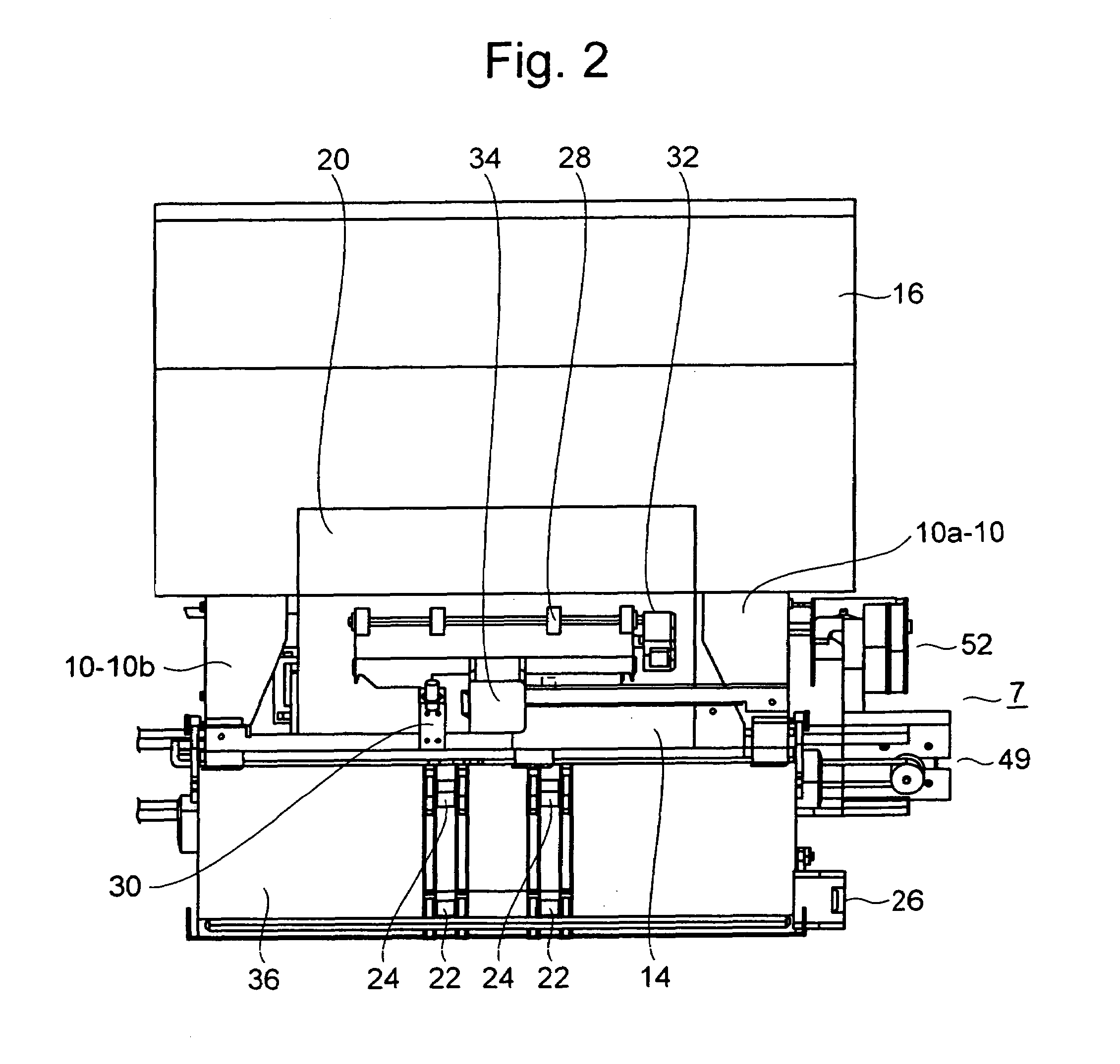

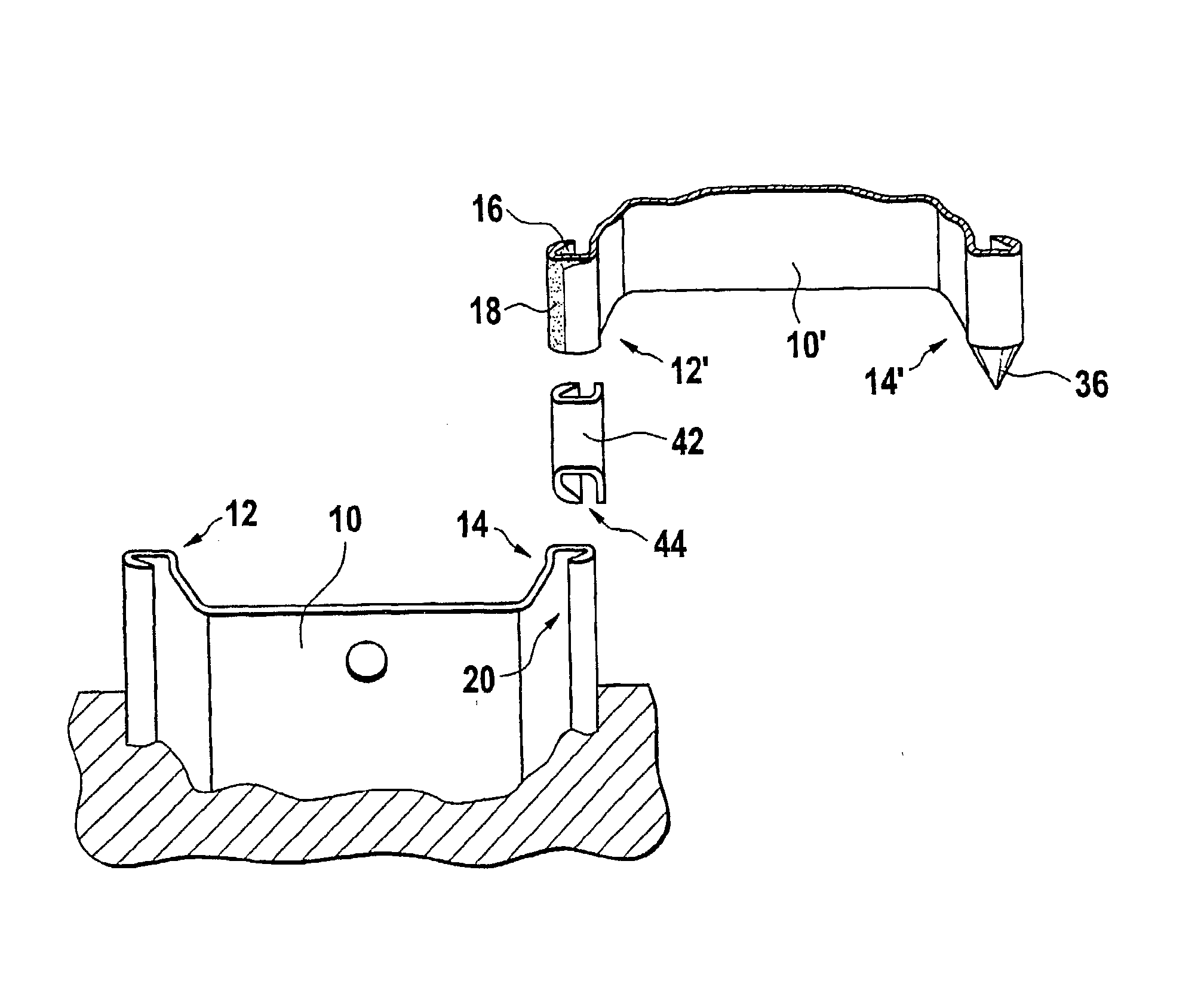

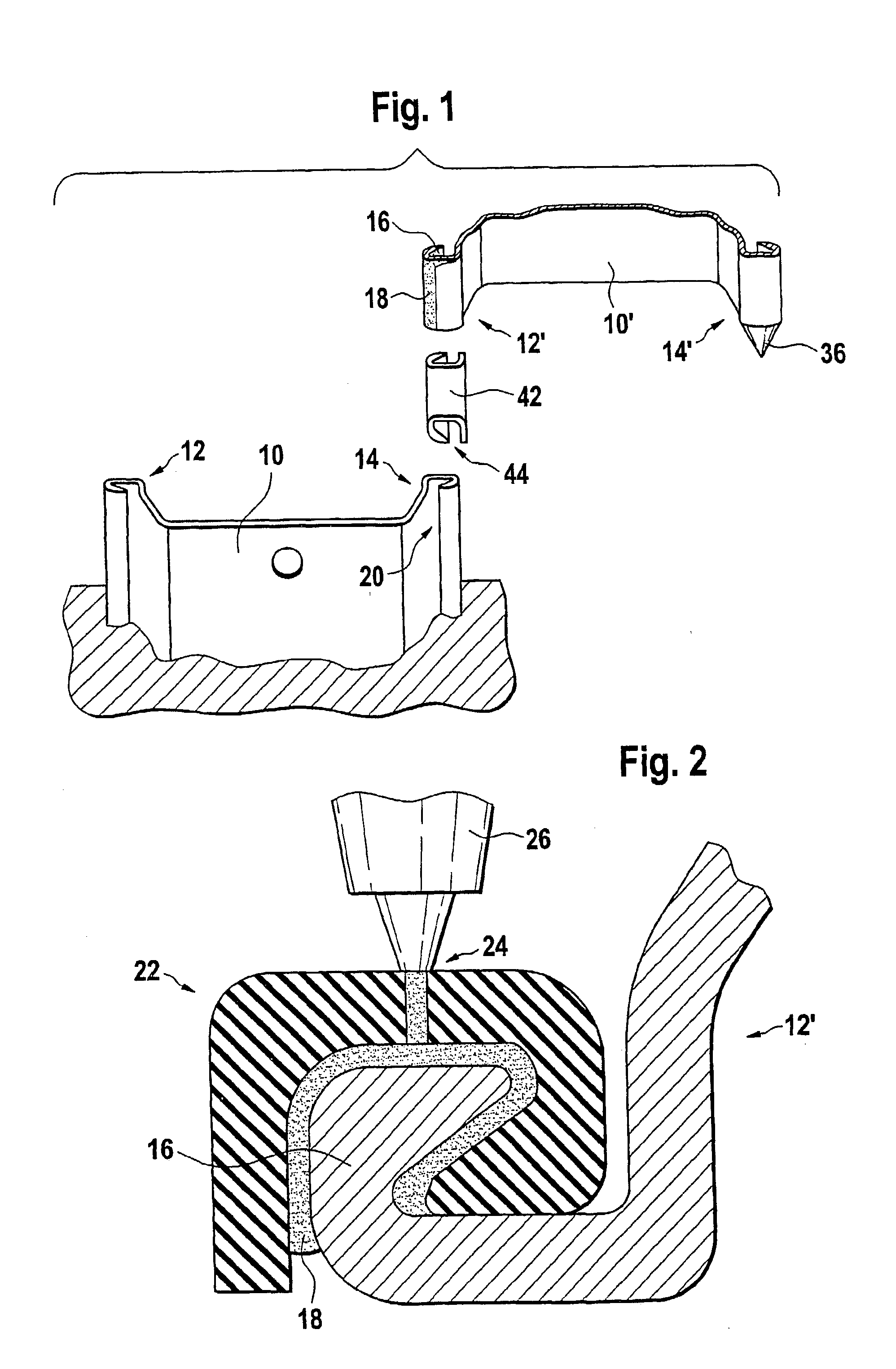

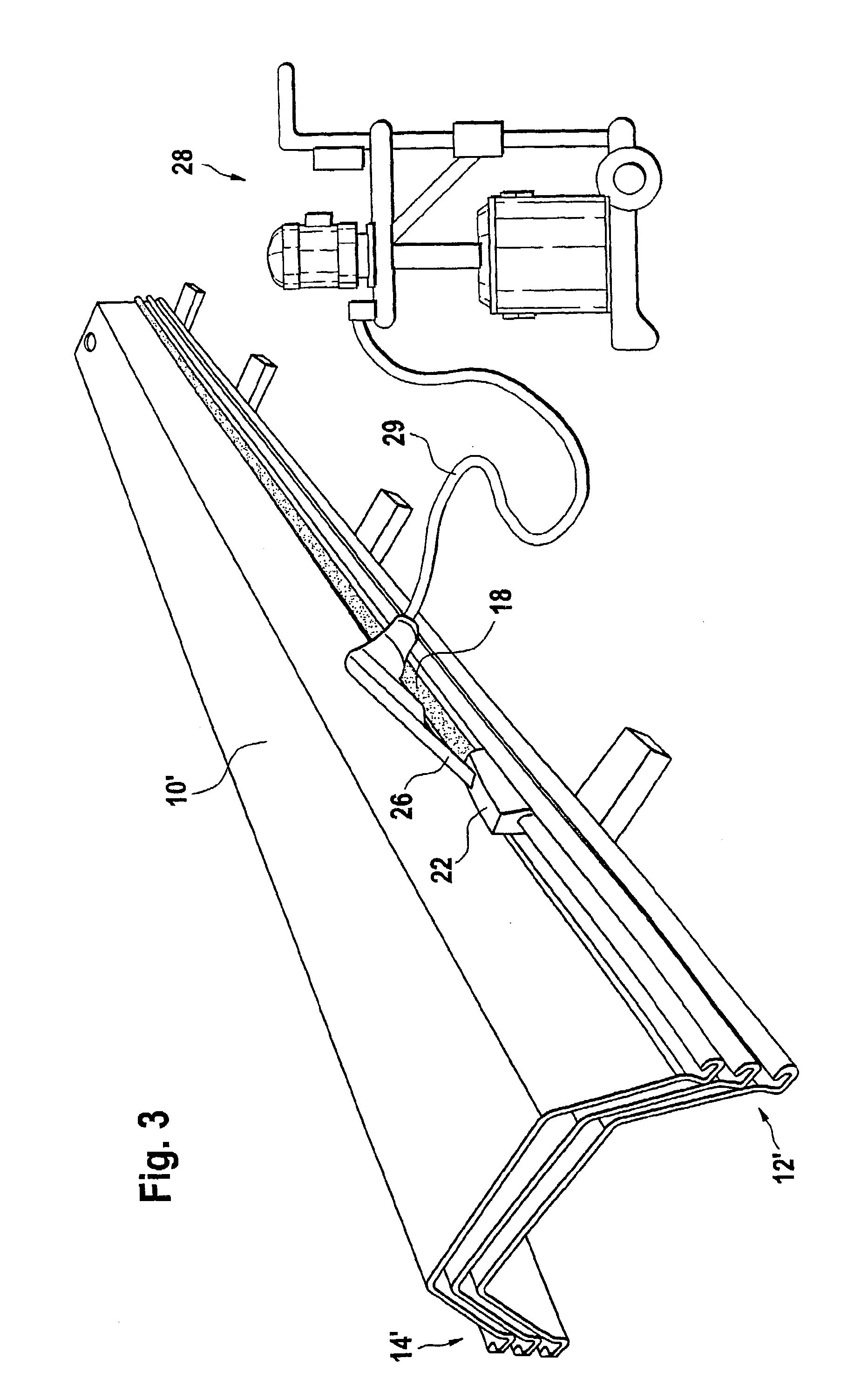

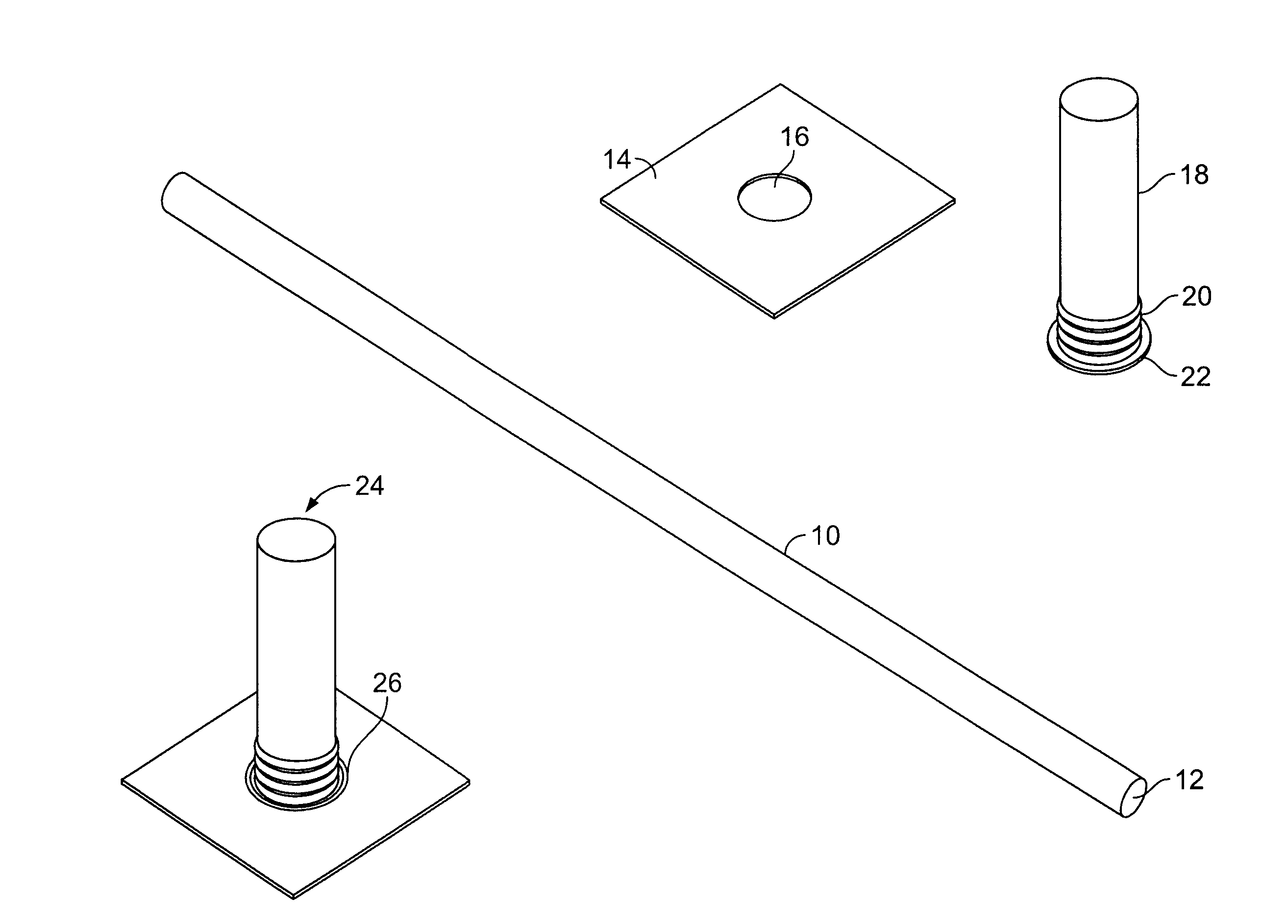

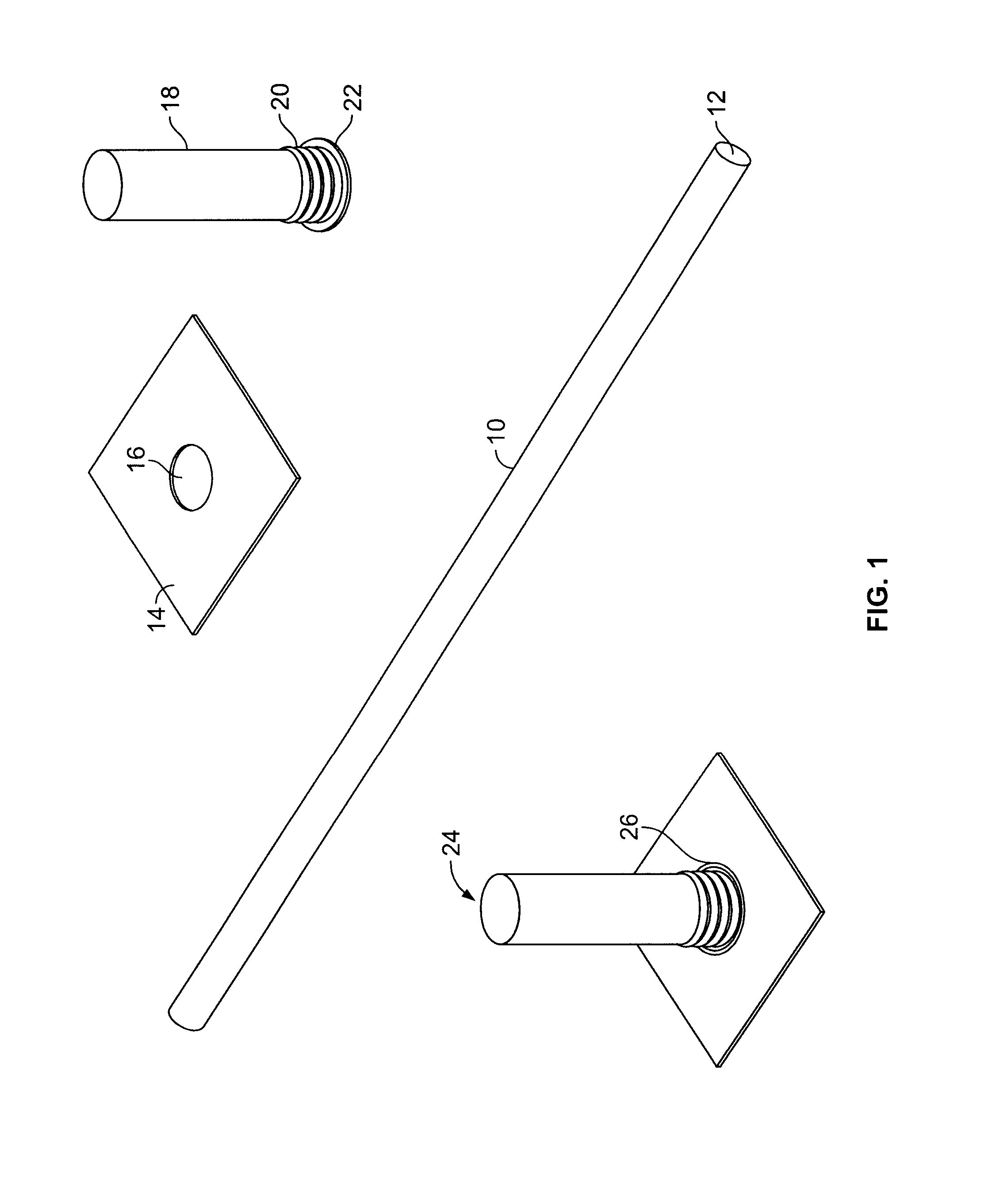

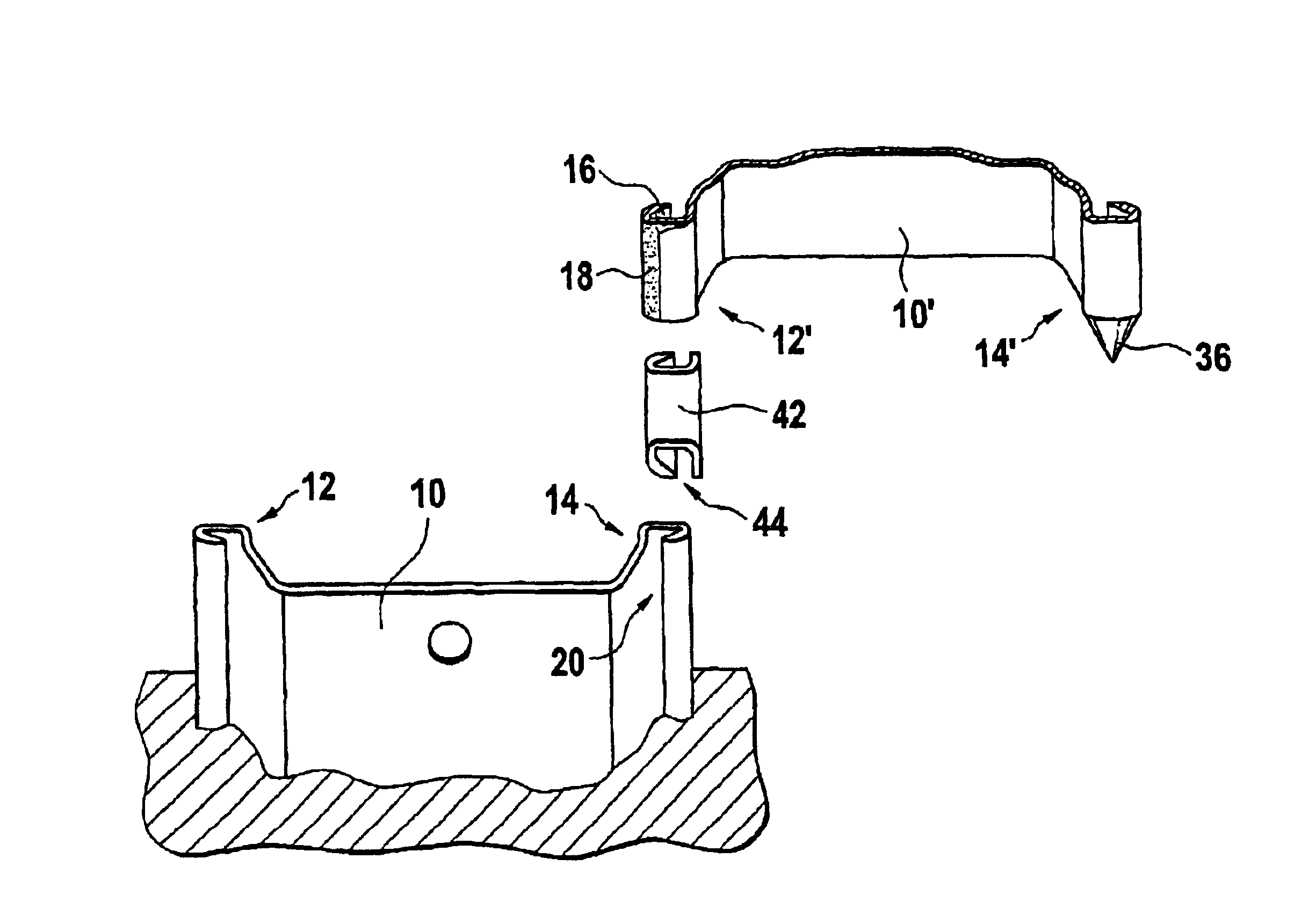

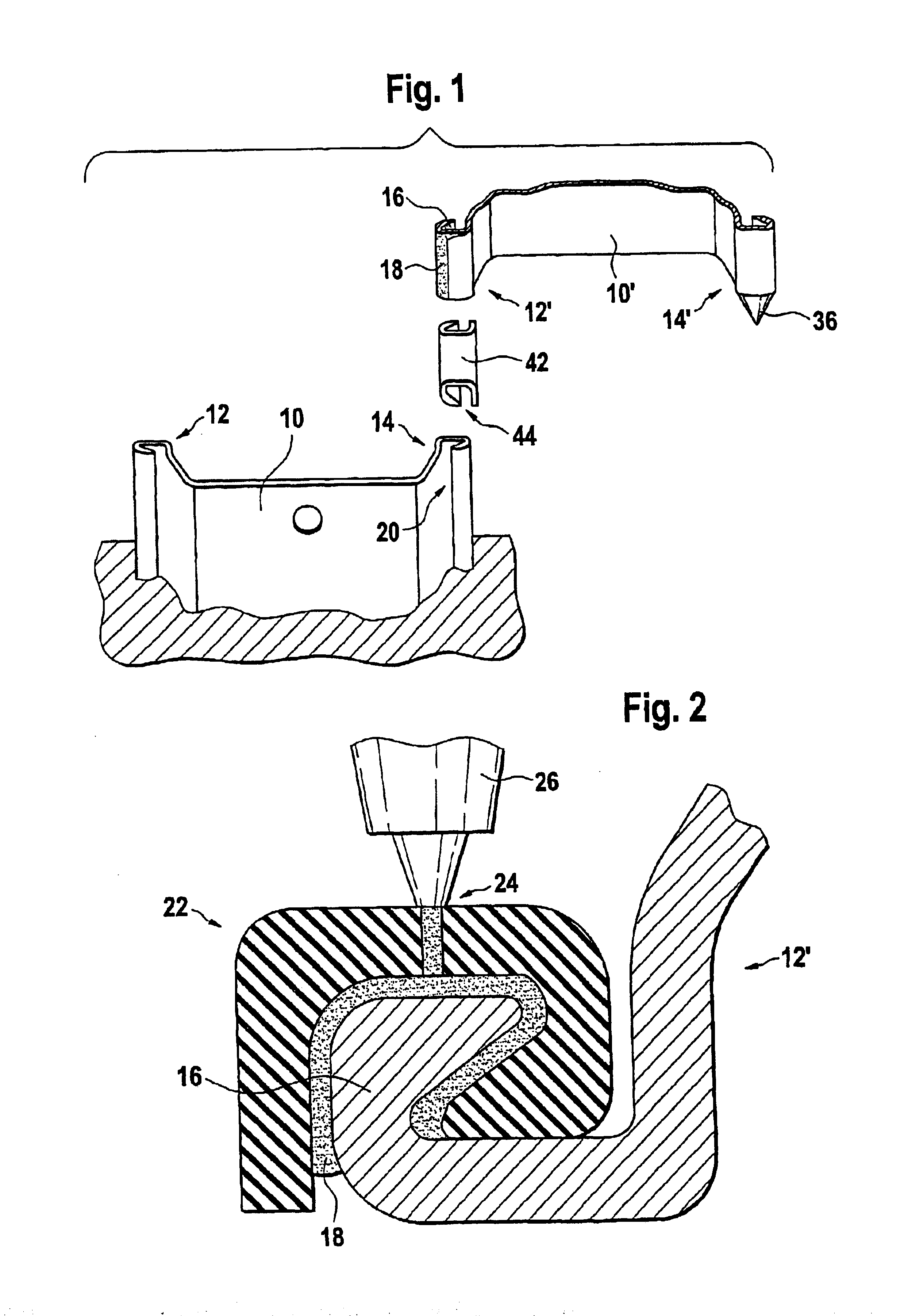

Method for building sheet pile walls

A method for building sheet pile walls comprises the steps of providing a first sheet pile (10), said first sheet pile (10) having a leading sheet pile interlock (14) with an interlock chamber (20); driving said first sheet pile (10) into the ground while protecting said interlock chamber (20) from ground material; providing a second sheet pile (10'), said second sheet pile (10') having a trailing sheet pile interlock (12') with an interlock head (16); engaging said interlock head (16) of said trailing sheet pile interlock (12') in said interlock chamber (20) of said leading sheet pile interlock (14); driving said second sheet pile (10') into the ground. The method further comprises the step of coating said interlock head (16) of said trailing sheet pile interlock (12') with fixing agent prior to engaging said interlock head (16) of said trailing sheet pile interlock (12') in said interlock chamber (20) of said leading sheet pile interlock (14).

