Method for building sheet pile walls

a technology of sheet pile walls and building sheets, which is applied in the direction of walls, building repairs, parkings, etc., can solve the problems of fluid adhesive, difficult curing of caliber pieces, and long curing time of adhesives,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

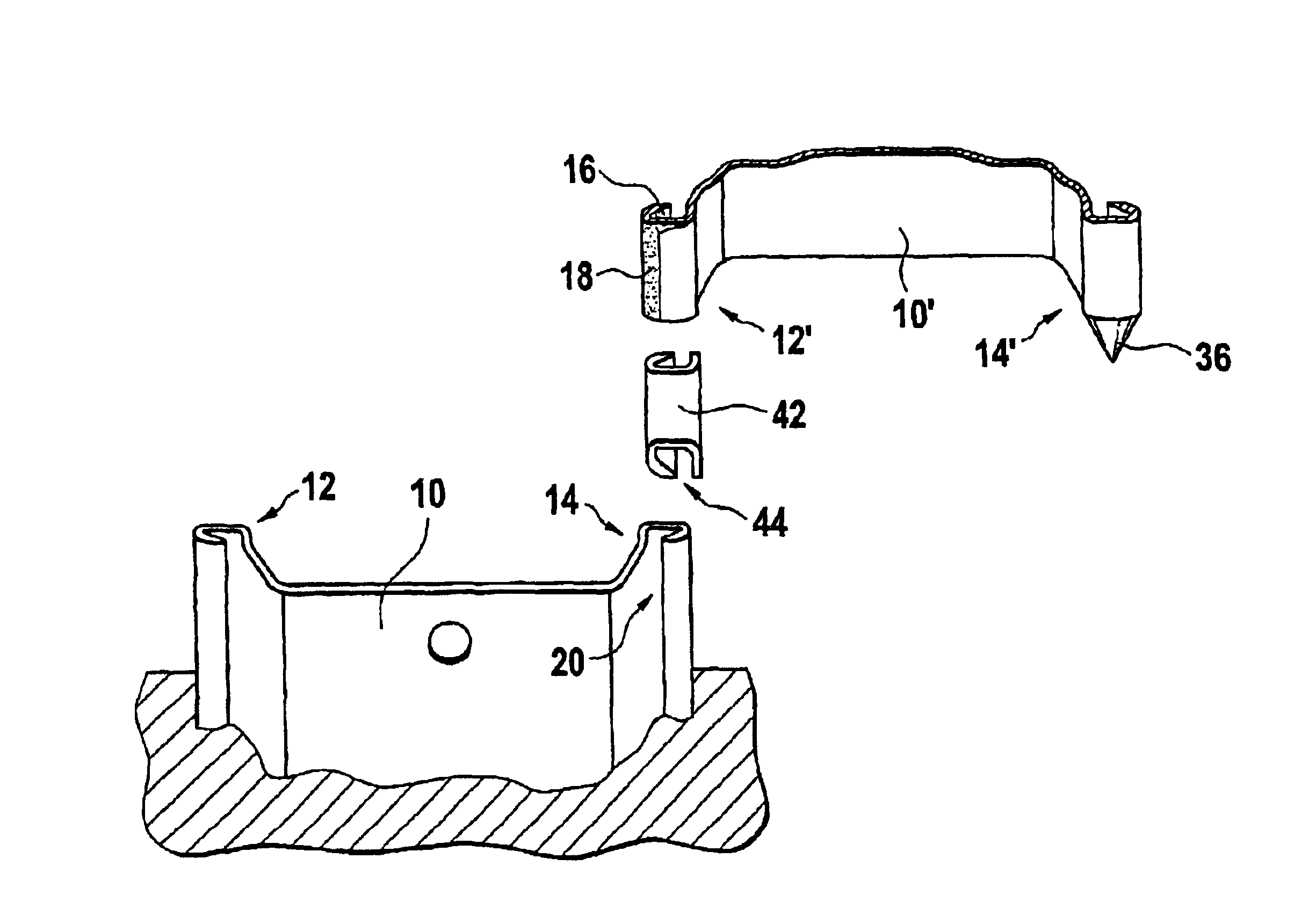

[0031]On FIG. 1, a first sheet pile 10 with its trailing and leading sheet pile interlocks 12, 14 can be seen in place in the ground. A second sheet pile 10′ with its trailing and leading sheet pile interlocks 12′, 14′ is ready to be interlocked with the first sheet pile 10. The trailing sheet pile interlock 12′ of the second sheet pile 10′ has an interlock head 16 coated with a fixing agent 18. This interlock head 16 engages in an interlock chamber 20 of the leading sheet pile interlock 14 of the first sheet pile 10. The interlock chamber 20 is clean, i.e. it is free from any ground material. The interlock head 16 of the trailing sheet pile interlock 12′ of the second sheet pile 10′ slides down the clean interlock chamber 20 of the leading sheet pile interlock 14 of the first sheet pile 10 as the second sheet pile 10′ is driven into the ground.

