Lead sheet cold cutting pelleter

A granulator and lead flake technology, applied in the field of lead flake cold-cut granulator, can solve the problems of low production efficiency and complex structure of the granulator, and achieve the effects of improving production efficiency, facilitating shedding, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

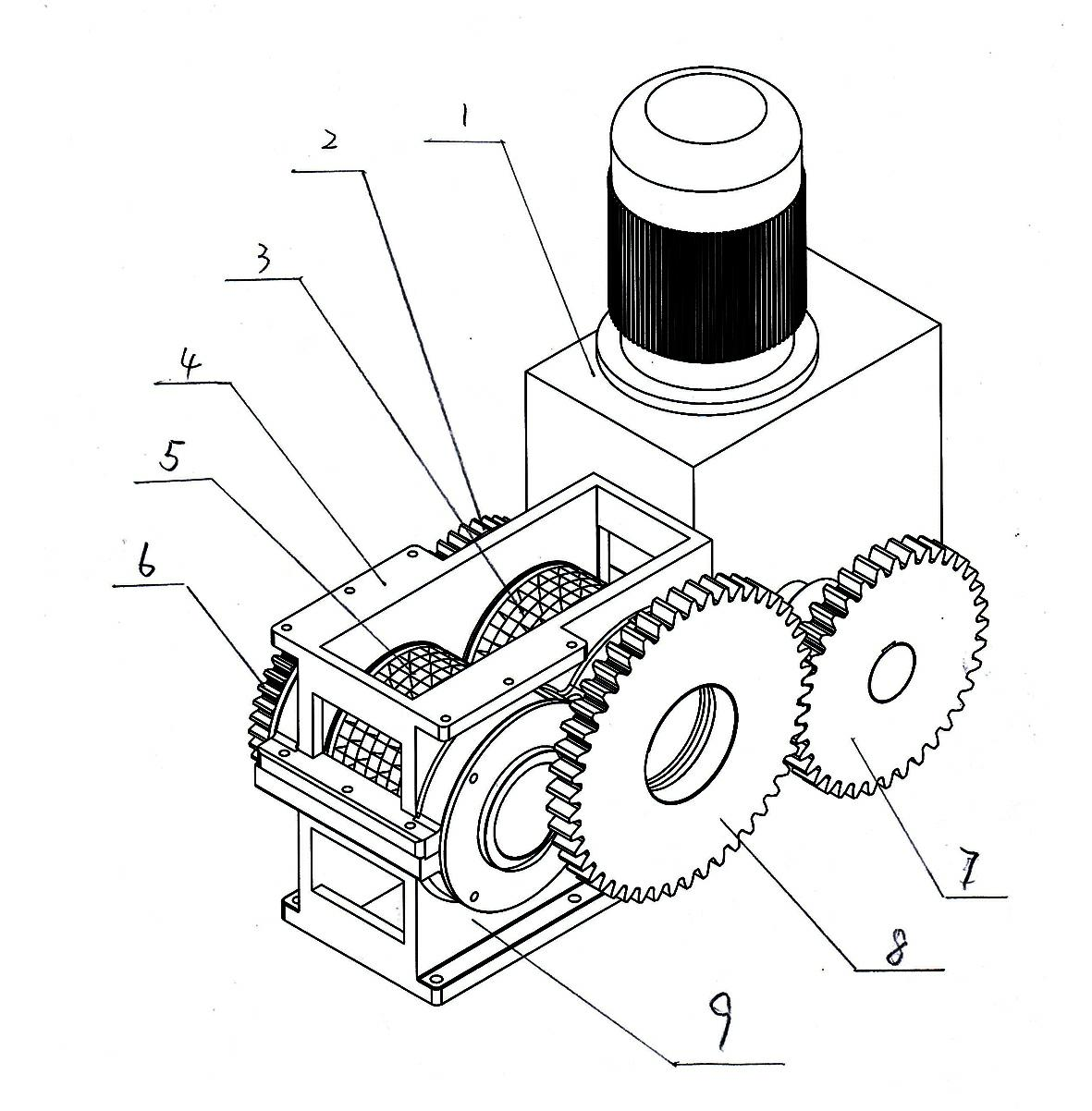

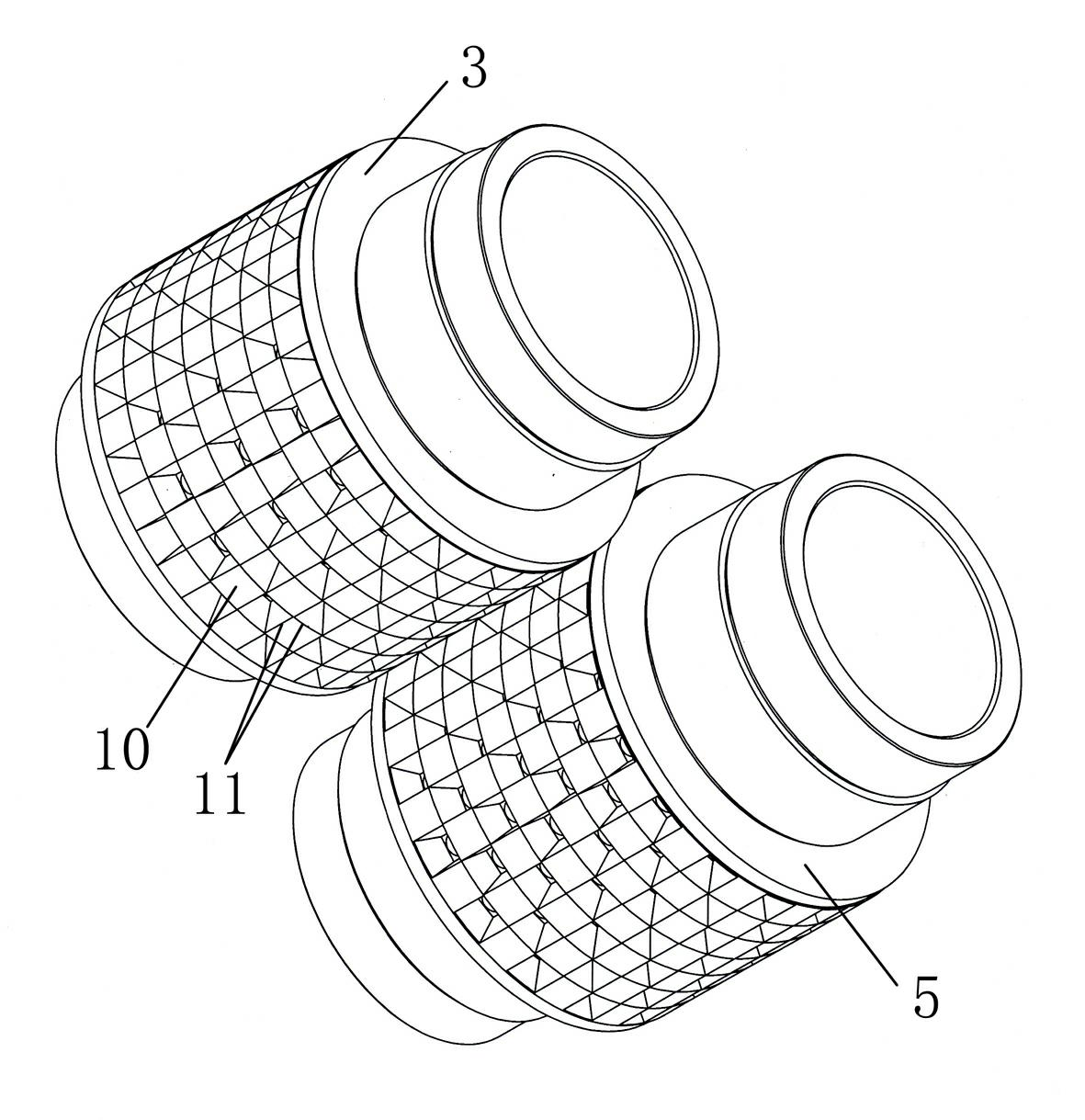

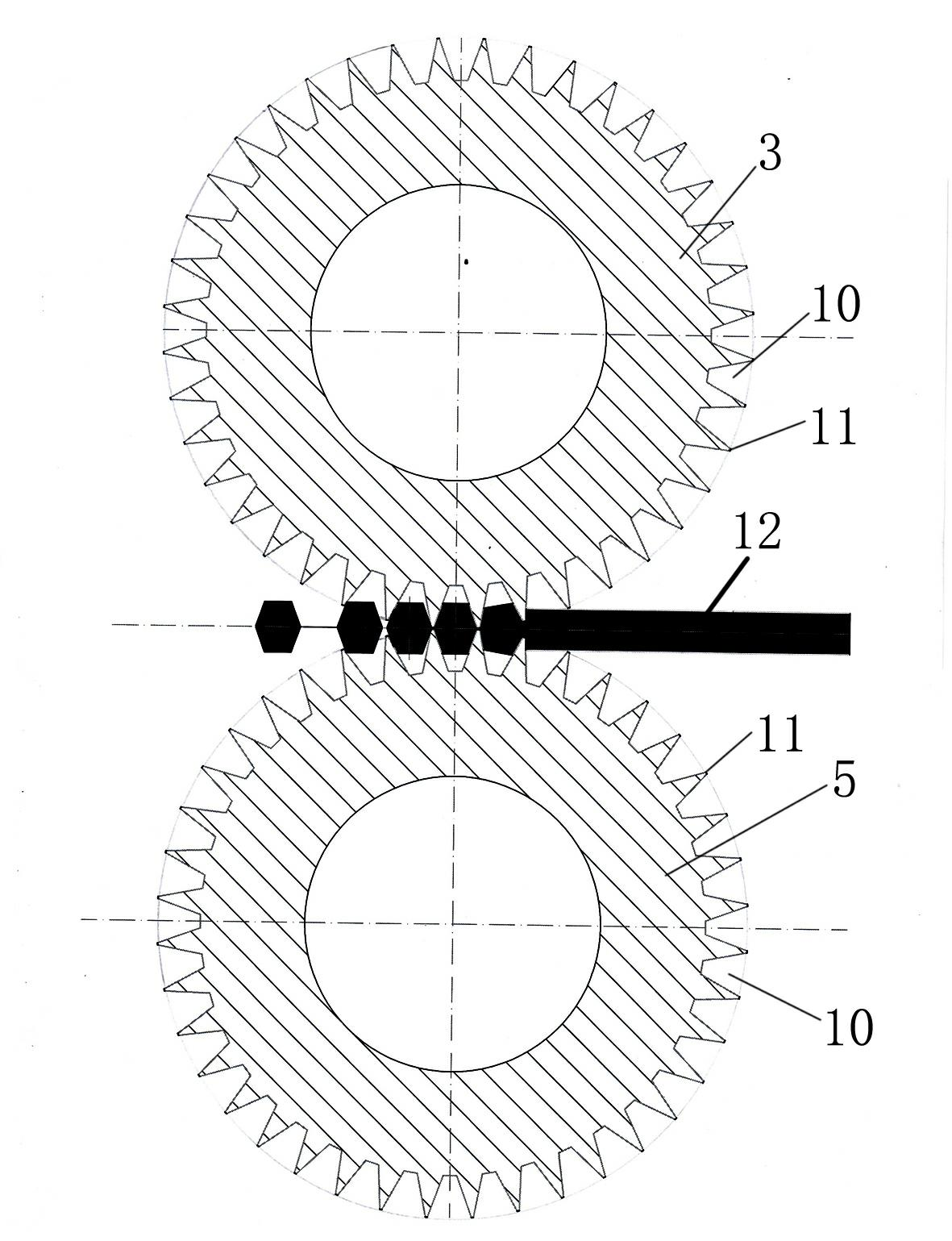

[0013] Such as figure 1 As shown, the lead flake cold-cut granulator of the present invention comprises a frame, and the frame is formed by connecting an upper box body 4 and a lower box body 9, and a pair of synchronous counter-rotating first cutting rollers 3 and The second cutting roll 5, the two cutting rolls have the same level in the casing, and the outer peripheral surface of each cutting roll is provided with a mold cavity 10, such as figure 2 As shown, the outer peripheral surface of each cutting roller is provided with a continuous mold cavity 10 along the circumferential direction and the axial direction. The thin wall in the middle of the adjacent cavity 10 has a cutting edge 11 for cutting off the lead sheet. The lead block is cold cut into small particles according to the shape of the cavity. The two ends of each cutting roller are fixed on one side of the box through bearings On the opposite side wall, and a pair of cutting rollers are installed on the frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com