Lead sheet suspension stud

a technology of suspension studs and lead sheets, which is applied in the direction of girders, fireproofing, building repairs, etc., can solve the problems of electrical and plumbing fixtures disturbing the integrity of drywall, and achieve the effects of reducing the potential for back injuries, reducing the weight of material handling, and minimizing employee lost tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

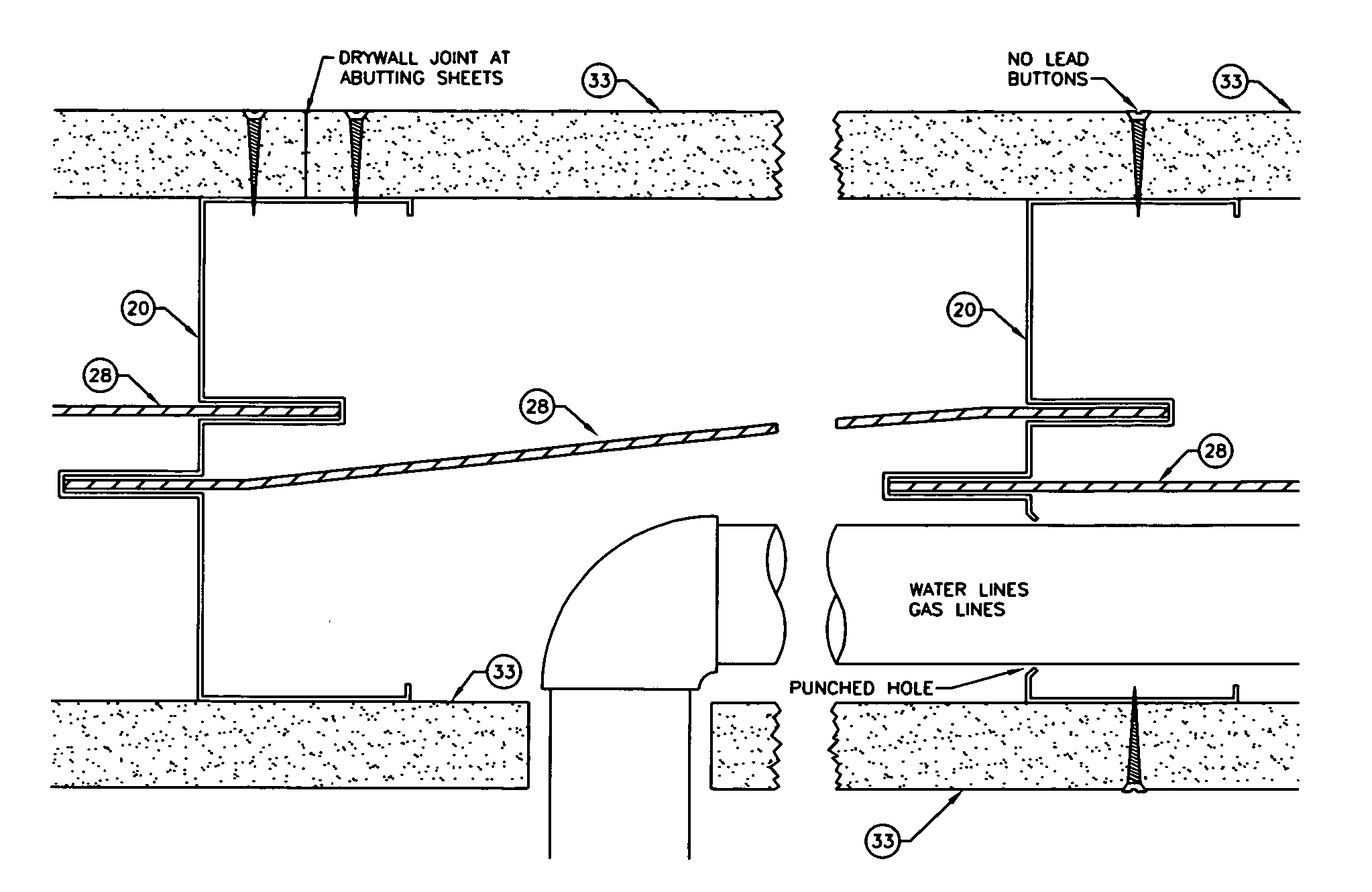