Owner:ARCELORMITTAL COMML RPS SRL

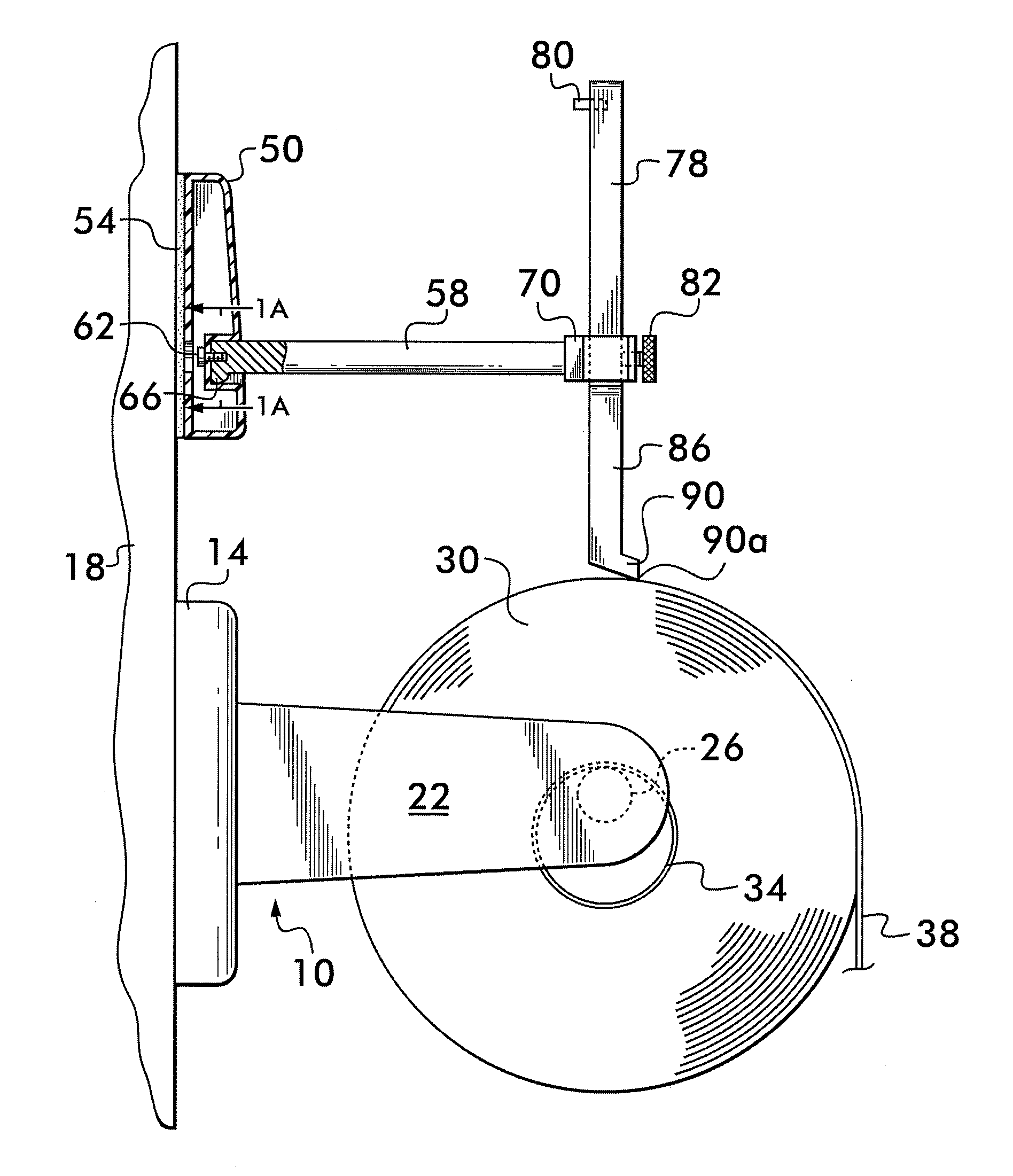

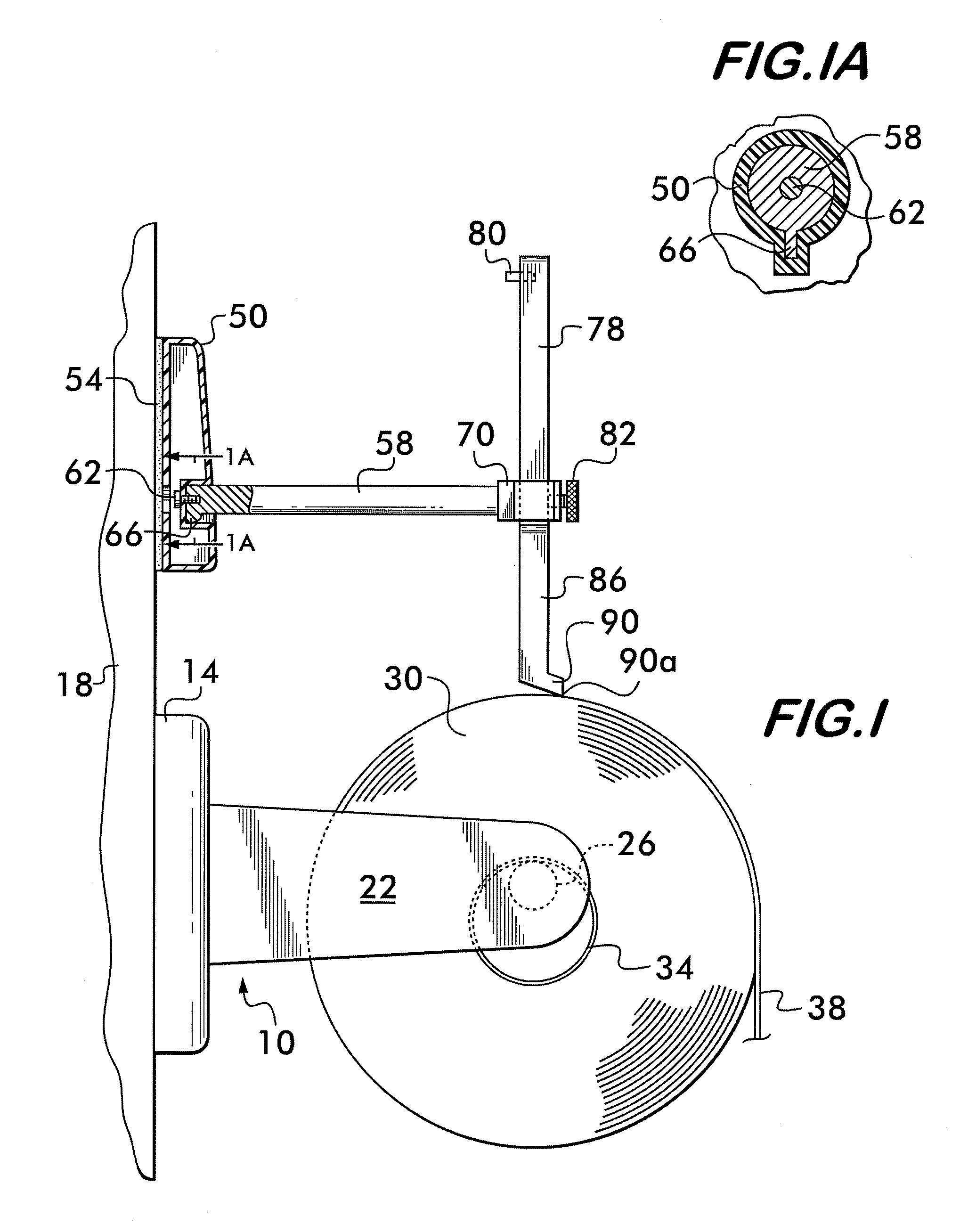

Device to Restrain the Unwinding of a Web of Roll Material

A device to restrain the unwinding of a roll of paper for use in combination with a paper dispenser is disclosed. The paper dispenser includes a back plate mountable upon a wall, a pair of opposed side plates extending from the back plate for rotatably supporting a roll of paper having a depending lead sheet. The restraining device comprises a base portion mountable to the wall and a support arm extending laterally from the base portion over the roll of paper. The support arm includes a collar located at its free end, the collar including a central opening. The roll braking arm is oriented substantially vertically and extends through the central opening of the support arm. The roll braking arm contacts and applies its weight as a braking force against the roll of paper to restrain the roll of paper from unwinding unnecessarily.

