Device and method for concrete interior strain testing

A strain testing and concrete technology, applied in electromagnetic measuring devices, electrical/magnetic solid deformation measurement, etc., can solve the problems of unfavorable implantation, large volume of optical fiber sensors, high cost, and achieve the effect of good coordination of deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

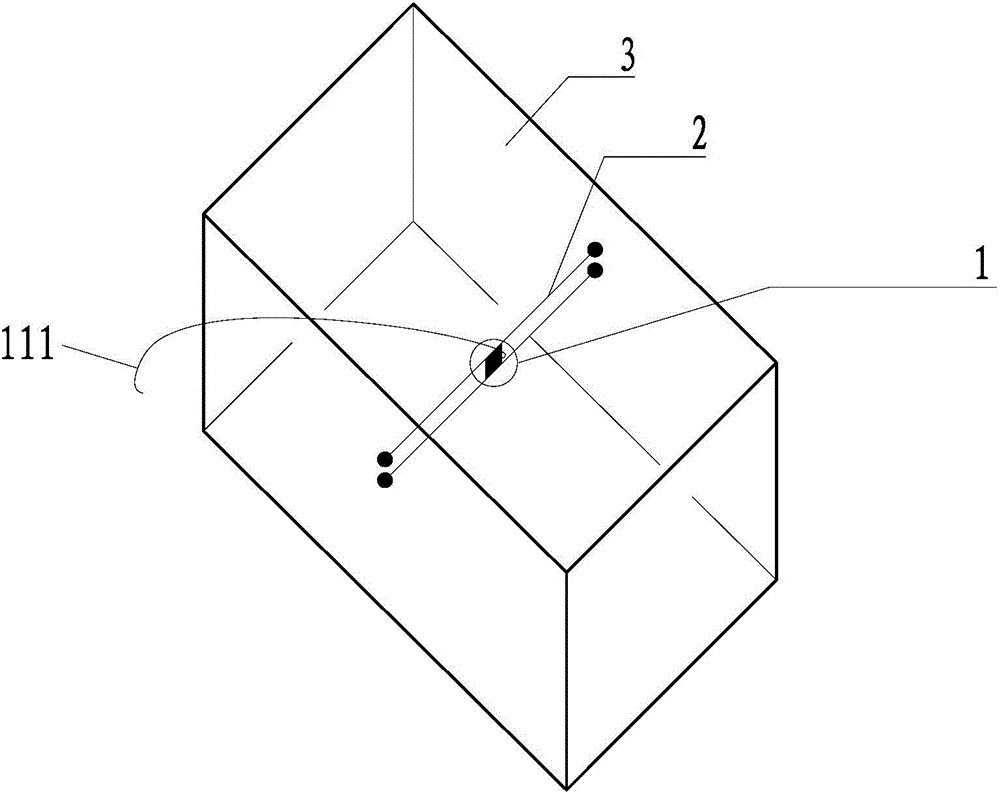

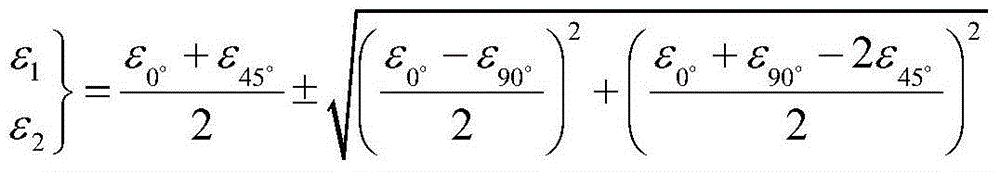

[0031] refer to Figure 1-2 , a method for concrete internal strain testing, comprising the following steps:

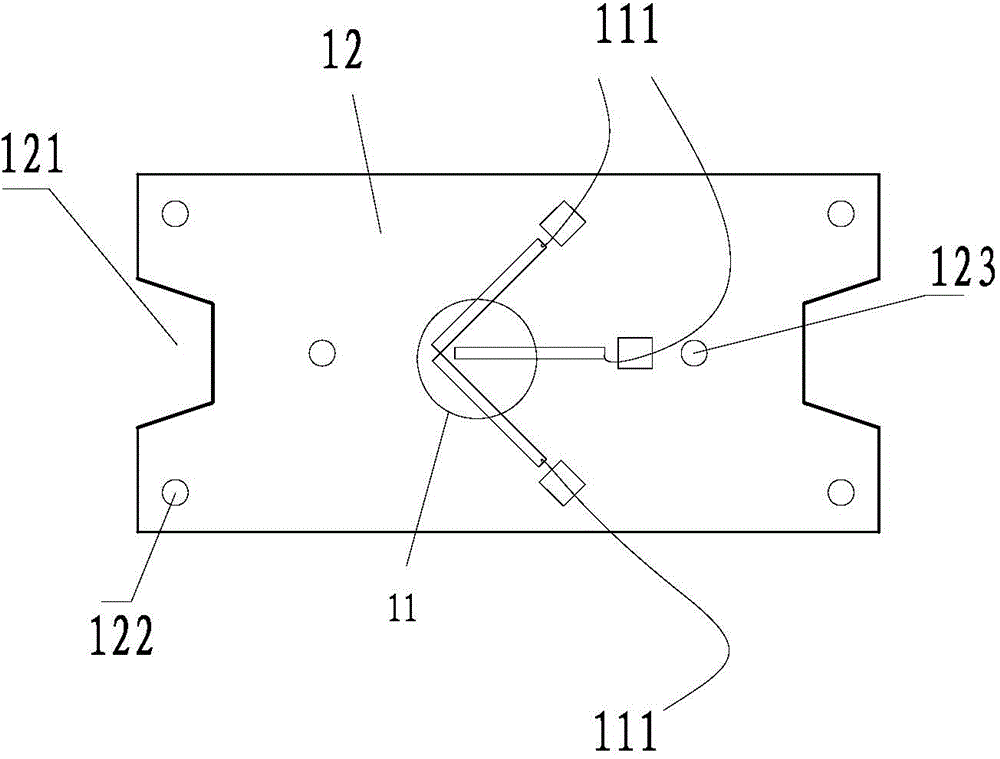

[0032] 1) According to the test plan, the number of internal measuring points of the concrete, this embodiment is the case where the internal measuring point is 1, and the base sheet 1 corresponding to it is processed and manufactured; the base sheet 1 is pasted with rosettes 11 and A lead sheet 12 coated with a layer of waterproof glue; the left and right ends of the lead sheet 12 have a recess 121 respectively, and the four corners of the lead sheet 12 are respectively provided with connection holes 122, and the lead sheet 12 A grip enhancing hole 123 is respectively provided on the left and right sides close to the recessed portion 121 .

[0033] In order to accurately reflect the internal strain of concrete, it is necessary to select a material with a similar elastic modulus and better coordinated deformation ability as the base sheet 1 to paste the strain rosett...

Embodiment 2

[0042] In this embodiment, there are plural internal measuring points, and there are plural corresponding base sheets; the four vertices of the plural base sheets are connected in series with connecting wires and then fixed to the template.

[0043] In addition, the wires drawn from the rosettes of the plurality of base sheets are fixed to the outside of the concrete test specimen after being bundled and bound, and are separated from the concrete test specimen by a safe distance; thus, the pouring of concrete is not affected.

[0044] When pouring concrete, stop whenever the pouring reaches the position where there is a base sheet, vibrate, and after compaction, adjust the predetermined position and orientation of the base sheet, and then pour to cover the base sheet; repeat this until all The base sheets are covered.

[0045] Every remaining part is the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com