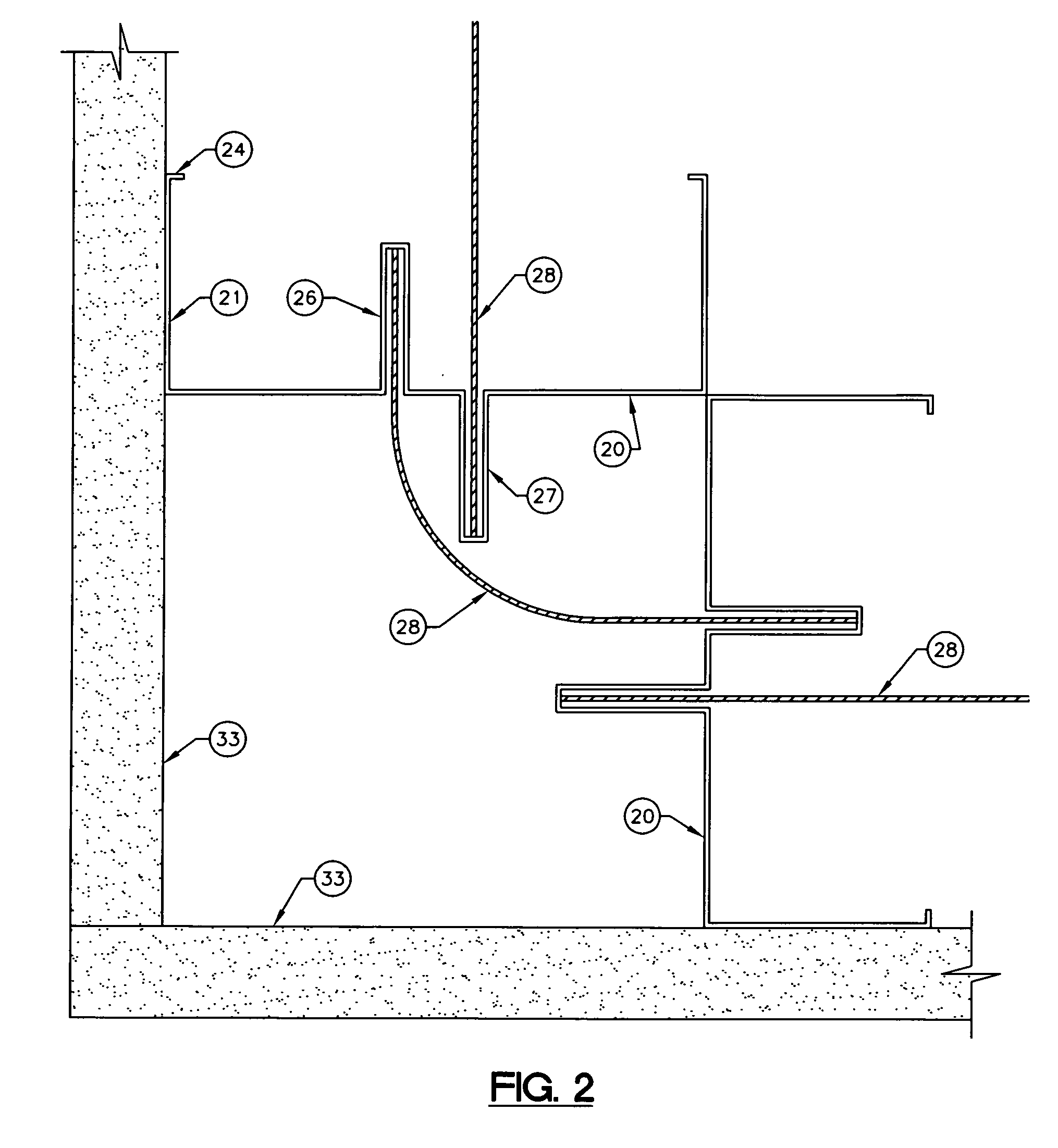

[0021]A metal stud system for accepting and suspending lead sheets for radiology suite construction wherein the metal stud is configured to have two holding cavities wherein the first holding cavity and the second holding cavity are constructed and aligned along a vertical plane so that when a lead sheet is held in the first holding cavity and a lead sheet is held in the second holding cavity, the lead sheets overlap, and thereby, create a radiation leak-proof metal stud system.