Owner:BRUNER MATES A

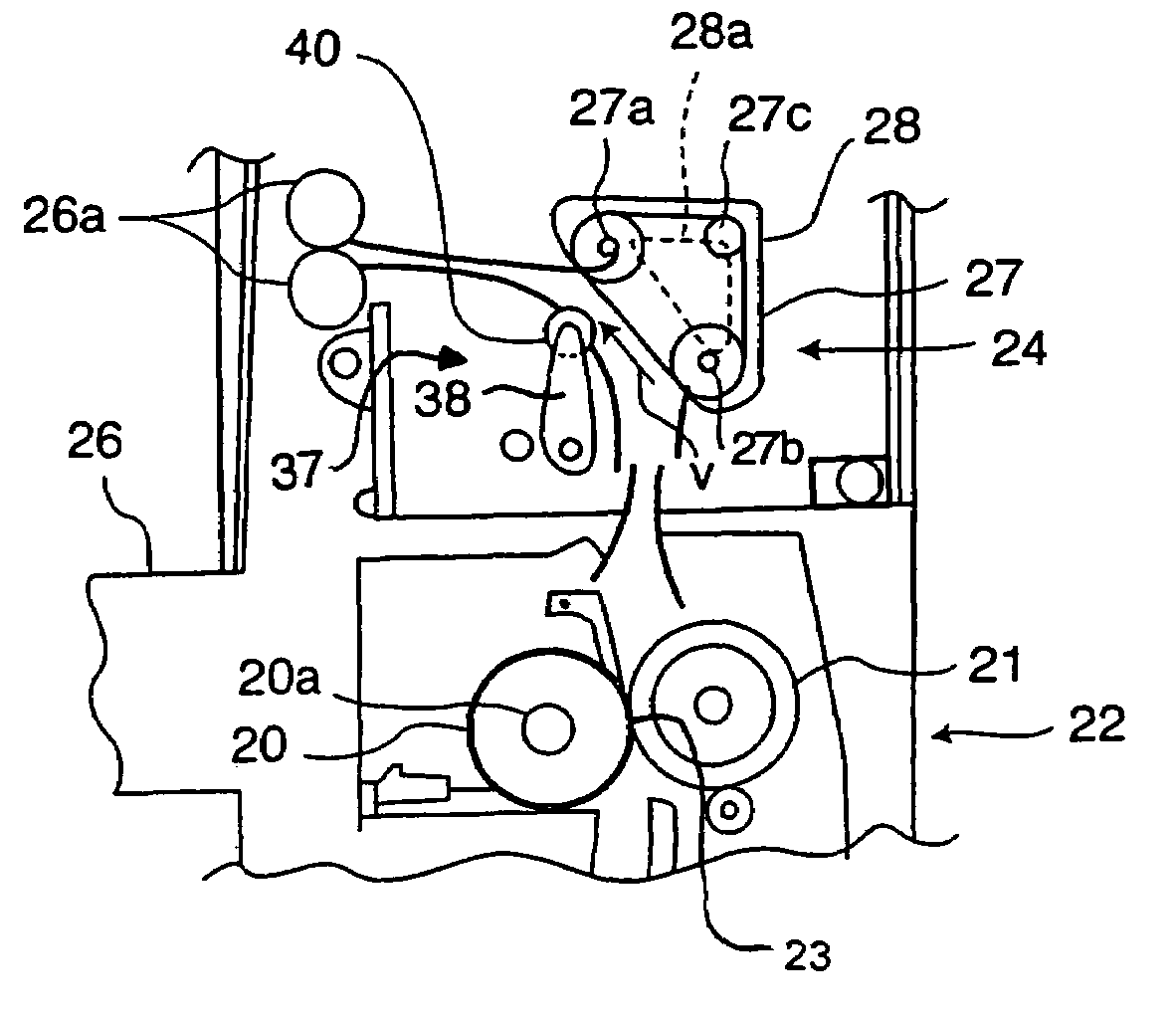

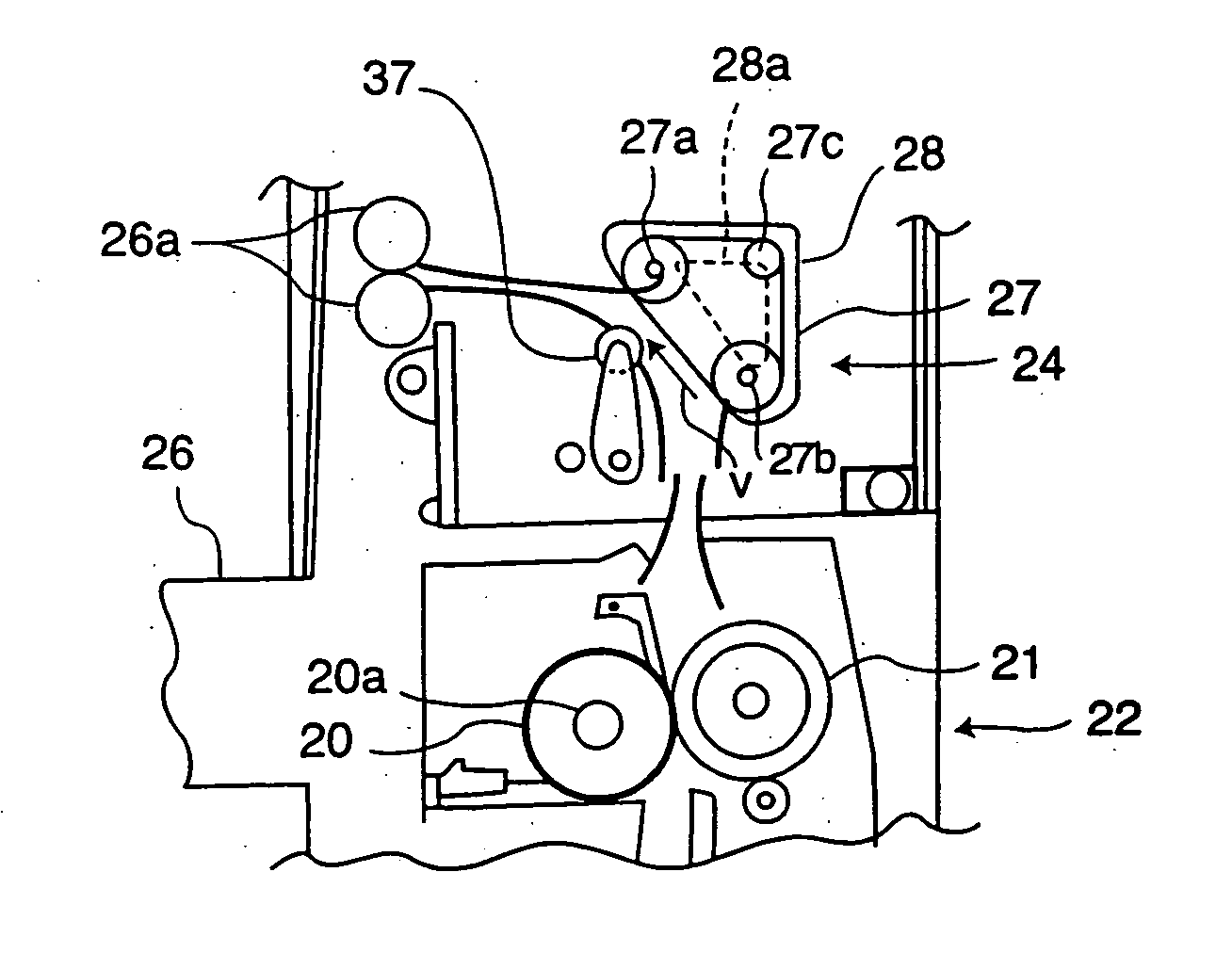

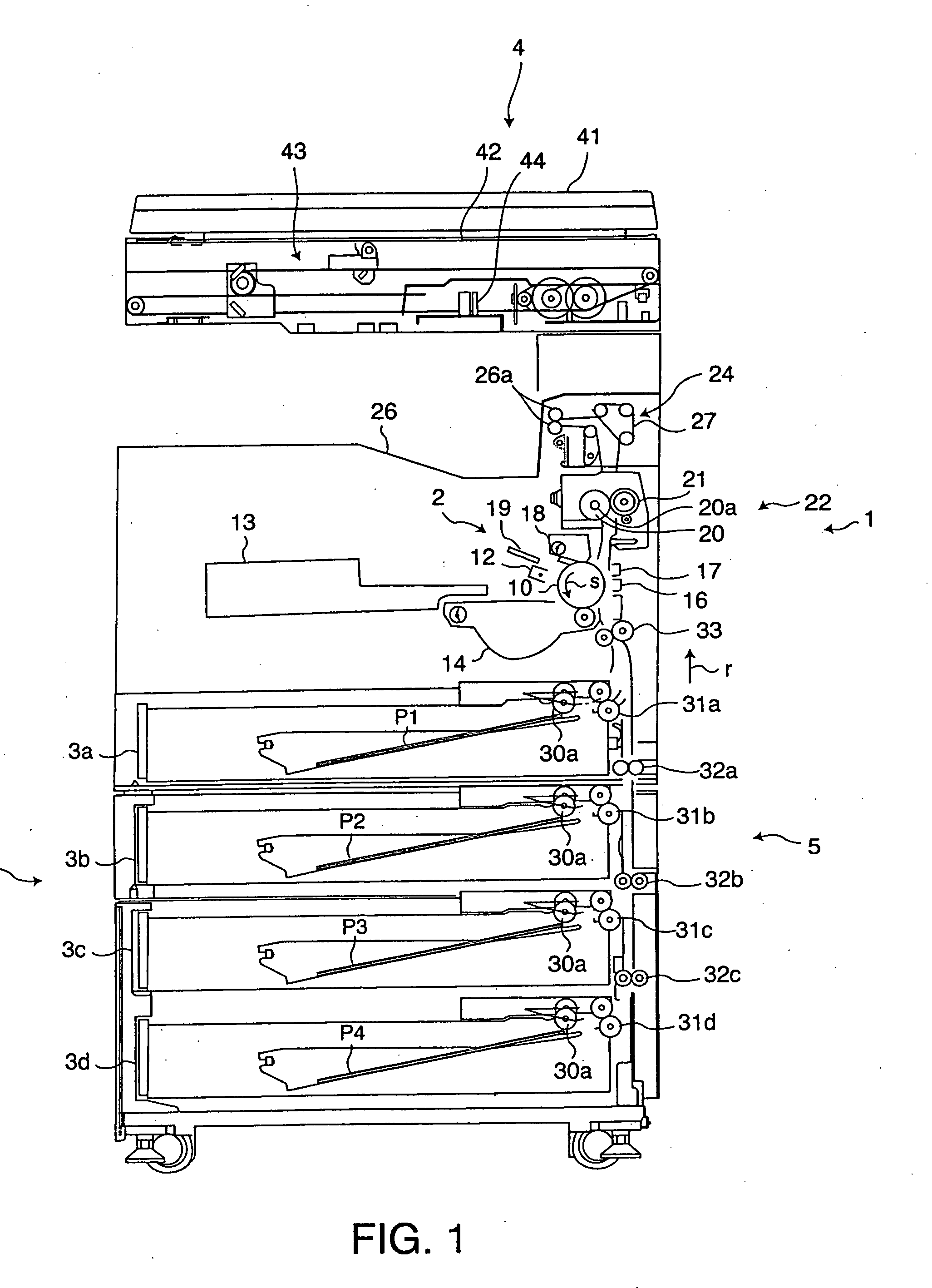

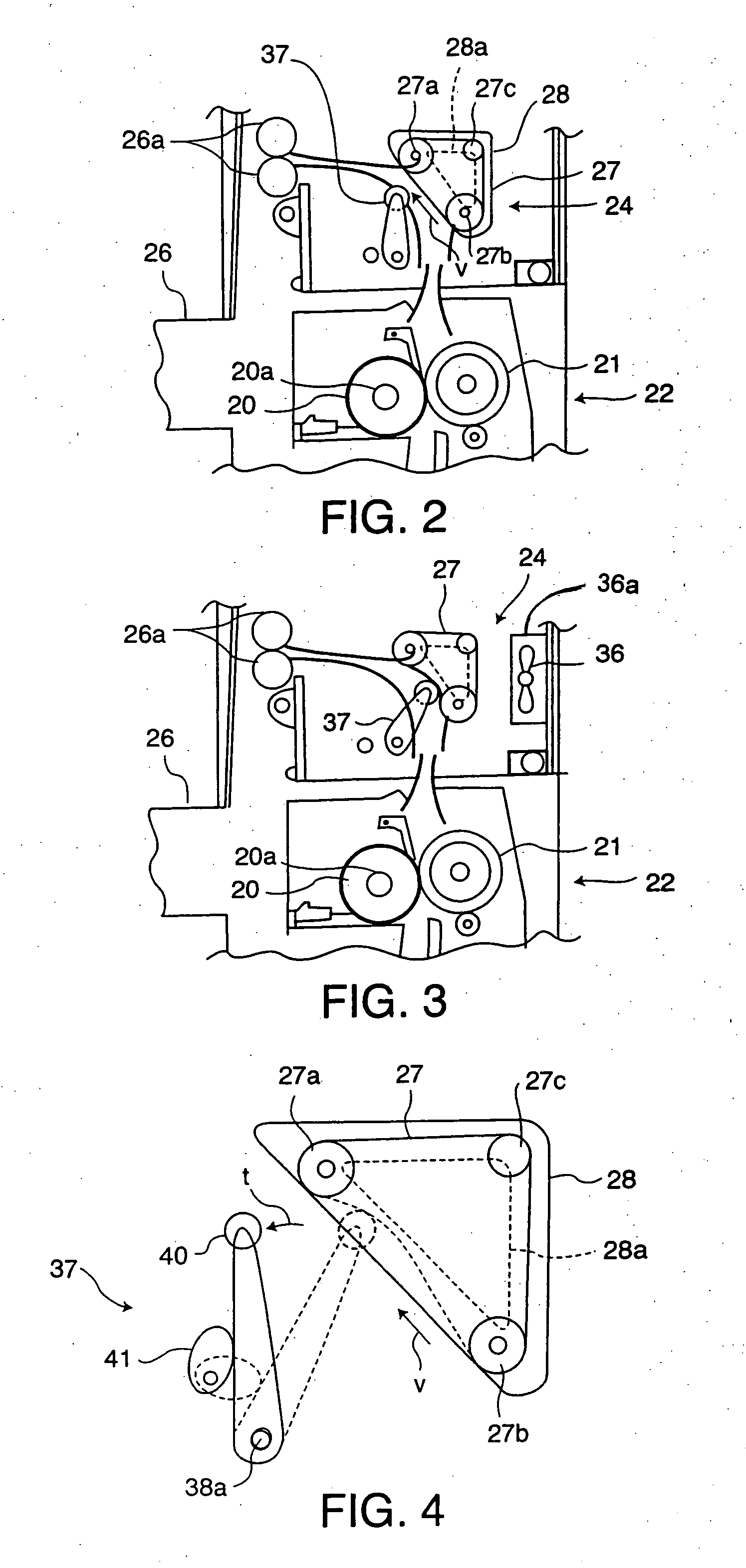

Image forming apparatus

InactiveUS6965750B2Impairing downsizingElectrographic process apparatusPile receiversLead sheetImage formation

Owner:KK TOSHIBA +1

Image forming apparatus

InactiveUS20050084307A1Impairing downsizingElectrographic process apparatusPile receiversLead sheetImage formation

Owner:KK TOSHIBA +1

Method for manufacturing multi-pitch flashing

A method for manufacturing lead flashing for a roof pipe is disclosed. A lead pipe is straightened and then pushed into a frictionally engaged knurled clamp. Pressure is applied between a knurled head of a knurler and the inner surface of the lead pipe and the knurler is rotating about the inner surface of the lead pipe. This causes the lead pipe to conform to the knurles of the knurled clamp and the knurled head, while causing a portion of the lead pipe extending beyond the knurled clamp to be contoured and swaged into a flange. At a multi-position horizontally positioned rotatable table, the flange of the knurled lead pipe is flattened to overlap a flat lead sheet having a hole cut from its center. The knurled lead pipe flange and flat lead sheet are arc-welded together with a TIG weld gun. After welding, the finished lead pipe flashing is moved onto a packaging feed conveyor via a vacuum lifter.

Owner:METALICO INC

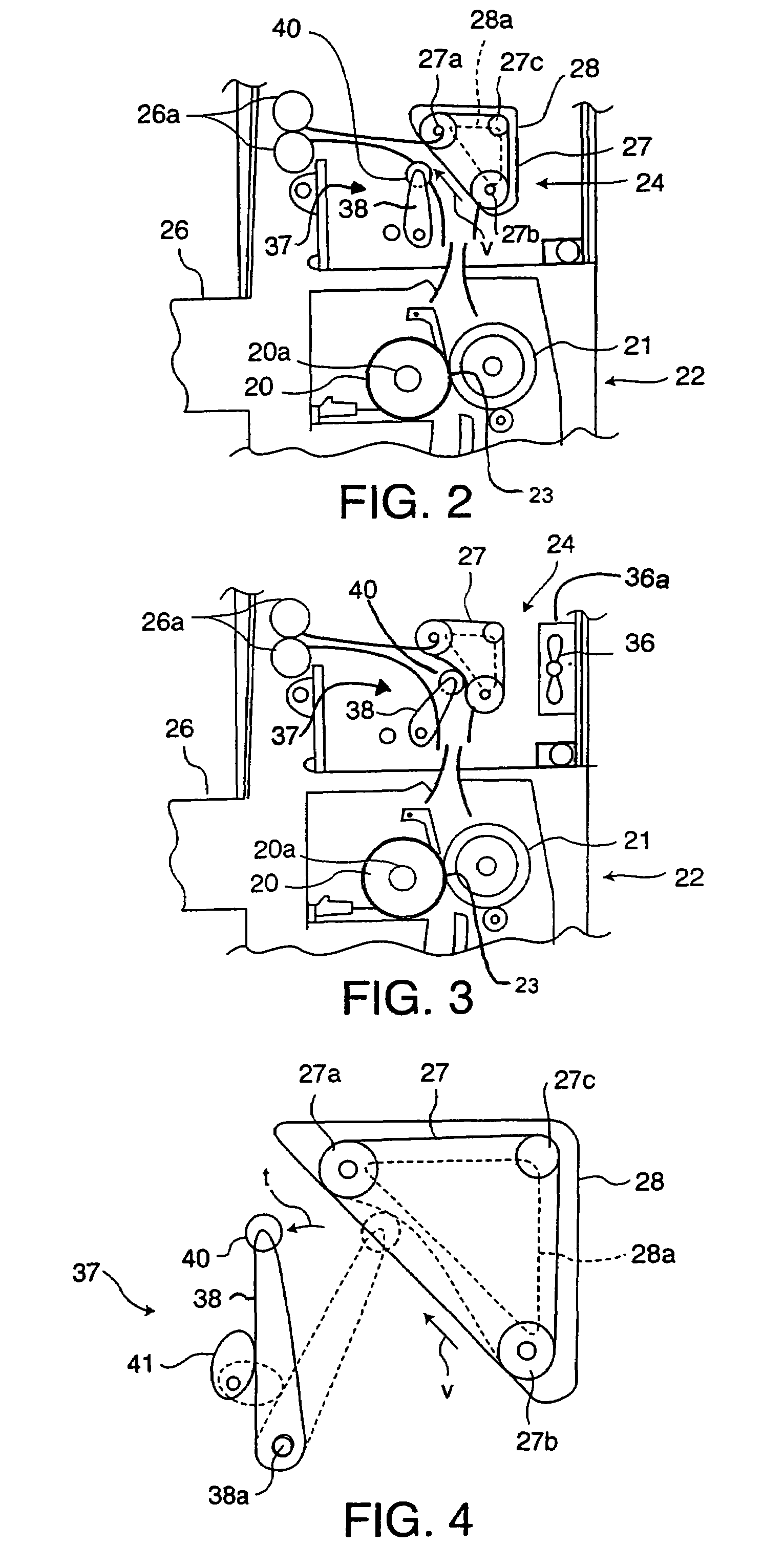

Sheet finishing apparatus

InactiveUS20060214347A1Process can be stoppedPile receiversArticle deliveryLead sheetImaging equipment

A sheet finishing apparatus of the present invention includes a gate for conveying sheets of paper ejected from an image forming apparatus by switching to a first conveying path requiring post processing or to a second conveying path requiring no post processing and a manual introduction unit for post-processing the sheets of paper conveyed via the first conveying path by a processing mechanism and ejecting them to a first paper ejection tray and manually leading sheets of paper requiring post processing to the processing mechanism, and when the post process is executed in a manual mode, switches the gate to the second conveying path, and when sheets of paper are taken in from the image forming apparatus, ejects the sheets of paper to a second paper ejection tray via the second conveying path.

