Air suction system of laser cutting machine and laser cutting machine

A laser cutting machine, laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of working environment pollution, low cutting quality, easy deviation of plates, etc., to ensure quality and prevent plates deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

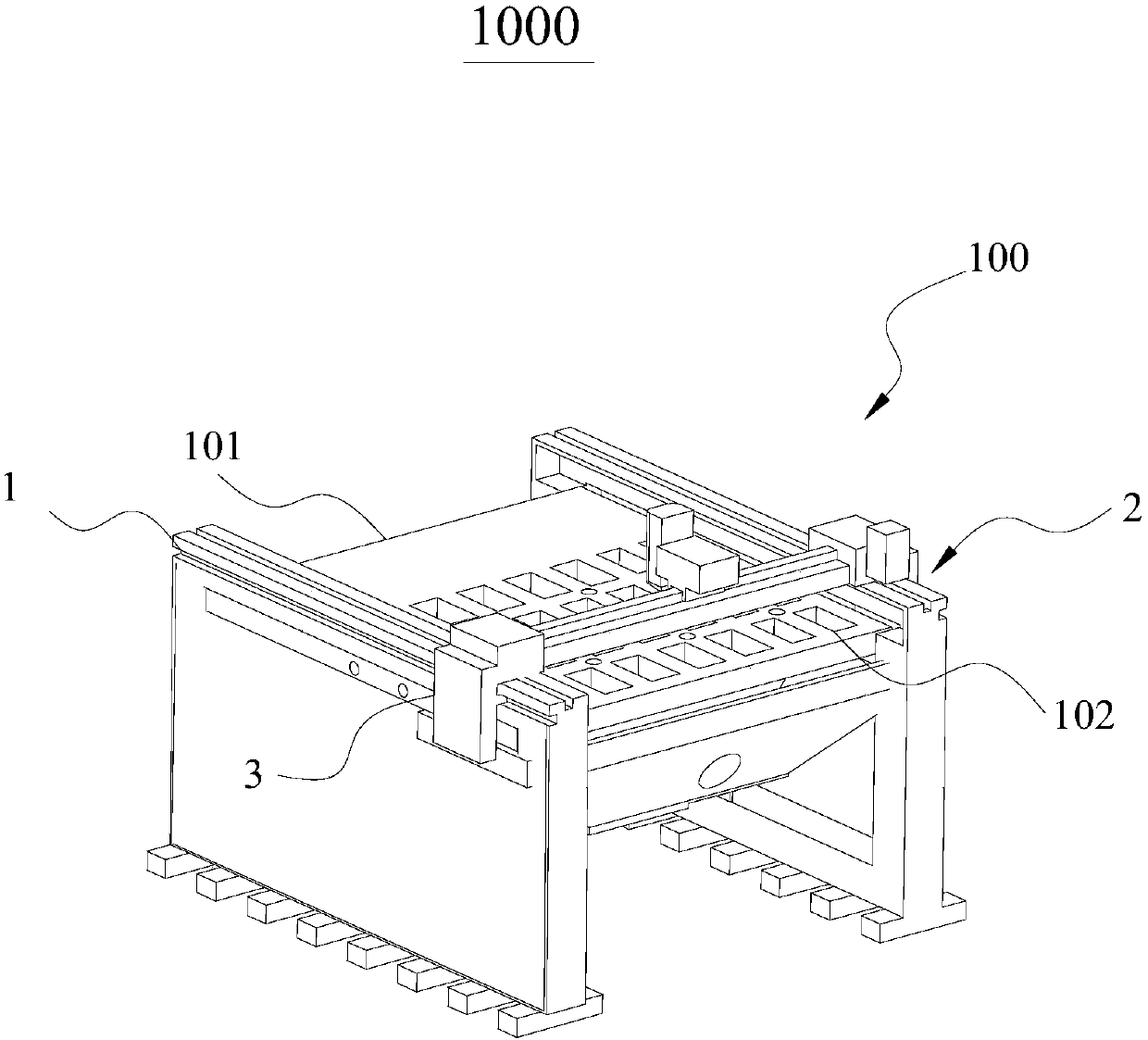

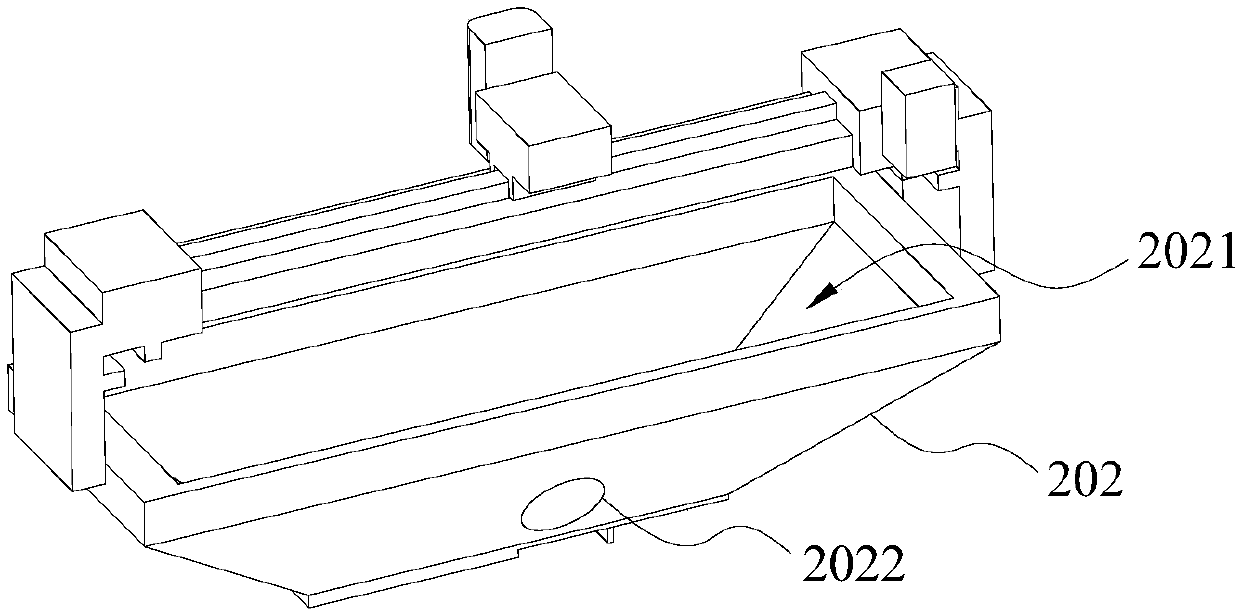

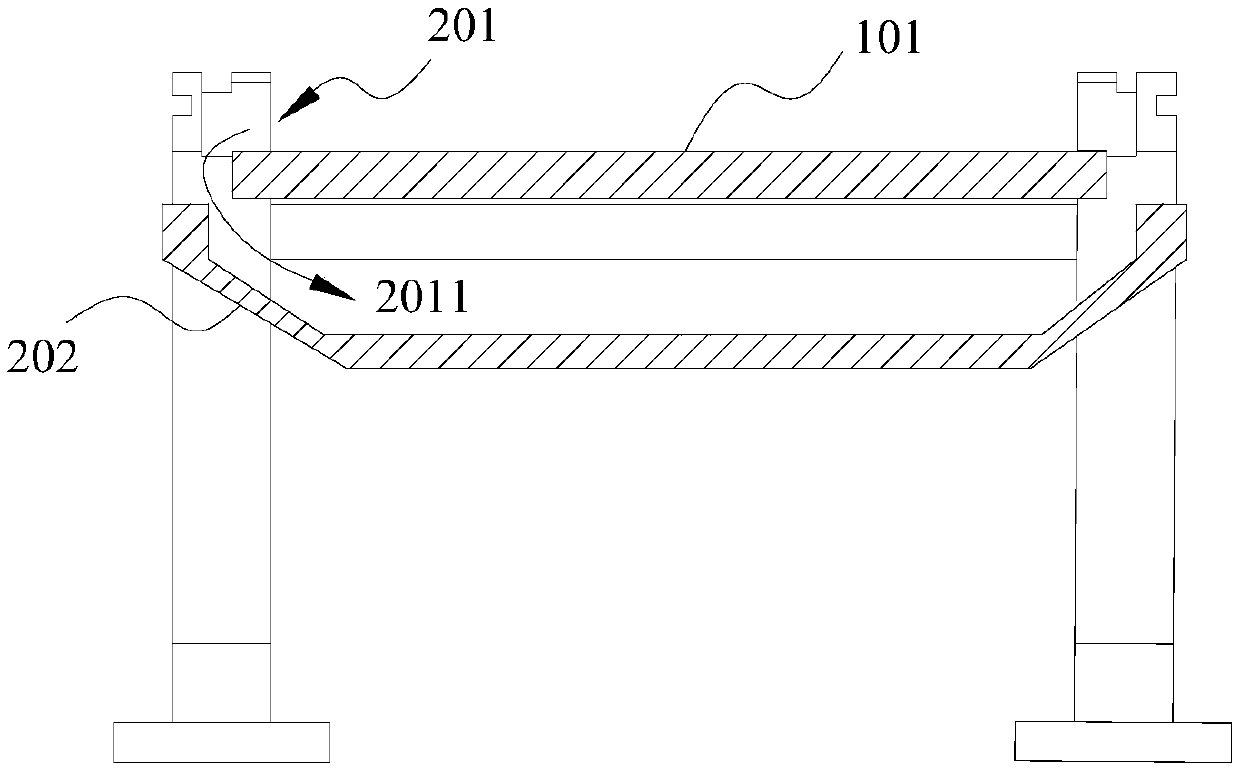

[0042] Please refer to figure 1 , figure 1The specific structure of a laser cutting machine 1000 provided in this embodiment is shown, and the laser cutting machine 1000 is used for the workbench 1 of laser cutting plates; wherein the workbench 1 is provided with a suction system 100 of the laser cutting machine 1000, The suction system 100 includes a suction structure 2 and a moving assembly 3, the purpose of which is not only to smoothly absorb the cut material on the workbench 1, but also to suck the waste gas generated during cutting.

[0043] The laser cutting machine 1000 includes a workbench 1 for laser cutting plates, a moving assembly 3 arranged above the workbench 1, and a suction structure 2 arranged below the workbench 1; Located on both sides of the workbench 1, the moving assembly 3 is provided with a laser cutting head 4; the air suction structure 2 is connected with the moving assembly 3, and is used for synchronous air suction as the moving assembly 3 moves. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com