Semitrailer bottom plate laser welding equipment

A technology of laser welding and laser welding head, applied in the field of laser welding equipment for semi-trailer bottom plates, can solve the problems of automatic welding machine not matching the bottom plate pressing mechanism, pressing and fixing the semi-trailer bottom plate and frame, and unable to carry out laser welding, etc. , to achieve the effect of improving production safety, avoiding virtual welding, and ensuring health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

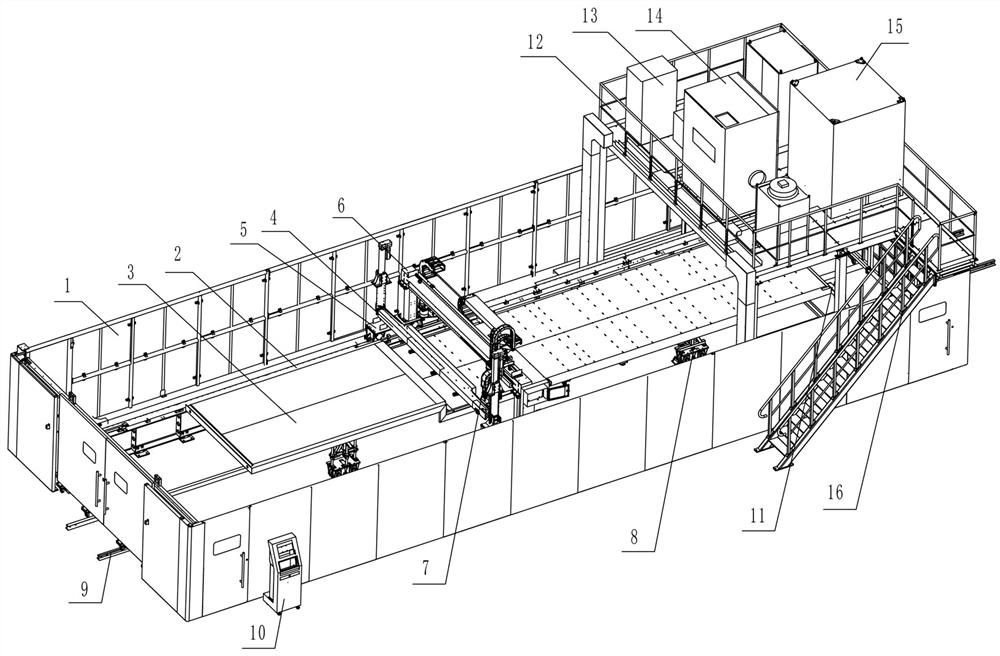

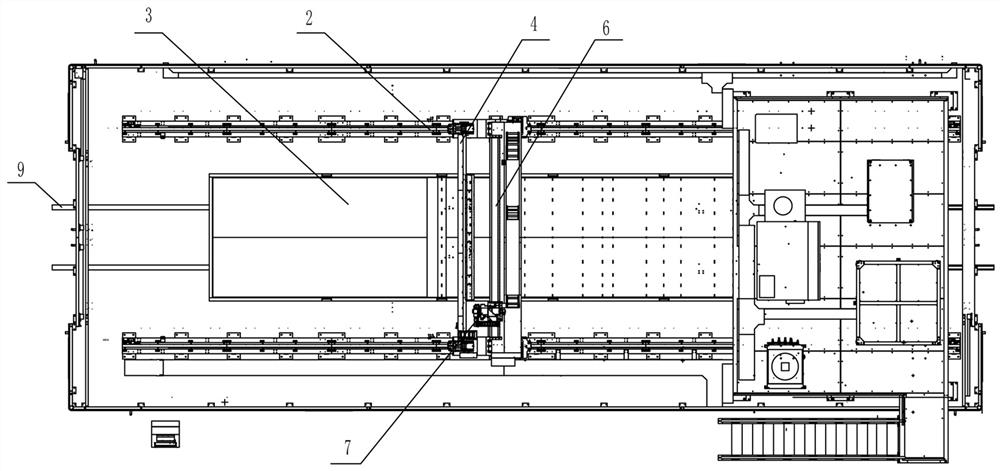

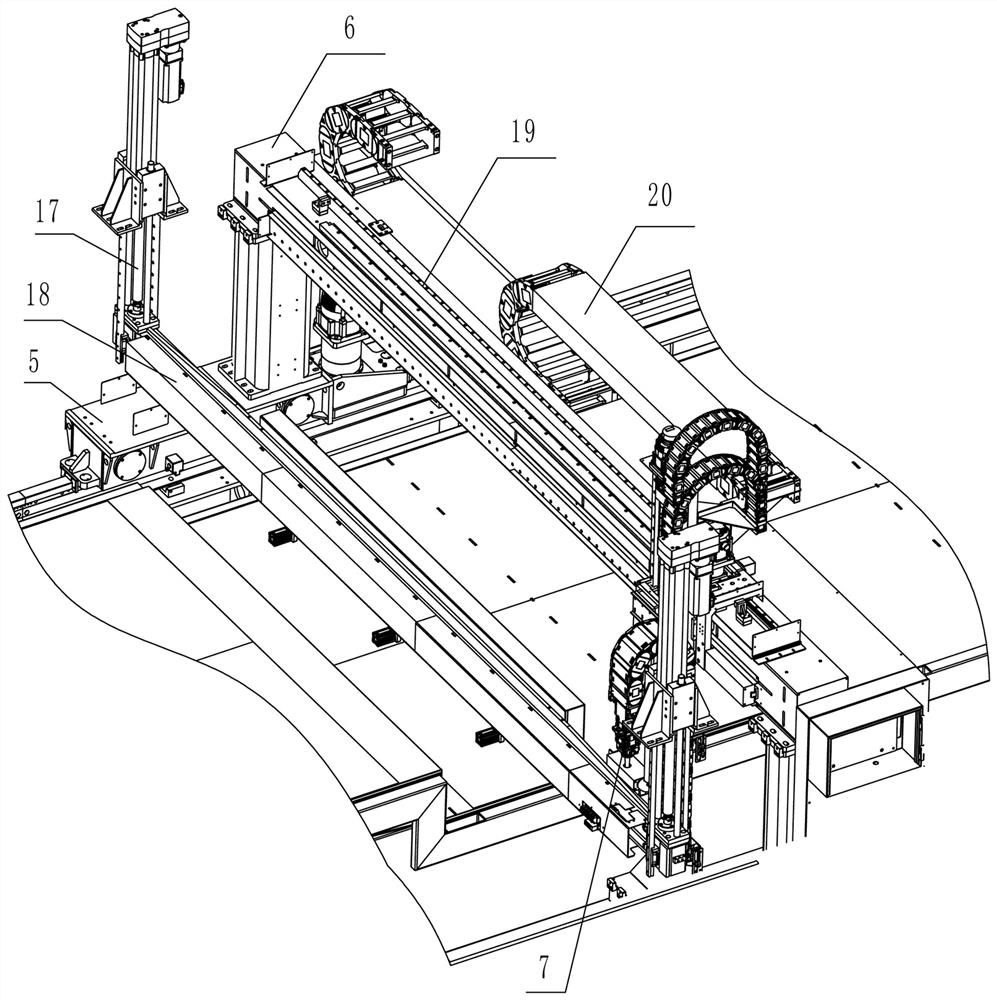

[0031] This embodiment provides a kind of semi-trailer floor laser welding equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a pair of bed rails 2 and a pair of trolley rails 9 arranged between the bed rails 2 .

[0032] The logistics trolley 8 for supporting the semi-trailer floor 27 and the vehicle frame 3 is slidably arranged on the trolley track 9 . A group of traveling end beams 5 are slidably arranged on the bed rail 2 . A welded gantry beam 6 and a lifting and pressing mechanism 4 for fixing and pressing the bottom plate of the semi-trailer are respectively arranged between the two traveling end beams 5 .

[0033] The welding gantry beam 6 is provided with a welding head system 7 capable of moving horizontally and lifting up and down. The welding head system 7 is provided with a flexible pressure wheel 25 which is used to follow and compress the bottom plate of the semi-trailer. The flexible pressing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com