Owner:TOSHIBA TEC KK

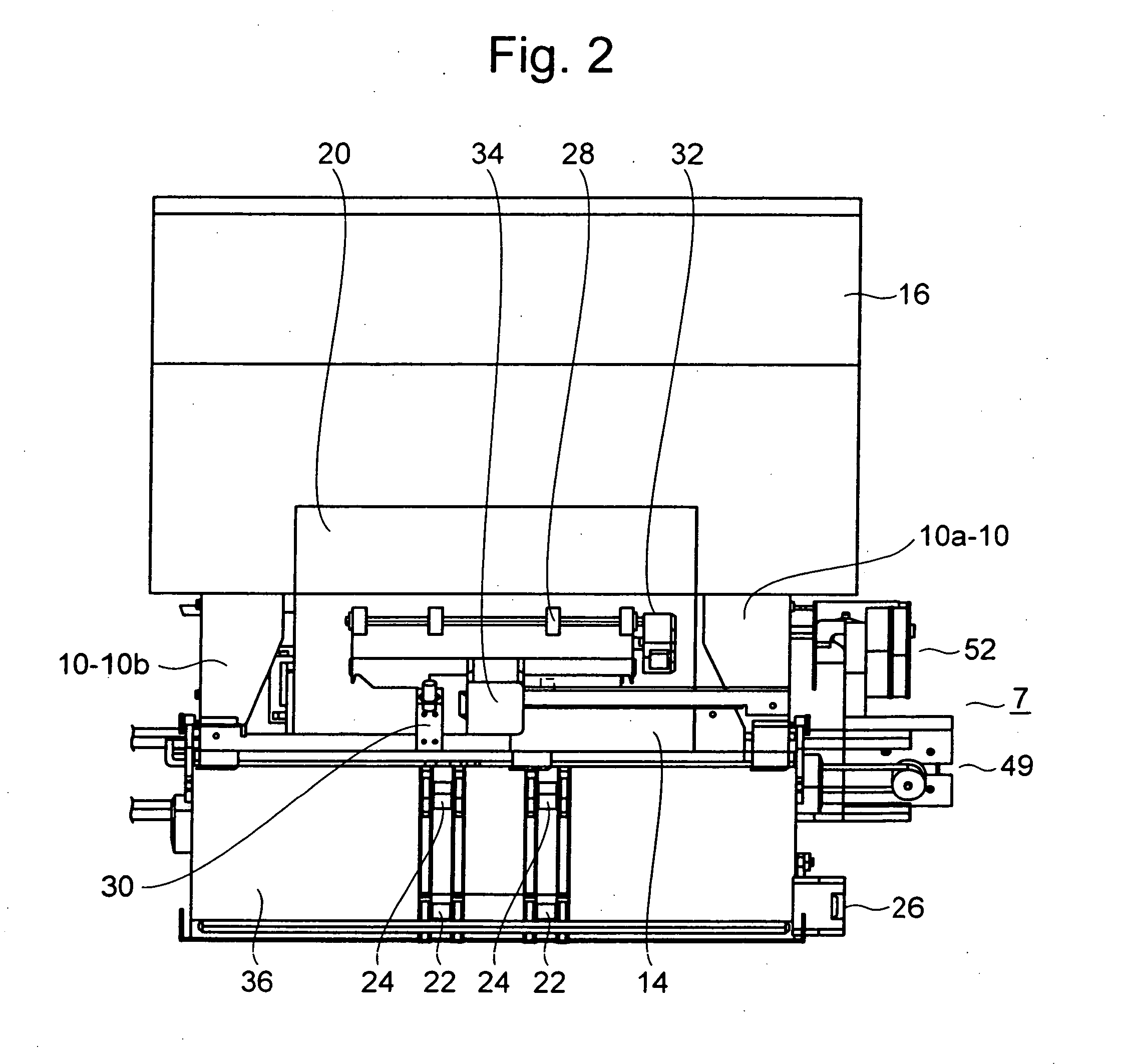

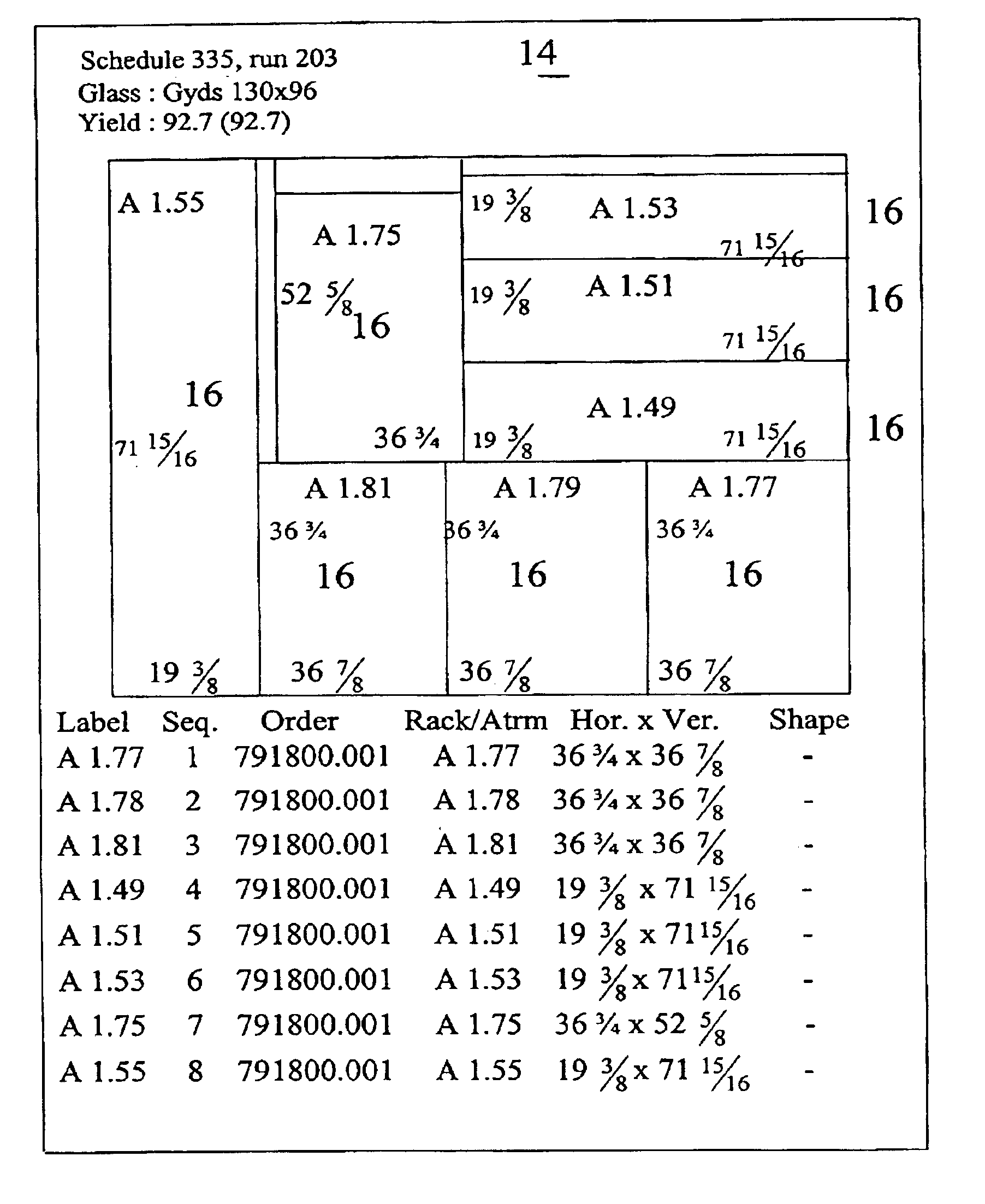

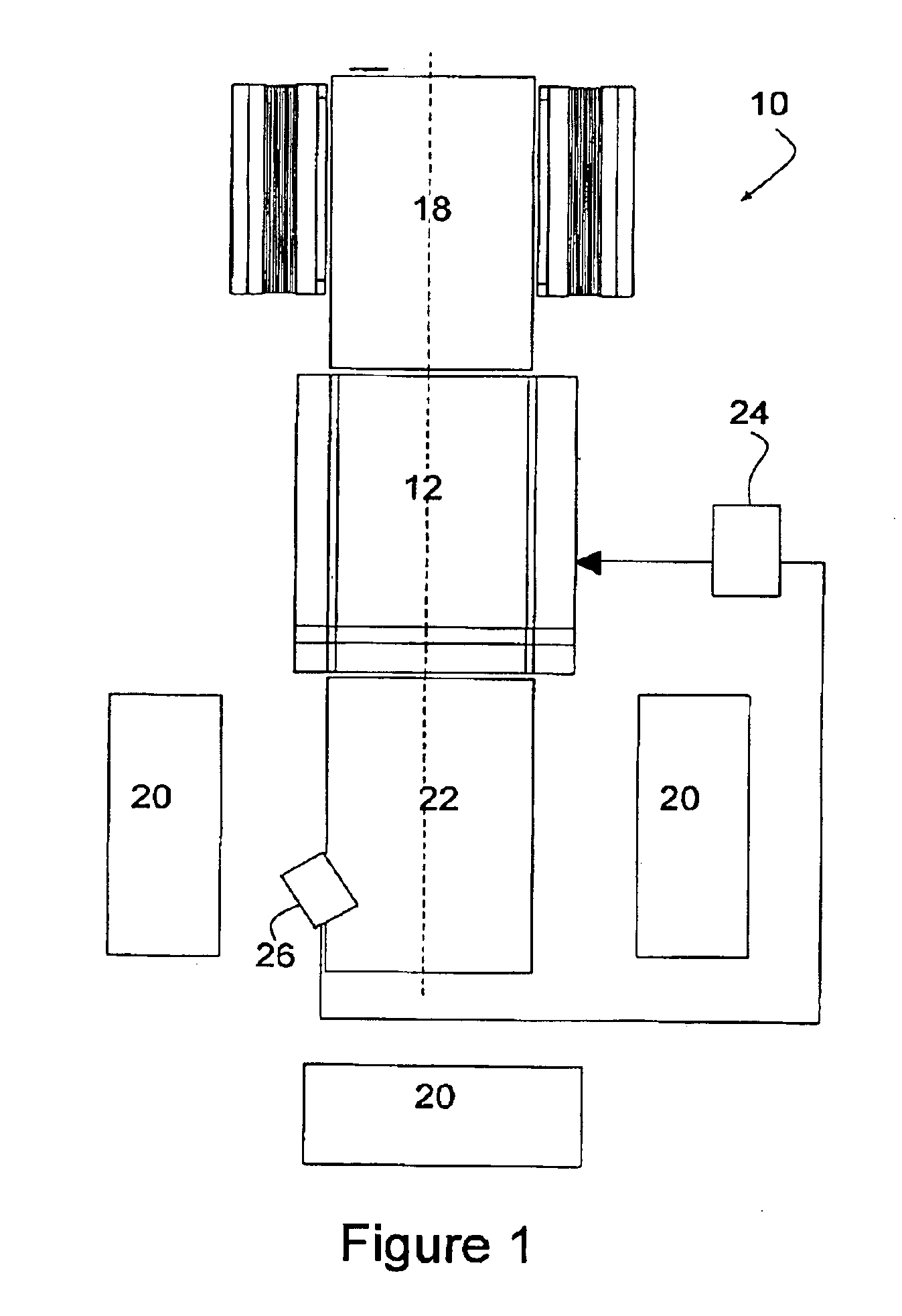

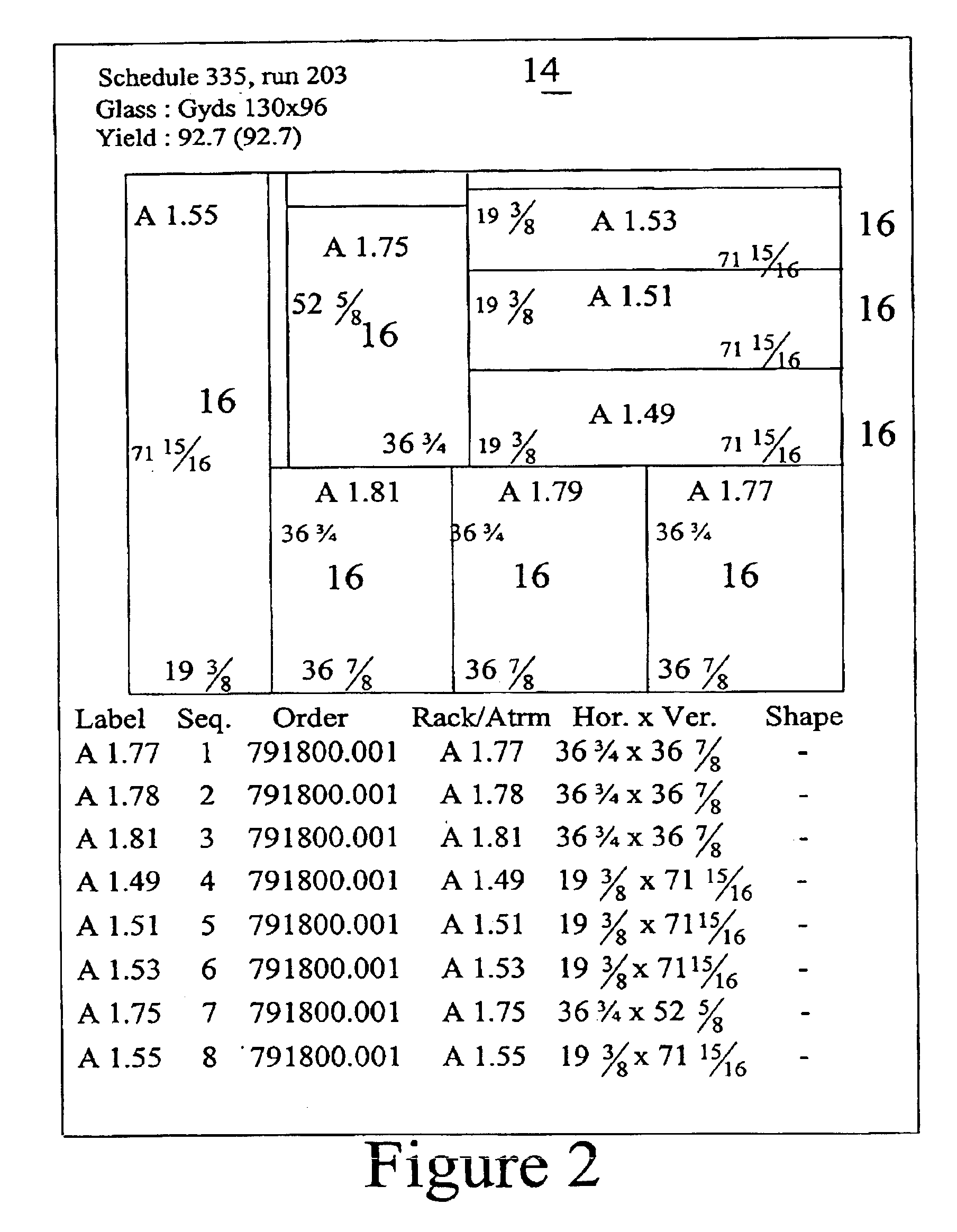

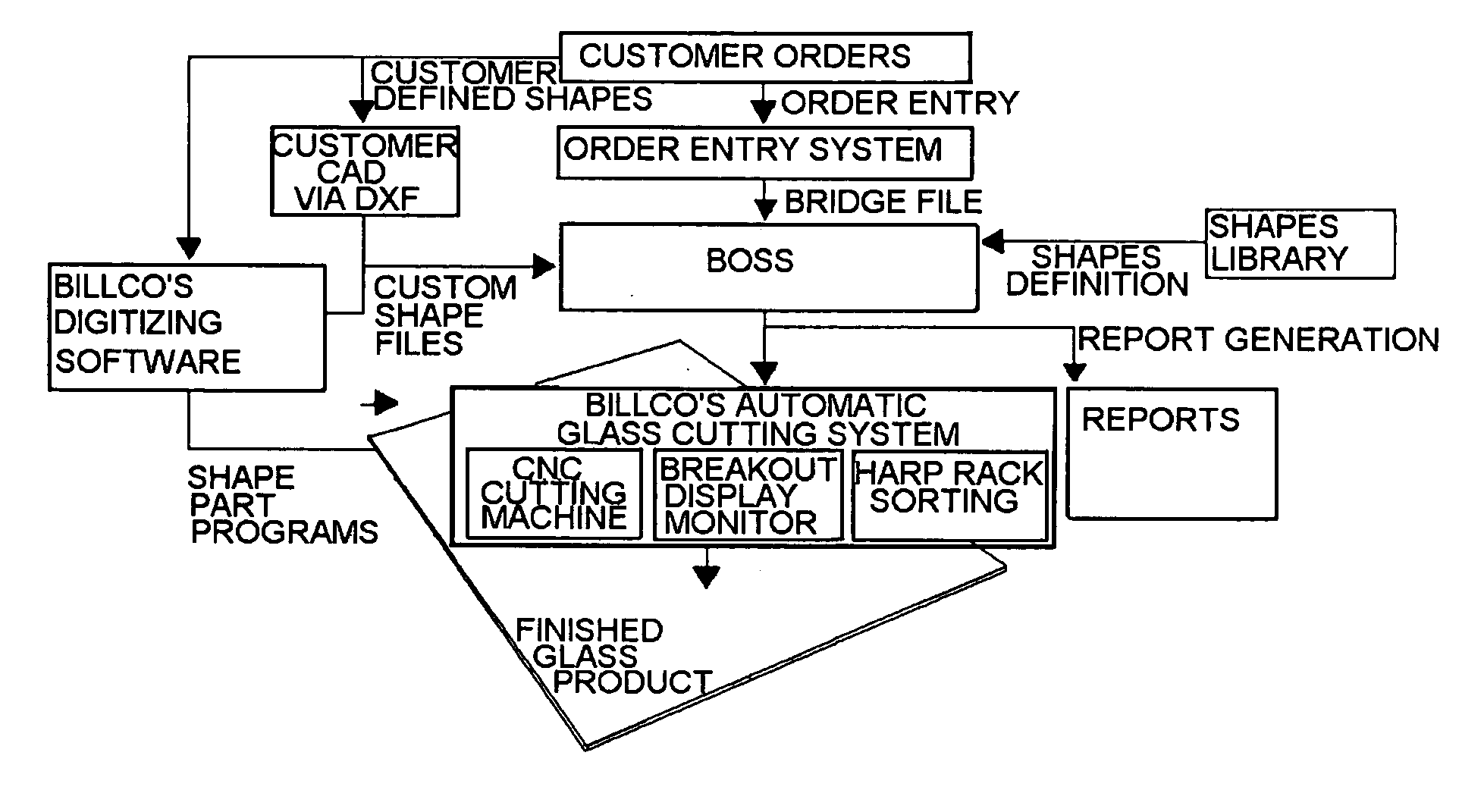

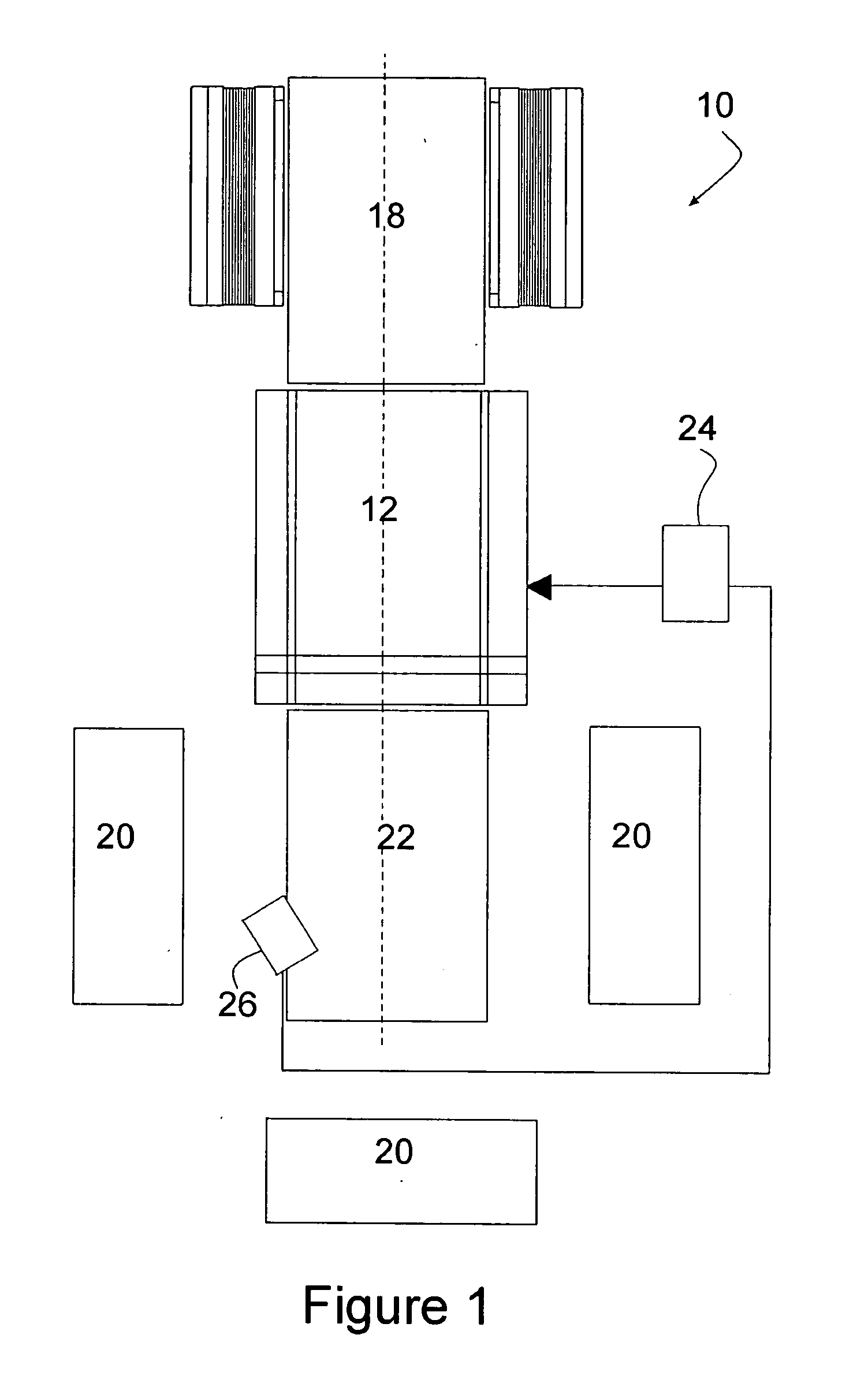

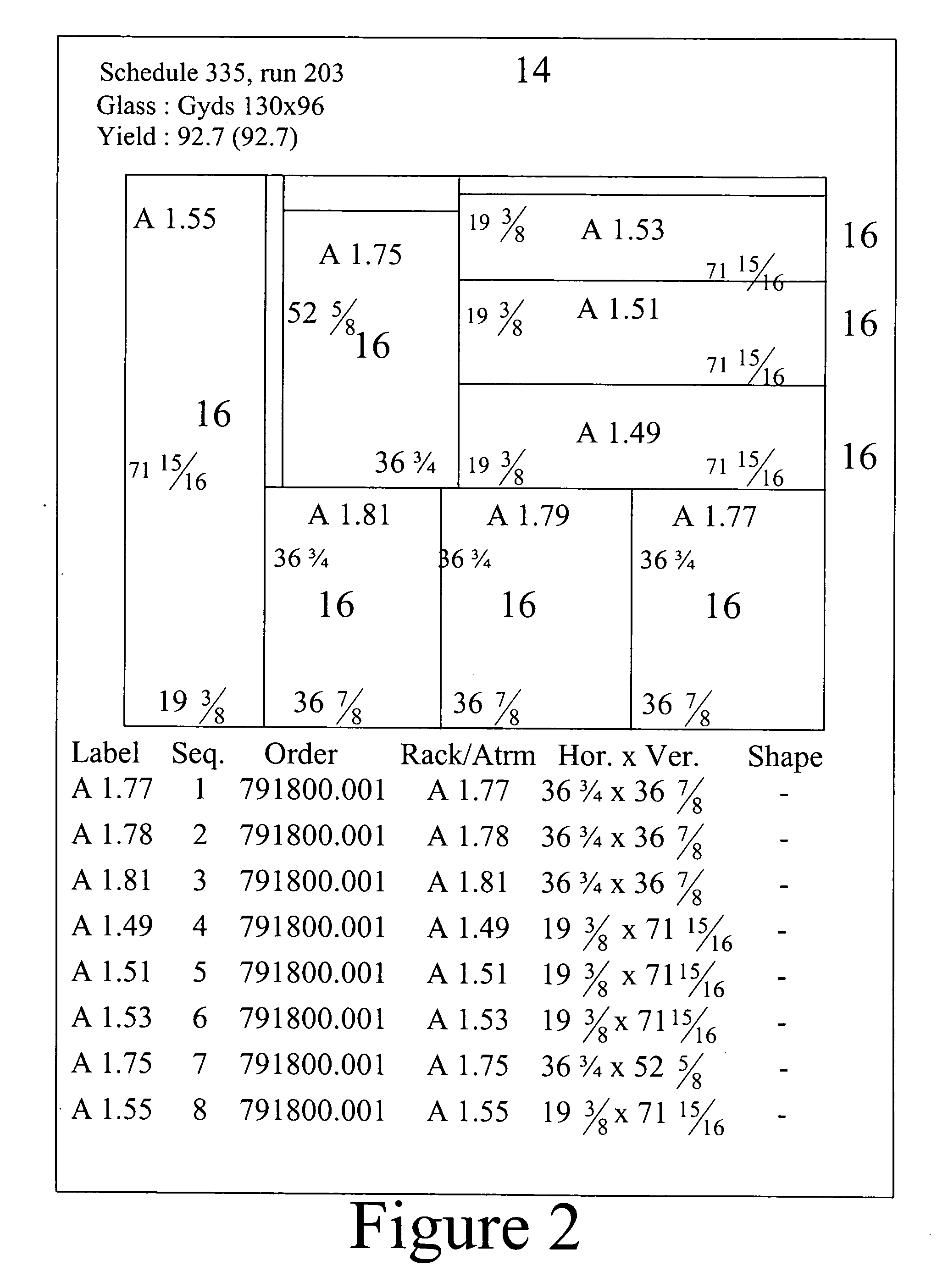

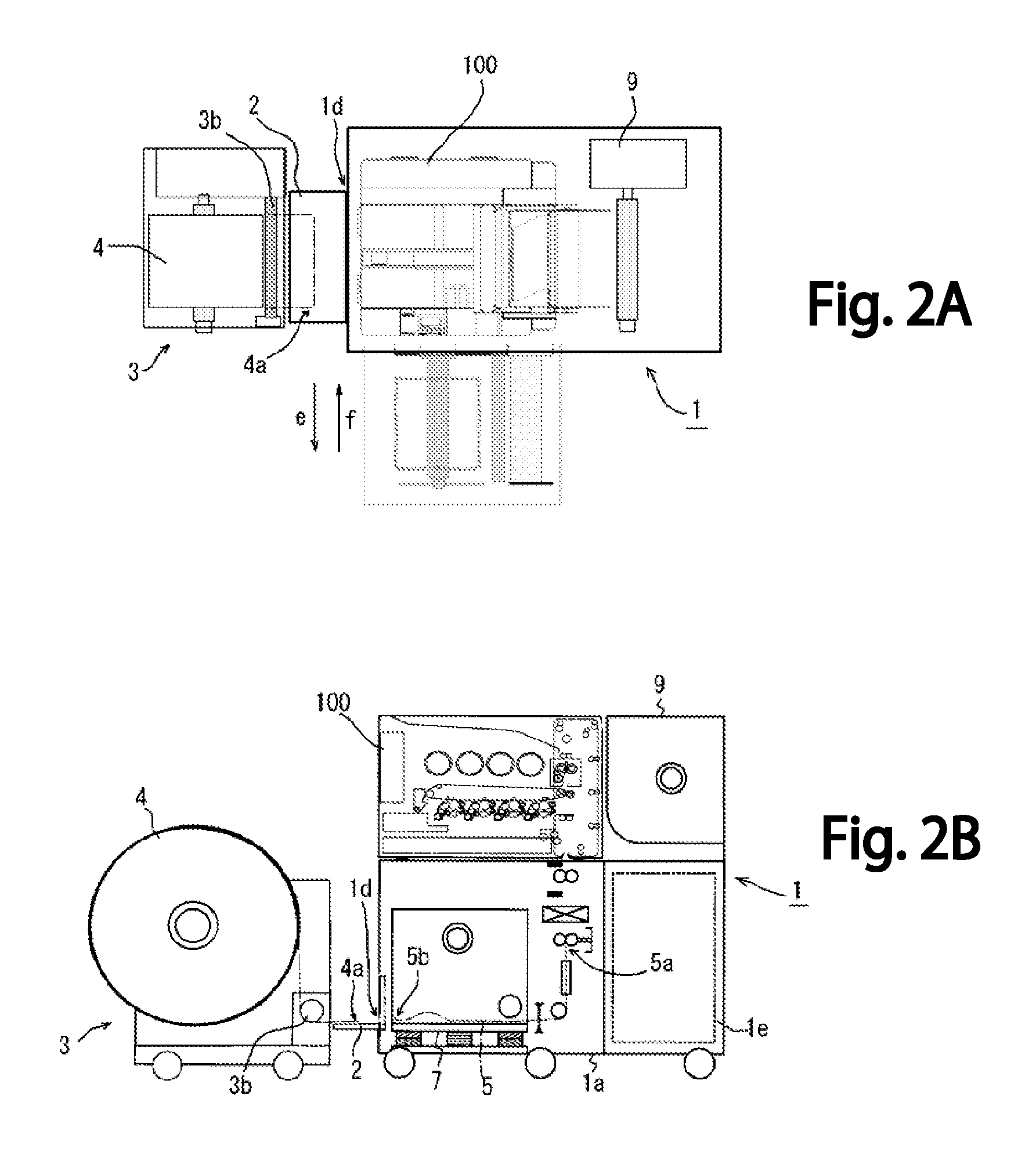

CNC glass cutting line with dynamic continuous production control system

A glass product cutting line includes a CNC cutting table, a sheet feeding device for feeding glass sheets to the glass cutting table, a plurality of harp racks, a sorting device and a dynamic cutting line control system. The control system optimizes the workpiece layout on the individual sheets with a biasing favoring individual workpieces assigned to a leading harp rack. The bias tends to cut workpieces of the leading harp rack on leading sheets fill the leading harp rack in a minimum time. The system allows for removal of a filled leading harp rack, by designating a new leading harp rack for the control system, which then dynamically adjusts the bias and associated cutting scheduling.