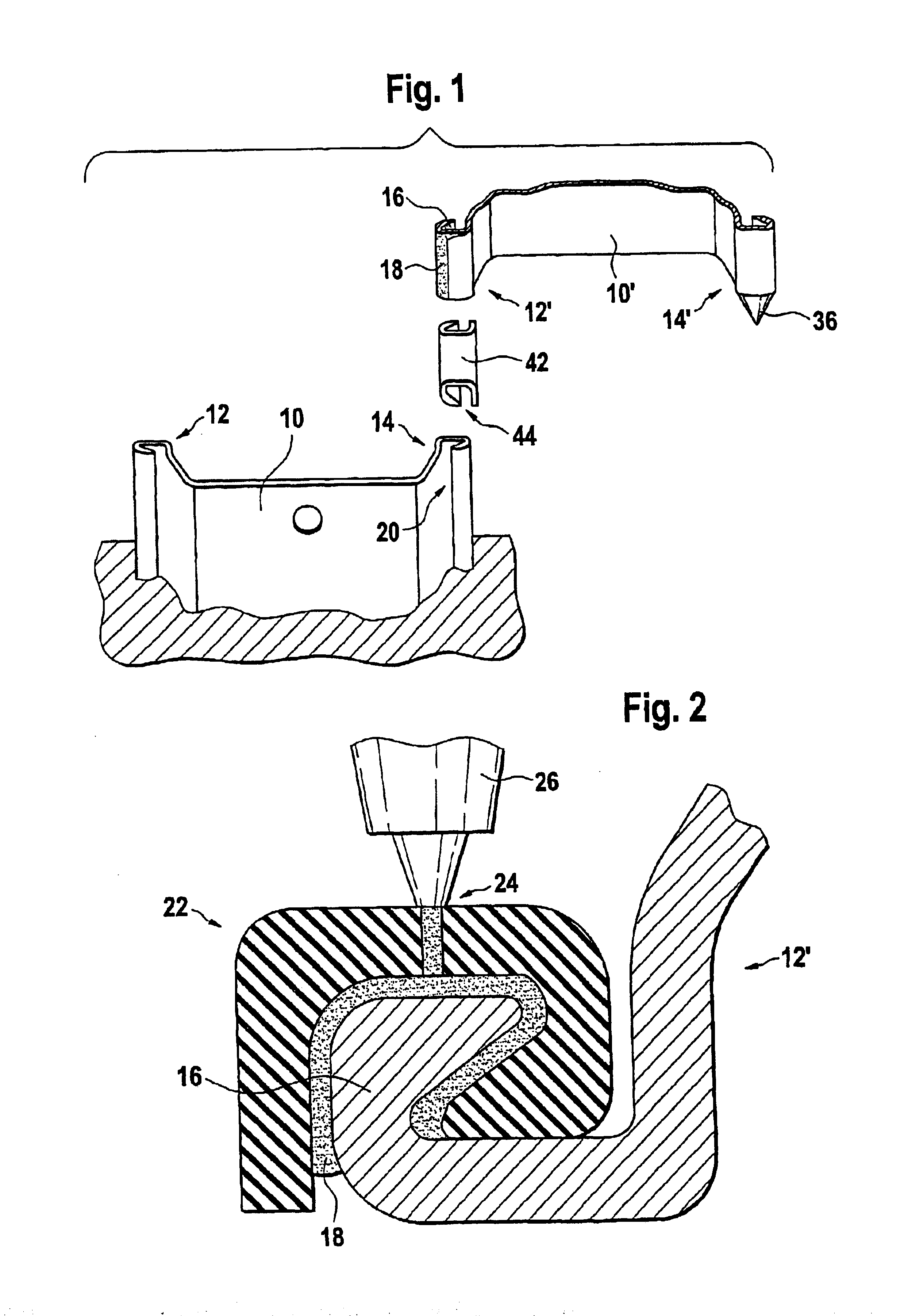

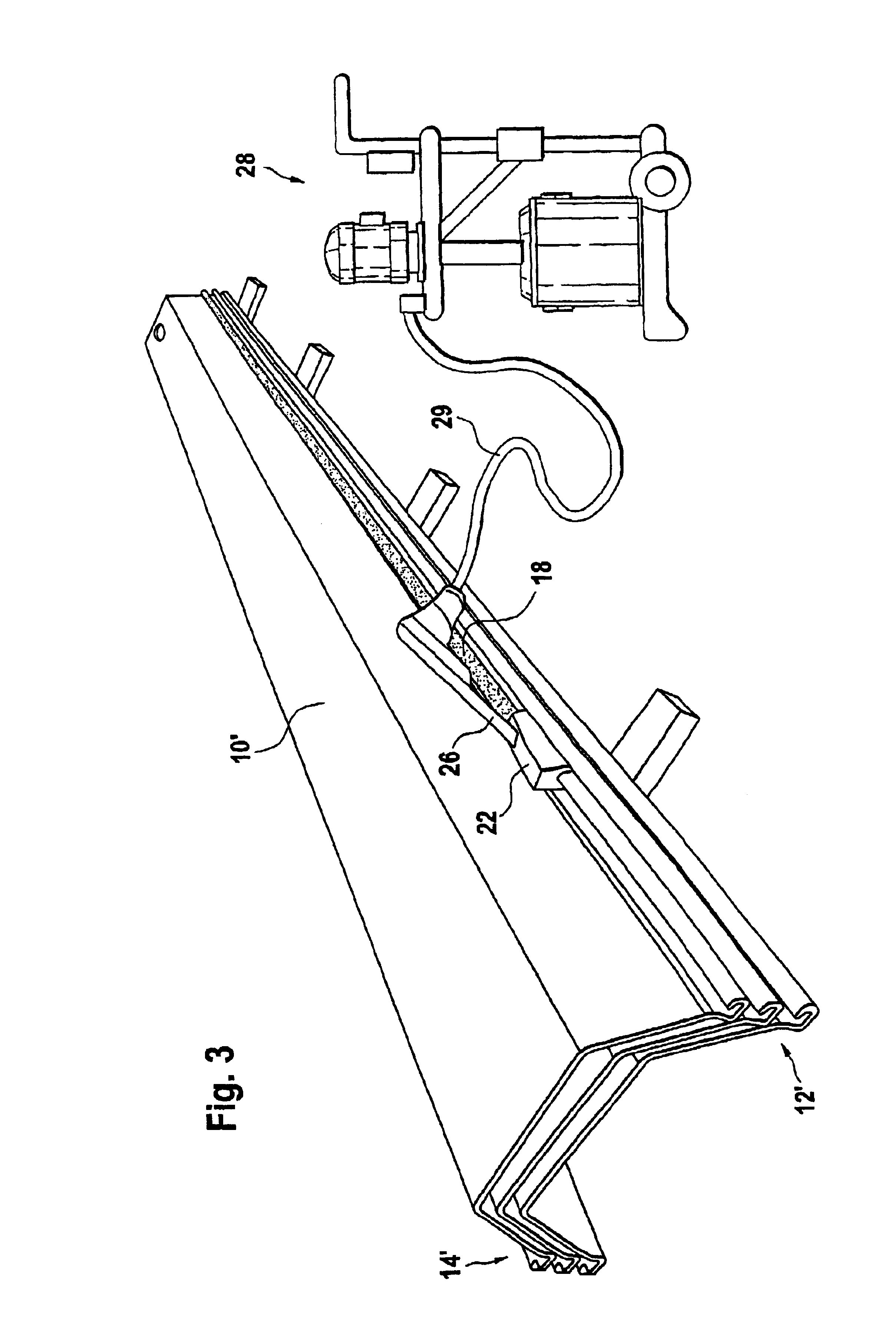

[0032]FIG. 2 shows a trailing sheet pile interlock 12′ whose interlock head 16 is being coated with a fixing agent 18. The fixing agent 18 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com