Novel AF camera module motor PIN connection method

A camera module and connection method technology, applied in image communication, TV, color TV components and other directions, can solve problems such as increased labor costs, module AF function impact, virtual welding, etc., to improve product yield and avoid problems. The effect of virtual welding and preventing excessive glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the embodiments are only for illustrating the present invention, rather than for limiting the protection scope of the present invention.

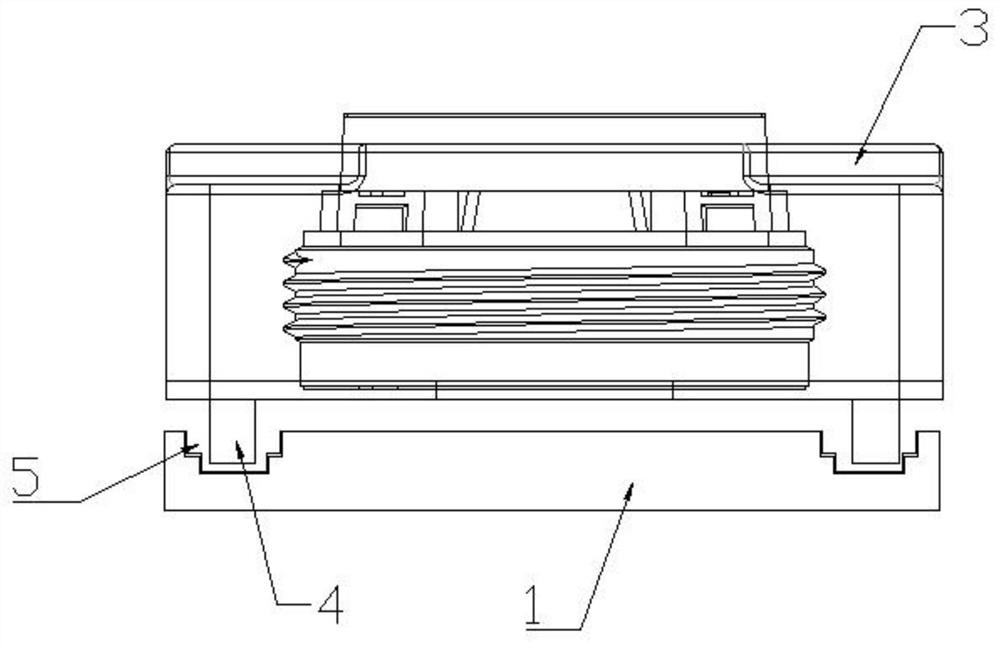

[0017] As shown in the figure, a new AF camera module motor PIN pin connection method includes the following steps:

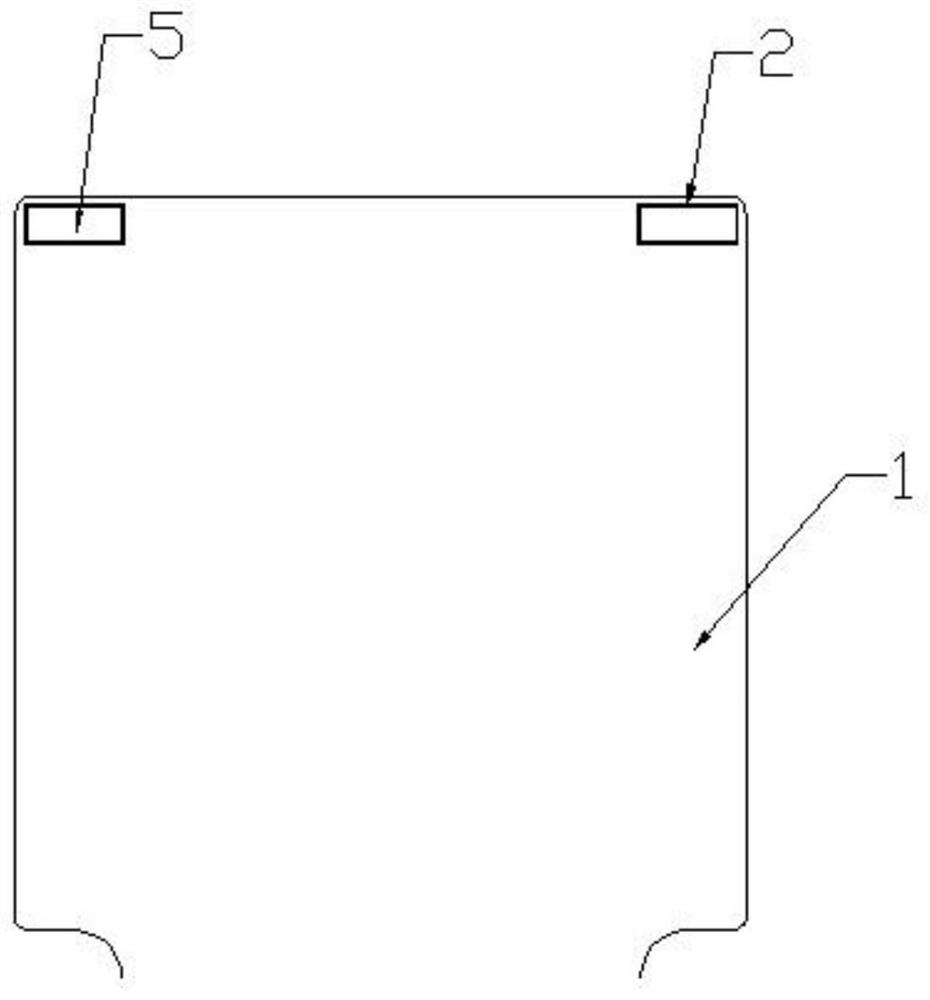

[0018] S1. Hollow out the middle of the VCM pad 2 on the FPC board 1 to form a set of concave portions 5 for the contact of the motor PIN pin 4 on the AF camera module HOLDER3;

[0019] S2. Coat the surface 4 of the motor PIN pin with liquid conductive adhesive, and insert it into the recess 5 of the VCM pad 2;

[0020] S3. The liquid conductive adhesive is solidified by high temperature heating, so as to realize the tight connection between the VCM pad 2 and the PIN pin 4 of the motor.

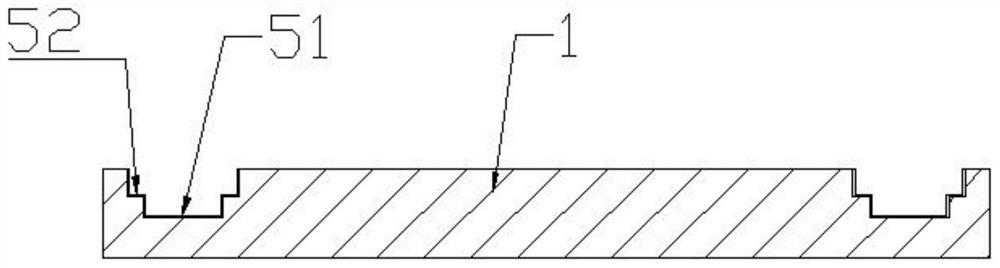

[0021] In another technical solution, the recessed portion 5 in S1 is a stepped struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com