Owner:BILLCO MFG

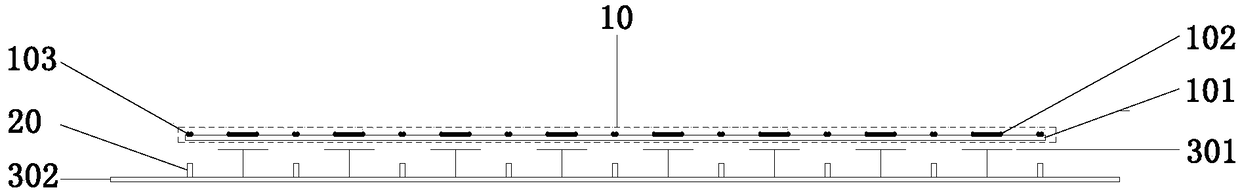

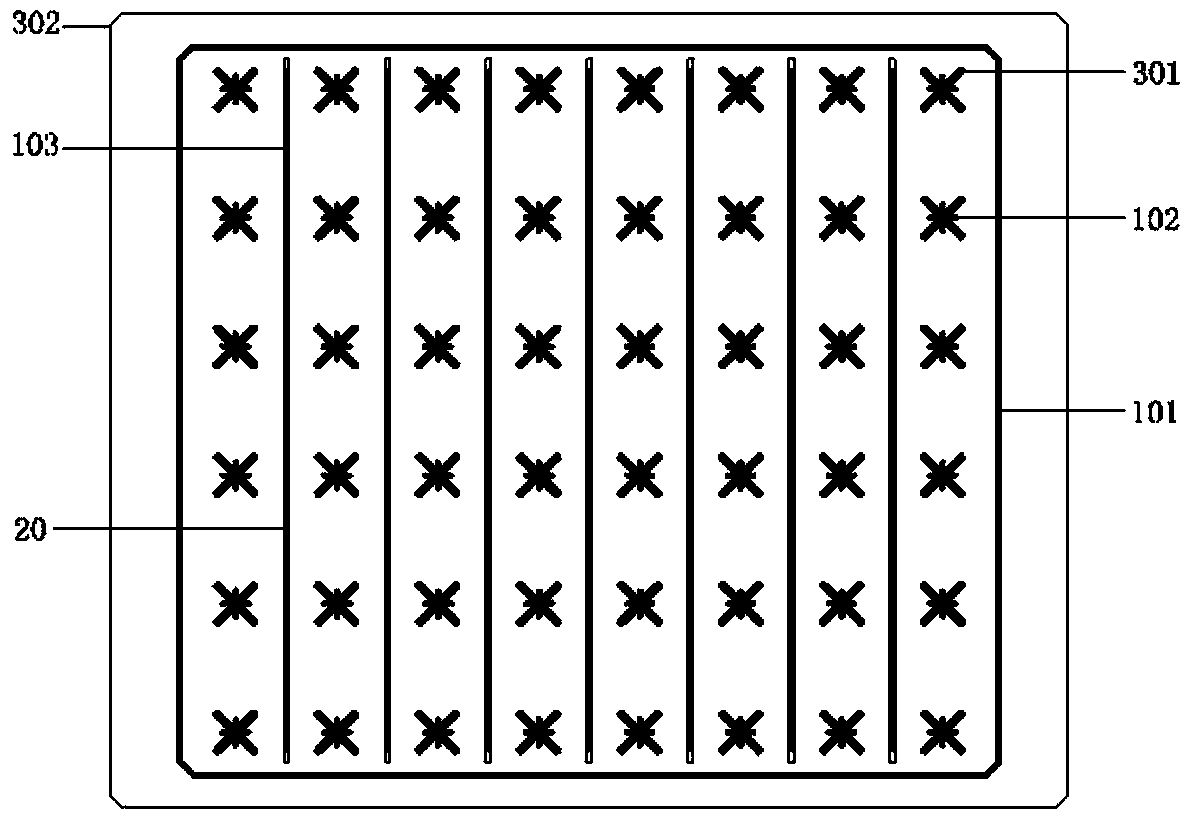

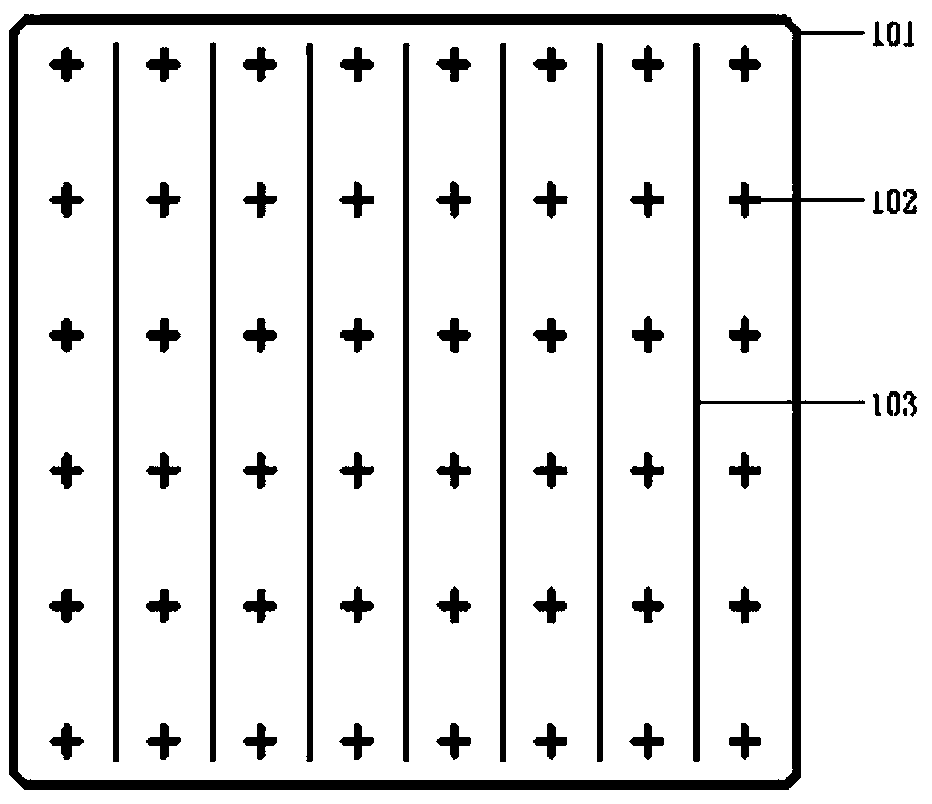

A decoupling device and a MIMO antenna

PendingCN109149108AImprove isolationImprove front-to-back ratioIndividually energised antenna arraysAntenna couplingsLead sheetDielectric substrate

The invention belongs to the technical field of wireless communication, A decoupling device and a MIMO antenna are disclosed, The decoupling device comprises a first decoupling device, wherein the first decoupling device is positioned above the array of radiating units; the first decoupling device comprises a dielectric substrate, a lead sheet, a decoupling strip, a lead sheet and a decoupling strip are arranged on the dielectric substrate; the lead sheet is positioned directly above the radiating units; and the decoupling strip is positioned between two rows of radiating units; the decouplingdevice comprises a dielectric substrate, a lead sheet, a decoupling strip and a decoupling strip. The MIMO antenna comprises an antenna reflector, a radiation unit and a decoupling device. The invention solves the problems of poor isolation degree and pattern distortion of MIMO antennas (5G large-scale array antennas) in the prior art.

Owner:WUHAN HONGXIN TECH DEV CO LTD

Glass processing equipment with dynamic continuous production control system

A glass product cutting line includes a CNC cutting table, a sheet feeding device for feeding glass sheets to the glass cutting table, a plurality of harp racks, a sorting device and a dynamic cutting line control system. The control system optimizes the work piece layout on the individual sheets with a biasing favoring individual work pieces assigned to a leading harp rack. The bias tends to cut work pieces of the leading harp rack on leading sheets fill the leading harp rack in a minimum time. The system allows for removal of a filled leading harp rack, by designating a new leading harp rack for the control system, which then dynamically adjusts the bias and associated cutting scheduling.

Owner:BILLCO MFG

Air suction system of laser cutting machine and laser cutting machine

PendingCN107552978AAvoid deformationGuaranteed pass rateLaser beam welding apparatusMetal workingLead sheet

The invention discloses an air suction system of a laser cutting machine and the laser cutting machine, and relates to the technical field of laser machining equipment. The air suction system comprises an air suction structure and a movable assembly, wherein the air suction structure comprises air suction holes and an air suction box; the air suction holes are located in the two sides of a workbench in the width direction and used for adsorbing waste gas and impurities such as dust produced during cutting; the air suction box located on the lower end face of the workbench is provided with an air suction cavity connected with an external suction fan; and a metal plate located on the upper end face of the workbench is stably adsorbed to the workbench through negative pressure generated by the air suction cavity, thus, the to-be-cut plate can be prevented from being deformed through internal stress springback, the cutting accuracy is improved, and the percent of pass of cut plates is ensured.

Owner:河南艾顿机床有限公司

System and method for creating cross-reference links, tables and lead sheets for tax return documents

Owner:SUREPREP

Lead melting copper removal refining process for industrial frequency coreless-type electric induction furnace

ActiveCN103540762ANo emissionsMeet the technical requirements of the processPhotography auxillary processesProcess efficiency improvementElectrolysisLead sheet

The invention relates to a lead melting copper removal refining process for an industrial frequency coreless-type electric induction furnace. The process comprises the following steps: heating and melting a lead bullion raw material through the industrial frequency coreless-type electric induction furnace, pressing slag, and performing quick cooling to liquate copper from lead bullion; injecting the lead bullion obtained after copper removal into an anode casting unit to cast an anode plate, putting a lead anode plate into an electrolytic tank, applying direct current, and liquating anode lead on a cathode after the anode lead forms lead ions and enters an electrolyte; melting the liquated lead through the industrial frequency coreless-type electric induction furnace, sequentially performing oxidation refining and alkaline refining, dredging the slag, and then injecting a lead solution into a pouring unit to obtain an electrolytic lead ingot and oxidized slag; pumping the lead solution after slag dredging into a cathode sheet unit to enable a lead-solution-adhered roller to rotate so as to obtain a cathode lead sheet. The lead melting copper removal refining process for the industrial frequency coreless-type electric induction furnace is respectively applied to the working procedures such as lead melting copper removal, liquated lead refining ingot casting and cathode sheet manufacturing with electric energy, which is conveniently and easily obtained, through the industrial frequency coreless-type electric induction furnace, and has the advantages of reasonable process, low equipment investment, low energy consumption, great economic benefit, good environment-friendly effect and the like.

Owner:SHAANXI ZINC IND

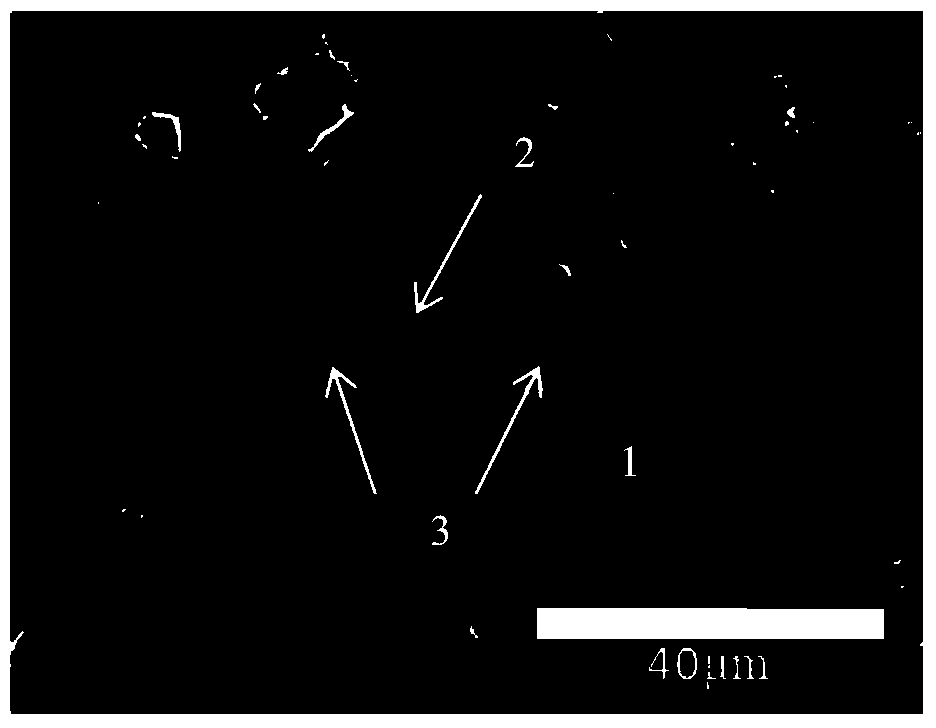

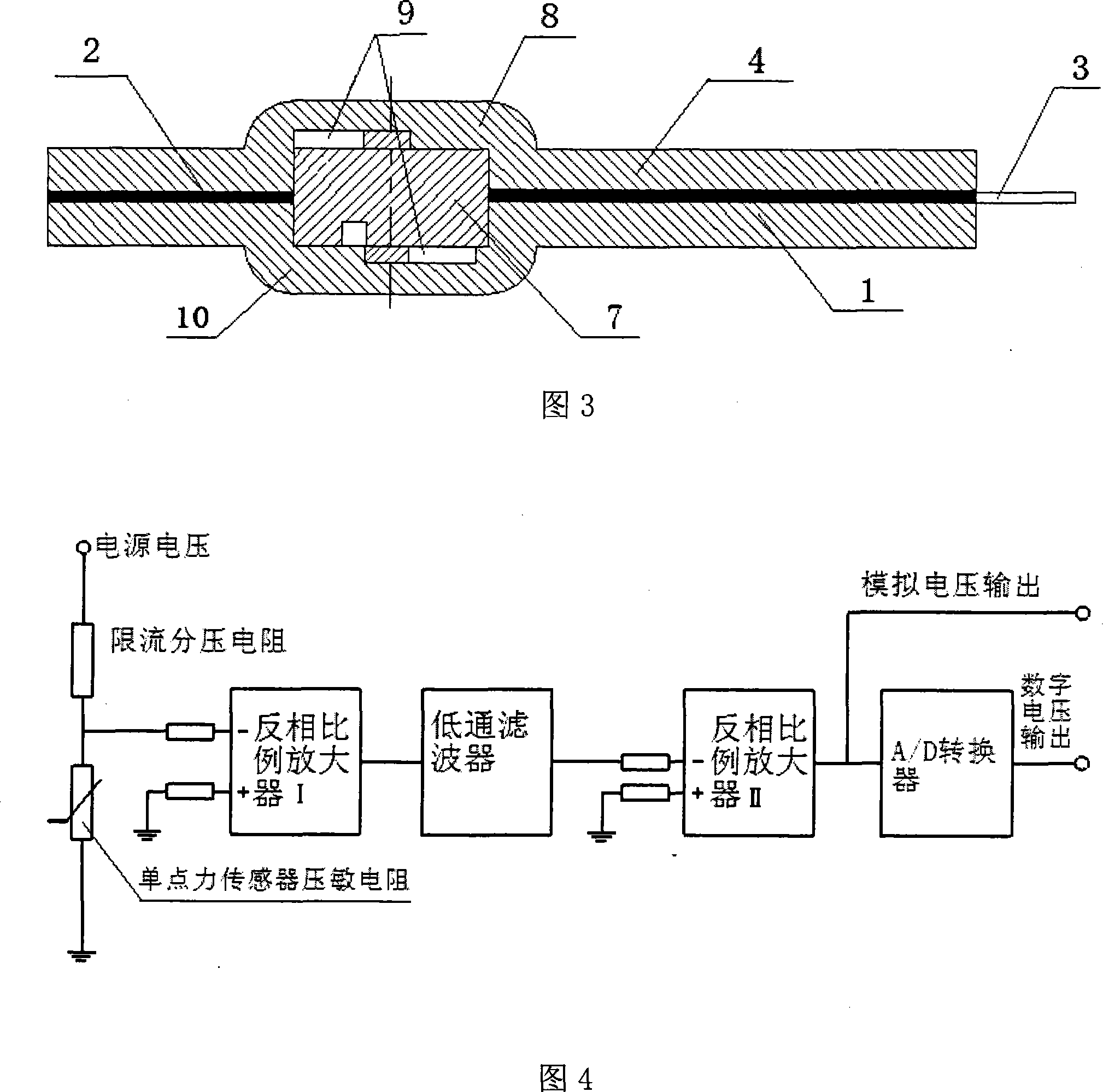

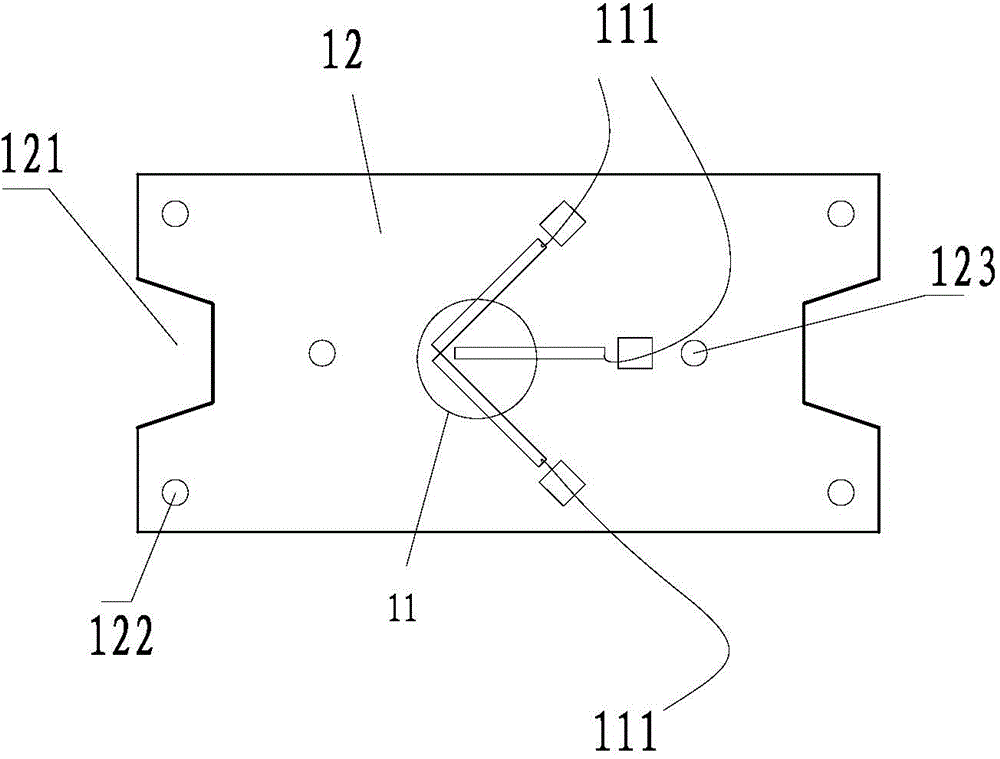

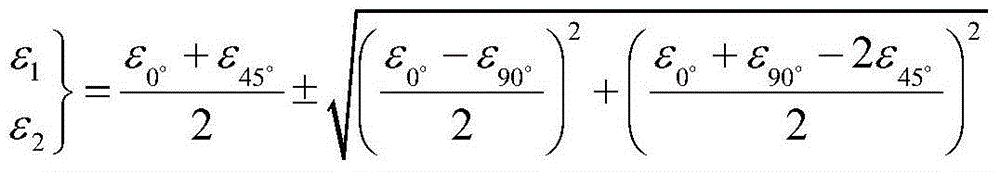

Method for testing current distribution uniformity inside monolithic piezoresistor valve plate

InactiveCN103353563AEfficiently spot performance inhomogeneitiesCurrent/voltage measurementElectrical testingElectrical field strengthLead sheet

The invention relates to a method for testing current distribution uniformity inside a monolithic piezoresistor valve plate, and belongs to the technical field of electric materials. The method comprises the following steps: first, grinding and polishing upper and lower surfaces of a ZnO piezoresistor valve plate, and obtaining a microelectrode array through photoetching and sputtering; combining the lower surface of the ZnO piezoresistor valve plate with a thin lead sheet, dividing the upper surface into a plurality of units in equal area, contacting each silver electrode on any unit area by a microprobe; and applying continuously changing voltage between the thin lead sheet contacting with the lower surface and the probe or the thin lead sheet contacting with the upper surface, measuring corresponding current, obtaining a volt-ampere characteristic curve by current density as X-coordinate and electric field intensity as Y-coordinate, selecting corresponding current density values according to certain rules, and evaluating current ununiformity of the ZnO piezoresistor valve plate. The method can effectively assess uniformity of internal structure and performance of the ZnO piezoresistor valve plate, so as to test influence of current distribution uniformity on the operating characteristics of ZnO.

Owner:TSINGHUA UNIV

Flexible one point force sheet type sensor and production method

InactiveCN101226089AAvoid short circuitWith anti-interferenceForce measurementConverting sensor output electrically/magneticallyLead sheetBiochemical engineering

The invention discloses a flexible single-point force sheet sensor which can detect the force of a certain point that contacts to an object and a preparation method. The sensor comprises an upper base plate and a lower base plate in the same shape and size, a pressure sensitive body, two electrode connecting sheets which are arranged at both end surfaces of the pressure sensitive body; the position between the upper base plate and the lower base plate is sealed by an adhesive coating; a projection is arranged at one side close to the upper base plate in the length direction; a hollow is is arranged at the lower base plate corresponding to the projection; a sealed pressure sensitive body chamber is formed between the projection and the hollow, wherein the pressure sensitive body and the electrode connecting sheets are positioned at the sealed pressure sensitive body chamber; two mutual parallel printing electrodes are arranged at the position between the lower base plate apart from the side of hollow and the length direction of the hollow; each printing electrode is connected with one electrode connecting sheet at one side of the hollow of the lower base plate; one end of the lower base plate apart from the side of hollow is connected with an electrode lead sheet which is exposed at the lower base plate; an electrode protecting film is positioned at an upper surface which is connected the electrode connecting sheet with the electrode lead sheet.

