Draw welding method for micro-miniature conduction slip ring

A technology of conductive slip ring and welding method, applied in the direction of slip ring manufacturing, circuit, connection, etc., can solve the problems that the strength of solder joints cannot be effectively controlled, the thermal expansion coefficient is inconsistent, and the operating space is small, and it is easy to achieve electrical parameters. Guarantee, improve welding quality, improve the effect of overall performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

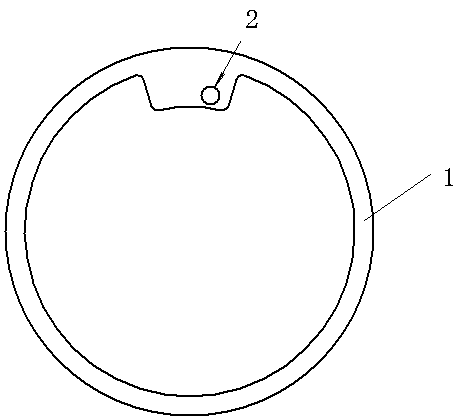

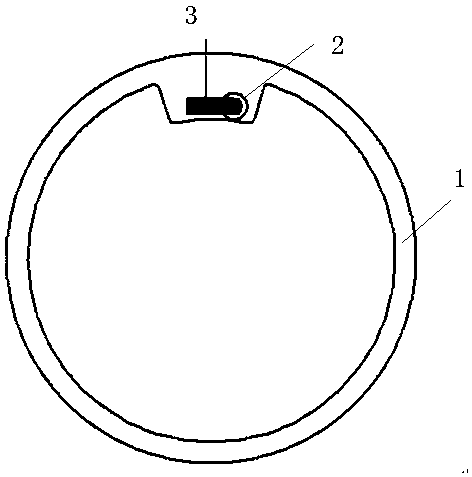

[0030] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

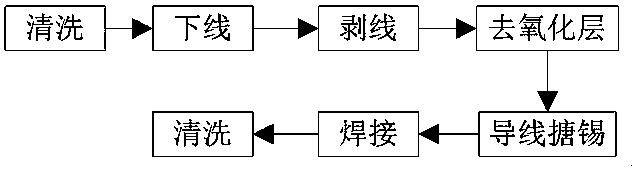

[0031] A hook welding type welding method for a miniature conductive slip ring is characterized in that the specific steps are as follows:

[0032] A. Cleaning: Check the edge burrs and bumps of all rings 1, and deal with them accordingly, and then clean the rings 1 with gasoline;

[0033] B. Offline: Offline according to the technical requirements of external components, standard parts summary table and assembly drawing. In order to prevent the impact force from being transmitted to the vulnerable parts, the pliers used for cutting the wire 4 should be particularly sharp, and should be cut along the entire length from beginning to end. The edges are cut with a clean, smooth shear surface; there should be no twisting action during this off-line shearing process;

[0034] C. Wire stripping: use H OT we e z e ts wire therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com