Lithium ion battery case with prefabricated burrs on bottom and lithium ion battery preparation method

A lithium-ion battery and shell technology, which is used in the manufacture of electrolyte batteries, battery pack components, non-aqueous electrolyte batteries, etc., to achieve the effects of reducing internal resistance, improving welding strength, and improving comprehensive electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

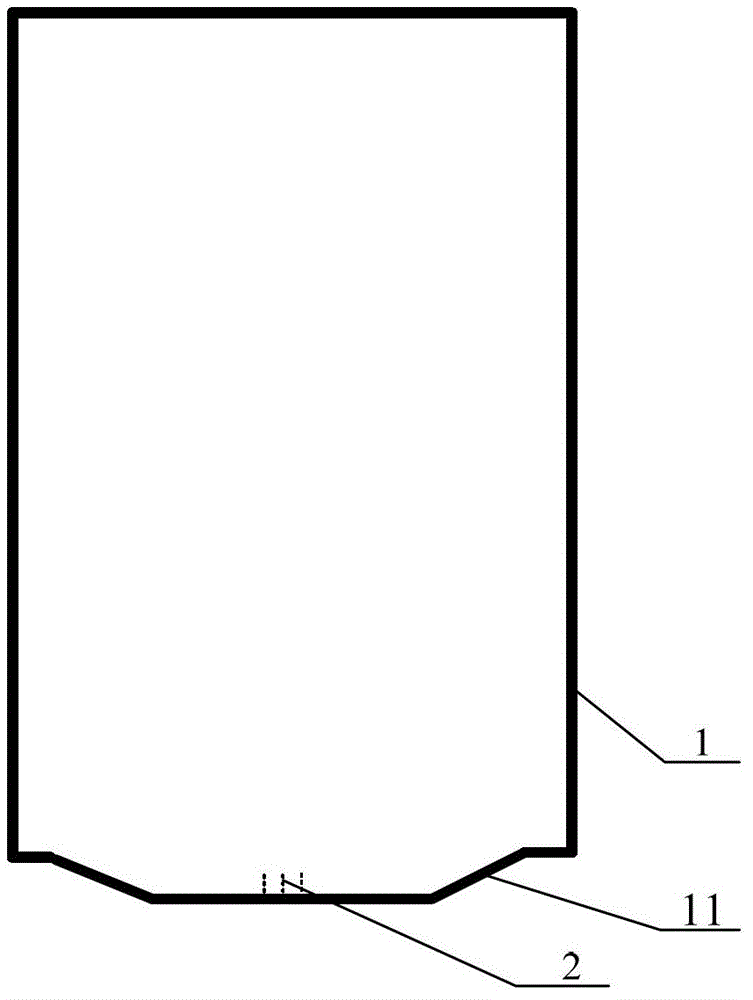

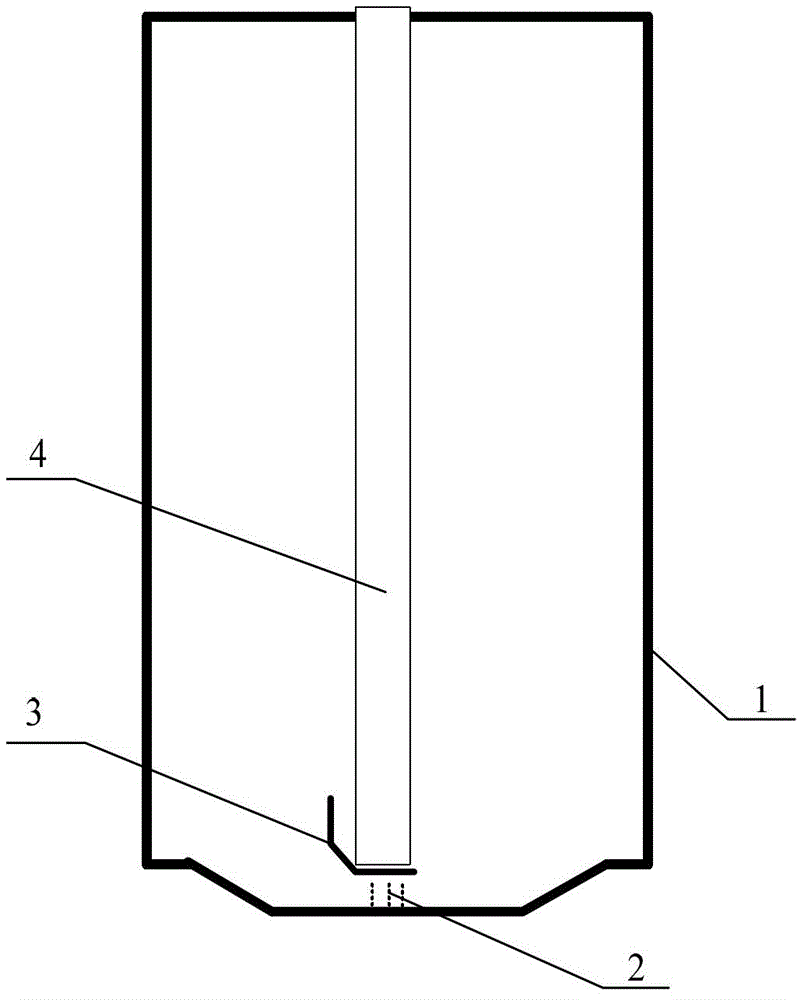

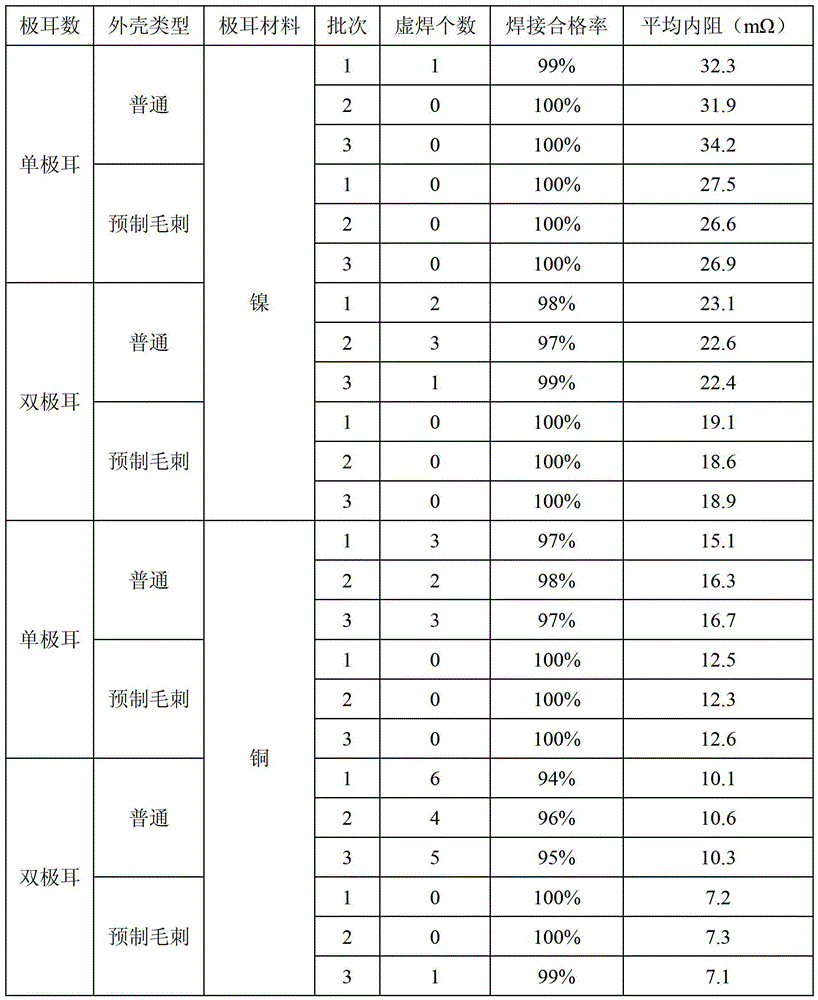

[0027] likefigure 1 , figure 2 Shown, a kind of preparation method of lithium ion battery comprises the following steps:

[0028] 1) Preparation of the lithium-ion battery case with prefabricated burrs at the bottom: During the deep-drawing process of the lithium-ion battery case, a concave hole of a certain shape is pre-processed on the top of the punch of the forming die, and after deep-drawing, the lithium-ion battery can be formed. Protruding burrs 2 of a certain shape are processed inside the boss 11 at the bottom of the shell 1 to obtain a lithium-ion battery shell 1 with prefabricated burrs 2 at the bottom;