Owner:XI AN JIAOTONG UNIV

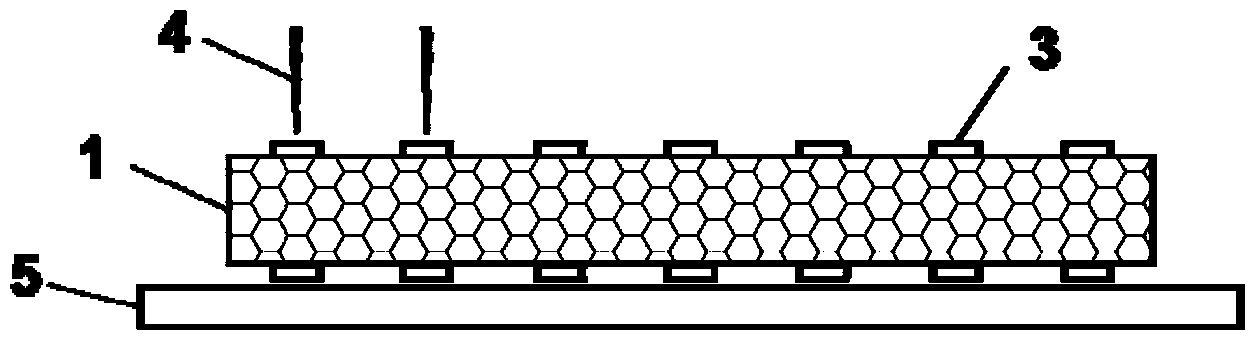

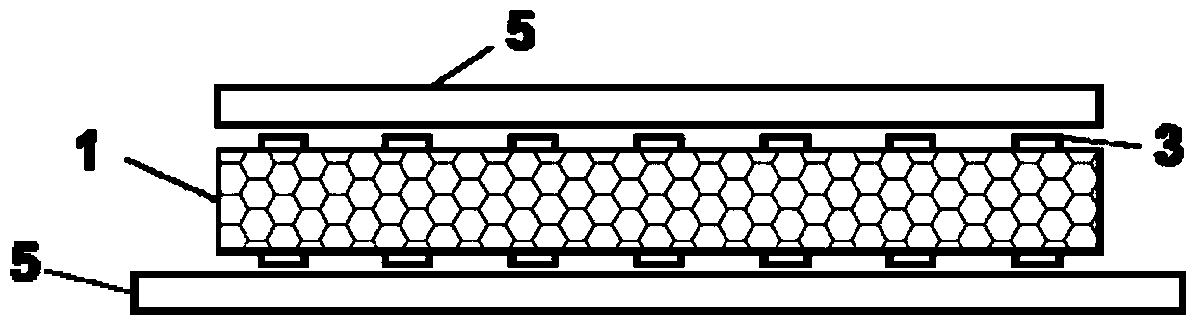

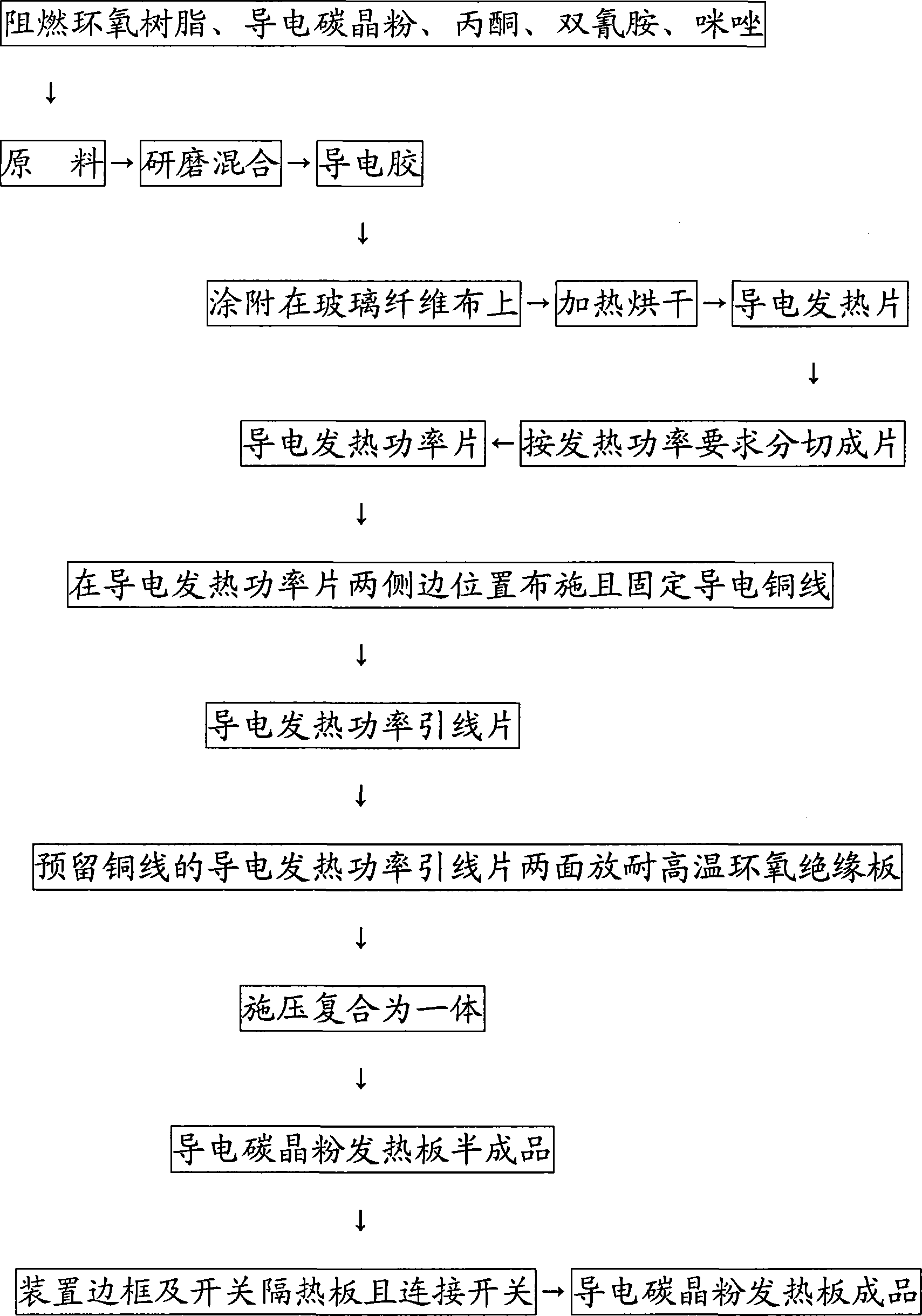

Production method of conductive carbon crystal powder heating plate

The invention relates to the technical field of heating plates, in particular to a conductive carbon crystal powder heating plate. The production method includes: grinding and mixing, by weight, 100 parts of flame-retardant epoxy resin, 5-30 parts of conductive carbon crystal powder, 30-50 parts of acetone, 2-3 parts of dicyandiamide and 0.5 part of imidazole to obtain conductive adhesive, coating glass fiber cloth with the conductive adhesive, heating and drying to obtain a conductive heating sheet, slicing the conductive heating sheet into conducive heating power sheets, spreading fixed copper wires to two sides of each conductive heating power sheet to obtain conductive heating power lead sheets, and pressing and combining the conductive heating power lead sheets with reserved conductive copper wires, and high-temperature-resistant epoxy resin insulation boards on two sides to obtain a semi-finished integrated product, mounting a frame and a switch heat-insulating board to the semi-finished product, and connecting a switch to the product to obtain the finished conductive carbon crystal powder heating plate. The conductive carbon crystal powder heating plate is applicable to everyday life, industrial and medical aspects such as floor heating, wall heating and office heating, and is simple in process, high in quality, low in cost, and convenient to popularize.

Owner:SHENZHEN JUMBO COPPER LAMINATE TECH CO LTD

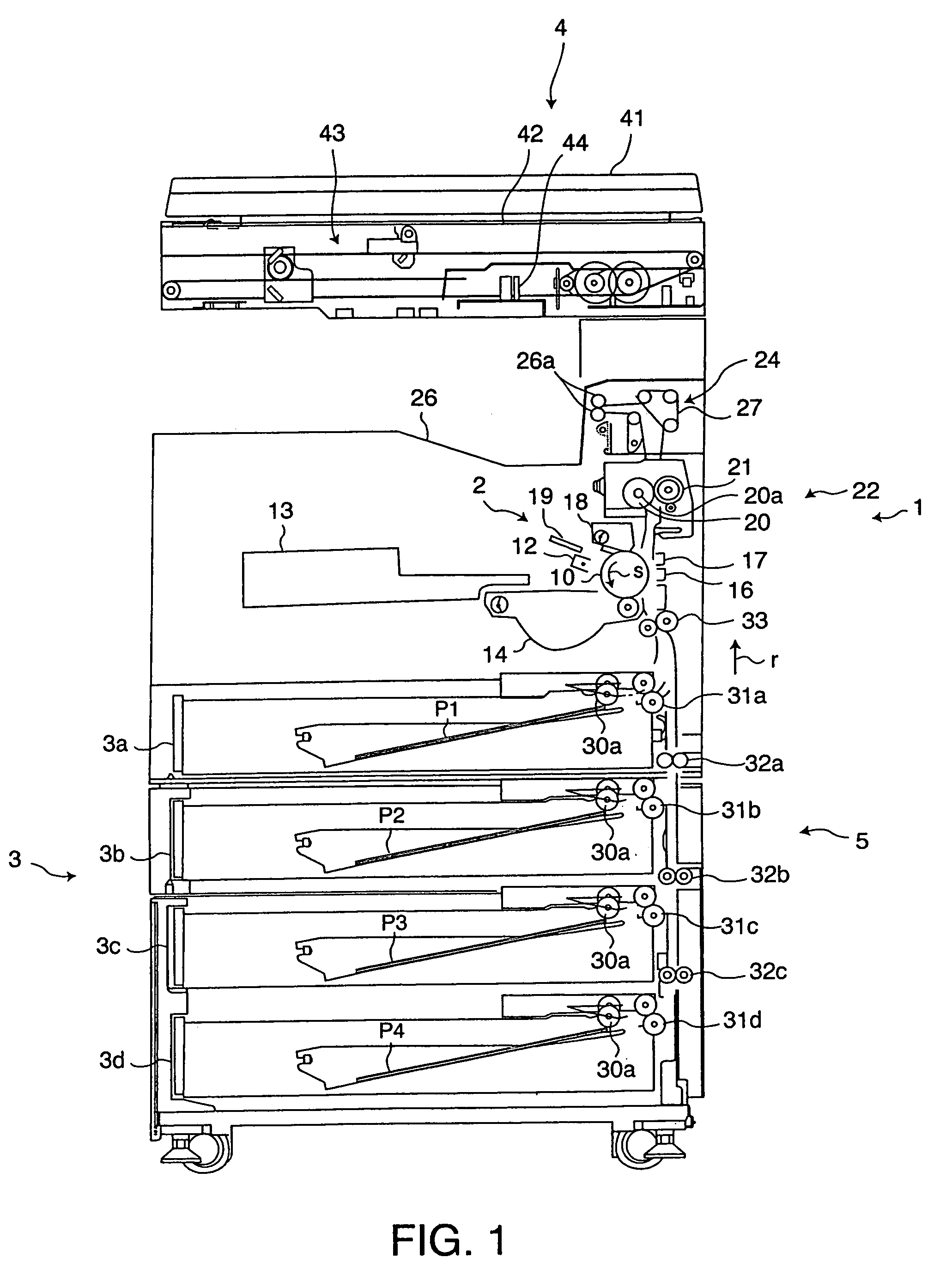

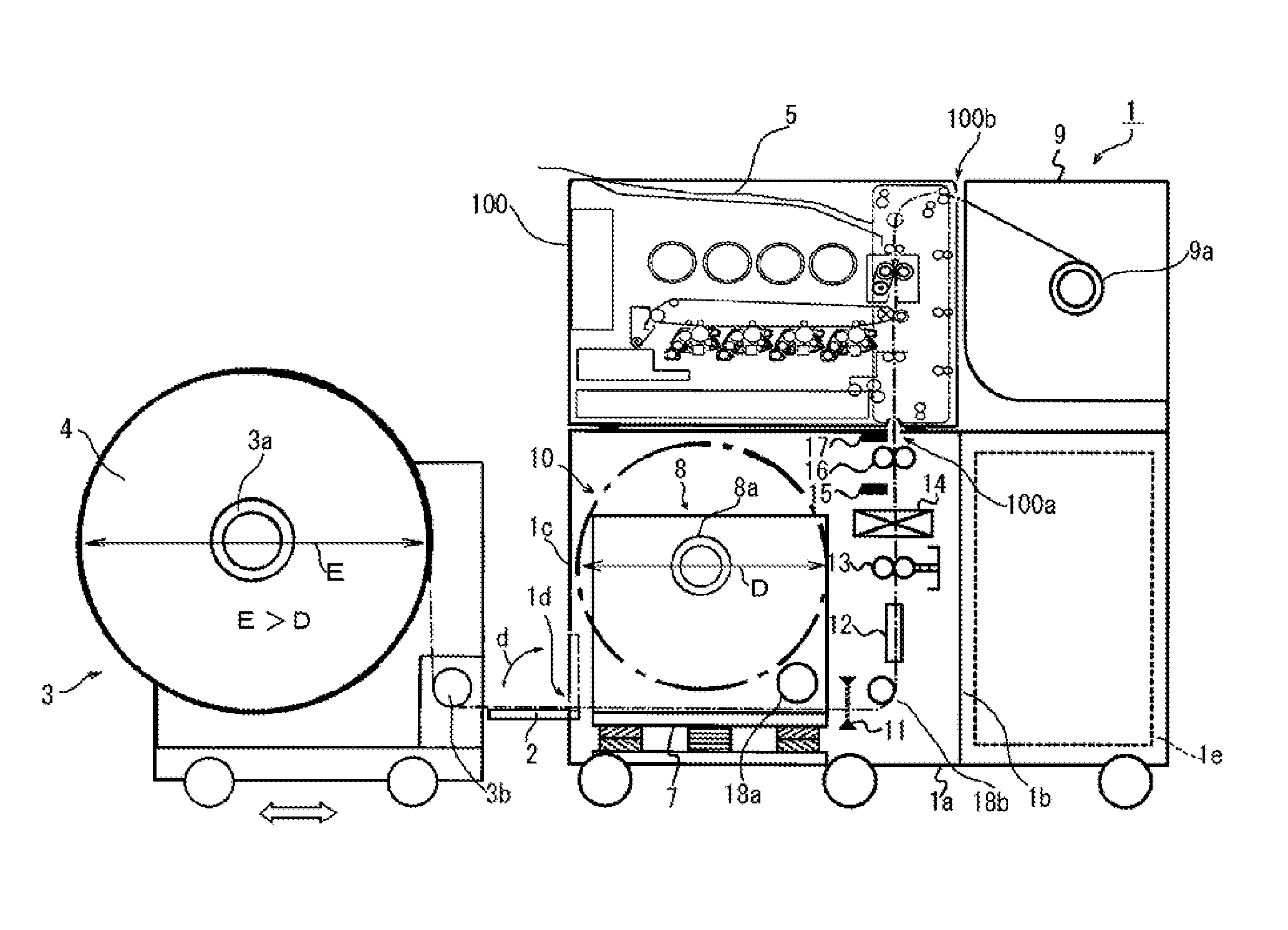

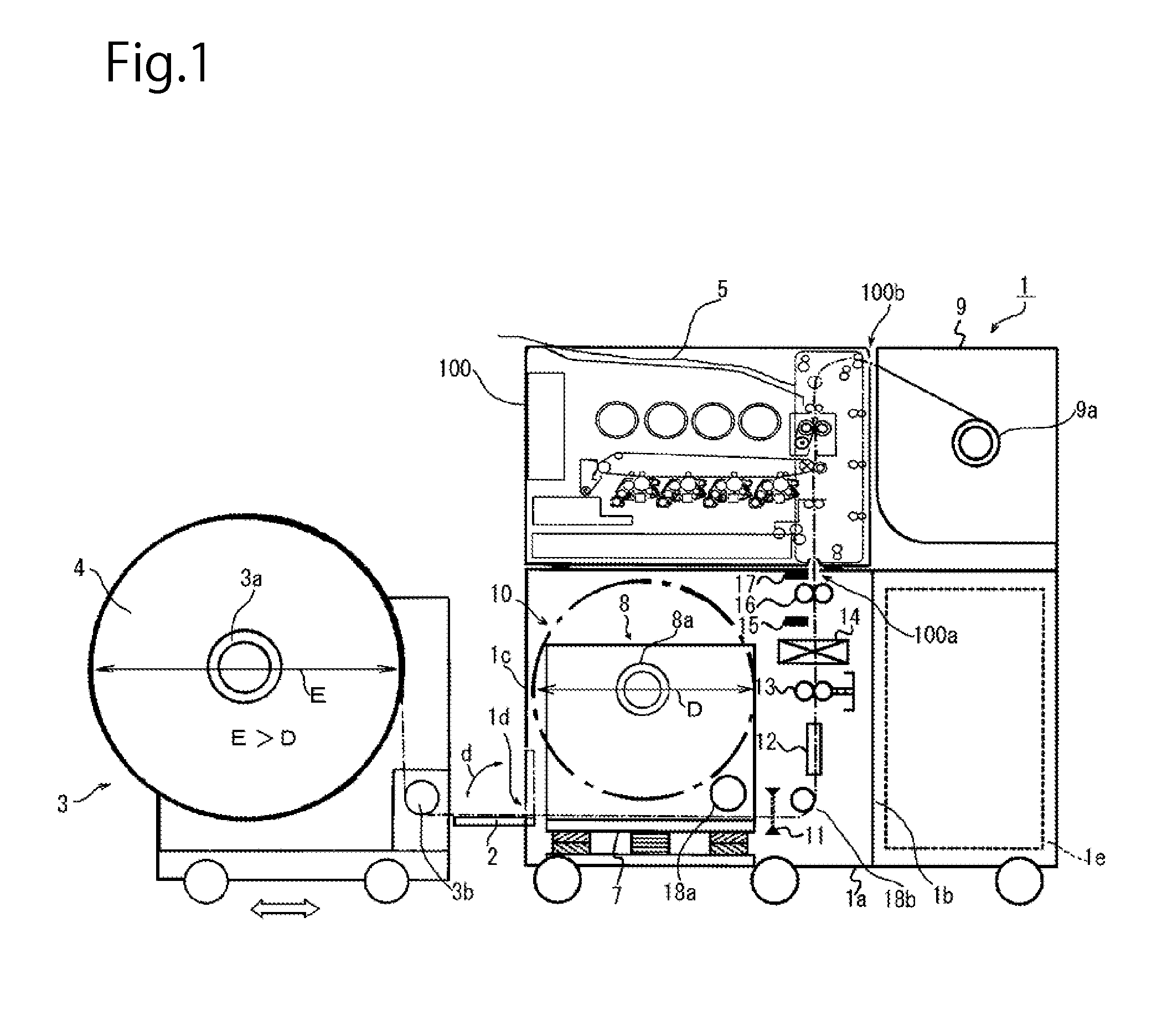

Roll sheet image forming apparatus

InactiveUS20160041515A1Easy feedingEasy to guideElectrographic process apparatusLead sheetSheet material

A roll sheet image forming apparatus includes an introduction opening and a guide plate. Instead of a continuous sheet held in an apparatus main body, a continuous sheet for option feeding provided at an outside is introduced into the apparatus main body through the introduction opening. The guide plate is for splicing a lead sheet and a continuous sheet. When feeding the continuous sheet, a feeding unit is pulled out from the apparatus main body, a lead sheet is set to be conveyable towards an image forming unit, the feeding unit is again accommodated in the apparatus main body, a front end of the continuous sheet is placed on the guide plate, a rear end of the lead sheet is placed on the guide plate through the introduction opening, the rear end and the front end are spliced by a bonding member and then the feeding unit operates.

Owner:CASIO COMPUTER CO LTD

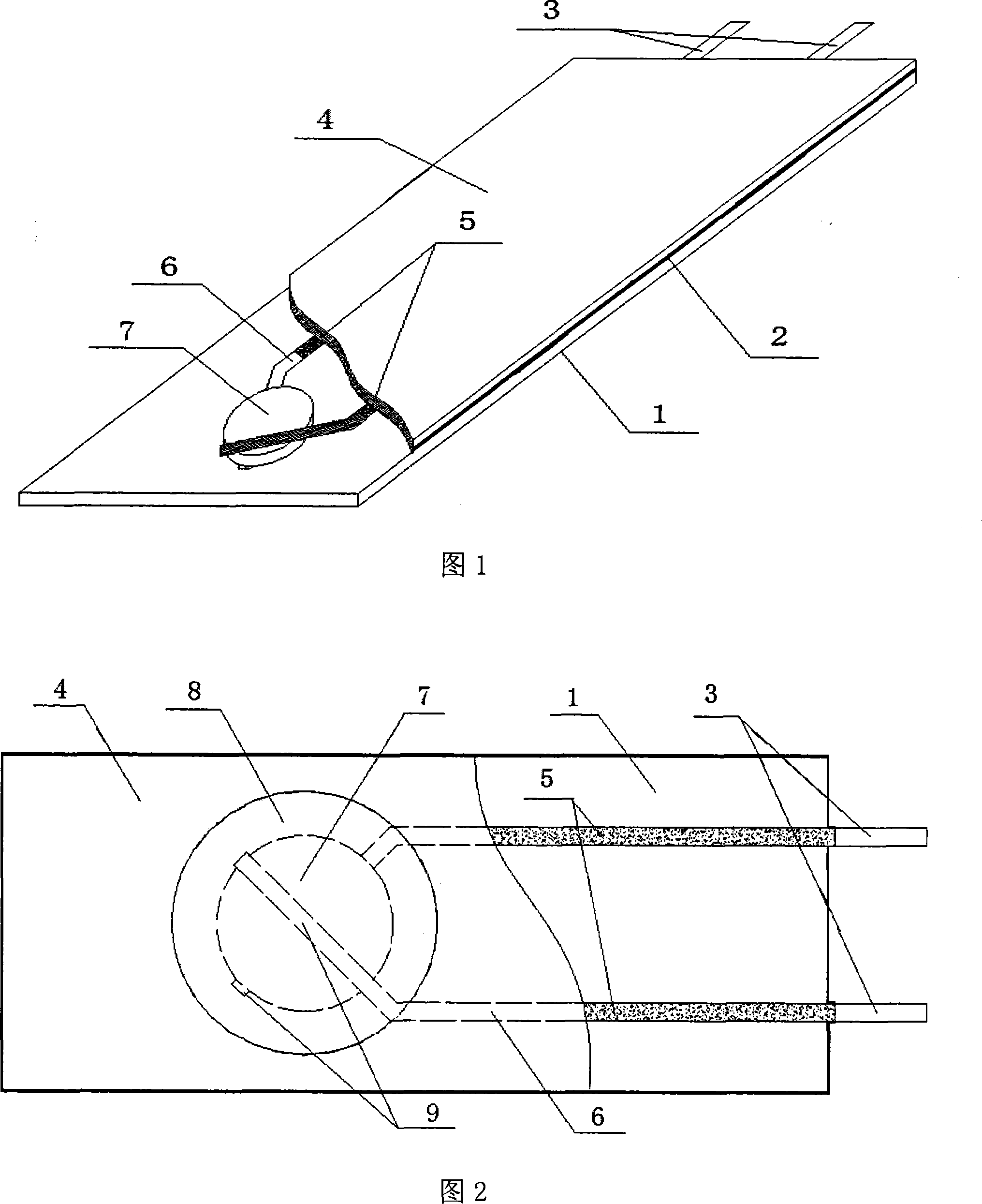

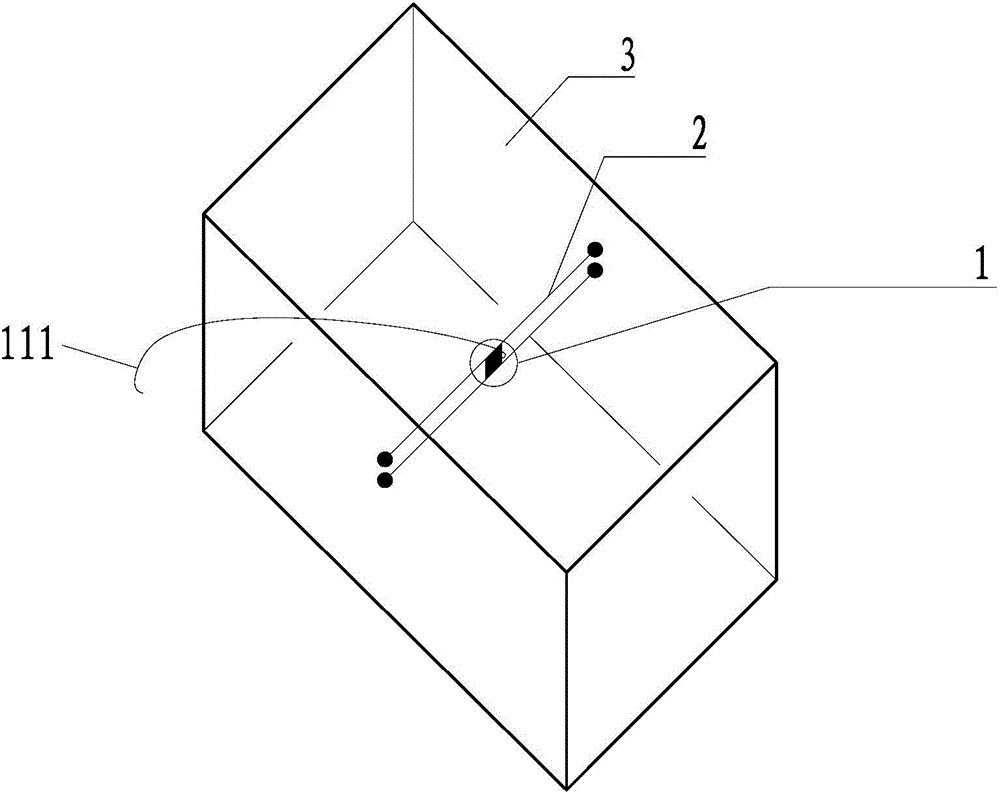

Device and method for concrete interior strain testing

InactiveCN104792256AGood for studying internal deformationConducive to researchElectrical/magnetic solid deformation measurementAdhesiveLead sheet

Owner:HUAQIAO UNIVERSITY

Tissue paper dispenser

InactiveUS20060289555A1Easy constructionEasy and smooth dispensingDomestic applicationsArticle separationLead sheetEngineering

A tissue paper dispenser includes a holding member for holding a stack of separated sheets of tissue paper and having an access opening and a dispensing slot, and an actuator including an actuating member terminating at an enlarged dragging portion contacting a leading sheet of the stack with a friction force, a shifted member operable to move the dragging portion between standby and ready-to-dispense positions, and a key confronting the access opening and interposed between the actuating member and the shifted member. A guiding member is disposed on the holding member, and has a keyway to guide the key to move between initial and end regions along forward and backward paths. The keyway is configured such that the friction force between the dragging portion and the leading sheet is instantly decreased when the key reaches the end region by following the forward path.