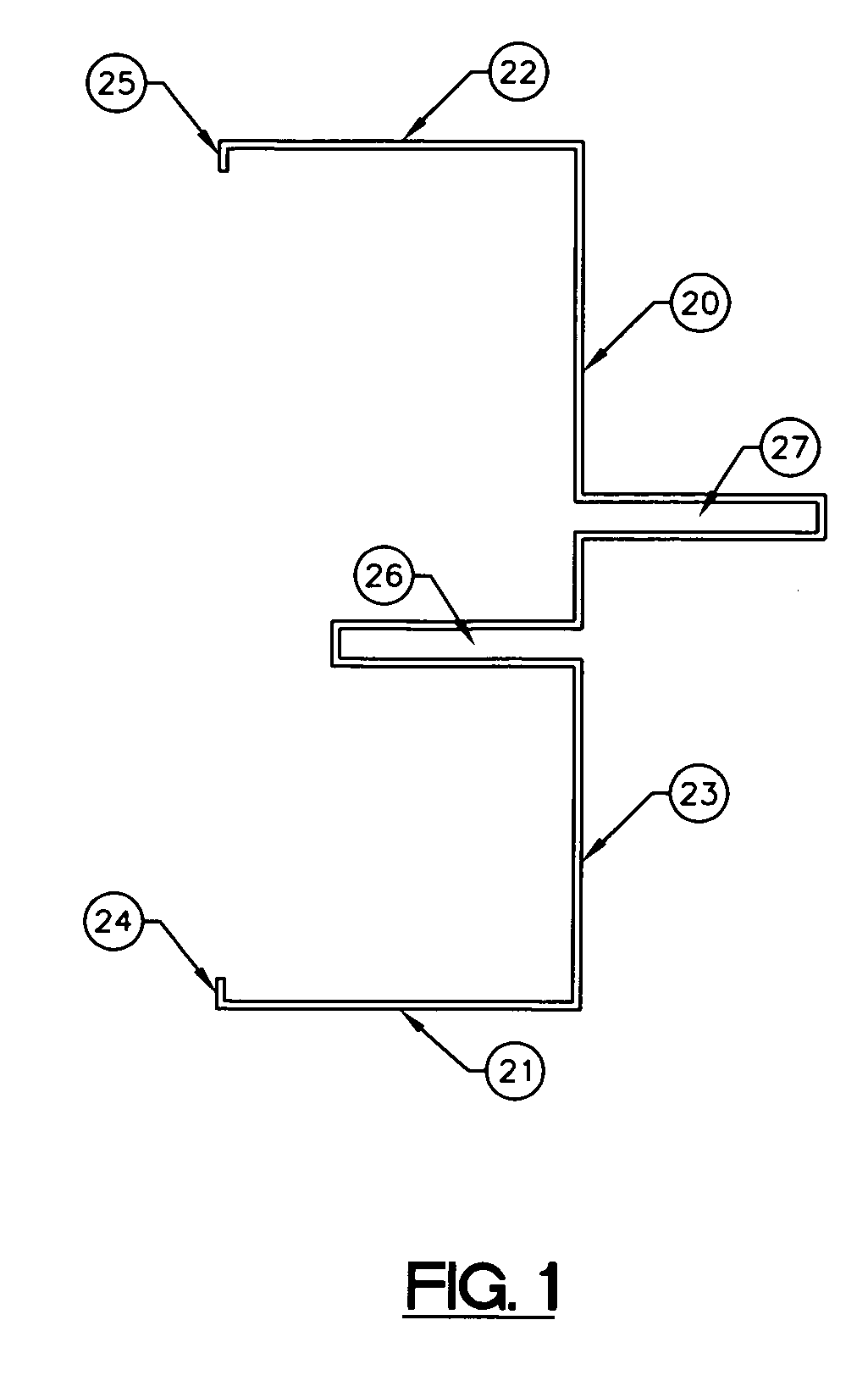

[0022]FIG. 1 illustrates a full scale view of the radiation leak-proof sheet metal stud, 20, suitable for suspending lead sheets for radiology suite construction in the present invention. The metal stud, 20, of the present invention is created by two holding cavities, 26 and 27 respectively. The first holding cavity 26 is configured and aligns along the central planar portion, 23, and extends inwardly between the front planar portion 21 of the metal stud, 20, and the rear planar portion 22 as illustrated. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com