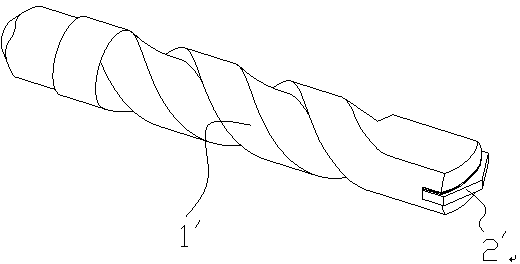

Automatic drill bit welding machine

A technology for automatic welding machines and drills, which is applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., and can solve problems such as adverse effects on the body of operators, high labor intensity, and eye injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

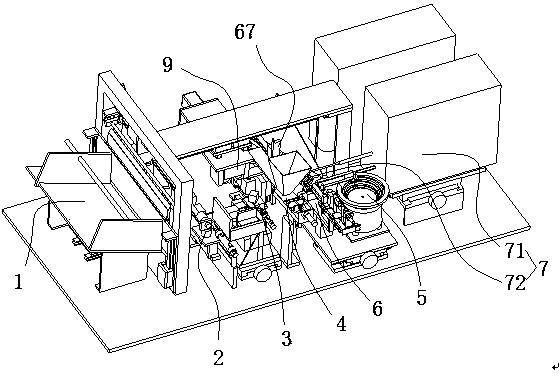

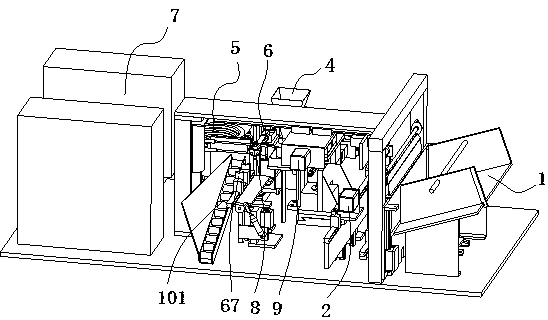

[0034] Such as Figure 2-3 As shown, an automatic drill bit welding machine mainly includes a single feeding mechanism for the drill bit body connected to each other 1, a horizontal alignment device for the incision of the drill bit body 2, an automatic copper strip feeding device 3, a solder adding mechanism for welding 4, and an alloy sheet The material mechanism 5, the precise alignment mechanism 6 of the alloy sheet and the drill body, the high-frequency heating device 7 and the alloy sheet calibration device 8 after welding.

[0035] Such as Figure 4 As shown, the drill body single feeding mechanism 1 sends the drill body to be processed into the drill body incision horizontal alignment device 2 in a single horizontal manner. The single feeding mechanism 1 of the drill body includes a hopper 11 with a bottom panel 111 inclined inwardly, and a push plate 12 is installed on the inner side plate 112 close to the hopper 11, and the push plate 12 is movably installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com