Owner:TSAI JUI AN

Method for building sheet pile walls

InactiveUS6939422B2Good conditionWithdrawal of the protection means is made easierWallsPublic buildingsSurface layerLead sheet

A method for building a sheet pile wall includes providing a first sheet pile having a leading sheet pile interlock with an interlock chamber, driving the first sheet pile into the ground while protecting the interlock chamber from ground material and providing a second sheet pile having a trailing sheet pile interlock with an interlock head. The method further includes coating a fixing agent as a surface layer on the interlock head of the trailing sheet pile interlock, engaging the coated interlock head of the trailing sheet pile interlock in the interlock chamber of the leading sheet pile interlock and driving the second sheet pile into the ground so that the trailing sheet pile interlock interlocks with the leading sheet pile interlock.

Owner:ARCELORMITTAL COMML RPS SRL

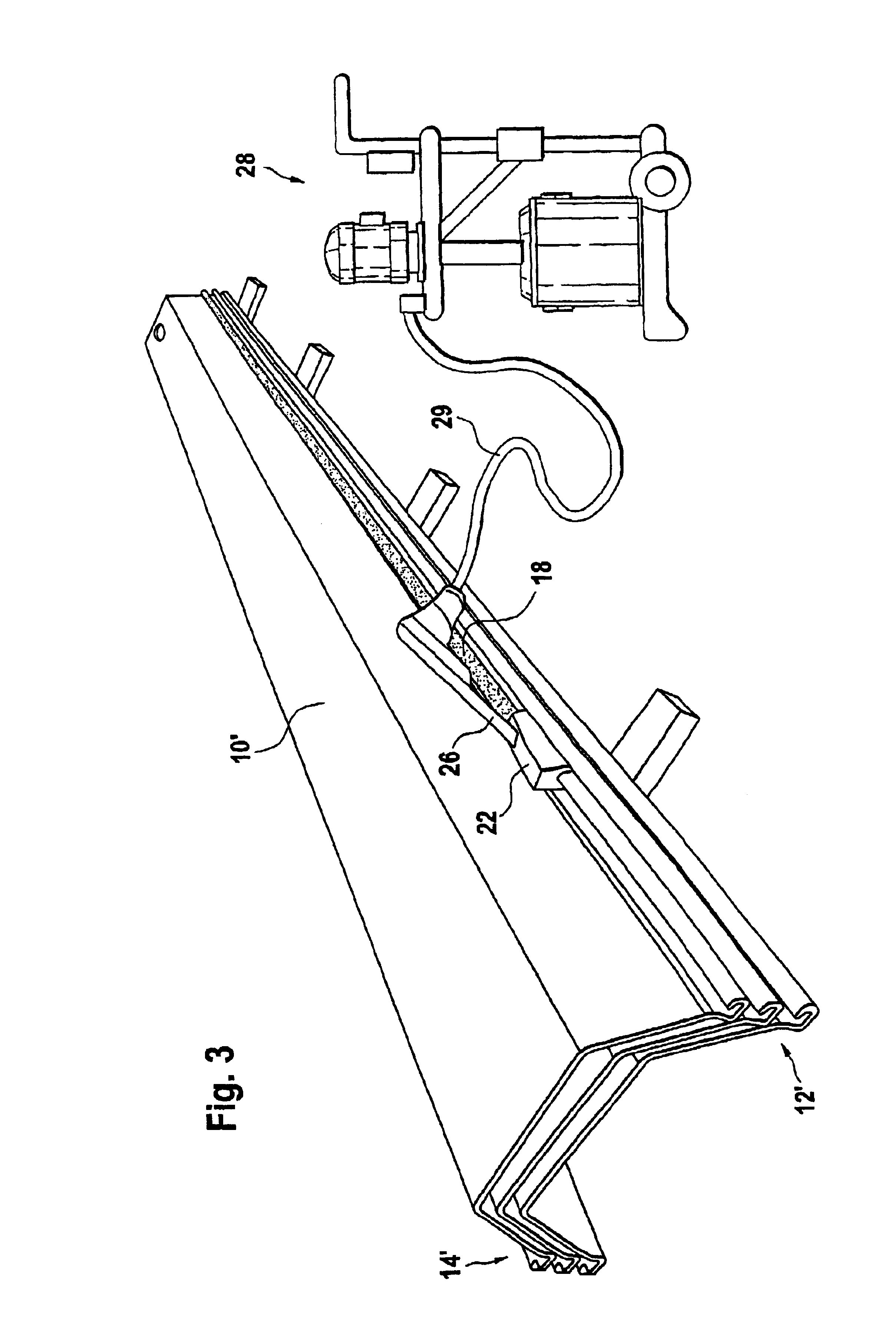

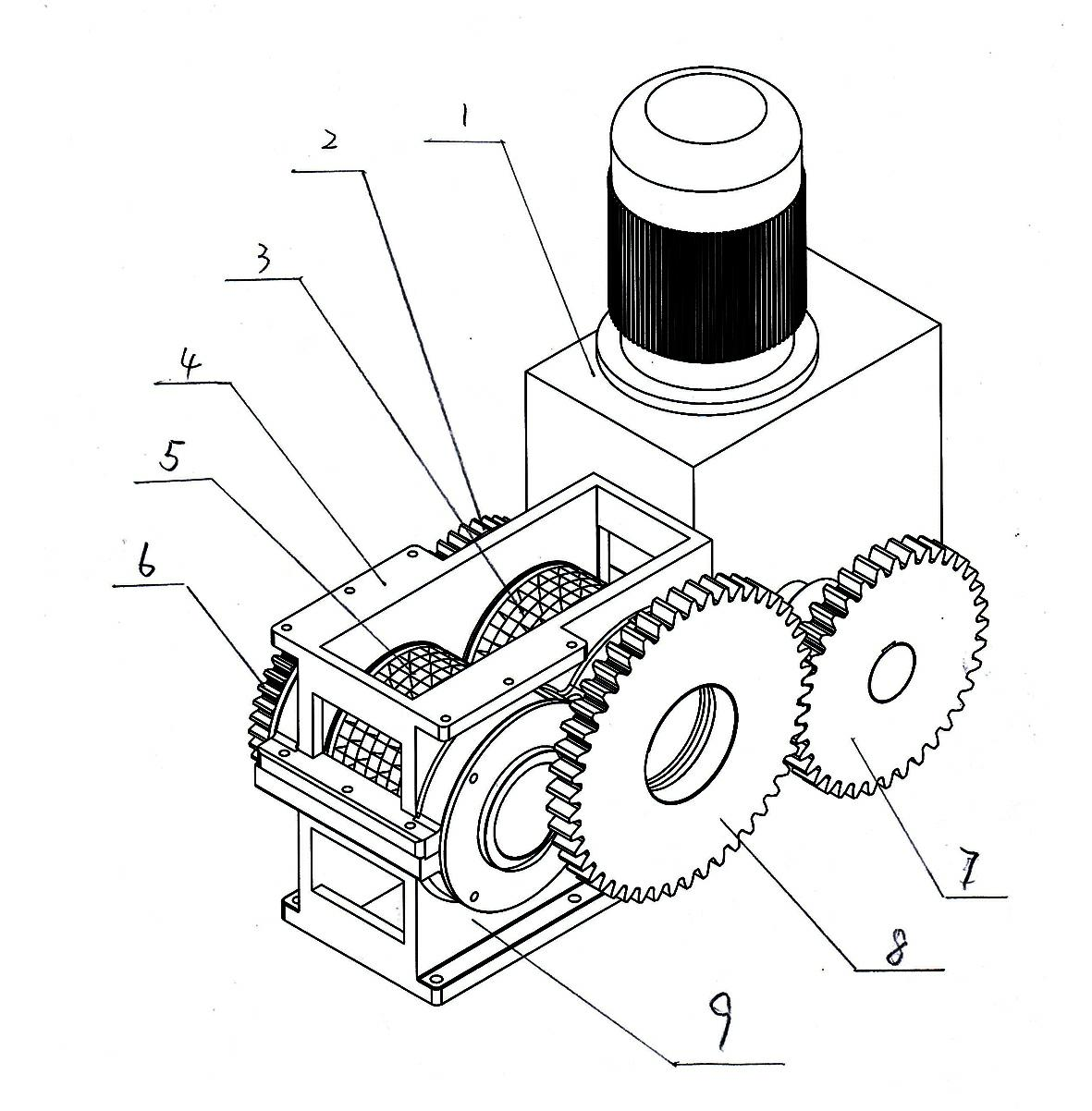

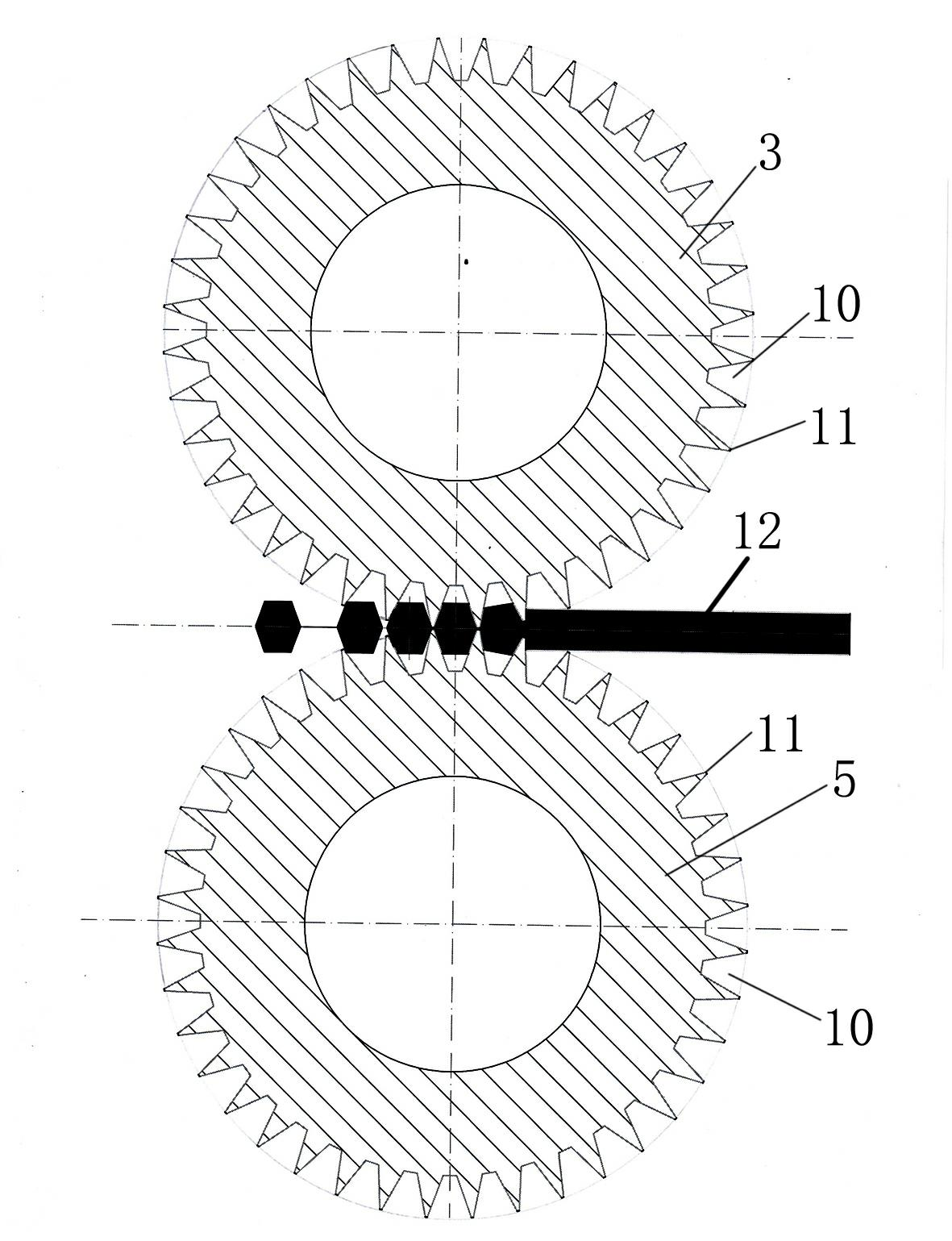

Lead sheet cold cutting pelleter

The invention relates to a lead sheet cold cutting pelleter. The pelleter comprises a rack, a pair of cutting rollers which rotate synchronously and oppositely are arranged on the rack, a power device (1) is also arranged on the rack and used for providing power for the cutting rollers to perform cold cutting on a lead block, and the power device (1) drives the cutting rollers to work through a transmission device. The pelleter is characterized in that continuous die cavities (10) are arranged on the peripheries of the cutting rollers in circumferential direction and axis direction, a middle thin wall arranged between two adjacent die cavities (10) is provided with a cutting blade (11) for cutting off a lead sheet, and the pair of cutting rollers are installed on the rack in a die cavity-to-die cavity and cutting blade-to-cutting blade fit manner. The invention has the beneficial effects that because the continuous die cavities are arranged on the peripheries of the cutting rollers in circumferential direction and axis direction and the middle thin wall arranged between two adjacent die cavities is provided with a cutting blade for cutting off the lead sheet, the production efficiency of the lead sheet cold cutting pelleter is improved; in addition, since the die cavities are inverted-trapezoid-shaped die cavities, lead pellets can fall off form the die cavities conveniently and the structure of the pelleter is simplified.