[0029] 2) Weld the lithium-ion battery case 1 with the prefabricated burr 2 on the bottom with the tab 3 on the battery cell, and the welding head 4 is close to the burr 2 at the bottom of the lithium-ion battery case 1, so that the tab 3 is in contact with the bottom burr 2 During the welding process, a large current is discharged through the burr 2, which can e...

Embodiment 1

[0032] like figure 1 As shown, the lithium-ion battery casing with prefabricated burrs at the bottom (that is, the 18650 steel casing for lithium-ion power batteries with prefabricated burrs), including the lithium-ion battery casing 1, the specific dimensions of the lithium-ion battery casing 1 are shown in Table 1, where the unit In mm, the outer diameter and inner diameter are diameters.

[0033] Table 1

[0034] model

Outer diameter ±0.05

Inner diameter ±0.05

Height ±0.1

Shell wall thickness ±0.02

Boss diameter

18650

18

17.52

66.9

0.24

13.5

[0035] Burrs 2 are provided on the inside of the bottom of the lithium-ion battery case 1 (that is, the side used to connect with the tab on the battery cell). The bottom of the lithium-ion battery case 1 faces outwards (that is, the direction along the bottom of the lithium-ion battery case 1 away from the burrs) forms a boss 11 , and the burrs 2 are arranged on the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com