Flexible one point force sheet type sensor and production method

A manufacturing method and force sheet technology, which is applied in the field of flexible single-point force sheet sensors and their manufacturing, can solve the problems of pressure sensors that cannot be detected, inconvenient operation, and large volume, and achieve light weight, simple manufacture, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

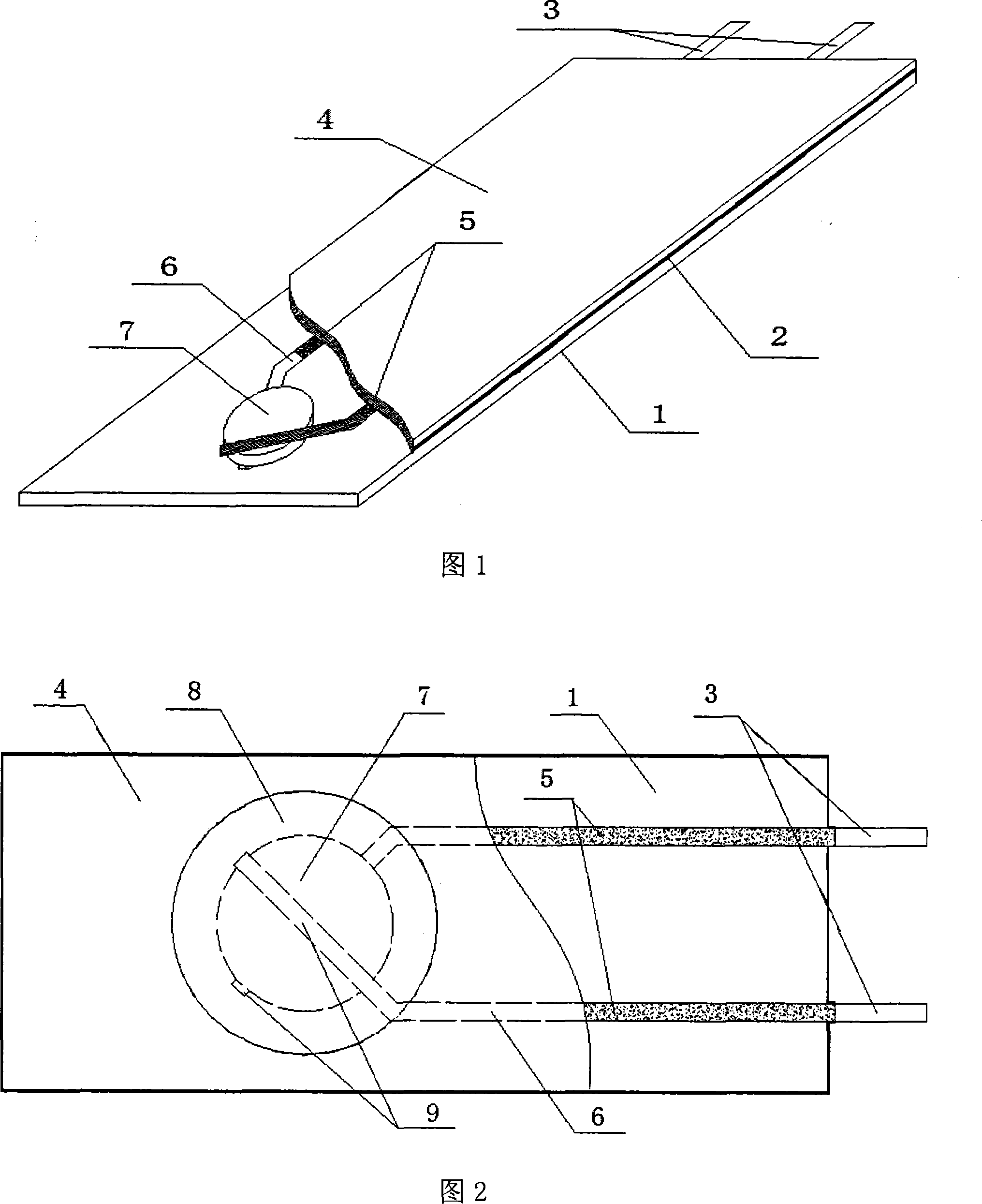

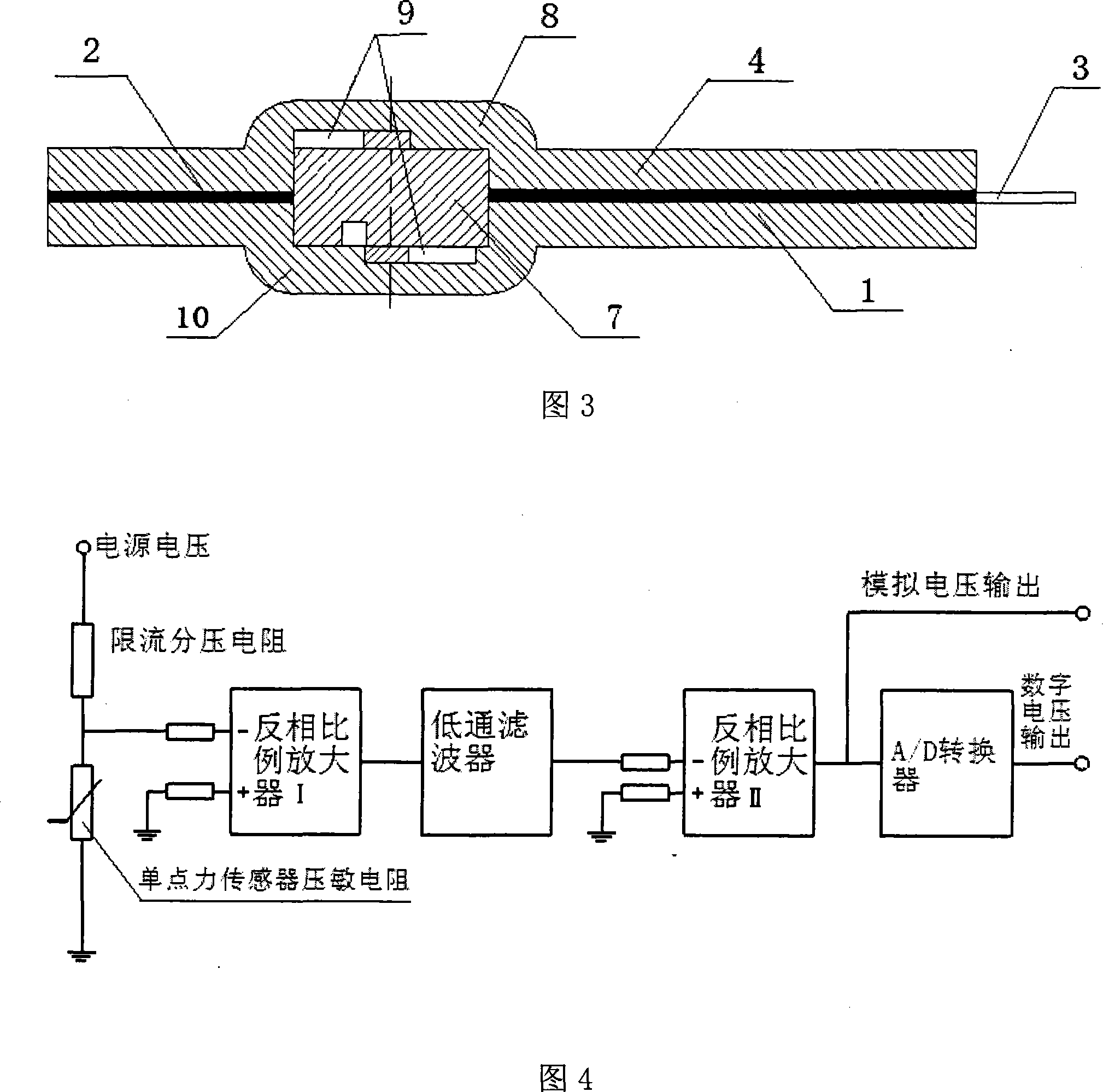

[0022] As shown in FIG. 1-FIG. 3, a flexible single-point force sensor includes an upper substrate 4 and a lower substrate 1, a pressure-sensitive body 7, and two electrode connecting sheets 9 arranged on the vertical ends of the pressure-sensitive body 7, The upper and lower substrates are sealed by an epoxy resin adhesive layer 2; the upper and lower substrates 4 and 1 can be made of polyvinyl chloride (PVC) as rectangular substrates of the same size; A protrusion 8 is provided on the side; a depression 10 is provided on the lower substrate opposite to the protrusion 8, and a closed pressure-sensitive body chamber is formed between the depression and the protrusion, and the pressure-sensitive body 7 and the electrode connecting sheet 9 are encapsulated therein. , the size of the pressure-sensitive body chamber just matches the size of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com