Owner:安徽奥鑫机械制造有限公司

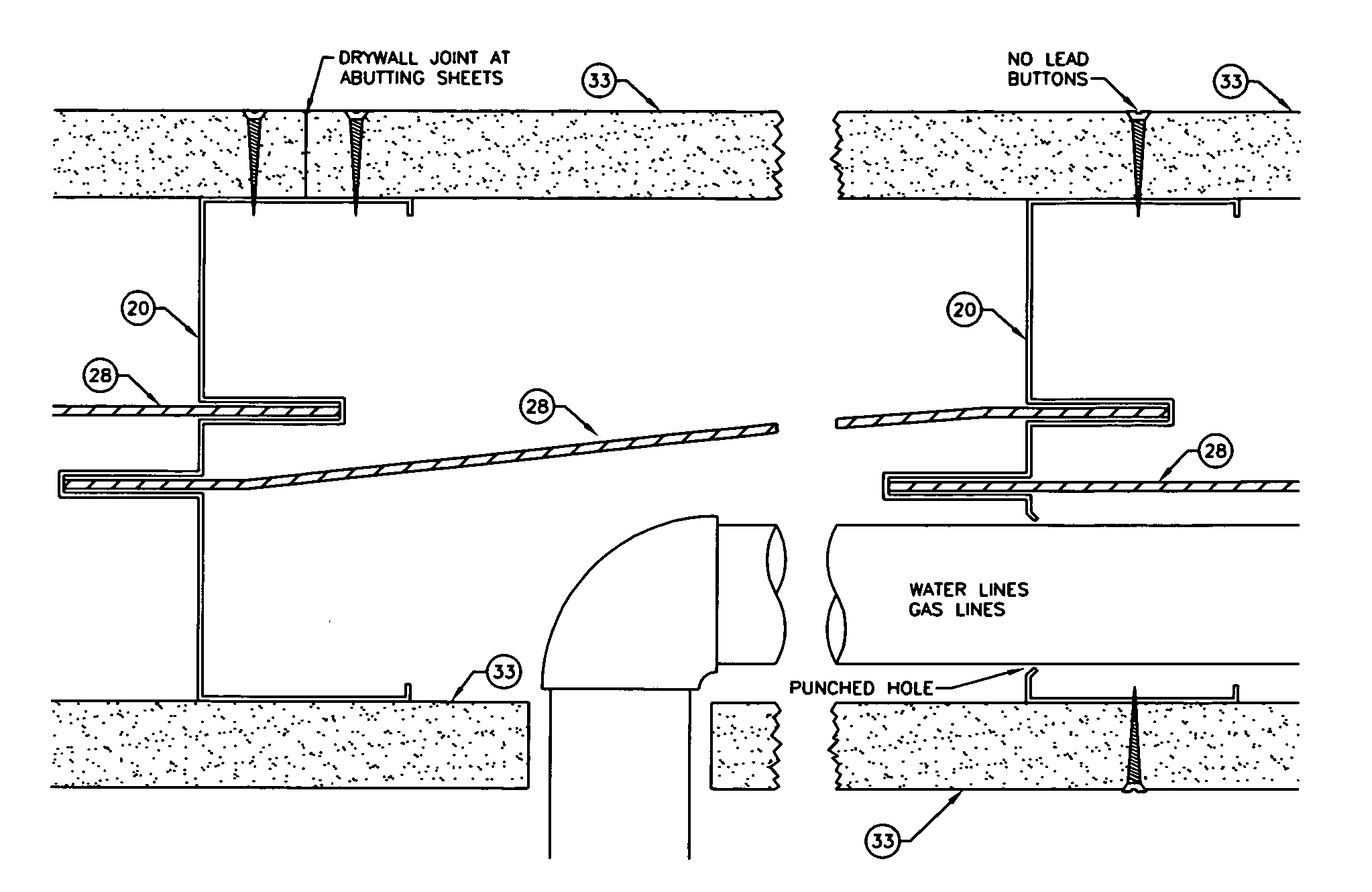

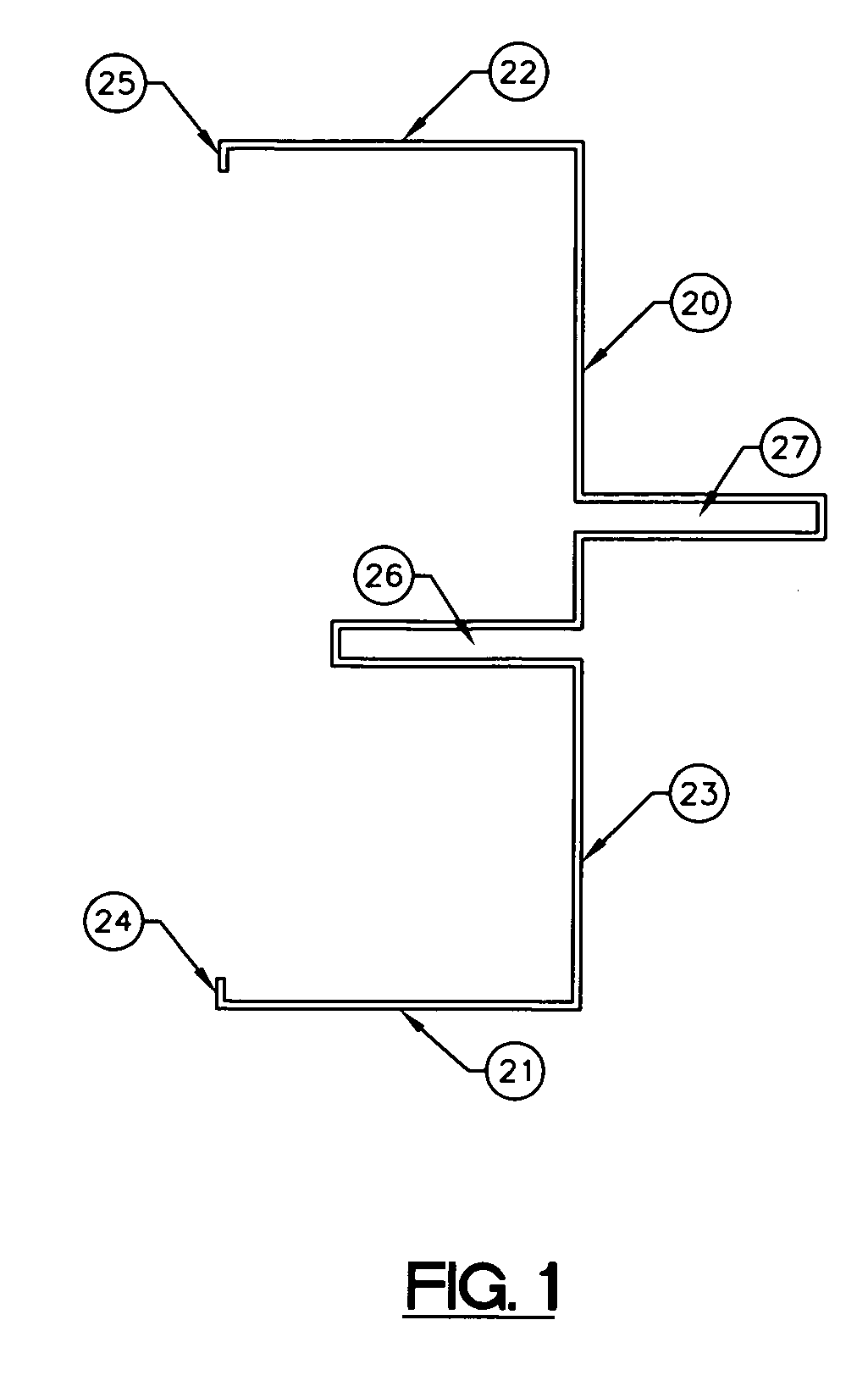

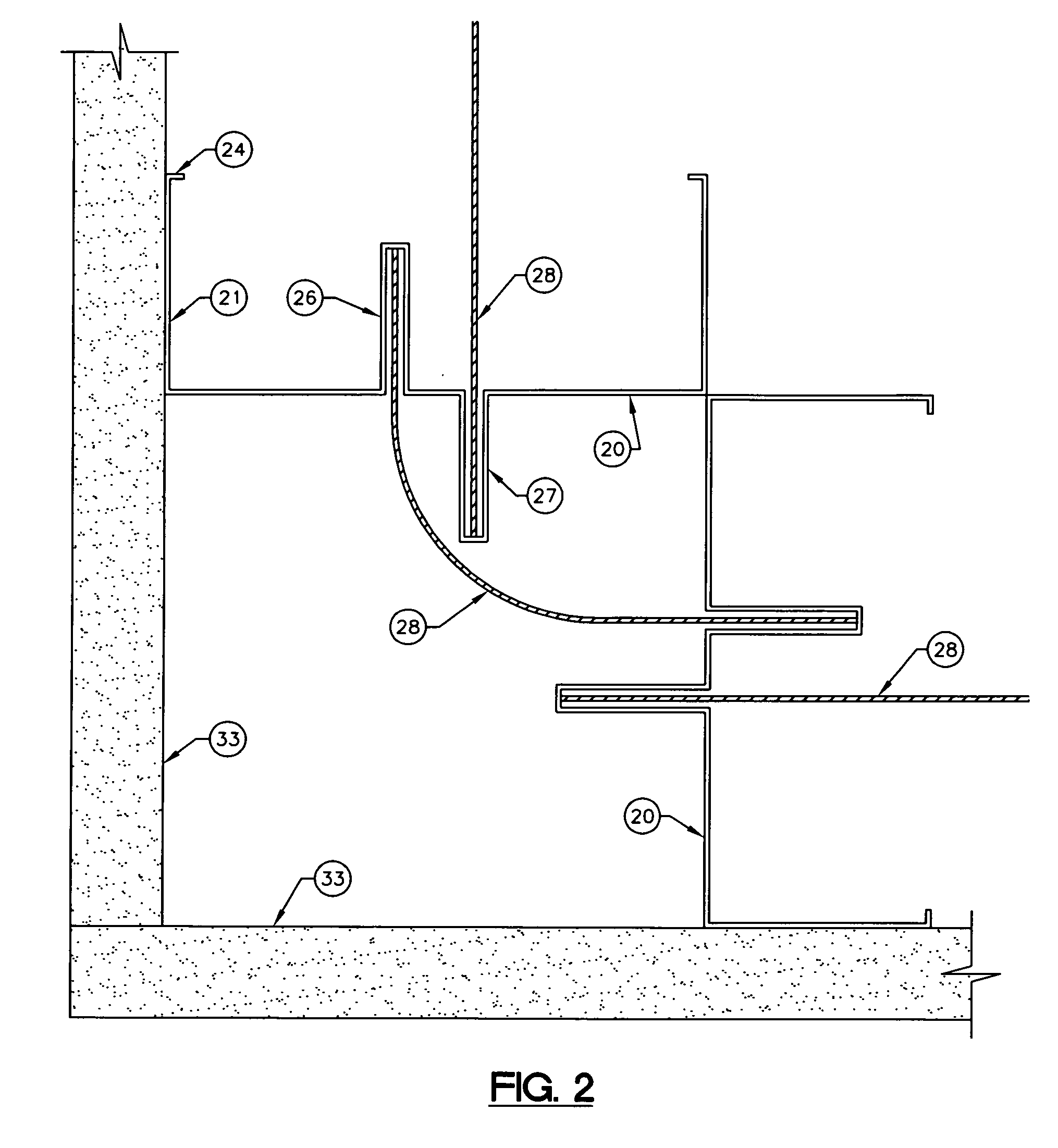

Lead sheet suspension stud

InactiveUS20100212243A1Eliminate needReduce potential for back injuryWallsGirdersLead sheetEngineering

Owner:LESOINE DAVID ALLEN

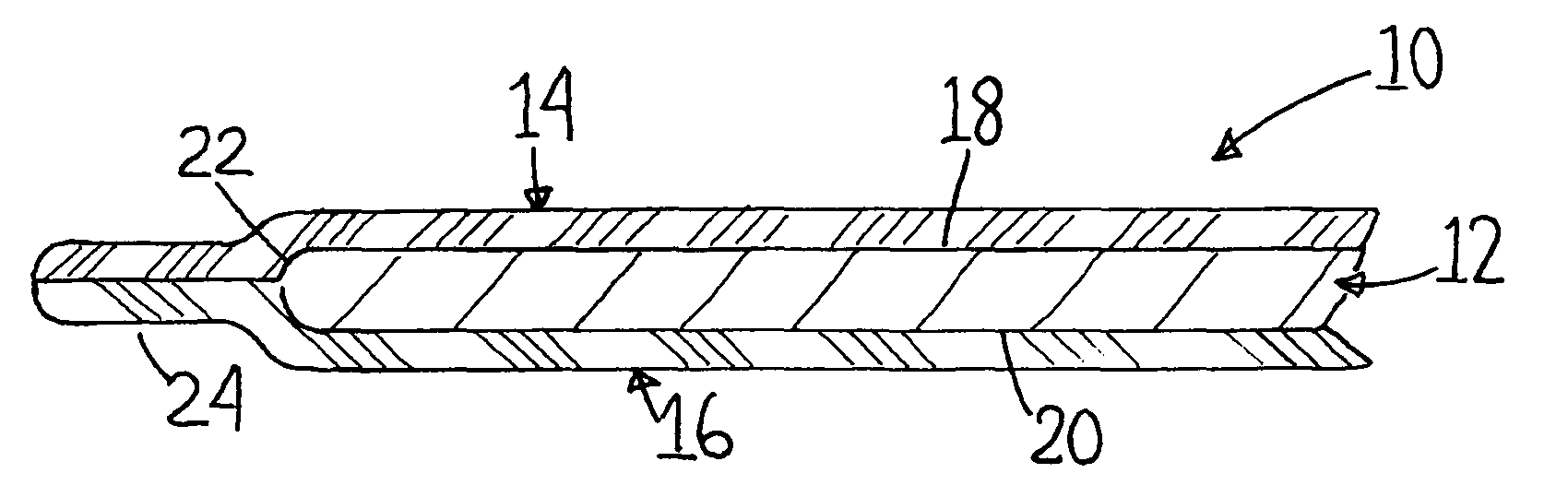

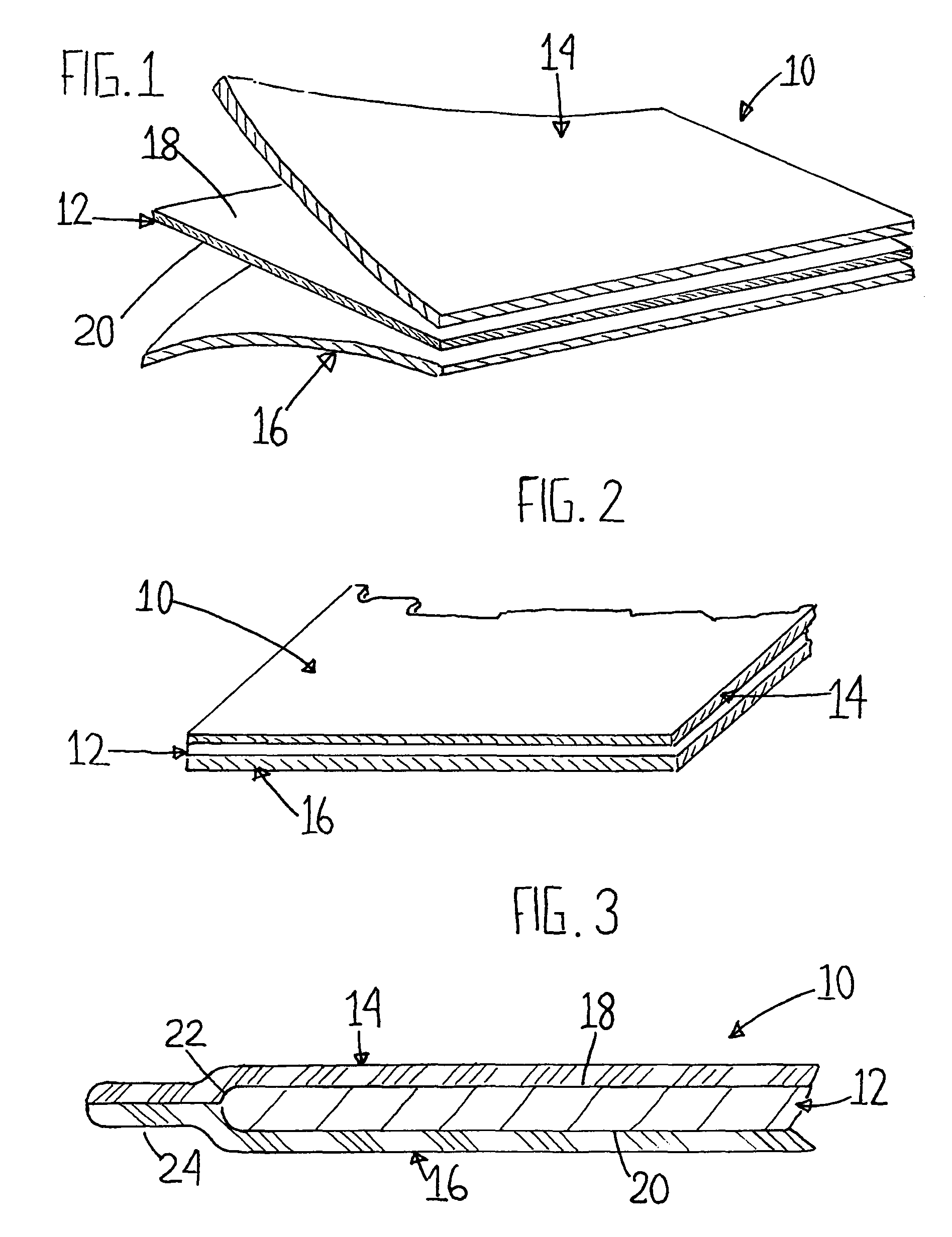

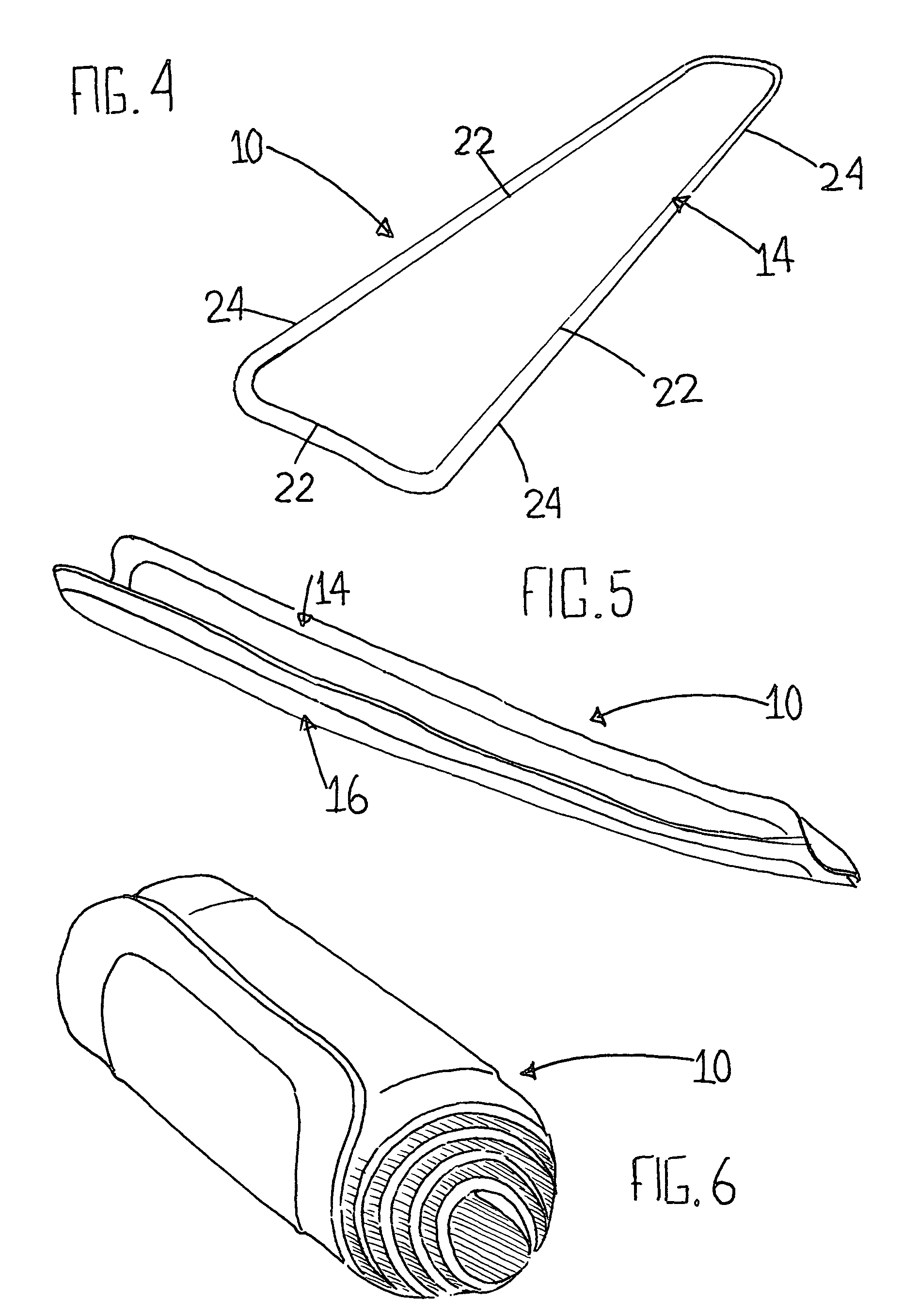

Three-part laminated pliable hand-moldable surface construction

ActiveUS7851038B2Easily decontaminated and reused multiple timeShieldingPortable shielded containersLead sheetEngineering

A three-part laminated surface construction can be shaped and molded by hand and will retain that shape until the particular need is met, such as controlling the flow of liquids and resins, or establishing a protective cover. The surface construction includes a center sheet of lead with rubber layers secured over the lead. The perimeter of the rubber layers are secured together. The lead sheet can be provided with outer flaps, one soft rubber side and the other rubber side abrasion-resistant for folding around and protection from sharp objects.

Owner:LOHMEIER KEVIN F

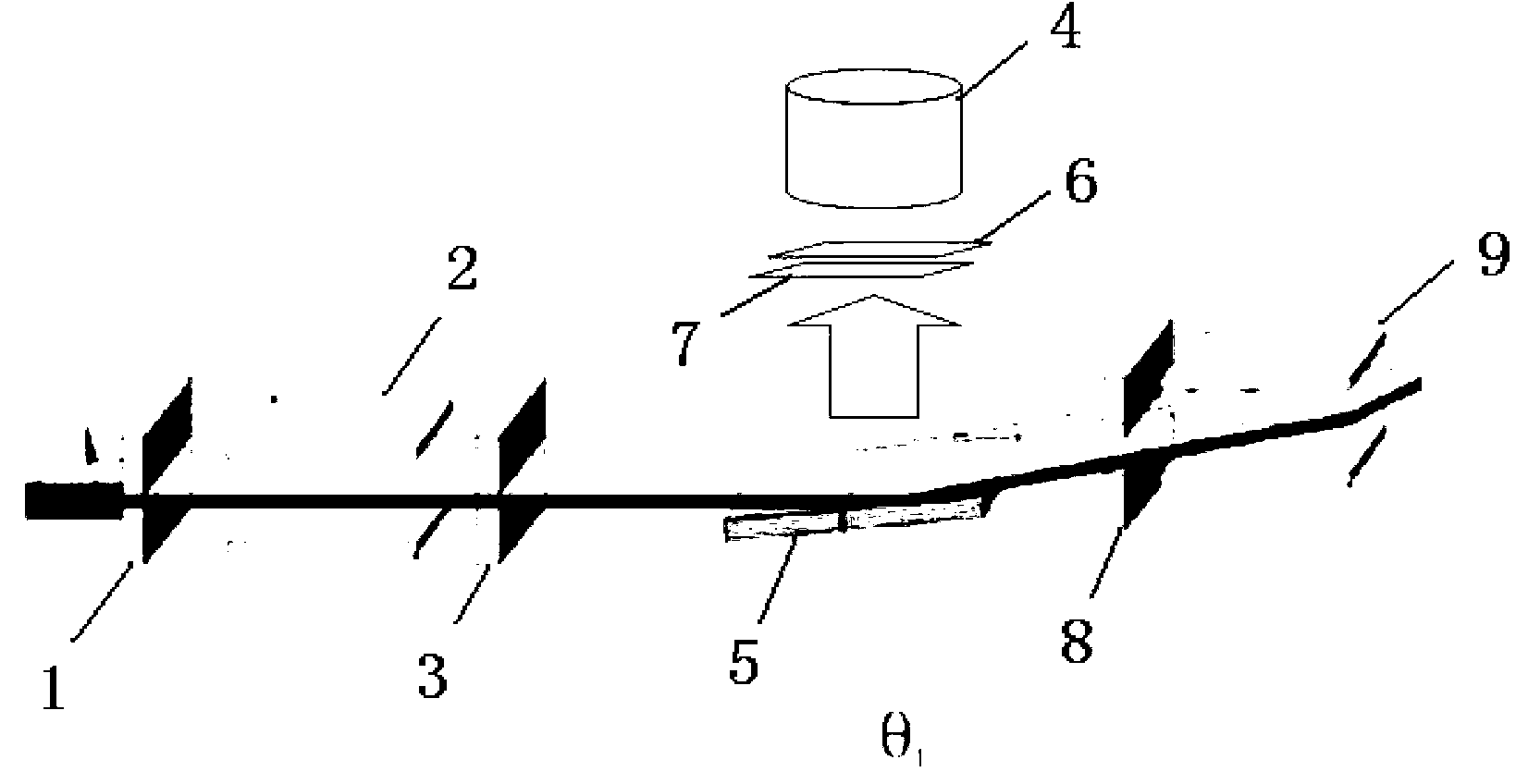

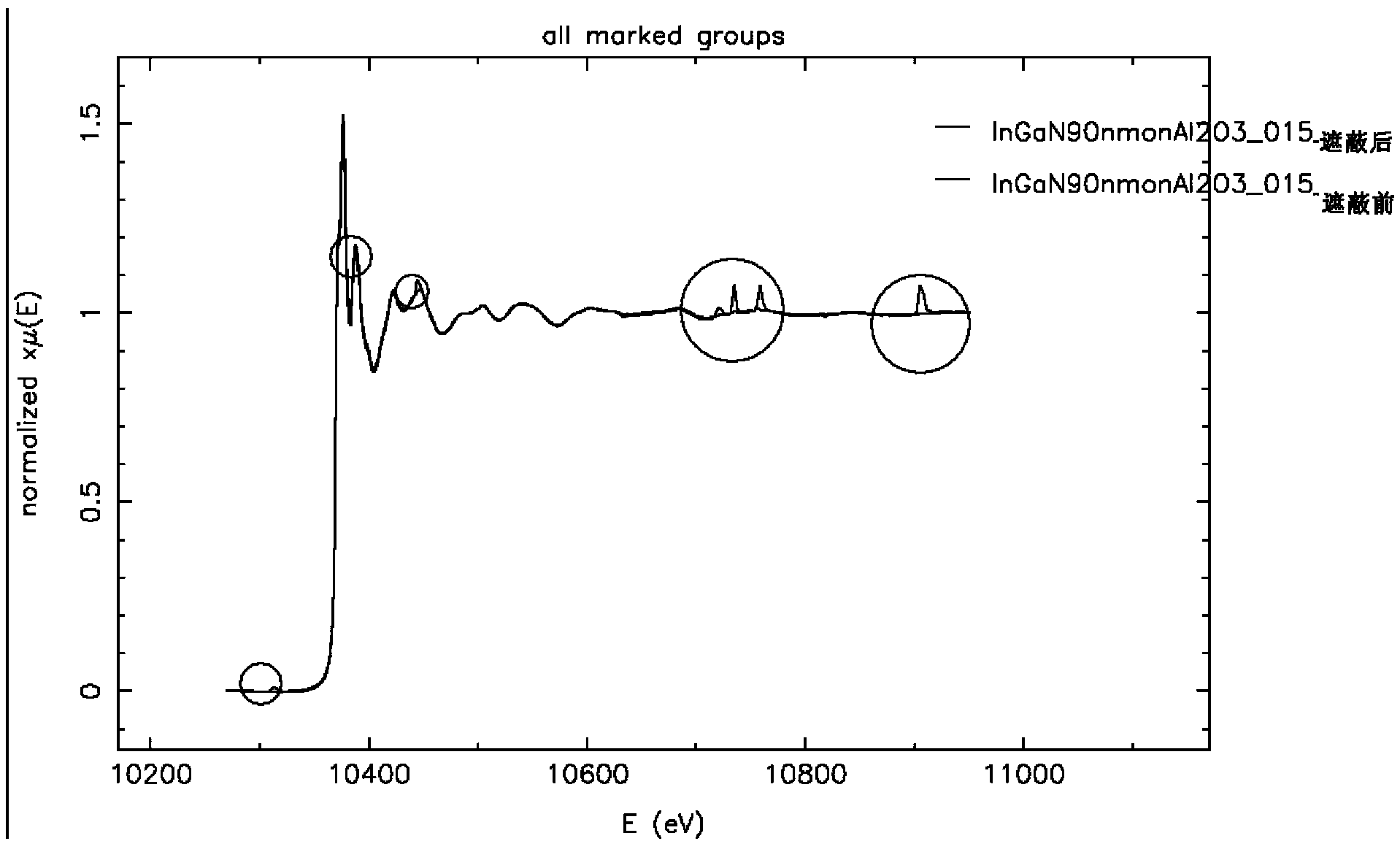

Method for obtaining high-quality X-ray absorption spectrum of thin film sample

ActiveCN103076352ASolving Diffraction Peak ProblemsHigh precisionMaterial analysis using wave/particle radiationDiffraction effectHard X-rays

The invention discloses a method for obtaining a high-quality X-ray absorption spectrum of a thin film sample. In a measuring process of the thin film sample, after diffraction spots are generated by exposing a single-crystal substrate of the thin film sample through a dry film, exposure points are shielded by a lead sheet to prevent diffraction signals caused by the substrate from entering a detector so as to obtain the high-quality X-ray absorption spectrum of the thin film sample. The dry film consists of carbon, nitrogen, oxygen and a trace element lithium, has an effective atomic number within 6-8 and the film thickness of about 100-200 microns, does not cause a serious background to the hard X-ray absorption spectrum, and particularly can be integrated with a light filter in the detector to filter out a scattering effect caused by incident light and a diffraction effect caused by the substrate of the thin film sample. Therefore, a simple and effective way for obtaining the high-quality X-ray absorption spectrum of the thin film sample is provided.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com